Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.34 no.2 Bogotá May/Aug. 2014

https://doi.org/10.15446/ing.investig.v34n2.41621

http://dx.doi.org/10.15446/ing.investig.v34n2.41621

J. Fontalvo1

1 Javier Fontalvo. Grupo de Investigación en Aplicación de Nuevas Tecnologías, Laboratorio de Intensificación de Procesos y Sistemas Híbridos, Departamento de Ingeniería Química. Universidad Nacional de Colombia - Sede Manizales, Colombia. E-mail: jfontalvoa@unal.edu.co

How to cite: Fontalvo, J. (2014). Using user models in Matlab® within the Aspen Plus® Interface with an Excel®. Ingeniería e Investigación, 34(2), 39-43.

ABSTRACT

Process intensification and new technologies require tools for process design that can be integrated into well-known simulation software, such as Aspen Plus®. Thus, unit operations that are not included in traditional Aspen Plus software packages can be simulated with Matlab® and integrated within the Aspen Plus interface. In this way, the user can take advantage of all of the tools of Aspen Plus, such as optimization, sensitivity analysis and cost estimation. This paper gives a detailed description of how to implement this integration. The interface between Matlab and Aspen Plus is accomplished by sending the relevant information from Aspen Plus to Excel, which feeds the information to a Matlab routine. Once the Matlab routine processes the information, it is returned to Excel and to Aspen Plus. This paper includes the Excel and Matlab template files so the reader can implement their own simulations. By applying the protocol described here, a hybrid distillation-vapor permeation system has been simulated as an example of the applications that can be implemented. For the hybrid system, the effect of membrane selectivity on membrane area and reboiler duty for the partial dehydration of ethanol is studied. Very high selectivities are not necessarily required for an optimum hybrid distillation and vapor permeation system.

Keywords: Matlab, Aspen Plus, process simulation, process intensification, hybrid systems, distillation, membrane technology.

RESUMEN

El diseño de procesos intensificados y de nuevas tecnologías requiere de herramientas de simulación como Aspen Plus®. Sin embargo, las operaciones unitarias que no se incluyen en Aspen Plus pueden ser simuladas usando Matlab e integradas con la interfaz de Aspen Plus. De esta forma se pueden aprovechar todas la capacidades de Aspen plus como la optimización, el análisis de sensibilidad y la estimación de costos. Este artículo describe en detalle cómo implementar esta integración. La interfaz entre Matlab y Aspen Plus se logra enviando información de la simulación desde Aspen Plus a Excel y desde éste a Matlab, quien la retorna procesada hacia Excel y finalmente es retroalimentada a Aspen Plus. Este artículo incluye los archivos base de Excel y Matlab que le permitirán al lector desarrollar sus propias simulaciones en Aspen Plus. En este artículo se aplica este protocolo para simular un sistema híbrido de destilación y permeación de vapor para la deshidratación parcial de etanol como un ejemplo del tipo de aplicaciones que se puede implementar. Para este sistema híbrido se estudia el efecto de la selectividad de la membrana sobre el área de membrana y sobre el consumo de energía en el rehervidor. Se encuentra que no necesariamente las altas selectividades son convenientes para desarrollar un sistema híbrido óptimo de destilación y permeación de vapor.

Palabras clave: Matlab, Aspen Plus, simulación de procesos, intensificación de procesos, sistemas híbridos, tecnología de membranas.

Received: January 17th 2014 Accepted: March 23th 2014

Introduction

Process intensification is a strategy for achieving dramatic reductions in environmental impacts, energy consumption, plant footprint, and operating costs while increasing the productivity of an industrial plant compared with conventional ones (Stankiewicz and Moulijn, 2002, 2000; Van Gerven and Stankiewicz, 2009). In order to design new plants and to evaluate their performance and impacts, process simulation software has become important, and several options are available in the market.

