Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Accesos

Accesos

Links relacionados

-

Citado por Google

Citado por Google -

Similares en

SciELO

Similares en

SciELO -

Similares en Google

Similares en Google

Compartir

Ingeniería e Investigación

versión impresa ISSN 0120-5609

Ing. Investig. vol.35 no.2 Bogotá mayo/ago. 2015

https://doi.org/10.15446/ing.investig.v35n2.49710

DOI: http://dx.doi.org/10.15446/ing.investig.v35n2.49710.

Glucose obtained from rice bran by ultrasound-assisted enzymatic hydrolysis

Glucosa obtenida de salvado de arroz por hidrólisis enzimática asistida por ultrasonido

P. Sfalcin1, F. C. Lunelli2, T. P. S. Maleski3, V. S. Foletto4, M. Souza5, E. Zimmermann6, V. Dal Prá7, E. L. Foletto8, R. C. Kuhn9 and M. A. Mazutti10

1 Pâmela Sfalcin, Chemical Engineer. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: pamelasfalcin@gmail.com.

2 Felipe Cavalheiro Lunelli, Chemical Engineer. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: fiunelli_92@hotmail.com.

3 Tanisa Paula Silveira Maleski, Chemical Engineer. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: tan.psm@hotmail.com

4 Vitória Segabinazzi Foletto, Pharmacy student, Affiliation: Researcher, Undergraduate Course in Pharmacy. Federal University of Santa Maria, Brazil. E-mail: vitoria_sfoletto@yahoo.com.br.

5 Matheus Souza, Chemical Engineer. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: matheus_souza07@hotmail.com.

6 Eduardo Zimmermann, Chemical Engineer. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: dudo_91@yahoo.com.br.

7 Valéria Dal Prá, Pharmacist, MSc. Affiliation: Researcher, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: vdpdalpra@gmail.com.

8 Edson Luiz Foletto, Chemical Engineer, Dr. Affiliation: Associate Professor, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: efoletto@gmail.com.

* Raquel Cristine Kuhn, Food Engineer, Dr. Affiliation: Associate Professor, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: raquelckuhn@yahoo.com.br.

9 Marcio Antonio Mazutti, Food Engineer, Dr. Affiliation: Associate Professor, Department of Chemical Engineering, Federal University of Santa Maria, Brazil. E-mail: marciomazutti@gmail.com.

How to cite: Sfalcin, P., Lunelli, F. C., Maleski, T. P. S., Foletto, V. S., Souza, M., Zimmermann, E., Dal Prá, V., Foletto, E. L., Kuhn, R. C., & Mazutti, M. A. (2015). Glucose obtained from rice bran by ultrasound-assisted enzymatic hydrolysis. Ingeniería e Investigation, 35(2), 61-66. DOI: http://dx.doi.org/10.15446/ing.investig.v35n2.49710.

ABSTRACT

In this work ultrasound-assisted solid-state enzymatic hydrolysis of rice bran to obtain fermentable sugars was investigated. For this purpose, process variables such as temperature, enzyme concentration and moisture content were evaluated during the enzymatic hydrolysis with and without ultrasound irradiation. The enzyme used is a blend of amylases derived from genetically modified strains of Trichoderma reesei. Kinetic of the enzymatic hydrolysis of rice bran at the constant-reaction rate period were measured. The best results for the ultrasound-assisted enzymatic hydrolysis was obtained using 3 wt % of enzyme, 60 oC and moisture content of 65 wt %, yielding 0.38 g sugar/g rice bran, whereas for the hydrolysis in the absence of ultrasound the highest yield was 0.20 g sugar/g rice bran using 3 wt % of enzyme, 60 oC and moisture content of 50 wt % . The use of ultrasound-assisted enzymatic hydrolysis of rice bran was intensified, obtaining around 74 % more fermentable sugar than in the absence, showing that the use of ultrasound is a promising technology to be used in enzymatic reaction as an alternative of process intensification.

Keywords: Ultrasound-assisted, enzymatic hydrolysis, rice bran, amylases.

