Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.33 no.1 Bogotá Jan./Apr. 2013

N. Torres Castellanos1, J. Torres Agredo2 and R. Mejía de Gutiérrez3

1 Nancy Torres Castellanos. Doctor (c) Ciencia y Tecnología de Materiales, M. Sc. Estructuras, Ingeniera Civil, Universidad Nacional de Colombia, Bogotá, Colombia. Affiliation: Asociate Professor, Escuela Colombiana de Ingeniería, Colombia. E-mail: nancy.torres@escuelaing.edu.co.

2 Janneth Torres Agredo. Doctora en Ingeniera con énfasis en Ingeniería de Materiales. Universidad del Valle, Affiliation: Associate Professor, Universidad Nacional de Colombia, Palmira, Colombia. E-mail: jtorresa@unal.edu.co.

3 Ruby Mejía de Gutiérrez. Doctora en Ciencias Químicas (Materiales), Universidad Complutense, Madrid, España, Maestria en Ciencias Químicas, Química, Universidad del Valle, Colombia. Affiliation: Universidad del Valle, Colombia. E-mail: ruby.mejia@correounivalle.edu.co.

How to cite: Torres Castellanos, N., Torres Agredo, J., Mejía, R., Performance under sulfate attack of concrete additioned with Fluid Catalytic Cracking catalyst residue (FCC) and Metakaolin (MK)., Ingeniería e Investigación. Vol. 33, No. 1. April 2013, pp. 18-22.

ABSTRACT

In this work the evaluation of the performance of concrete added with Fluid Catalytic Cracking Catalyst residue (FCC) from a Colombian petroleum company, under sulfate attack, is presented. The results of this concrete are compared with the results of Metakaolin (MK) added concrete. The analysis of the pozzolanic materials included the determination of the particle size, the pozzolanic activity and the chemical and mineralogical composition. Different percentages of FCC were used as Portland cement replacement in proportions of 0, 10, 20 and 30%; similarly concrete added with 20% of MK as replacement was elaborated. Compressive strength and performance under sulfate attack were evaluated. Results showed that concrete with FCC and MK as well as control concrete had similar behavior; however its expansion was higher. In addition, the performance of the two types of concrete (FCC y MK) under sulfate attack was comparable; this could be due to fact that FCC and MK showed similarities regarding of their chemical and mineralogical composition. Importantly, after 360 days of exposure the specimens with MK and FCC showed no significant deterioration.

Keywords: Fluid catalytic cracking catalyst residue, metakaolin, pozzolanic addition, concrete, compressive strength, durability.

RESUMEN

En este trabajo se presenta la evaluación del desempeño de concretos adicionados con un residuo de catalizador de craqueo catalítico (FCC) frente al ataque de sulfatos. Los resultados son comparados con concretos adicionados con metacaolín (MK). Los análisis de los materiales puzolánicos incluyen la determinación del tamaño de partícula, la actividad puzolánica y la composición química y mineralógica. Se utilizaron diferentes porcentajes de adición de FCC como reemplazo de cemento, en proporciones de 0, 10, 20 y 30%; de manera similar, se elaboraron concretos adicionados con MK en un 20%. Se evaluó la resistencia a la compresión y el desempeño frente al ataque de sulfatos. Los resultados mostraron que los concretos adicionados con FCC y MK tuvieron un comportamiento mecánico similar a la muestra control; sin embargo, frente a la expansión fueron superiores. Adicionalmente, el desempeño de los dos tipos de concretos (FCC y MK) bajo la acción de la solución de sulfatos fue comparable; esto puede deberse a que el FCC y el MK presentan similitudes en cuanto a su composición química y mineralógica. Se destaca que después de 360 días de exposición las muestras con MK y FCC no presentaron deterioro importante.

Palabras clave: residuo de catalizador de craqueo catalítico, metacaolín, adiciones puzolánicas, concreto, resistencia a compresión, durabilidad.

Received: October 24th 2012 Accepted: March 12th 2013

Introduction

Reinforced concrete is still the protagonist in the construction of structures, due to its numerous advantages over other materials (Fernández, 2002). It is the most widely used material in the construction industry in developed and developing countries; compared with other materials it is cheaper and has adequate strength and durability, (Malhotra & Mehta, 1996).