Aspen Plus® is a well-known software for process design with integrated tools for optimization, sensitivity analysis and economic evaluation. Although Aspen Plus possesses an important number of unit operations that can be simulated, some new technologies and units used for process intensification are not included. However, user models and special units required for process intensification can be simulated with programming software, such as Matlab®. Thus, a tool that keeps the full functionality and numerical power of Aspen Plus and that can integrate Matlab user models is important for designing new and intensified processes.

Some years ago, Fontalvo et al. (Fontalvo et al., 2005) presented simulation results of a hybrid distillation-membrane process using an integrated system of Matlab within the Aspen Plus interface. In this publication, the specific details for this connection were not shown. Although other authors have also used this integration between Aspen Plus and Matlab (Kiss et al., 2012; Vázquez-Ojeda et al., 2013), no specific information can be found on the web or in the Aspen Customer support web page.

This paper describes a detailed protocol for using the Aspen Plus user interface for calling Matlab user models. It does not intend to show the specific numerical performance or computation speed of this integration, which depends on each specific application. The described integration retains the capabilities of Aspen Plus for optimization, sensitivity analysis and cost estimation. Additionally, a hybrid distillation and vapor permeation process is shown as an application example. The effect of membrane selectivity on the required membrane area and reboiler duty is presented.

Incorporating Matlab® within the Aspen Plus® Interface

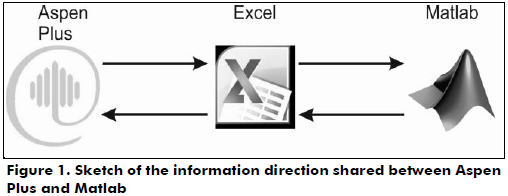

Within the Aspen Plus interface, a Matlab user model (MUM) can be included by a process that is described in Figure 1. Aspen Plus supplies to Excel properties of the several streams of the user block or user model and some additional parameters. The Excel file organizes and sends this information to the Matlab routine. The Matlab routine calculates, for the user block, the properties of the outlet streams and, if required, additional parameters. This information is returned to Excel® which then returns it to the Aspen Plus interface. Once the information is obtained by Aspen Plus, the modeling of other units within Aspen Plus will continue as usual. Due to the structure presented in Figure 1, it is possible to use tools of Aspen Plus for optimization, sensitivity analysis and plotting. Also specific plots generated by the Matlab routine regarding the user model itself can be obtained within the Aspen Plus simulation.

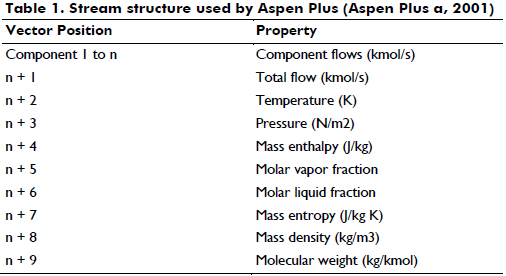

Table 1 presents the inlet and outlet stream structure used by Aspen Plus. The stream structure is a vector with n + 9 elements, where n is the number of components in the mixture. The units of physical quantities used for each property are indicated in the table. The order of these properties is important because once the information is received by Matlab, it has to be processed taking into account the given structure and units.

The outlet stream properties (and the inlet stream properties) calculated by the MUM should be a matrix with a size of (n + 9) x m, where m corresponds to the number of outlet (or inlet) streams, and each of the m columns have the same order and the same units of physical quantities to those presented in Table 1. However, in the Matlab routine, it is necessary to calculate only the first n+3 elements of each of the outlet stream vectors. Elements n+4 to n+9 can be calculated by Aspen Plus using stream composition, temperature and pressure.

Parameters are a specific type of information that is required or calculated by the Matlab user model. Two types of parameters are used by Aspen Plus (Aspen Plus b, 2001): real and integer. Real parameters correspond, for example, to membrane area, heat supply, tube length, catalysts weight, specific surface area, etc. Integer parameters are, for example, the number of tubes, units, heat exchangers, finite elements for a specific numerical method, membrane modules, etc. Some of these parameters are inputs, while others are calculated by the MUM routine. The real and the integer parameters are vectors of different sizes that are previously organized in the Aspen Plus interface. The order of these vectors used in the Aspen Plus interface should be conserved in the MUM.

