Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.33 no.1 Bogotá Jan./Apr. 2013

L. M. Centeno1, E. Castillo2, L. O. Becerra3, A. Rochin4

1 Luz María Centeno González. M.Sc. Tecnología Avanzada, CICATA, Instituto Politécnico Nacional. Affiliation: Centro Nacional de Metrología, México. E-mail: lcenteno@cenam.mx.

2 Dr. Eduardo Castillo Castañeda. Dr. in Automatic Control, Institut National Polytechnique de Grenoble. France. Affiliation: CICATA, Instituto Politécnico Nacional, México. E-mail: ecastilloca@ipn.mx.

3 Luis Omar Becerra Santiago. M.Sc. Diseño Mecánico, Instituto Tecnológico de Celaya, Gto. México. Affiliation: Centro Nacional de Metrología, México. E-mail: lbecerra@cenam.mx.

4 Alberto Rochín García. M. en C. en Electrónica, INAOE. Puebla. México. Affiliation: Facultad de Filosofía, UNAM, México. E-mail: rochin_alberto@hotmail.com.

How to cite: Centeno, L. M., Castillo, E., Becerra, L. O., Rochin, A., A Magnetic Suspension System for Measuring Liquid Density., Ingeniería e Investigación Journal, Vol. 33, No.1, Apr., 2013, pp. 46-51.

ABSTRACT

Density is a derived quantity of mass and length; it is defined as mass per volume unit and its SI unit is kg/m3. National metrology institutes have been designing and building their own magnetic suspension systems during the last 5 decades for making fluid density measurements; this has allowed them to carry out research into liquids and gases' physical characteristics. This paper was aimed at designing and developing a magnetic suspension system for a magnetic balance used in determining liquid density to be used in CENAM's metrology density laboratories.

Keywords: Hydrostatic weighing, density, magnetic suspension.

RESUMEN

La densidad es una magnitud derivada de las magnitudes de base masa y longitud, está definida como masa por unidad de volumen y su unidad en el Sistema Internacional de Unidades (SI) es el kg/m3. En las últimas cinco décadas, en el ámbito de la metrología primaria, se han desarrollado sistemas de suspensión magnética para la determinación de densidad de fluidos, lo que ha permitido realizar investigaciones sobre las características físicas de líquidos y gases. El presente trabajo tiene como objetivo el desarrollo y diseño de un sistema de suspensión magnética que será utilizado en una balanza de suspensión magnética para determinar la densidad de líquidos en los laboratorios de metrología de densidad, en el Centro Nacional de Metrología (Cenam).

Palabras clave: densidad, suspensión magnética, fuerza magnética.

Received: May 23th 2011 Accepted: January 10th 2013

Introduction

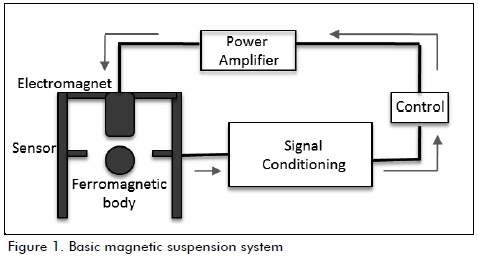

The magnetic suspension system has been studied and developed by authors such as Hurley, Ziehlmann and Mizuno. The common factor in their works is that they have followed a basic type of system consisting of an electromagnet, a ferromagnetic body, a position detection system and a closed loop control, as shown in Figure 1 (Hurley, 1997; Ziehlmann, 2000).

A variant of the previous system may be obtained by placing a permanent magnet which interacts with the electromagnet; the force needed by the electromagnet to levitate an object thus becomes reduced, not necessarily being a ferromagnetic one [Kleinrahm, 1986]. This variant minimises electromagnet power consumption, which is reflected in the heat so generated and, thereby, in low variation of its current. The latter system configuration is widely used in the field of density metrology.

There are many ways of using the magnetic levitation in different kinds of measurement systems; another configuration proposed for density metrology has two permanent magnets and capillary tubes, and sample density is obtained as a function of a levitated object's height (Mirica K. A., 2009).