The main binder material to produce concrete is the Portland cement; however, its production generates large amounts of greenhouse gases, (Gartner, 2004). The reduction of these gases emissions can be achieved by increasing the efficiency in the cement production process, reducing fuel consumption and reducing the use of clinker (Price et al., 1999). The latest can be achieved through the incorporation of mineral admixtures at the time of manufacturing mortar or concrete, besides, the use of mineral admixtures is an alternative to improve concrete resistance to different aggressive environments (Lothenbach et al., 2011). For this reason it has become a common practice to use additions of cementitious materials, which usually are byproducts of industrial processes or other materials of natural origin (Garcia-Lodeiro et al., 2007; Sánchez de Rojas et al., 1996; Hwang & Sheen, 1991; Cohen & Bentur, 1998).

There are several benefits associated with the use of pozzolans in mortar and concrete, including improved mechanical strength and increased durability, (ACI, 2001; Lothenbach et al., 2011). Additionally, the use of pozzolans brings in many cases economic and environmental benefits. It is considered that in the future, a concrete without pozzolanic or cementitious additions will be an exception to the rule, (Malhotra & Mehta, 1996). The use of these pozzolanic waste materials brings environmental two-fold benefits: on one hand the substitution of a portion of cement, and on the other hand, the consumption of waste materials from other industrial processes, which when not used, would have to be stored in landfills. (Roskovic & Bjegovic, 2005).

Among the latest breakthroughs in additions, there is another pozzolanic material that is able to improve the performance of binders. It is the residue of the catalyst used in the process of oil catalytic cracking (FCC - Fluid Catalityc Cracking) which has been used on research in pastes, mortars and concrete (Castellano & Torres, 2010; Al-Jabri et al., 2013)). It has been found that this material acts as a very active pozzolan since the early ages of curing, as indicated by (Soriano, 2008; Payá et al., 2001; Antiohos et al., 2006). Its activity is due to its ability to react with the calcium hydroxide (portlandite) released in the hydration of Portland cement and form compounds with hydraulic properties. This behavior causes additional increase in the mechanical strength of mortar and concrete (Borrachero et al, 2002). Since FCC has a high reactivity at an early age, it may improve the mechanical properties and durability of Portland cement concretes when added as cementing material (Morozov et al., 2013). From environmental and economical points of view, the use of this residue could contribute to the conservation and preservation of the environment as well as obtaining better performance concrete.

This article presents a study on the characteristics of a Colombian residue of catalytic cracking (FCC), the evaluation of compressive strength and the expansion, of concrete with partial replacement of cement subjected to sulfate attack. It also compares performance against another addition such as Metakaolin (MK), because its chemical and mineralogical characteristics are similar to the FCC.

Experimental Procedure and Materials

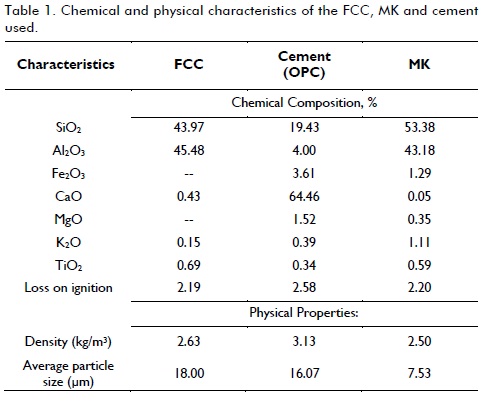

For the study, a catalyst residue from catalytic cracking (FCC) from a Colombian Petroleum Company (Ecopetrol) plant located in the city of Cartagena, Metakaolin (MK) from a Colombian company located in the Department of Antioquia, a region which has major kaolin quarries, and ordinary Portland cement (OPC) were used. Table 1 shows the chemical and physical properties of cement and cementitious additions.

As shown in Table 1, FCC is composed almost entirely of silica and alumina 43.97% and 45.48% respectively, similar to the quantification obtained by (Pacewska et al, 2011), with a composition similar to Metakaolin with 53.38 % silica and 43.18% alumina, this similarity in chemical composition of the two materials has also been reported by Payá et al., (2003).