RESUMEN

En este trabajo se investigó la hidrólisis enzimática de salvado de arroz por ultrasonido para obtener glucosa. Se evaluaron variables del proceso tales como la temperatura, la concentración de enzima y la humedad para la hidrólisis enzimática con y sin la aplicación de la irradiación ultrasónica. La enzima utilizada fue una mezcla de amilasa de Trichoderma reesei. Se evaluó la cinética de la hidrólisis enzimática de salvado de arroz en el período constante de la velocidad de reacción. Los mejores resultados para la hidrólisis enzimática con la aplicación de ultrasonidos fueran utilizando 3% de enzima, 60 ° C y 65% de humedad, el rendimiento obtenido fue 0,38 g de azúcar / g de salvado de arroz, mientras que el más alto rendimiento de la hidrólisis en ausencia de ultrasonido fue 0,20 g de azúcar / g de salvado de arroz utilizando 3 % de enzima, 60 ° C y 50 % de humedad. El uso de ultrasonido mejora la hidrólisis enzimática permitiendo obtener 74 % más azúcares fermentables que en la ausencia de ultrasonidos, lo que demuestra que el uso de ultrasonido es una promisora tecnología que se puede utilizar en las reacciones enzimáticas y como una alternativa de intensificación de procesos.

Palabras clave: Ultrasonido, hidrólisis enzimática, salvado de arroz, amilasa.

Received: March 19 th 2015 Accepted: July 02 th 2014

Introduction

Rice production for the 2010/2011 harvest in Brazil was around 13.456 million tons. From this amount, 8.942 million tons were produced at state of Rio Grande do Sul (RRI, 2015). This amount makes Brazil the 9th largest rice producer worldwide (BMALFS, 2015) and the largest out one from Asia. Rice bran and broken rice are major co-products in the milling of rice. Rice bran and, to a lesser extent, broken rice contain valuable components such as starch(Shih, Champagne, Daigle & Zarins, 1999), which is a low-cost alternative feedstock for biofuels production as bioe-thanol. Rice bran can be seen as a potential starch-based feedstock for conversion into fermentable sugars aiming ethanol production (Saxena, Adhikari & Goyal, 2009). Efficient and cost-effective hydrolysis of starch into monosac-charides using enzymes is a challenge, and for this reason, attention should be focused on this step.

There are several studies in specialized literature aiming the selection/production of enzymes for cold hydrolysis of starch as well as the obtainment of more efficient enzymes (Lin, Xian, Zhang, Luo, Tang & Feng, 2011; Castro, Andrea, Carvalho, Teixeira, Castilho & Freire, 2011; Castro, Castilho & Freire, 2011) improvement in feedstock pretreatment (Khanal, Montabo, Leeuwen, Srinivasan & Grewell, 2007; Nikolic, Mojovic, Rakin, Pejin & Pejin, 2010) shortening of fermentation time, lowering the enzyme dosages, improving the overall starch hydrolysis (Rodríguez, Alameda, Gallegos, Requena & López, 2006) and integration of the simultaneous saccharification and fermentation process (Nikolic, Mojovic, Rakin, Pejin & Pejin, 2010; Ogbonna & Okoli, 2010; Yingling, Zongcheng, Honglin & Li, 2011).

However, little attention has been paid in the design of intensified enzyme-based processes for hydrolysis of starch. An example of these processes is the use of a solid-state enzyme reaction, which is defined as the reaction involving solids (rice bran) in absence (or near absence) of free water; however, substrate must possess enough moisture to support the action of the enzymes. The main advantage of this procedure is the fact that the process is conducted in the absence of a free aqueous phase, resulting in minimum water consumption and thus a low production of effluent. As the amount of water can be adjusted to a minimum during the extraction of hydrolyzed sugars, the resulting solution is more concentrated that traditional enzyme hydrolysis. On the other hand, there are also disadvantages associated with mass-transfer. The reaction rates and mass transfer have been improved by using ultrasound, which can be considered as an auxiliary source of energy (agitation and/or heating) in enzymatic reactions, through formation of microbubbles during sonication treatments due to cavitation phenomenon. The cavitation phenomenon involves a localized increase of temperature and pressure at the solid-solvent interface. It is known that ultrasound pretreatment application may significantly increase the conversion of starch materials into glucose as well as overall biofuel yield (Nikolic, Mojovic, Rakin, Pejin & Pejin, 2010). Furthermore, the potential of ultrasound irradiation on increasing the enzyme activity has been shown (Leaes, Lima, Miklasevicius, Ramon, Dal Prá, Bassaco et al., 2013; Souza, Mezadri, Zimmermann, Leaes, Bassaco, Dal Prá etal., 2013).