This paper presents a design for and stability analysis of a magnetic levitation system; it will become part of a complete measurement system for measuring liquid density. Stability regarding mass measurement is thus very important, varying by no more than 1 mg, since the standard deviation of measurements represents the second largest contribution to liquid density uncertainty budget (Becerra L, 1998), i.e. on the proposed system, determined by the levitated object's position stability.

Magnetic suspension systems in determining liquid density

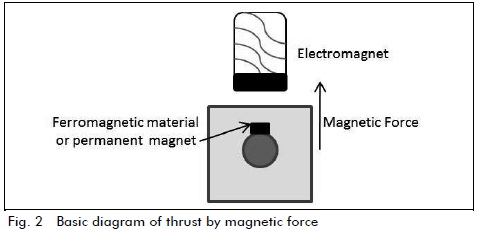

The reference object (solid density standard) in a hydrostatic weighing system is connected to the balance by a wire (through a thread passing over the surface of the liquid to be measured). The reference object's apparent weight loss indicates displaced liquid mass (liquid buoyancy). The force acting on the balance is a measure of the mass of the reference object. If the connecting wire were removed, then the reference object would float or sink freely in the liquid, depending on its density. If a magnetic field were generated to maintain the reference object at a defined position (height), a magnetic suspension system could be obtained (Figure 2).

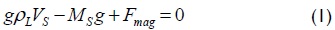

where, if just the vertical forces are considered, and a magnetic force is acting, the balance condition is (Bignell, 2006):

(Vs) is reference object volume, (ρL) is the density of the liquid to be measured, (Ms) is reference object mass, (g) is local gravity acceleration and (Fmag) is the magnetic force needed to levitate the reference object.

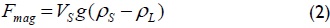

As ρS is reference object density (Bignell, 2006), the magnetic force could be obtained from:

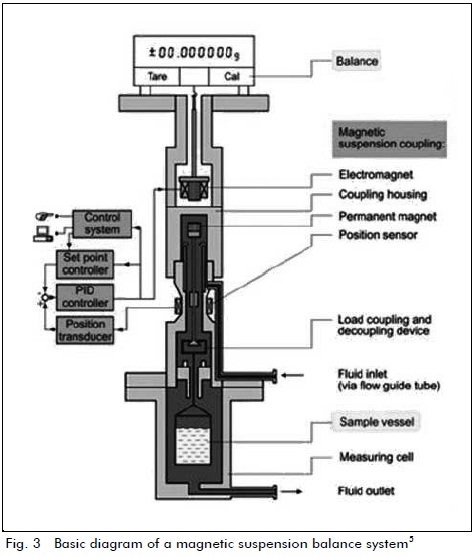

A magnetic coupling is used in such magnetic systems consisting of an electromagnet and a permanent magnet (Kleinrahm, 1986), where the first is hung directly from the balance and the second one is located inside a load cell. The reference object is fixed to the permanent magnet by means of a coupling and decoupling device. Figure 3 gives a general scheme of a liquid density measurement system involving magnetic suspension.

5

5 Design requirements

The main uncertainty contributions for density determination of liquids in a conventional hydrostatic weighing system are solid standard volume and measurement variability (Becerra L, 1998; Gupta, 2002). The latter is represented by standard deviation of the measurements taken directly from the balance.

Liquid density, using a magnetic levitation density meter, is measured by using the Archimedes' principle; however, a comparison is made with and without reference object levitation instead of establishing two equations between a reference and a submerged object (Kano, 2006).

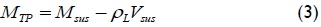

The following equation can be established using forces equilibrium for the tare weighting:

where Msus and Vsus are the subjection systems' mass and reference object volume and ρL is liquid density.

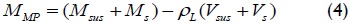

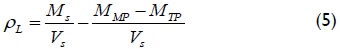

A second equation is established taking into account the hanging object by means of the suspension system and the magnetic coupling:

The density of the liquid being tested can be obtained by the next formula obtained from equations 3 and 4:

There are two possibilities for evaluating the degree of dependency between input quantities regarding measured liquid density; a numerical simulation (JCGM: 101, 2008 ) may be done or partial derivatives of liquid density may be calculated regarding each input quantity (JCGM:100, 2008 ) and the data then being organised in a table as the uncertainty budget. The input quantities diagram is shown in Figure 4, where ρL is liquid density, Ms and Vs are reference object mass and volume (solid density standard), ΔL is the difference between balance readings for MTP and Muss, MTP is the balance reading in tare position, Msus is.the balance reading where the reference object is hung up, Fmag is the necessary magnetic force for hanging up the solid, i is the current applied to the coil and h is the height difference between the coil core and the hanging reference object when submerged in the liquid.

