Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.34 no.1 Bogotá Jan./Apr. 2014

https://doi.org/10.15446/ing.investig.v34n1.40049

http://dx.doi.org/10.15446/ing.investig.v34n1.40049

Cassava starch separation: evaluation of sedmientation by gravity in channels

La separación del almidón de yuca: Evaluación de la sedimentación por gravedad en canales

P. Torres-Lozada1, L. F. Marmolejo-Rebellón2 and A. A. Cajigas-Cerón3

1Patricia Torres-Lozada. Sanitary Engineer, Universidad del Valle, Colombia. Magister and PhD. Hydraulic and sanitation engineering, Universidad de São Paulo, Brasil. Affiliation: Study and Control of the Environmental Contamination Research Group – ECCA, Facultad de Ingeniería, Universidad del Valle, Colombia. E-mail: patricia.torres@correounivalle.edu.co.

2Luis Fernando Marmolejo-Rebellón. Sanitary Engineer, Universidad del Valle, Colombia. Magister Health management, Universidad del Valle, Colombia. PhD. Sanitary and environmental engineering. Affiliation: Study and Control of the Environmental Contamination Research Group – ECCA, Facultad de Ingeniería, Universidad del Valle, Colombia.

3Álvaro Andrés Cajigas-Cerón. Sanitary Engineer, Universidad del Valle, Colombia. Magister Sanitary and environmental engineering, Universidad del Valle, Colombia. Affiliation: Faculty of Environmental Engineering, Universidad Pontificia Bolivariana - Bucaramanga, Colombia.

How to cite: Torres-Lozada, P., Marmolejo-Rebellón, L. F., Cajigas-Cerón, A. A., Cassava starch separation. Evaluation of gravity settling on channels., Ingeniería e Investigación, Vol. 34, No. 1, April, 2014, pp. 42 – 47.

ABSTRACT

The production of cassava starch in Colombia comes mainly from the northern region of the Cauca Department in small agricultural industries known as "rallanderías", in which the settling of the slurry occurs in channels. Due to the fact that the settling process determines the capacity of the starch industry, it is important to evaluate the sedimentation process performed in rectangular channels (0.3 m high; 0.4 m wide; 165 m long), which are generally used in the region. Two main components were evaluated: determination of the change in the concentration of the slurry entering the settling zone and determination of the particle size distribution in the settling zone. In relation to the affluent of the channels, it was found that the concentration of the slurry during strainer operation was between 0.1 to 6% most of the time; the settling of discrete particles, for which the Stokes Law may be applied, predominated. During the settling process, the flow varied between 0.82 to 1.44 L/s with a predominance of laminar flow and a hydraulic retention time greater than 150 minutes. In the first 104m of the channel, particles greater than 10 µm in size were efficiently retained; particles between 6,7 to 8,8 µm were not retained and were discharged into local bodies of water, generating environmental problems.

Keywords: Cassava starch industry, sedimentation by gravity, sedimentation channels, starch particles.

RESUMEN

La producción de almidón de yuca en Colombia proviene principalmente del norte del departamento del Cauca, en pequeñas industrias agrícolas llamadas "rallanderías", en las cuales la sedimentación de las partículas suspendidas ocurre en canales. Puesto que el proceso de sedimentación determina la capacidad de la industria del almidón, razón por la cual, se consideró importante evaluar el proceso de sedimentación en los canales rectangulares (0.3x0.4 x 165 m), utilizados generalmente en la región. Se evaluaron dos componentes principales en la zona de decantación: el cambio en la concentración de la suspensión afluente y la distribución del tamaño de la partícula. Con relación al afluente de los canales, se encontró que la concentración de la suspensión durante el funcionamiento del filtro, la mayor parte del tiempo fue entre 0.1 a 6%, predominando la sedimentación de partículas discretas para las cuales aplica la ley de Stokes. En la sedimentación, el flujo varió entre 0.82 a 1.44 L/s con predominio de flujo laminar yTRH> 150 minutos. En los primeros 104 m del canal, las partículas con tamaños> 10 µm fueron retenidas eficientemente; las partículas con tamaños entre 6.7 a 8.8 μm no fueron retenidas, siendo vertidas a los cuerpos de agua y generando así, problemas ambientales.