Based on these aspects, the present work evaluates the ultrasound-assisted solid-state enzyme hydrolysis of rice bran to obtain fermentable sugars. For this purpose, process variables such as temperature, enzyme concentration and moisture content were evaluated during the enzymatic hydrolysis of rice bran.

Materials and Methods

Rice bran was obtained from a local processing factory (Primo Berleze, Santa Maria, Brazil). As soon as the samples were received, they were maintained at a temperature of -18 oC. The composition of rice bran is (8.9 %) moisture, (12.6 %) protein, (15.5 %) fat, (51%) carbohydrates and (12 %) ash. The enzyme was STARGEN™ 002, obtained from Genencor (Brazil). This enzyme is an optimized blend of amylases derived from genetically modified strains of Trichoderma reesei. The 3.5 dinitrosalicylic acid was purchased from Vetec.

The experiments were carried out in an ultrasonic bath (Unique Inc., model USC 1800A, Brazil) equipped with a transducer with longitudinal vibrations. The ultrasonic unit has an operating frequency of 40 kHz and a maximum-rated electrical power output of 132 W. The ultrasonic transducer is fitted at the bottom of the bath horizontally along the length of bath (surface area of 282.2 cm2).

All reactions were carried out during 4 h, being evaluated the kinetic releasing of fermentable sugar at 0, 0.5, 1.0, 1.5, 2.0, 3.0 and 4.0 h in duplicate. Taking into account the difficulties on sampling the solid material, a new reaction was started for each time and the whole content of the bioreactor was sampled for sugar extraction. The reactions were carried out using a beaker containing 20 g of rice bran (dry basis). Before the reactions, temperature, moisture and enzyme contents were adjusted to the appropriated values. Sodium acetate buffer 0.1M pH 5.2 was used to adjust the moisture content of rice bran, since this pH was considered to be optimum for cellulase activity (Balsan, Astolfi, Benazzi, Meireles, Maugeri, Di Luccio et al., 2012). The influence of temperature (40-65 oC), enzyme concentration (1-10 wt %) and moisture content (50-80 wt %) were evaluated in the presence and absence of ultrasound irradiation. In the experiments without ultrasound the ultrasonic bath was used as thermostatic bath.

After the hydrolysis, the fermentable sugars were extracted from the solid material using distilled water at solid to liquid ratio of 0.1 (dry basis). The extractions were carried out at 30 oC under orbital shaker agitation of 150 rpm during 30 min. Afterwards, the solution was filtered by vacuum filtration (Whatman qualitative filter paper, grade 1) and the supernatant was used to determine the amount of reducing sugars by the 3.5-dinitrosalicylic acid method (DNS) (Miller,1959). The results were expressed in terms of gram of glucose equivalent (fermentable sugars) per gram of dry solid material. The total amount of hydrolysable sugars of rice bran was obtained by means of acid hydrolysis using HCl 2N under boiling for 30 min. Afterwards, the solution was cooled and neutralized using NaOH 2N, determining the total reducing sugar by the DNS method. The value obtained was used to calculate the efficiency of hydrolysis.

The kinetic evaluation used in this study was adapted from the analysis of overall extraction curves during the supercritical fluid extraction of bioactive compounds (Miller, 1959). Although the process are different, the overall kinetic of hydrolysis present similar profiles to the overall extraction curves in such a way that the parameters determined for fluid extraction of bioactive compounds can be applied with few changes to kinetics of hydrolysis. Generally, kinetic reaction curves are characterized by three time periods: (1) a constant-reaction rate period (CRR); (2) a falling-reaction rate period (FRR); and (3) a diffusion-controlled reaction rate period (DCRR) (Pereira & Meireles, 2010).

Among the kinetic parameters that can be obtained from overall kinetic curve, some of them are the more relevant to compare the performance of two or more kinetics. In this work, were only considered the catalytic constant for the CRR period (kCRR) that is obtained by the ratio between the rate of hydrolysis of period and the amount of enzyme used, presenting units of grams of fermentable sugar per gram of enzyme per hour (g.g-1.h-1); and the yield of the CRR period and the efficiency of hydrolysis that was calculated taking into account the content of total hydrolysable sugars obtained according to the procedure defined above.