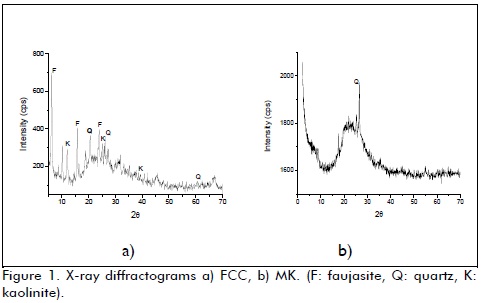

Figure 1 shows two X-ray diffractograms (XRD) for FCC and MK. In this case a RX Rigaku RINT 2200 machine was used. In the case of the FCC, it's shown that it has both amorphous and crystalline material, identifying in greater scale a crystalline pattern similar to that of a hydrated sodium aluminosilicate type material character similar to the faujasite zeolite (F) of the formula Na2[Al2Si10O24].nH2O with peaks located in 2q= 6.19 o, 15.6 o, 23.58 o; also present kaolinite (K) and quartz (Q). In the case of MK, an amorphous material characteristics is shown, which is presented by the baseline survey in the region 2q = 20 to 30 o, and the disappearance of the peaks corresponding to kaolinite.

Pozzolanic activity

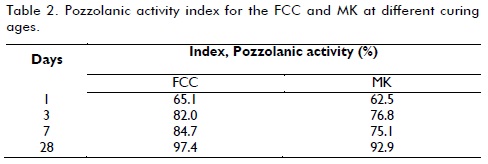

A comparison was performed regarding the pozzolanic activity of FCC and MK, which was determined from compressive strength using ASTM C311 and ASTM C618 standards. As indicated by the standard, mortars were made with standard sand and replacement of cement by the cementitious addition at 20%. Specimens were prepared and cured immersing them in saturated water with Ca(OH)2 at room temperature for time periods of 1, 3, 7 and 28 days. Table 2 shows the results of the pozzolanic activity index for the two additions at different ages.

For the evaluation of the pozzolanic activity index, the ASTM C618 standard requires a minimum pozzolanic index of less than 75% at 28 days of curing, to consider a material as a pozzolan. According to Table 2, both the FCC and the MK, comply with that parameter. It also shows that the rates are slightly higher for FCC compared to MK, which is in agreement with those reported in the literature of (Pacewska et al., 1998; Payá et al., 2003).

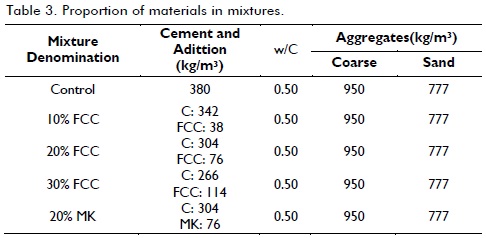

Preparation of concrete mixes

A control concrete mixture¸ was made along with four concrete mixtures added with the following proportions of cement replacement: FCC 10, 20 and 30%, in the case of MK was used by 20%, because in previous studies it was the optimum (Torres et al., 2011). Alluvial aggregates were used. The coarse aggregate had maximum nominal size of 12.7 mm, nominal density of 2668 kg/m3, unit weight of 1542 kg/m3 and absorption of 3.0%. Sand had nominal density of 2679 kg/m3, unit weight of 1667 kg/m3, absorption of 2.1% and a fineness modulus of 2.84. Table 3 shows the proportions of materials used in each of the mixtures.

A constant water-to-binder ratio (w/C) of 0.5 was selected based on the durability requirements specified in the Colombian Earthquake Resistant Construction Code NSR-10, item C.4.2. The amount of water was kept constant at 190 kg/m3, and to achieve a settlement between 50 mm and 100 mm, it was necessary to incorporate a high efficiency superplasticizer. Specimens were cured in water saturated with Ca(OH)2 at room temperature for periods up to 360 days.