Palabras clave: industria del almidón de yuca, sedimentación por gravedad, canales de sedimentación, partículas de almidón.

Received: September 18th 2013 Accepted: December 20th 2013

Introduction

Cassava is one of the tropical crops richest in starch, with a content level between 25 and 30%. Given its high viscosity, bland taste and neutral flavor, easy degradation, low cost and easy extractability, cassava starch has wide application in food, textile, paper, pharmaceutical, confection, alcohol and adhesive industries among others (FAO, 2006). In Latin America and the Caribbean, almost all cassava starch production is realized in small and midsized factories, with intensive labor and traditional techniques, most of this production being in Brazil and Colombia.

The main region of Colombia dedicated to benefitting from cassava for starch production is the northern sector of the department of Cauca, which is responsible for 80% of the national production and whose extraction is carried out in small agroindustries called "rallanderías" (grating facilities) (CRC, 2005).

The sour cassava starch production begins with the extraction of the cassava starch, which consists of cleaning, peeling, chopping, pressing, and straining the cassava roots. Fiber is separated from the starchy water ("starch milk") and the starch is separated from water either by decantation or by centrifugation, depending on the factory's production capacity; smaller factories employ decantation, while larger ones use the centrifugation process (Avancini et al., 2007). The cassava starch is then either dehydrated for the production of a sweet cassava starch or subjected to natural fermentation for the production of sour cassava starch (Alarcón and Dufuor, 1998; Demiate et al., 1999).

In productive terms, the grating stage is the most critical, given that the percentage of starch extraction depends on it; if the grated mass is too thick, much starch is lost in the bran discarded and if it is too fine, the starch granules will lose density, endure enzymatic degradation and the sedimentation will be slower and less efficient. During the straining stage, the starch particles are dragged by abundant water, creating an aqueous suspension made of starch and water, known as slurry, which is then taken to settling channels or tanks (Torres et al., 2010).

The settling process determines the production capacity of the starch industry (Sajeev and Kailappan, 2008). According to Rivier et al. (2001), the principle of sedimentation in the channels consists of a selective precipitation of the starch suspension in movement; at the end of the channel, the slurry is received and during its passage along the channel sections, the starch granules start to sediment, while the light particles and compounds in solution continue with the current, exiting at the other end with the wastewater. According to Tkatchenko (1959), cited by Tischer and Moreno (1959), to avoid sedimentation of fine particles, the flow rate must be above 4 m/min and to avoid losses of starch, it is necessary to guarantee the occurrence of laminar flow and a flow rate below 10 m/min.

The Stokes Law (Equation 1), permits the determination of the sedimentation volume for spherical particles below 100 microns if the flow is laminar and if the concentration of solids is below 5%.

Where:

Vs : sedimentation volume (m/s)

g : acceleration due to the force of gravity (m/s2)

dp : size of the starch particle (m)

ρp : density of the starch particles (kg/m3)

ρa : density of water (kg/m3)

v: dynamic viscosity (m2/s)

Sajeev et al. (2002) studied the kinetics of sedimentation by gravity of cassava starch, finding that the particles present in the slurry are due to the sedimentation of discrete and flocculent particles, when the concentration of the suspension is below 6% and zonal or compression sedimentation, when it is above 10%. According to Sajeev and Kailappan (2008), the efficiency of settling is determined by the speed of settling and also by the compactness of the settled starch; in the rallanderías that use settling channels, this operation takes place continuously for several days until filling the capacity of the channels.

In the design of the ideal settling units, uniform flow and the laminar regime of the fluid must be considered. For the determination of the type of flow, the Reynolds dimensionless number (Re) is used to classify the flow in laminar regime (Re < 2000) and turbulent regime (Re > 2000); additionally, the effect of the flow regime originated in the fall of the particle (Re*- modified Reynolds dimensionless number), must be below 1.0 to be considered laminar and to be able to apply Equation 2 in the calculation of the surface load or critical settling volume - Vsc.