Table 1 gives the uncertainty budget ( JCGM: 100, 2008 ) for determining liquid density.

Table 1 shows that ΔL represents 97.20% of total uncertainty regarding liquid density, this being due to the standard deviation of the balance readings. Levitation system design should thus be focused so that balance reading standard deviation does not affect liquid density uncertainty by more than 2x10-4 g/cm3.

ΔL is influenced by two input quantities: balance resolution and balance reading repeatability. Furthermore, repeatability depends on the stability of the magnetic force generated by the electromagnet and the stability of levitation determined by control position performance. The magnetic force could be calculated by the following formula (Moudgalya, 2007):

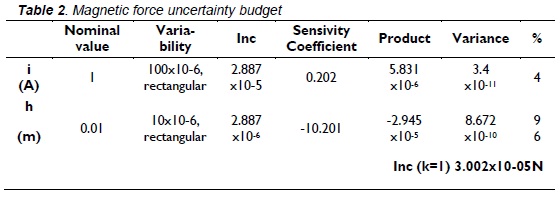

Assuming 1 A maximum current (i), the object to be hung up positioned 1 cm from the coil core (h) and 10 µm variability at this height, then the uncertainty budget will be as follows:

Table 2 shows that taking 100 µA current variability and 10 µm height, height variability is the magnetic force's largest contribu-tion to final uncertainty, so it can be stated that the greatest height variability will be magnetic force variability and therefore the largest uncertainty in measurement repeatability. Height (h) would thus need to be measured with at least 10 µm resolution, assuming the largest contribution of uncertainty in this kind of measurement would be the resolution of the instrument used to measure the height. The levitation system controller should provide better than or equal to 10 µm height position stability.

Figure 3 shows a complete magnetic suspension balance system. The suspension system would consist of an electromagnet, a permanent magnet, a positioning system and its corresponding controller.

Coil design

The number of coil turns would be given by (Resnick, 2004 ; Eisberg, 1982):

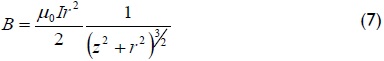

The behaviour of the magnetic field generated by the coil must be understood to complete the coil design; the magnetic field may be described mathematically by means of Biot-Savart's law (Eisberg, 1982):

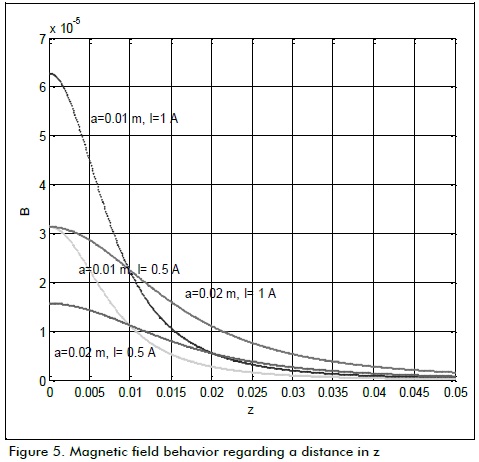

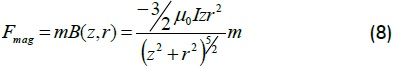

Z is the vertical distance above the z axis from the base of the coil and r is coil radius. Figure 5 gives a simulation of the field's behaviour with different currents according to equation (7).