Results and discussion

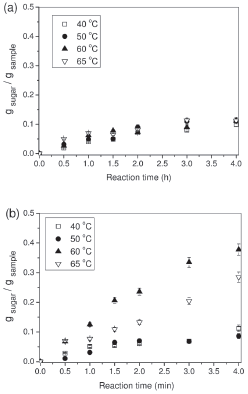

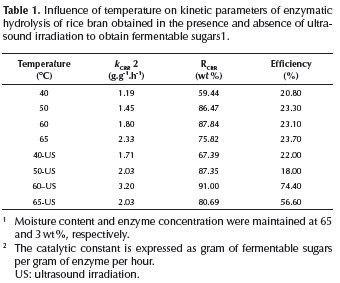

The effects of temperature were analyzed aiming to evaluate the hydrolysis performance. Experiments at temperatures ranging from 40 to 65 oC were carried out in the presence and absence of ultrasound irradiation. The amylase concentration and moisture content were maintained constant at 3 wt % and 65 %, respectively. The reducing sugar concentration was used as indicator to evaluate the rice bran hydrolysis performance. The results concerning the effects of temperature on rice bran hydrolysis performance can be observed in Figure 1.

In Figure 1a the effects of temperature on the hydrolysis in the absence of ultrasound treatment are compared. In practice, there is no difference in the yield of hydrolysis among the temperatures studied, although the highest yield was achieved at 60 oC, with maximum hydrolyzed rice bran of 0.11 g sugar/g rice bran. The efficiency of hydrolysis ranged from 20.8 to 23.7 % (Table 1).

The effects of temperature on the hydrolysis in the presence of ultrasound treatment are shown in Figure 1b. It is shown that a maximum increase in glucose concentration (0.38 g sugar/g rice bran) was achieved after 4 h of the ultrasound treatment at 60 oC, leading to increase 74 % the amount of reducing sugar released in the hydrolysis, when it is compared to the case without ultrasound. For all temperatures studied, the amount of reducing sugars released in the presence of ultrasound was always greater than in the absence, although this difference was low for temperatures in the range of 40-50 oC, whereas for temperatures higher than 50 oC significant differences in the kinetics were verified.

The efficiency of hydrolysis in the presence of ultrasound ranged from 18.0 to 74.4 %, with the highest value obtained at 60 oC. At low temperatures, the efficiency was comparable to the hydrolysis in the absence of ultrasound. However,, at temperatures of 60 and 65 oC the efficiency obtained in the presence of ultrasound was considerably increased (Table 1).

The increase in the yield obtained at 60 and 65 oC could be attributed to a decrease in the saturation constant in the Michaelis-Mentem equation (km) and an increase in the maximum reaction rate (vmax ). Souza etal. (2013) determined the parameters of Michaelis-Mentem equation for the enzyme STARGEN™ 002 in the ultrasound and water baths for temperatures of 35 and 65 oC and they verified that the value of km in the ultrasound bath is practically constant with the increase of temperature, whereas the maximum reaction rate (vmax) increases slightly. On the other hand, in the water bath, the saturation constant decreases about 65 % its value with the temperature, indicating that the enzyme affinity to substrate was improved, whereas the maximum reaction rate also increase about 190 % with the temperature. Some researchers also defined the temperature of 60 oC for the ultrasound treatment. Nikolic et al. (2010) selected an optimal duration of the ultrasound treatment of 5 min and sonication temperature of 60 oC for the corn meal liquefaction. Whereas Sun et al. (2002) the optimum sonication temperature was 60 oC , but they investigated the effect of ultrasound pretreatment (20 kHz; 20 min) on lignocellulosic material (wheat straw), which verified that applying sonication in wheat straw resulted in an increasing yield of hemicelluloses in comparison with the experiment performed without ultrasonic assistance.

Data on Figure 1 was used to determine the catalytic constant for the CRR period (kCRR), the yield of the CRR period (RCRR - wt %) and the efficiency of hydrolysis and the results obtained are presented in Table 1.