Where:

CS: Surface load (m/s)

Vsc: Critical settling volume (m/s)

Q: Volume (m3/s)

As: Surface area (m2)

In real settling units, the surface load can be affected by factors such as inadequate distribution of water at the sedimentor entrance, accumulation of sediment interfering with uniform flow distribution and density changes in the fluid associated to temperature changes or to the concentration of solids (AWWA, 2002).

To calculate the Re of the fluid, Equation 3 is used and to calculate Re* Equation 4 is used (Huisman, 1978).

Where

Re: Reynolds number

VF: Rate of flow (m/s)

v: Kinematic Viscosity

A: Transversal area of the channel (m2)

P: Wet perimeter in the channel (m)

Where:

Re: Modified Reynolds number

v: Kinematic Viscosity

Vsc: Critical settling volume (m/s)

d: Particle diameter (m)

The efficiency of the settling does not depend solely on the surface rate or settling volume of particles, but also on the height of settling and on the time of retention in the unit or theoretical hydraulic retention time - HRT (Equation 5) (Chow, 2000).

Where:

HRT: Hydraulic retention time (s)

V: volume of liquid in structure (m3)

Q: operation volume (m3/s)

Modeling of the settling of starch granules, as it occurs in the channels is complex. Studies on the settling of suspended solids in drinking water and wastewater treatment plants are vast (Di Bernardo, 1993; von Sperling, 2007); however, evaluation of the settling process of cassava starch present in an aqueous suspension like slurry is still quite limited. For that reason, we evaluated the behavior of the slurry settling in the sedimentation channels commonly employed in the sour cassava starch extraction process in the northern region of the Department of Cauca, Colombia.

Experimental development

The evaluation was conducted at the facilities of a rallandería located in the township of La Agustina in the municipality of Mondomo, northern region of the Department of Cauca, which is at an altitude of 1200 m above sea level.

Determination of the change in the concentration of the slurry entering the settling zone

Change in the concentration of starch slurry entering the channels during the time of operation of the strainer was determined according to the classification by Sajeev et al. (2002). To determine this change, four trials were conducted during different operating times.

Slurry samples were taken every two minutes during the first ten minutes and every five minutes during the remaining time of strainer operation; each of these samples was subjected to sedimentation in Imhoff cones to determine the ratio (V/V) and relate it to the type of predominant sedimentation (i.e. discrete, flocculent or zonal particles and compression particles); the measurement of the sediment volume on the cone was done at a time where no visible changes in sedimentation were observed, according to preliminary observations by Ayala (2005).

Determination of particle size distribution in the sedimentation zone

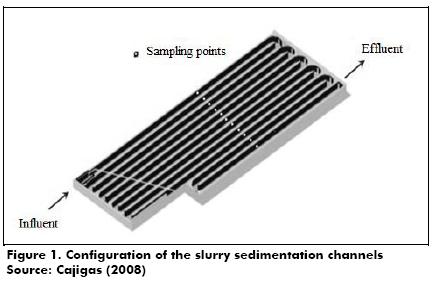

Upon identifying the predominance of the discrete particles, we proceeded to evaluate the particle size distribution of the slurry (starch plus water) in the settling zone in the rallandería under study. This zone was comprised of 11 channels (nine of 16 m and two of 10.5 m) with a total length of 165 m, whose transversal section is 0.3 m high by 0.4 m wide. The points selected to take the sample and measurements correspond to the line formed at the intermediate points of the first channels (see Figure 1).

Evaluation of operational conditions to determine the viability of the Stokes law application. Determination of volume, Re, and HRT

Conditions that could limit the sedimentation principle of the Stokes Law, such as hydraulic conditions (Volume, Re and HRT) and the slurry concentration at the exit of the strainer equipment were checked during the time of operation. It is worth highlighting that of the components of the Stokes equation, the only one that can vary in the operation of the channels is the sedimentation volume, which depends on two factors: volume and surface area. Bearing in mind that the area is constant, volume was the only variable condition in the study and determinant in the size of the particles that could be removed.