Matlab user model (MUM) and Excel link

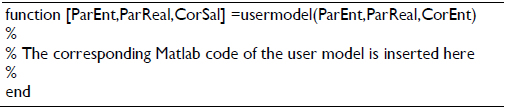

Matlab (usermodel.m) and Excel (usermodel.xls) template files are available for this paper. The structure of the Matlab template file is:

where ParEnt and ParReal are column vectors of integer and real parameters, respectively. CorEnt and CorSal are matrices of inlet and outlet streams to and from the user unit, respectively. Within the MUM routine (file: usermodel.m), the user calculates the outlet stream properties (CorSal) and the unknown values of elements in the real and integer parameter vectors.

Excel versions to use with Aspen Plus should be 2007 or older. It is expected that AspenTech will soon make Aspen Plus compatible with newer versions of Excel. The Excel template file contains special functions that are required to send and receive information to and from Aspen Plus. More information about these special functions (Aspenhooks) is found elsewhere (Aspen Plus c, 2001). Also the Excel file contains some commands to send and receive information to and from the MUM. More information about these Commands of Matlab in Excel can be found in the Excel Link user manual of Matlab toolboxes (Spreadsheet Link, 2013).

The attached Excel file template is ready to use and does not require any further modification. In this file, the MUM routine is called "usermodel". If a different name is used, the user can access the Excel file, open the macro, "calculate", and modify it by changing the line:

[ParEnt,ParReal,CorSal]=usermodel(ParEnt,ParReal,CorEnt)

to the new Matlab subroutine name, as follows:

[ParEnt,ParReal,CorSal]=newname(ParEnt,ParReal,CorEnt)

Prior to linking the Excel file to Matlab, the user has to include the excellink add-ins. To activate an Excel add-in (Excel 2007):

1. Click the office button tab, click Options, and then click the Add-Ins category.

2. In the Manage box, click Excel Add-ins, and then click Go. The Add-Ins dialog box appears.

3. In the Add-Ins available box, select Browse (in the Add-Ins dialog box) to locate the add-in. The add-in is typically located in: C:\Program Files\MATLAB\R2008a\toolbox\exlink\excllink.xla

Once the Excel add-in is installed, a Matlab command window will appear. Click "File" in the Matlab command window, click "set-path" and add the corresponding folder for the "usermodel.m" file. The Excel file (usermodel.xls) can be stored in the same folder as the MUM file.

An example of using a Matlab® user model in Aspen Plus®

This and the following sections present examples of the applications that might be used, so the reader can, based on these examples, implement and simulate different and more complex systems. The inlet streams to a MUM can come from other unit operations that are simulated within Aspen Plus or by other routines, such as Excel, Fortran or Matlab. Additionally, the outlet streams can feed, if required, other unit operations. This section describes the main steps to implementing a single MUM in Aspen Plus. For a process simulation where several units are present, the described protocol can be repeated. An example is shown in the next section.

The MUM file (usermodel.m) is an example routine that evaluates a vapor permeation membrane (VP) unit for the selective removal of water from ethanol. The simulation of this unit operation is demonstrative, and it is not the aim for this paper to simulate a rigorous vapor permeation membrane unit. However, some important conclusions will be presented in the design example below. The routine uses ideal gas and constant temperature for the retentate and permeate streams. Permeability values for water and ethanol remain constant.

In Aspen Plus, go to "User Models" and insert a unit operation called "User2". The User2 block allows any number of inlet and outlet streams. There are five steps in extending the User2 model to incorporate a Matlab user model:

1. Place a User2 block.

2. Connect any streams.

3. Specify the name of the Excel workbook file that calls the Matlab routine that represents the unit operation model for the block.