The kCRR increased with temperature in both presence and absence of ultrasound. However, the increase was more pronounced with ultrasound, which intensified the enzymatic hydrolysis in the step of constant-reaction rate period. In general, the time-span of constant-reaction rate period in the absence of ultrasound was higher than in the presence (data not tabled, but verified in Figure 1), leading to similar yield of the CRR period (RCRR) in both cases. The lower time-span of CRR for hydrolysis in the presence of ultrasound is probably occurring because the cavitation improves the mass transfer in the system, facilitating the access of enzyme to starch. As a consequence, the reaction rate is faster than in the absence of ultrasound irradiation. This is confirmed by analyzing catalytic constant for the CRR for the hydrolysis under ultrasound, which was always greater than in the absence, and also on yield of CRR period (RCRR), where similar values were obtained for both cases. However, the time-span of CRR period in the absence of ultrasound was longer than the one in presence.

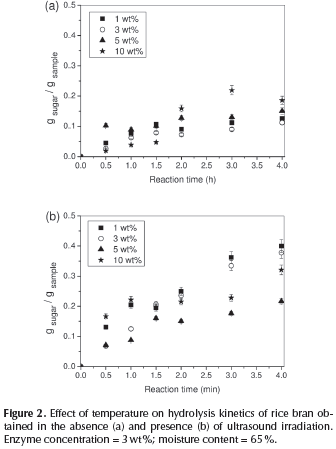

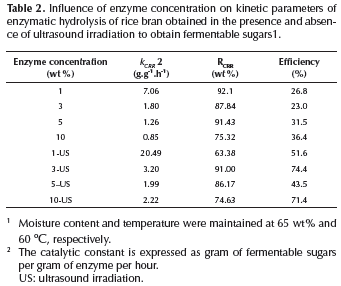

The hydrolysis performance was also evaluated taking into account the effects of amylase concentration. Different amylase concentrations, ranging from 1 to 10 (wt %), were analyzed through similar experiments in the presence and absence of ultrasound irradiation. In such experiments, the temperature was maintained constant at 60 oC and the moisture content at 65 wt %. Figure 2 presents the results concerning the hydrolysis of rice bran in function of amylase concentration in the absence (Figure 2a) and presence (Figure 2b) of ultrasound irradiation. As can be seen in Figure 2a, a slight variation in hydrolysis yield was observed after 2 h of reaction. The highest hydrolysis yields were achieved using amylase concentration of 1 and 3 %, in which the hydrolyzed substrate amount were quite similar for both experiments. Thus, the amylase concentration of 3 % was preferred because it leads to an efficiency of hydrolysis of 74.4 % (Table 2), which is about 3.2 times higher than that obtained in the absence of ultrasound irradiation. In this condition, the maximum hydrolyzed rice bran was 0.38 g sugar/g rice bran under ultrasound-assisted hydrolysis (Figure 2b). The use of ultrasound during the hydrolysis makes possible to increase the yield in about 40 %, independent of enzyme concentration used.

Data of Figure 2 was used to determine the catalytic constant for the CRR period (kCRR), the yield of the CRR period (RCRR - wt %) and the efficiency of hydrolysis; the results obtained are presented in Table 2. The kCRR decreased with enzyme concentration in both presence and absence of ultrasound. However, the kCRR in the presence of ultrasound were always higher than in the absence. The yield of CRR (RCRR) period in the absence of ultrasound presented similar values, independent of enzyme concentration used, whereas in the presence the best results were obtained using 3 and 5 wt % of enzyme.