Volume gauging was done in volumetric manner during eight grating sessions, through six measurements per session; values reported from each measurement, correspond to the average of four consecutive gauging. Once the gauging is done to determine the volume ranges predominant in the operation of the settling channels, we theoretically checked the hydraulic conditions that relate these volumes to the type of flow in order to identify under what conditions the Reynolds number (Re) determines the occurrence of laminar flow. This was carried out by using a spreadsheet, calculating the Re associated to the different volumes that could be present in the rallandería, taking into account the different heights of water surface used in settling in the channels (17, 21, 24, and 28 cm).

Another check performed was that of the hydraulic retention time (HRT), determined using the operation volumes and the water volume obtained with the different heights of water surface.

Theoretical calculation of the size of particle that can be removed in sedimentation channels

The calculation of the particle size was performed through the application of the Stokes equation combined with the configuration of channels; these two elements determine the size of particle that can be removed in each channel. For the calculation the Reynolds number (Re) of the particle was kept in mind.

In calculating the critical sedimentation volumes of the particles, the actual conditions of water density and kinematic viscosity were accounted for and taken according to the mean temperature of the channels; the density of the starch particles was measured in the laboratory via the volumetric method. Using a spreadsheet, the critical sedimentation volume was calculated for different particle sizes. Given that the settling volume is associated to the surface area of the channels, we calculated the volume that can be applied to remove a specific particle size at different channel lengths.

Amount of starch retained in the channels and visual determination of particle size

The profile conformed by the slurry was constructed in four operation sessions along the channels and an average tendency of the areas under the curve was estimated in order to establish (in percentages) the amount of starch retained per channel.

To verify the size of the particles retained in the different sections of channels evaluated through microscopy studies, particle size was determined by using an optical microscope with a 100X objective, that together with the microscope eyepiece (10X) determined a total magnification of 1000 to 1. To facilitate reading the size of particles, the microscope eyepiece had a millimeter ruler that permitted having a direct reading in µm. The microscope image was captured by using digital photography; to distinguish the starch particles, these were stained with an iodine solution. A drop of the sample from the settling channels was added to the glass slide followed by a drop of iodine solution, which upon contact, generates a purple coloring. The glass slide was covered with another slide and immersion oil was applied to avoid diffraction.

To keep from interfering in the settling process and the possible resuspension of the sedimented material, samples were taken from the supernatant water of the channels. The determined size of particles is of those not retained at the specific point where the simple was taken, assuming that particles bigger than those identified are those retained in the channels.

Results

Determination of the change in the concentration of the slurry entering the sedimentation zone

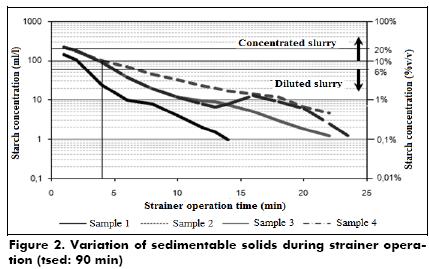

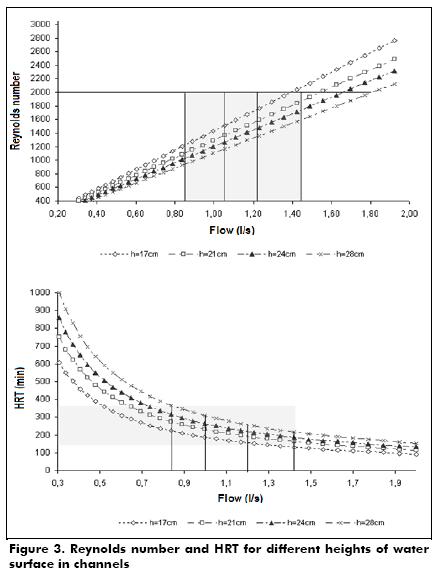

Figure 2 shows the behavior of the sedimentable solids during four strainer operation sessions. According to these results, the concentration of the slurry was classified into the three conditions presented by Sajeev et al. (2002), as shown in Table 1.