4. Enter the operating parameters by filling out the real and integer parameter arrays.

5. Specify the "stream flash" for the outlet streams to calculate stream properties that are dependent on composition, temperature and pressure.

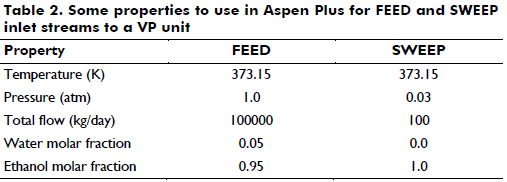

Insert the corresponding inlet streams. The order of these streams is important because the inlet stream information is supplied to the Matlab routine in this specific order. Specifically, for the Matlab file that is provided with this paper (usermodel.m), two inlet streams, FEED and SWEEP, will be used to preserve this order. Insert the outlet streams preserving this order: RETENTATE and PERMEATE. Table 2 shows the properties for the FEED and SWEEP streams.

It is important to remark that regardless of the units of the physical quantities the user has supplied in the Aspen Plus interface for the inlet streams (Table 2), the units reported to the MUM routine will always be those found in Table 1.

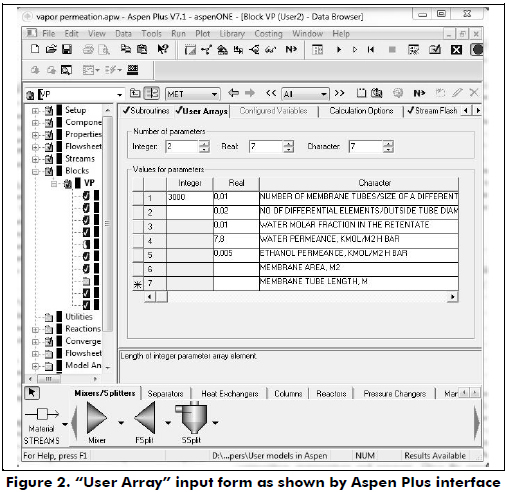

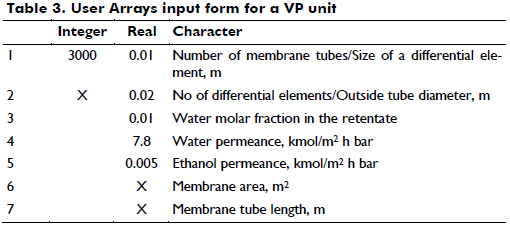

Double click on the User2 block and a new window will pop-up; click the subroutine input form. In "Excel file name" browse for the Excel file, usermodel.xls. For this specific example, the MUM will work with 2 integer (i.e., the number of membrane tubes and the number of differential elements for simulating the membrane unit) and 7 real parameters (i.e., the size of a differential element, outside tube diameter, outlet water molar fraction in the retentate, water permeance, ethanol permeance, membrane area and membrane tube length) that have to be specified in the Aspen Plus interface. Thus, in the "User Arrays" input form (Figure 2) input 2 integer parameters, 7 real parameters and 7 characters (the number of "characters" has been specified in 7, so one can include a short description of each of the integer and real parameters) and input the information shown in Table 3. Integer and real parameters in Aspen Plus are treated as both input and output. The cells filled with an "X" correspond to unknown information that will be calculated by the Matlab routine. The column Character in the table presents a brief description of the corresponding integer and real parameters.

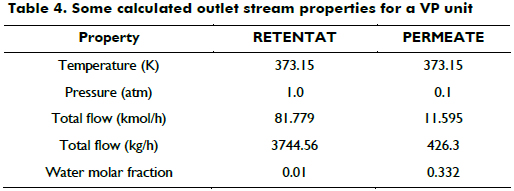

Select the "Stream Flash" sheet; in the stream dialog box, select each of the outlet streams (RETENTAT and PERMEATE), and for each stream in the flash type dialog box, select "Temperature & pressure". By selecting "Temperature & pressure" other properties such as enthalpy, entropy, molecular weight, vapor fraction and other properties in Table 1 are calculated by Aspen Plus using the composition, temperature and pressure. Once the simulation is run, the following results are found:

1. Number of differential elements: 827.

2. Membrane area: 1558.9 m2.

3. Tube Length: 8.3 m.

Table 4 presents results for the outlet streams.