The force acts on magnet moment m, in the presence of a mag-netic field B; this force is proportional to m times B. For a core of air in a coil, B is proportional to current I in the coil and for radius r, the force is given by (Bignell, 2006):

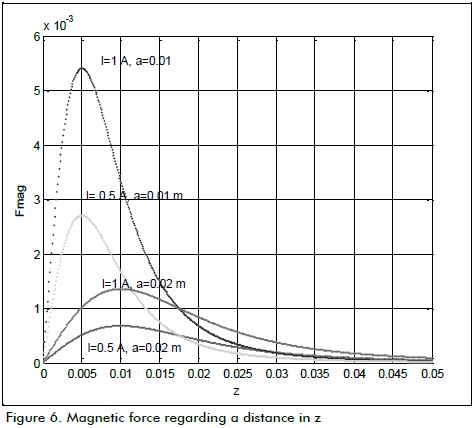

where, B (z, r) is the partial derivative regarding z from equation (7). Figure 6 shows a simulation of magnetic force with different current values and coil radius.

Figure 6 shows that the largest magnetic force would be obtained 5 mm from the origin of the field by applying 1 A current to a coil having 0.01 m radius. Applying equation (6), a 1,600 turn coil can be calculated for hanging up a mass of around 20 g.

Positioning sensor

Sensor selection is important since it provides feedback for the control system; it thus needs resolution having the desired position stability, as well as a suitable response time. The sensor should be contactless with around 10 µm resolution.

The above led to a PSD sensor being proposed because it is an economical choice, having up to 1 µm resolution and excellent time response (UDT Sensors Inc, 1982).

Characterising the positioning sensor

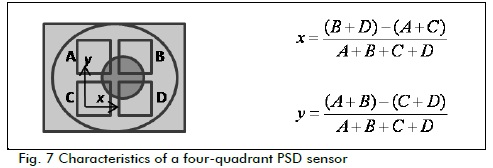

Positional detectors (PSD) are silicon photodiodes providing a direct analogue output proportional to the position of the light over an active area (Figure 7):

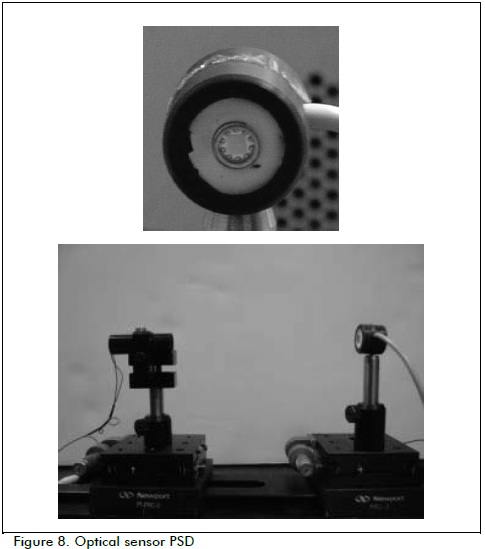

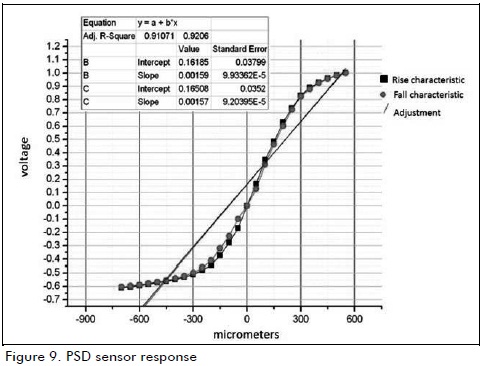

The position would be measured by total cell illumination and a light beam interrupting means involving an anodised board having a 0.5 mm wide slot. Figure 8 shows optical system assembly. Scanning every 50 µm (680 nm wave length laser) from top to bottom and vice versa characterised the PSD's optical area (Figure 9); the response was not totally linear.

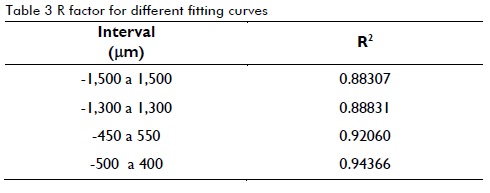

A fitting curve was calculated to determine the working area, changing the working interval and thus finding the highest factor (R2 = 1), besides trying to exploit the largest work interval.

Table 3 shows that the best fitting linear area came within the -500 µm to 400 µm interval; a 1 mV/10 µm resolution was obtained in this interval. This resolution was appropriate according to the results of the sensitivity stability study for the system.