It is noted that most of the time (approximately 20 minutes: 80%), settling of discrete particles predominates, for which the Stokes equation may be applied to predict their behavior. In a rallandería with a configuration of settling channels similar to that of the study, Tischer and Moreno (2004) found that the concentration of the slurry varied from 7.3% at the start of the screening to almost zero after 15 to 20 minutes, which is in agreement with findings in this study.

The density of the starch measured in the laboratory was on average 1500 kg/m3, a value consistent with that of 1520 kg/m3 reported elsewhere (Sajeev et al., 2002); the values of the water density and the dynamic viscosity for a temperature of 23°C correspond to 998 kg/m3 and 9.41*10-7m2/s, respectively, and were calculated according to temperature.

Determination of the particle size distribution in the sedimentation zone

Evaluation of operational conditions to determine the viability of applying the Stokes law. Determination of volume, Re, and HRT

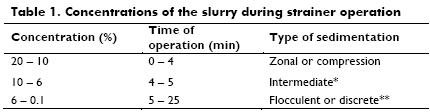

The volume of the slurry entering the settling zone in channels during the operation of the rallandería varied within a range between 0.82 and 1.44 L/s with a median of 1.15, with the most representative interval of operation between 1.05 and 1.22 l/s (50% of the data). With these values, the theoretical calculation of Re and HRT was performed for the different operation water levels (17, 21, 24, and 28 cm), as shown in Figure 3.

Predominance of laminar flow (Re < 2000) is mainly noted for strap 21, 24, and 28 cm and considering that there is no accumulation of sediments; however, in the smaller strap (17 cm) increase of volume could cause major interference in the sedimentation of the particles and compromise the laminar flow condition and, hence, the efficiency of the process.

Regarding the HRT calculated, a directly proportional relation was found between the water surface and the HRT; the minimum 150-minute value coincides with experimental tests conducted in this plant, where it was found that retention times should be consid-ered above 150 minutes (Ayala, 2005), which indicates an adequate operation; nevertheless, the operation of channels with water level heights below those evaluated could also compromise the HRT and, hence, the efficiency of the process.

Theoretical calculation of the size of particle that can be removed in sedimentation channels

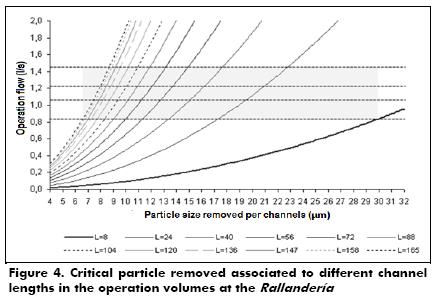

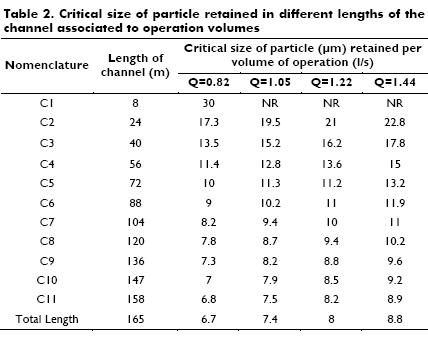

With the results found, we determined the critical particle size that can be removed in different channel lengths, as shown in Figure 4. The shaded region highlights the operation volumes of the rallandería.

Taking as a starting point the volumes of operation range in the rallandería, Table 2 was constructed, summarizing the critical particle size retained in different channel lengths associated to operation volumes.