The water molar fraction in the RETENTAT stream, shown in Table 4, corresponds to the required water molar fraction in the retentate, specified in Table 3.

An example for a hybrid distillation-vapor permeation process

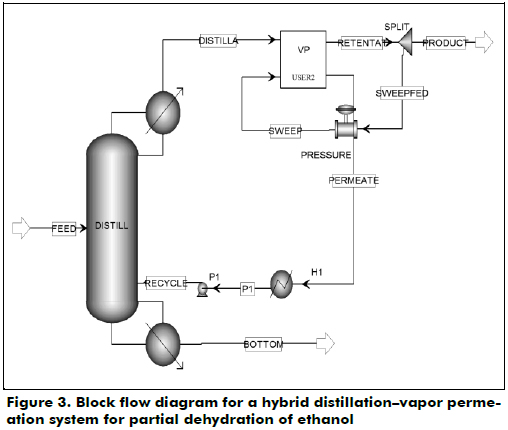

A more complex application example of the protocol described above is presented in this section for a hybrid system. Figure 3 presents a hybrid distillation and vapor permeation system for the partial dehydration of ethanol. The information for the vapor permeation (VP) unit is given in Table 3, except: 100 tubes have been used in the calculation, the required water molar fraction is 0.05 and ethanol permeability has been modified depending on membrane selectivity. The retentate stream is split: a small fraction (4.167 kg/h) is recycled as a sweep stream to the VP unit and a product stream of 98 wt% of ethanol is obtained. The permeate stream from the VP unit is condensed, pumped and recycled to the reboiler of the distillation tower. The permeate pressure is 0.05 atm, and thus, cooling water can be used.

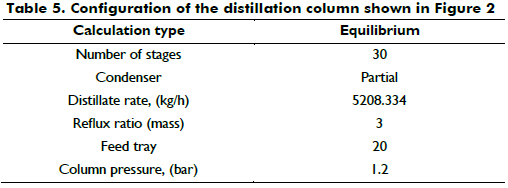

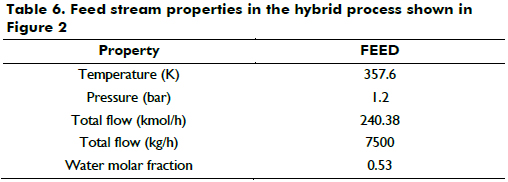

The specific configuration used for the distillation column in Figure 3 is shown in Table 5, and the corresponding feed stream properties are presented in Table 6.

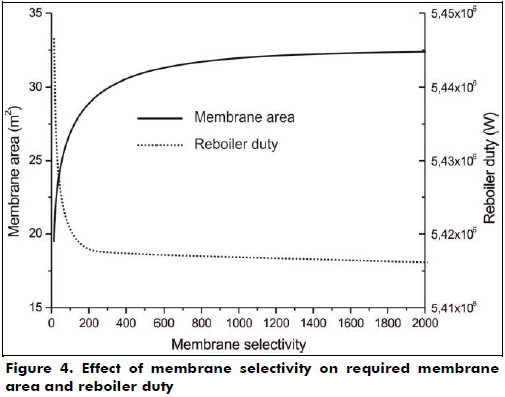

Membrane selectivity is defined as the ratio of the water-to-ethanol permeance (Baker et al., 2010). Using a constant water permeance (Table 3) but changing the ethanol permeance makes it possible to simulate the influence of the membrane selectivity on the required membrane area and reboiler duty for the hybrid system (Figure 3).