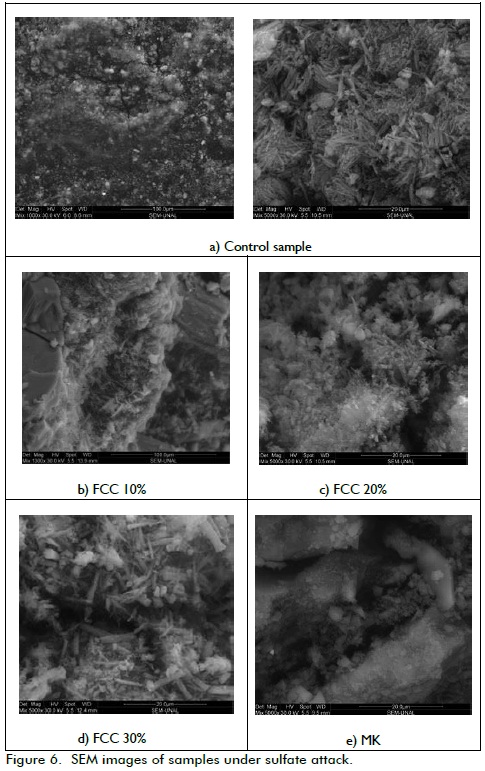

To evaluate the impact of sulfate attack on the compressive strength and expansion, after 28 days of curing under water, samples were immersed in a solution of 5% Na2SO4 (33800 ppm SO42-) maintaining the pH of the solution between 6 and 8, during the entire testing period. Test conditions complied with ASTM C 1012. Samples were tested after immersion in the sulfate solution for periods of 28, 62 and 152 days for compressive strength and 605 days for expansion test. Additionally, images were obtained by means of Scanning Electron Microscope (SEM), with the aim of comparing the morphological status of the samples.

Results and discussion

Compressive Strength

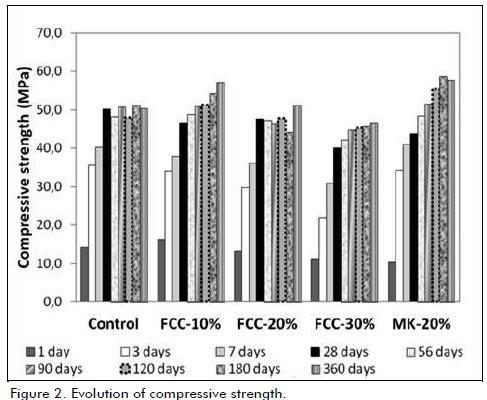

Figure 2 presents the evolution of compressive strength for each of the mixtures after being cured for 1, 3, 7, 28, 56, 90, 120, 180 and 360 days. Testing was conducted according to ASTM C39 standard, in cylinders of 10 cm diameter and 20 cm high.

As expected, regardless of the type or rate of addition, strength increases with age. It can be seen that the 1-day strength of the mixtures with FCC is higher than that of the mixture with MK and that the strength of the FCC-10% mixture is slightly higher than that of the control mixture. This may be due to the reported high reactivity of FCC at early age (Soriano, 2008; Payá et al., 2001, 2003; Antiohos, 2006). Likewise, it has also been reported superior performance of FCC as compared to MK, (Payá et al, 2001, 2003).

For ages over 3 days, concrete with FCC and MK additions showed resistance slightly lower than the control sample. The 28-day compressive strength of concrete added with the FCC at 10 and 20%, exceeds the strength of those containing MK. Results agree with Paya et al., (2002), who mentioned that the FCC is more reactive than the MK. Figure 4 shows that for FCC additions of more than 20 % resistance decreases, results that agrees with Antiohos et al., (2006).

Behavior under sulfate exposure

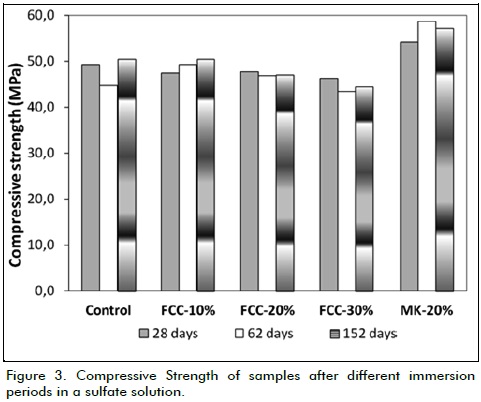

Figure 3 shows the compressive strength values, after keeping the samples immersed in a solution of 5% Na2SO4 for 28, 62 and 152 days.