Amount of starch retained in the channels and visual determination of the particle size

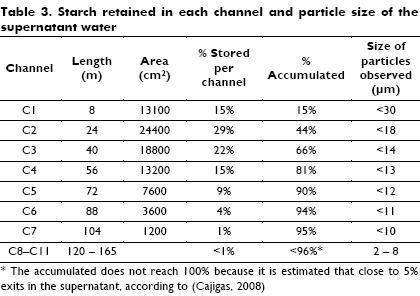

Figure 5 shows the profile that makes up the starch sediment along the 11 channels. The shaded section represents the average area and shows the tendency of different grating days with which the starch retention percentages were calculated, along with the accumulated percentages shown in Table 3, in addition to particle size of the supernatant water in sedimentation channels.

Table 3 shows that 95% of the particles was retained within the first 104 m (up to channel 7), which is according to mass balances carried out in the rallandería (Marmolejo et al., 2008).

The critical particle size theoretically determined (Table 2) are very consistent with those observed in the different lengths of channel shown in Table 3; this range of values (2 – 30 µm) is within the ranges cited by other authors (Alarcón & Dufour, 1998; Defloor et al., 1998; Sriroth et al., 1999; Santisopasri et al., 2001)

For the total length of the cannel, it was found that the smallest particle size that can be retained is in the range between 6.7 and 8.8µm, values close to those obtained in the last four channels, given that these types of particles are difficult to retain for the configuration of the sedimentation channels.

The critical particle size theoretically determined (Table 2) are very consistent with those observed in the different lengths of channel shown in Table 3; this range of values (2 – 30 µm) is within the ranges cited by other authors (Alarcón & Dufour, 1998; Defloor et al., 1998; Sriroth et al., 1999; Santisopasri et al., 2001)

For the total length of the cannel, it was found that the smallest particle size that can be retained is in the range between 6.7 and 8.8µm, values close to those obtained in the last four channels, given that these types of particles are difficult to retain for the configuration of the sedimentation channels.

Conclusions

The evaluation made on the sedimentation channels ratifies that the technology operated adequately in laminar flow regime with which the greatest retention of particles (above 10 µm) was obtained. It was found that within the first 104 m of longitude, we can efficiently retain particles greater than or equal to 8 µm and, in spite of having an additional longitude of approximately 60 m, the small size of the particles limits its physical separation; although this fraction, which constitutes close to 5% of the total, is not represented in significant losses for the producer, generates hydric contamination problems because of its dumping into bodies of water.

Acknowledgments

The authors express their gratitude to Universidad del Valle and COLCIENCIAS for the economic support granted to carry out the project "Clean production applied to the extraction process of cassava starch" and to the owner of the Piedras Negras rallandería, where the study took place.

References

Alarcon, F., Dufour, D., Almidón agrio de yuca en Colombia: Tomo I: Producción y Recomendaciones., Cali, Colombia, Centro Internacional de Agricultura Tropical - CIAT, Montpellier, Francia, Centre de coopération internationale en recherche agronomique pour le développement, Département d'amélioration des méthodes pour I'innovation scientifique - CIRAD, 1998. [ Links ]

Arboleda, J., Teoría y práctica de la purificación del agua., 3th ed., Bogotá D.C., Mc Graw Hill, 2000, pp. 792. [ Links ]

Avancini, S. R. P., Faccin, G. L., Vieira, M. A., Rovaris, A. A., Podestá, R., Tramonte, R., De Souza, N. M. A., Amante, E. R., Casava starch fermentation wastewater: Characterization and preliminary toxicological studies., Food and Chemical Toxicology, Vol. 45, No. 11, 2007, pp. 2273 - 2278. [ Links ]

AWWA - American Water Works Association., Calidad y tratamiento del agua, manual de suministros de agua comunitaria., 1st ed., España, McGraw-Hill, 2002. [ Links ]

Ayala, D., Evaluación de la separación física del almidón y la mancha en el proceso de extracción de almidón agrio de yuca., Grade work, Ingeniero Sanitario, Cali - Colombia, Escuela de Ingeniería de Recursos Naturales y del Ambiente - EIDENAR, Universidad del Valle, 2005, pp. 65. [ Links ]