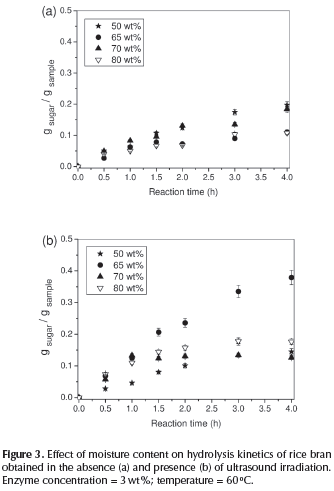

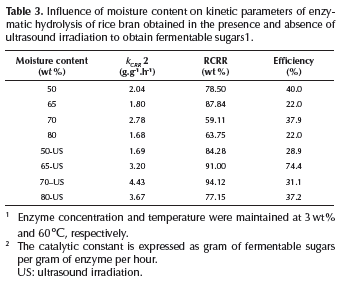

The results concerning the rice bran hydrolysis as function of moisture content are shown in Figure 3. From Figure 3a (absence of ultrasound irradiation), it is observed an increase in reducing sugars at moisture content (50 %) and a reduction on the amount of reducing sugars in high content moisture (80 %). This difference corresponds to a variation about 100 % on the efficiency of hydrolysis (Table 3), indicating that low moisture content is better for solid-state enzymatic hydrolysis of rice bran. On the other hand, the ultrasound-assisted enzymatic hydrolysis did not followed the same tendency, as can be seen in Figure 3b. The best hydrolysis yield was obtained with 65 % of moisture content (dry basis), whereas for the other tested moisture contents (50, 70 e 80 %) the amount of hydrolyzed substrate was practically constant, yielding around 0.15 g sugar/g rice bran after 4 h.

Data of Figure 3 was used to determine the catalytic constant for the CRR period (kCRR), the yield of the CRR period (RCRR - wt %) and the efficiency of hydrolysis; the results obtained are presented in Table 3. In a general way, the kCRR in the presence of ultrasound were always higher than in the absence, conform previously verified. Concerning the yield of CRR period (RCRR), the highest values were obtained at moisture content of 65 wt % for both, presence and absence of ultrasound irradiation.

In a general way, the ultrasound intensified the sugar releasing, contrary to the idea that highly reactive intermediates could severely damage or at least, inactivate complex structures of the enzyme proteins, leading to low yield of hydrolysis. According to Adewuyi and Deshmane (2015), the formation of highly reactive intermediates did not affect the long term catalytic/activity of dissolved enzyme ma-cromolecules in any significant way, because there is the possibility of enzyme macromolecules to be detained into a cavitation bubble and to encounter the highly reactive intermediates created by the collapsing bubbles should be very low.

Conclusions

This study evaluated the feasibility of ultrasound-assisted enzymatic hydrolysis at solid-state of rice bran to produce reducing sugar. The best results for the ultrasound-assisted enzymatic hydrolysis was obtained using 3 wt % of enzyme, 60 oC and moisture content of 65 wt %, yielding 0.38 g sugar/g rice bran, whereas for the hydrolysis and in the absence of ultrasound the highest yield was 0.20 g sugar/g rice bran using 3 wt% of enzyme, 60 oC and moisture content of 50 wt%. The catalytic constant for the CRR period was always higher in the presence of ultrasound, indicating that the ultrasound intensified the enzymatic hydrolysis in the step of constant-reaction rate period. The use of ultrasound-assisted enzymatic hydrolysis of rice bran was intensified, obtaining around 74% more reducing sugars in presence than in the absence of ultrasound irradiation, showing that the use of ultrasound is a promising technology to be used in enzymatic reaction as an alternative of process intensification.

Acknowledgment

Brazilian financial support provided by CAPES and CNPq is gratefully acknowledged.

References

Adewuyi, Y. G., & Deshmane, V. G. (2015). Intensification of enzymatic hydrolysis of cellulose using high frequency ultrasound: an investigation of the effects of process parameters on glucose yield. Energy & Fuels. DOI: 10.1021/acs.energyfuels.5b0066. [ Links ]

Balsan, G., Astolfi, V., Benazzi, T., Meireles, M. A., Maugeri, F., Di Luccio, M., Dal Prá, V., Mossi, A. J., Treichel, H., & Mazutti, M. A. (2012). Characterization of a commercial cellulose for hydrolysis of agroindustrial substrates. Bioprocess and Biosystems Engineering, 35, 1229-1237. DOI: 10.1007/s00449-012-0710-8. [ Links ]

BMALFS (Brazilian Ministry of Agriculture, Livestock and Food Supply). Retrieved February 10, 2015 from http://www.mapa.gov.br. [ Links ]

Castro, A. M., Andrea, T. V., Carvalho, D. F., Teixeira, M. M. P., Castilho, L. R., & Freire, D. M. G. (2011). Valorization of residual agroindustrial cakes by fungal production of multienzyme complexes and their use in cold hydrolysis of raw starch. Waste and Biomass Valororization, 2, 291-302. DOI: 10.1007/s12649-011-9075-5. [ Links ]

Castro, A. M., Castilho, L. R., & Freire, D. M. G. (2011). An overview on advances of amylases production and their use in the production of bioethanol by conventional and non-conventional processes. Biomass Conversion and Biorefinery, 1, 245-55. [ Links ]