It can be seen that in general, compressive strength does not change significantly with time of exposure to sulfate solution, with respect to the samples immersed in water (Figure 2), there is no appreciable resistance losses in any case until the age of testing.

The best performance was for concrete added with FCC and MK. It was considered that this good behavior of cementitious materials under sulfate environments, is mainly due to refinement of the porous structure and reduction of the Ca(OH)2 content due to the pozzolanic reaction, (Al-Moudi, 2002; Taylor, 1990; Al-Dulaijan et al., 2003). In the case of MK, these results are consistent with those of Torres et al., (2008) who found that the performance of mortars containing MK improves with the amount of addition.

In the case of concrete with addition of FCC, figure 3 shows that at 10% addition, its behavior is similar to the control sample, as the results in figure 2, but for higher percentages, there is a slight decrease in strength compared to the control sample. These results are consistent with those by Pacewska et al., (2000) and Bukowska et al., (2003), who found a slight decrease in compressive strength for mortars containing 20 % FCC in weight of cement. It may be due to the pozzolanic reaction of the material, causing densification of the structure, (Payá et al., 2003; Trochez et al., 2010).

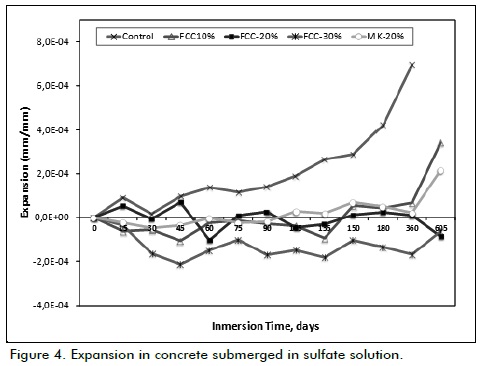

Figure 4 shows values of expansion of concrete beams (5cm x 5cm x 28.5cm) submerged in a 5% Na2SO4 solution for 605 days, according to ASTM C157 / C157M standard. Unlike the results obtained for the compressive strength, the best performance was for the sample with the substitution of 30% FCC, due to refinement of the pore structure, caused by pozzolanic reaction improving material impermeability to aggressive environments. (Bukowska et al., 2003, 2004).

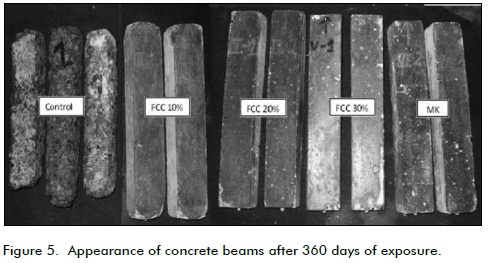

Figure 5 shows the state of concrete beams after 360 days of exposure. The deterioration of the control sample can be seen clearly, contrary to samples added with FCC at 20 and 30% and MK which are in very good condition, while the sample with 10% FCC shows a slight deterioration. From these observations, it can be concluded that the performance of samples added with FCC and MK exposed to sulfate solution was satisfactory.

Additionally, the microstructure of samples subject to sulfates attack, after 360 days of exposure was examined, by means of Scanning Electron Microscopy (SEM) on a FEI Quanta 200. Figure 6 shows images of the control sample and the samples added with FCC and MK. It can be seen the formation of ettringite and cracking of control sample, indicating poor behavior. On the other hand, little amounts of ettringite showed up on added samples, indicating better (good) performance and that the sulfate concentration used did not generates significant deterioration, for the times of exposure used.

Conclusions

From the results it can be concluded that:

FCC has properties similar to those of pozzolanic materials; therefore part of the cement can be replaced by this residue. This would bring environmental benefits by reusing and encapsulating industrial waste.

As for compressive strength, the best performance was presented by the samples with 20% of MK, compared with the addition of FCC, however concrete with FCC was slightly higher than the control sample.

The MK and the FCC have similarities in terms of chemical composition and the amorphous structure, consequently the behavior of the two additions, was comparable in regard of the properties evaluated.