Dynamic system and PID control

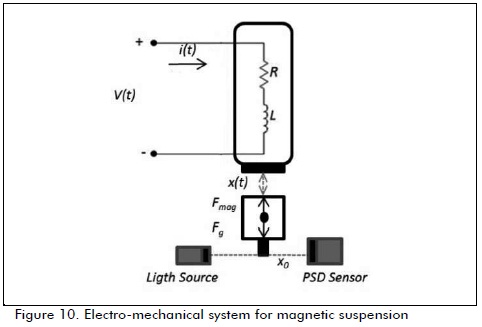

The electric representation of a magnetic suspension system is shown in Figure 10; the position of an object to be levitated was identified by an optical system where the signal was used as feedback for the control system. Coil inductance varied with the object's position; the current passing through the coil could change the magnetic force generated by the coil, thus allowing the object to fluctuate when being levitated. In Figure 10, i (t) is the circuit's current, x (t) is the object's displacement produced by means of the electromagnet and x0 is the desired position.

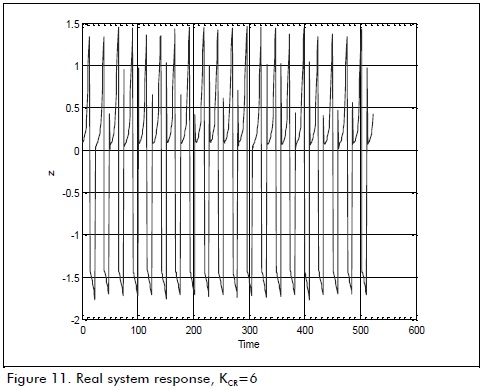

If the electric system was energised by a step voltage in an open loop, the response would be immediate and the permanent magnet absolutely attracted to the coil. So, a Ziegler Nichols method for tuning the PID control was used as a first approach to the control system.

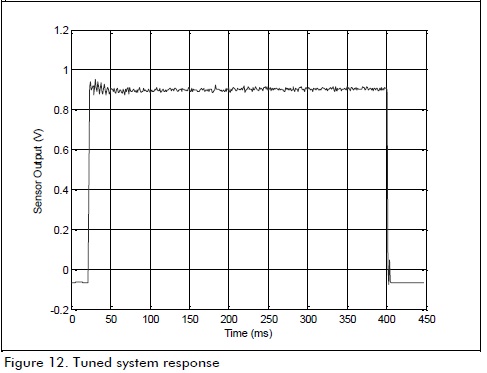

A value of 6 and 25 ms Pcr was obtained by varying Kp until obtaining a response with sustained oscillations (like that shown in Figure 11). Kcr was then calculated by applying the Ziegler-Nichols rules [Ogata, 2002] and Kpr= 3.6 and Td= 3.125 x 10-5 were deduced. Plant stability was around 0.03 seconds by applying constants Kp, Kd and Kito the control system (Figure 12).

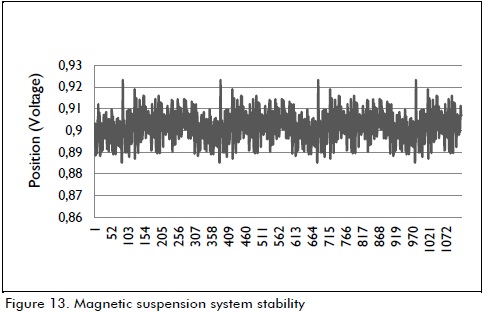

A 10 mV standard deviation was calculated after this response time. Figure 13 shows 3 to 6 second sensor exit after system stability.

A ± 10 µm variation led to a 10 mV standard deviation which, according to the system sensitivity study, was enough to reach 2 x 10-4 relative uncertainty when measuring liquid density. However, such uncertainty was not enough for the required uncertainty for density reference materials.

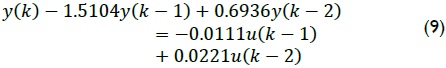

Knowing the magnetic suspension system's transfer function led to optimising the control loop. The system's transfer function was obtained by the least minimum squares' technique.

The magnetic suspension system's second order equation was stated as:

Control loop design will form part of future work in this field and such design will involve using zero power control and the aforementioned function, seeking better stability.