Khanal, S. K., Montabo, M., Leeuwen, J., Srinivasan, G., & Grewell D. (2007). Ultrasound enhanced glucose release from corn in ethanol plants. Bioengineering and Biotechnology 98, 978-85. DOI: 10.1007/s13399-01 1-0023-1. [ Links ]

Leaes, E. X., Lima, D., Miklasevicius, L., Ramon, A. P., Dal Prá, V., Bassaco, M. M., Terra, L. M., & Mazutti, M. A. (2013). Effect of ultrasound-assisted irradiation on the activities of α-amylase and amyloglucosidase. Biocatalysis and Agricultural Biotechnology, 2, 21-25. DOI: 10.1016/j.bcab.2012.08.003. [ Links ]

Lin, H. J., Xian, L., Zhang, Q. J., Luo, X. M., Tang, J. L., & Feng, J. X. (2011). Production of raw cassava starch-degrading enzyme by Penicillium and its use in conversion of raw cassava flour to ethanol. Journal of Industrial Microbiology & Biotechnology, 38, 733-42. DOI: 10.1007/s10295-010-0910-7. [ Links ]

Miller, G. L. (1959). Use of dinitrosalisylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426-428. DOI: 10.1021/ac60147a030. [ Links ]

Nikolic, S., Mojovic, L., Rakin, M., Pejin, D., & Pejin, J. (2010). Ultrasound-assisted production of bioethanol by simultaneous saccharification and fermentation of corn meal. Food Chemistry,122, 216-22. DOI: 10.1016/j.foodchem.2010.02.063. [ Links ]

Ogbonna, C. N., & Okoli, E. C. (2010). Conversion of cassava flour to fuel ethanol by sequential solid state and submerged cultures. Process Biochemistry, 45, 1196-1200. DOI: 10.1016/j.procbio.2010.04.004. [ Links ]

Pereira, C. G., & Meireles, M. A. A. (2010). Supercritical fluid extraction of bioactive compounds: fundamentals, applications and economic perspectives. Food and Bioprocess Technology, 3, 340-372. DOI: 10.1007/s1 1947-009-0263-2. [ Links ]

Rodríguez, V. B., Alameda, E. J., Gallegos, J. F. M., Requena, A. R., & López, A. I. G. (2006). Enzymatic hydrolysis of soluble starch with an a-amylase from Bacillus licheniformis. Biotechnology Progress, 22, 718-22. DOI: 10.1021/bp060057a. [ Links ]

RRI (Riograndense Rice Institute, Brazil). Retrieved February 10, 2015 from http://www.irga.rs.gov.br. [ Links ]

Saxena, R. C., Adhikari, D. K., & Goyal, H. B. (2009). Biomass-based energy fuel through biochemical routes: a review. Renewable and Sustainable Energy Reviews,13,167-78. [ Links ]

Shih, F. F., Champagne, E. T., Daigle, K., & Zarins, Z. (1999). Use of enzymes in the processing of protein products from rice bran and rice flour. Molecular Nutrition Food Reserach, 43,14-8. DOI: 10.1002/(sici)1521-3803(19990101)43:1<14::aid food14>food14>3.0.co;2-k. [ Links ]

Souza, M., Mezadri, E. T., Zimmermann, E., Leaes, E. X., Bassaco, M. M., Dal Prá, V., Foletto, E., Cancellier, A., Terra, L. M., Jahn, S. L., & Mazutti, M. A. (2013). Evaluation of activity of a commercial amylase under ultrasound-assisted irradiation. Ultrasonics Sonochemistry, 20, 89-94. DOI: 10.1016/j.ultsonch.2012.05.012. [ Links ]

Sun, R. C., Sun, X. F., & Ma, X. H. (2002). Effect of ultrasound on the structural and physiochemical properties of organo-solv soluble hemicellulose from wheat straw. Ultrasonics Sonochemistry, 9, 95-101.DOI: 10.1016/S1350-4177(01)00102-X. [ Links ]

Yingling, B., Zongcheng, Y., Honglin, W., & Li, C. (2011). Optimization of bioethanol production during simultaneous saccharification and fermentation in very high-gravity cassava mash. Antonie Van Leeuwenhoek, 99, 329-39. DOI: 10.1007/s10482-010-9494-5. [ Links ]