For the sulfate concentration and exposure ages, concretes with the FCC and MK, showed no noticeable deterioration. The addition of MK, showed the best performance against sulfate attack.

References

ACI Committee., Guide to Durable Concrete, Report ACI 201R, United States, American Concrete Institute, 2001. [ Links ]

Al-Amoudi, O., Attack on plain and blended cements exposed to aggressive sulfate environment., Cement and Concrete Composites, Vol. 24, Aug., 2002, pp. 305-316. [ Links ]

Al-Dulaijan, S. U., Maslehuddin, M., Al-Zahrani, M. M., Sharif, A. M., Shameem, M., Ibrahim, M., Sulfate resistance of plain and blended cements exposed to varying concentrations of sodium sulfate., Cement and Concrete Composites, Vol. 25, No. 4-5, May-July, 2003, pp. 429-437. [ Links ]

Al-Jabri, K., Baawain, M., Taha, R., Al-Kamyani, Z. S., Al-Shamsi, K., Ishtieh, A., Potential use of FCC spent catalyst as partial replacement of cement or sand in cement mortars., Construction and Building Materials, Vol. 39, Feb., 2013, pp. 77-81. [ Links ]

Antiohos, S. K., Chouliara E., Tsimas, S., Re-use of Spent Catalyst from Oil-Cracking Refineries as Supplementary Cementing Material., China Particuology, Vol. 4, No. 2, Apr., 2006, pp. 73-76. [ Links ]

Borrachero, M., Monzó, J., Payá, J., Mora, Vunda, Velásquez, S., Soriano, L., El Catalizador Gastado de Craqueo Catalítico Adicionado al Cemento Pórtland: Las Primeras 48 Horas de Curado y la Evolución de la Resistencia Mecánica., VIII Congreso Nacional de Propiedades Mecánicas de Sólidos, Gandia 2002. [ Links ]

Bukowska, M., Pacewska, B., Wilinska, I., Corrosion Resistance of Cement Mortars Containing Spent Catalyst of Fluidized Be Cracking (FBCC) as an Additive., Thermal Analysis and Calorimetry, Vol. 74, No. 3, 2003, pp. 931-942. [ Links ]

Bukowska, M., Pacewska, B., Wilinska, I., Influence of spent catalyst used for catalytic cracking in a fluidized bed on sulphate corrosion of cement mortars: I. Na2SO4 medium., Cement and Concrete Research, Vol. 34, No. 5, 2004, pp. 759-767. [ Links ]

Castellano, N., Torres, J., Uso del catalizador gastado de craqueo catalítico (FCC) como adición puzolánica - Revisión., Ingeniería e Investigación, Vol. 30, No. 2, Aug., 2010, pp. 35-42. [ Links ]

Cohen, M. D., Bentur, A., Durability of Portland cement-silica fume pastes in magnesium sulfate and sodium sulfate solutions., ACI Materials Journal, Vol. 85, No. 3, 1998, pp. 148-157. [ Links ]

Fernández, M., Hormigón, Colegio de Ingenieros de Caminos, Canales y Puertos., 6ta ed., 2002. [ Links ]

García-Lodeiro, I., Palomo, A., Fernández-Jiménez, A., Alkali-aggregate reaction in activated fly ash systems., Cement and Concrete Research, Vol. 37, Feb., 2007, pp. 175-183. [ Links ]

Gartner, E., Industrially Interesting Approaches to Low CO2 Cements., Cement and Concrete Research, Vol. 34, Sept., 2004, pp. 1489-1498. [ Links ]

Hwang, C. L., Sheen, D.H., The effect of blast-furnace slag and fly ash on the hydration of Portland cement., Cement and concrete research, Vol. 21, No. 2, 1991, pp. 410-425. [ Links ]

Lothenbach, B., Scrivener, K., Hooton, R. D., Supplementary cementitious materials., Cement and Concrete Research, Vol. 41, Dec. 2011, pp. 1244-1256. [ Links ]

Malhotra V, M., Mehta, P. K., Pozzolanic and Cementitious Material., Ottawa, Gordon and Breach Publishers, 1996. [ Links ]