This simulation can be performed using the tool sensitivity of Aspen Plus, and the results are presented in Figure 4. As the membrane selectivity decreases, the required membrane area is also reduced. Due to the relative high pressure in the permeate side, very highly selective membranes will produce high permeate water concentrations, reducing the water driving force and consequently, the water flux through the membrane. The lower the water flux through the membrane, the greater the membrane area. However, the drawback of low membrane selectivities is the resultant high energy consumption in the reboiler. Two opposite factors influence the operating cost of this hybrid system. For low selectivities, the required membrane area is low but the reboiler duty is high. Thus, the economic optimal membrane selectivity will be placed at relative low membrane selectivities. Essentially, very high selectivities are not necessarily required for hybrid distillation and vapor permeation systems. More results regarding this analysis can be found elsewhere (Fahmy et al., 2001; Fontalvo et al., 2005).

Conclusions

Process intensification and new technologies require tools for process design that can be integrated into well-known simulation software, such as Aspen Plus. A protocol is described for integrating Matlab user models within the Aspen Plus interface. With this integration, the user can take advantage of all of the tools of Aspen Plus, such as optimization, sensitivity analysis and cost estimation. The interface between Matlab and Aspen Plus is accomplished by sending the relevant information from Aspen Plus to Excel, which in turn feeds the information to a Matlab routine. Once the Matlab routine processes the information, it is returned to Excel and to Aspen Plus. This paper includes the Excel and Matlab template files so the reader can perform their own simulations. By implementing the protocol described in this paper a hybrid distillation-vapor permeation system has been simulated in order to show an example of the applications that can be implemented. In this example, the effect of membrane selectivity on membrane area and reboiler duty for the partial dehydration of ethanol has been explored using the sensitivity analysis tool of Aspen Plus. Very high selectivities are not necessarily required for designing optimal hybrid distillation and vapor permeation systems.

References

Aspen Technology, Inc. (2001). Aspen Plus a. User Models V 11.1 (pp. c-4). [ Links ]

Aspen Technology, Inc. (2001). Aspen Plus b. User Models V 11.1 (pp. 5-12). [ Links ]

Aspen Technology, Inc. (2001). Aspen Plus c. User Models V 11.1. 5-15 - 5-18. [ Links ]

Baker, R. W., Wijmans, J. G., & Huang, Y. (2010). Permeability, permeance and selectivity: A preferred way of reporting pervaporation performance data. Journal of Membrane Science, 348(1-2), 346-352. [ Links ]

Fahmy, A., Mewes, D., & Ebert, K. (2001). Design methodology for the optimization of membrane separation properties for hybrid vapor permeation-distillation processes. Separation Science and Technology, 36(15), 3287-3304. [ Links ]

Fontalvo, J., Cuellar, P., Timmer, J. M. K., Vorstman, M. A. G., Wijers, J. G., & Keurentjes, J. T. F. (2005). Comparing pervaporation and vapor permeation hybrid distillation processes. Industrial and Engineering Chemistry Research, 44(14), 5259-5266. [ Links ]

Kiss, A. A., Segovia-Hernández, J. G., Bildea, C. S., Miranda-Galindo, E. Y., & Hernández, S. (2012). Reactive DWC leading the way to FAME and fortune. Fuel, 95, 352-359. [ Links ]

Stankiewicz, A. J., & Moulijn, J. A. (2000). Process intensification: Transforming Chemical Engineering. Chemical Engineering Progress, 96(January), 22-34. [ Links ]

Stankiewicz, A. J., & Moulijn, J. A. (2002). Process Intensification. Industrial and Engineering Chemistry Research, 41, 1920-1924. [ Links ]

Van Gerven, T., & Stankiewicz, A. J. (2009). Structure, Energy, Synergy, Time - The Fundamentals of process Intensification. Industrial and Engineering Chemistry Research, 48(5), 2465-2474. [ Links ]

Vázquez-Ojeda, M., Segovia-Hernández, J. G., Hernández, S., Hernández-Aguirre, A., & Kiss, A. A. (2013). Design and optimization of an ethanol dehydration process using stochastic methods. Separation and Purification Technology, 105, 90-97. [ Links ]