Conclusions

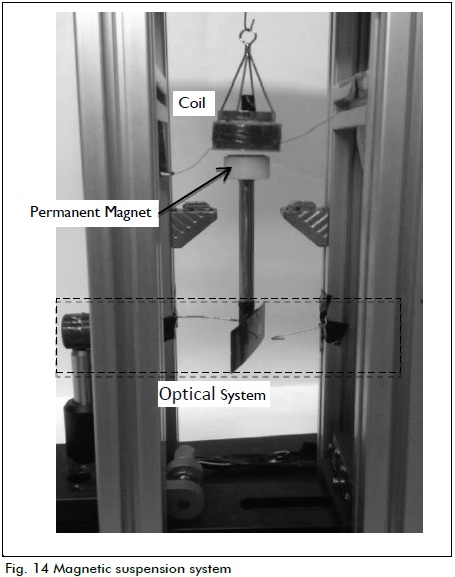

CENAM's design for a magnetic suspension system has been presented here. This magnetic suspension system was developed in the Density Laboratory as part of a project for designing and constructing a liquid density measurement system involving magnetic coupling (Figure 14). This design led to ±10 µm suspension stability which could be of reached along the z axis, representing ± 5 mg mass stability and up to 5x10-4 relative uncertainty when measuring liquid density (without taking possible corrections into account due to magnetic fields in the system's materials). The magnetic suspension system had all the requirements for designing a liquid cell, which is the next step to continue developing a liquid density measurement system by means of magnetic suspension. Controlling the magnetic suspension system must be improved by using with the transfer function so obtained.

Acknowledgements

The authors would like to thank CENAM for its support when developing this project, as well as CONACYT. We would also like to thank Dr. Eduardo Morales (CICATA) for his greatly appreciated contribution to this work.

5 Image obtained from de Rubotherm, www.rubotherm.com, manufacturer of magnetic suspension balances

References

Becerra, L., Pezet, S. F., Publicación técnica: Determinación de la Densidad de Sólidos y Líquidos., Publicación CNM-MMM-PT-002, Centro Nacional de Metrología, 1998. [ Links ]

Bignell, N., Magnetic flotation in densimetry., Measurement Science and Technology, 2006, pp. 2574-2580. [ Links ]

Eisberg, R. M., Lawrence, S. L., Física Fundamentos y Aplicaciones., Vol. II, Mc Graw Hill. [ Links ]

Gupta, S. V., Practical density measurement and hydrometry., Series in Measurement science and technology, Bristol and Philadelphia, Institute of physics publishing, 2002. [ Links ]

JCGM:100, Evaluation of measurement data - Guide to the expression of uncertainty in measurement (GUM 1995 with minor corrections), BIPM, IEC, IFCC, ISO, IUPAC, IUPAP, OIML, 2008. [ Links ]

JCGM: 101, Evaluation of measurement data - Supplement 1 of Guide to the expression of uncertainty in measurement., IEC, IFCC, ISO, IUPAC, IUPAP, OIML, 2008. [ Links ]

Kleinrahm, R., Wagner, W., Journal of Chemistry and Thermodynamics, 1986, pp. 739-760. [ Links ]

Hurley, W. H., Wölf, W., Electromagnetic Design of a Magnetic Suspension System., IEEE Transactions on education, Vol. 40, No. 2, 1997. [ Links ]

Kano, Y., Yohei, K., Fuji, K., Sato, H., A new method for correcting a force transmission error due to magnetic effects in a magnetic levitation densimeter., Institute of Physics Publishing, Measurement and Science Technology, 2007, pp. 659-666. [ Links ]

Mirica, K. A., Shevkoplyas, S. S., Phillips, S. T., Gupta, M., George, M., Whitesides, Measuring densities of solids and liquids using magnetic levitation: fundamentals., Harvard University, July 2009. Revised in: http://pubs.acs.org/ doi: 10.1021/ja900920s. [ Links ]

Moudgalya, K., Digital Control., Wiley & Sons, 2007, pp. 7-10. [ Links ]

Ogata, K., Ingeniería de Control Moderna., 3rd ed., Prentice-Hall. [ Links ]

Resnick, H., Krane, Fisica, Vol. 2, 5th ed., CECSA. [ Links ] [ Links ]