Morozov, Y., Castela, A. S., Dias, A. P. S., Montemor M. F., Chloride-induced corrosion behavior of reinforcing steel in spent fluid cracking catalyst modified mortars., Cement and Concrete Research, Vol. 47, May, 2013, pp. 1-7. [ Links ]

Payá, J., Monzó, J., Borrachero, M. V., Physical, Chemical and Mechanical Properties of Fluid Catalytic Cracking Catalyst Residue (FC3R) Blended Cements., Cement and Concrete Research, Vol. 31, Jan., 2001, pp. 57-61. [ Links ]

Payá, J., Monzó, J., Borrachero, M. V., Amahjour, F., Girbe's, I., Velazquez, S., Ordoñez, L. M., Advantages in the use of fly ashes in cements containig pozzolanic combustion residues: silica fume, sewage sludge ash, spent fluidized bed catalyst and rice husk ash., Chemical Technology and Biotechnology, Vol. 77, 2002, pp. 331-335. [ Links ]

Payá, J., Monzó, J., Borrachero, M. V., Velázquez, S., Evaluation of the Pozzolanic Activity of Fluid Catalytic Cracking Catalyst Residue (FC3R), Thermogravimetric Analysis Studies on FC3R Portland Cement Pastes., Cement and Concrete Research, Vol. 33, Apr., 2003, pp. 603-609. [ Links ]

Pacewska, B., Wiliñskaa, I., Kubissab, J., Use of Spent Catalyst from Catalytic Cracking in Fluidized Bed as New Concrete Additive., Thermochimica Acta, Vol. 322, No. 2, Nov., 1998, pp. 175-181. [ Links ]

Pacewska, B., Bukowska, M., Wiliñska, I., Influence of Some Aggressive Media on Corrosion Resistance of Mortars with Spent Cracking Catalyst., Journal of Thermal Analysis and Calorimetry, Vol. 60, No. 1, 2000, pp. 257-264. [ Links ]

Pacewska, B., Wiliñska, I., Bukowska, M., Hydration of Cement Slurry in the Presence of Spent Cracking Catalyst., Journal of Thermal Analysis and Calorimetry, Vol. 60, No. 1, 2000, pp. 71-78. [ Links ]

Price, L., Worrel, E., Phylipsen, D., Energy Use and Carbon Dioxide Emissions in Energy Intensive Industries in Key Developing Countries., Proceedings of the 1990 Earth Technologies Forum, Sept., 1999, pp. 1-15. [ Links ]

Roskovic, R., Bjegoviæ, D., Role of Mineral Additions in Reducing CO2 Emission., Cement and Concrete Research, Vol. 35, No. 5, May., 2005, pp. 974-978. [ Links ]

Sánchez de Rojas, M. I., Frías, M., The pozzolanic activity of different materials, its influence on the hydration heat in mortars., Cement and Concrete Research, Vol. 26, No. 2, Feb., 1996, pp. 203-213. [ Links ]

Soriano, M. L., Nuevas Aportaciones en el Desarrollo de Materiales Cementantes con Residuo de Catalizador de Craqueo Catalítico (FCC)., Tesis de Doctorado presentada en la Universidad Politécnica de Valencia, España, 2008. [ Links ]

Taylor, H. F. W., Cement Chemistry., London, Academic press, 1990, pp. 1-100. [ Links ]

Torres, J., Mejía de Gutierrez, R., Gutiérrez, C., The performance of mortar containing added metakaolin regarding sulfate action., Ingeniería e Investigación, Vol. 28, No. 1, Apr., 2008, pp. 117-122. [ Links ]

Torres, J., Mejía de Gutiérrez, R., Delvasto, S., Efecto del porcentaje de adición de Metacaolín en las propiedades finales del concreto adicionado., Revista Ingeniería y Universidad, Vol. 15, No. 1, 2011, pp. 77-90. [ Links ]

Trochez, J., Torres, J., Mejía de Gutiérrez, R., Study of hydration of cement pastes added with used catalytic cracking catalyst (FCC) from a Colombian refinery., Revista de la Facultad de Ingeniería Universidad de Antioquia, No. 55, Sept., 2010, pp. 26-34. [ Links ]