Cajigas, A., Evaluación del potencial de reducción de partículas del proceso de extracción de almidón de yuca con énfasis en la etapa de sedimentación., Master research work, Ingeniería Sanitaria y Ambiental, Cali - Colombia, Facultad de Ingeniería, Universidad del Valle, 2008, pp. 102. [ Links ]

Chow, V. T., Hidráulica de canales abiertos., Bogotá D. C., Mc Graw Hill, 2000, pp. 667. [ Links ]

CRC - Corporación Regional del Cauca, Rallandero Limpio. Cartilla educative., Popayán, Colombia, Corporación Regional del Cauca, 2005. [ Links ]

Defloor, I., Dehing, I., Delcour, J. A., Physico-Chemical Properties of Cassava Starch., Starch/Stärke, Vol. 50, No. 2-3, 1998, pp. 58-64. [ Links ]

Demiate, I. M., Barana, A. C., Cereda, M. P., Wosiacki, G., 1999 Organic acid profile of commercial sour cassava starch., Food Science and Technology (Campinas), Vol. 19, No. 1, pp. 131 - 135. [ Links ]

Di Bernardo, L., Métodos e Técnicas de Tratamento de Água., Vol. 1, Rio de Janeiro, ABES, 1993. [ Links ]

FAO - Food and Agriculture Organization, El mercado de almidón añade valor a la yuca., Estados Unidos, Departamento de Agricultura, Bioseguridad, Nutrición y Protección del Consumidor, 2006. [ Links ]

Huisman, L., Sedimentation and flotation. Mechanical filtration., 2nd ed., Delft, University of Technology, 1978. [ Links ]

Marmolejo, L. F., Pérez, A., Torres, P., Cajigas, A. A., Cruz, C. H., Utilization of the solid wastes generated in smallscale cassava starch production., Livestock Research for Rural Development, Vol. 20, No. 7, 2008, pp. 1-17. [ Links ]

Rivier, M., Moreno, M., Dufour, D., Almidón agrio de yuca en Colombia. Tomo 2: planta procesadora: descripción y planos de los equipos., Cali, Colombia, CIAT 323, 2001. [ Links ]

Sajeev, M. S., Kailappan, R., Effect of various processes on settling of cassava starch., Journal of Root Crops, Vol. 34, No. 2, 2008, pp. 148-156. [ Links ]

Sajeev, M. S., Kailappan, R., Sreenarayanan, V., Thangavel, K., Kinetics of gravity settling of cassava starch in its aqueous suspension., Biosystem Engineering, Vol. 83, No. 3, 2002, pp. 327-337. [ Links ]

Santisopasri, V., Kurotjanawong, K., Chotineeranat, S., Piyachomkwan, K., Sriroth, K., Oates, C. G., Impact of water stress on yield and quality of cassava starch., Industrial Crops and Products, Vol. 13, No. 2, 2001, pp. 115-129. [ Links ]

Sriroth, K., Santisopasri, V., Petchalanuwatc, C., Kurotjanawong, K., Piyachomkwansriroth, K., Oates, C. G., Cassava starch granule structure function properties: Influence of time and conditions at harvest on four cultivars of cassava starch., Carbohydrate Polymers, Vol. 38, No. 2, 1999, pp. 161-170. [ Links ]

Tischer, I., Moreno, M., Influencia de la localización del almidón nativo de yuca en el canal de sedimentación sobre la calidad del almidón agrio., Ingeniería y Competitividad, Vol. 6, No. 1, 2004, pp. 26-34. [ Links ]

Tkatchenko, B., Note technologique complémentaire pour les féculeries de Madagascar utilisant les bassins de dépôt, Iram, Tenanarive, 1959. [ Links ]

Torres, P., Pérez, A., Marmolejo, L. F., Ordoñez, J. A., García, R. E., Una mirada a la agroindustria de extracción de almidón de yuca, desde la estandarización de procesos., Revista Escuela de Ingeniería de Antioquia, No. 14, 2010, pp. 23-38. [ Links ]

Von Sperling, M., Biological Wastewater Treatment., Volume 2: Basic principles of wastewater treatment., London, IWA Publishing, 2007. [ Links ]