Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería e Investigación

versão impressa ISSN 0120-5609

Ing. Investig. vol.35 supl.1 Bogotá dez. 2015

https://doi.org/10.15446/ing.investig.v35n1Sup.53578

DOI: http://dx.doi.org/10.15446/ing.investig.v35n1Sup.53578

Electrical performance of distribution insulators with chlorella vulgaris growth on its surface

Desempeño eléctrico de aisladores de distribución ante el crecimiento de chlorella vulgaris sobre su superficie

H.E. Rojas1, C.D. Pérez2, A.F. León3, and L.F. Cantor4

1 Herbert Enrique Rojas Cubides: Electrical Engineer, M.Sc. in Electrical Engineering and Ph.D. candidate in Electrical Engineering from Universidad Nacional de Colombia, Colombia. Affiliation: Assistant Professor in Electrical Engineering Department, Electromagnetic Compatibility and Interference Group GCEM, Universidad Distrital Francisco José de Caldas Colombia.

E-mail: herojasc@udistrital.edu.co

2 Carlos Daniel Pérez Castiblanco: Electrical Engineering Student, Universidad Distrital Francisco José de Caldas, Colombia. Affiliation: Electromagnetic Compatibility and Interference Group GCEM.

E-mail: cdperezc@correo.udistrital.edu.co

3 Andrés Felipe León Morales: Electrical Engineering Student, Universidad Distrital Francisco José de Caldas, Colombia. Affiliation: Electromagnetic Compatibility and Interference Group GCEM.

E-mail afleonm@correo.udistrital.edu.co

4 Luis Felipe Cantor Babativa: Electrical Engineering Student, Universidad Distrital Francisco José de Caldas, Colombia. Affiliation: Electromagnetic Compatibility and Interference Group GCEM.

E-mail lfcantorb@correo.udistrital.edu.co

How to cite: Rojas, H.E., Pérez, C.D., León, A.F., & Cantor, L.F. (2015). Electrical performance of distribution insulators with chlorella vulgaris growth on its surface. Ingeniería e Investigación, 35(Supl), 21-27. DOI: http://dx.doi.org/10.15446/ing.investig.v35n1Sup.53578

ABSTRACT

This paper presents a study about electrical performance of ceramic and polymeric insulators bio-contaminated with alga Chlorella vulgaris. The performed tests involve ANSI 55-2 and ANSI 52-1 ceramic insulators and ANSI DS-15 polymeric insulators, all of them used in distribution systems of Colombia. Biological contamination of insulators is realized using a controlled environment chamber that adjusts the temperature, humidity and light radiation. The laboratory tests include measurements of flashover voltages and leakage currents and they were performed to determine how insulators are affected by biological contamination. After a series of laboratory tests, it was concluded that the presence of Chlorella vulgaris on the contaminated ceramic insulators reduces the wet flashover voltage up to 12 % and increases their leakage currents up to 80 %. On the other hand, for polymeric insulators the effect of algae growth on flashover voltages was not to strong, although the leakage currents increase up to 60 %>.

Keywords: Algae, biological contamination, chlorella vulgaris, distribution insulators, flashover voltage, leakage current.

RESUMEN

Este artículo presenta un estudio relacionado con el desempeño eléctrico de aisladores cerámicos y poliméricos bio-contaminados con el alga Chlorella vulgaris. Las pruebas realizadas involucran aisladores cerámicos tipo ANSI 55-2 y ANSI 52-1, y aisladores poliméricos tipo ANSI DS-15, todos ellos usados en sistemas de distribución de energía en Colombia. La contaminación biológica de los aisladores es realizada usando una cámara de ambiente controlado que ajusta temperatura, humedad y radiación de luz. Las pruebas experimentales incluyen la medición de tensiones de flameo y corrientes de fuga con el propósito de determinar de qué manera son afectados los aisladores por la contaminación biológica. Después de una serie de pruebas de laboratorio, se concluyó que la presencia de Chlorella vulgaris sobre los aisladores cerámicos contaminados reduce la tensión de flameo en húmedo hasta en un 12 % y aumenta sus corrientes de fuga hasta 80 %>. Por otra parte, para los aisladores poliméricos el efecto del crecimiento del alga sobre las tensiones de flameo no es muy fuerte, aunque las corrientes de fuga aumentan hasta 60 %>.

Palabras clave: Algas, aisladores de distribución, chlorella vulgaris, contaminación biológica, corriente de fuga, tensión de flameo.

Received: September 15th 2015 Accepted: October 10th 2015

Introduction

Electrical insulators are protection elements commonly used in distribution and transmission power systems. In the same way as lines, transformers, switchgear and other equipment that conform these systems, insulators require inspection, diagnosis and maintenance (Sierra, Lajes, Filiberto, & Barrios, 2013). An adequate inspection on insulators prevents malfunction of electrical systems, decreases the probability of faults by insulation and reduces the electrical losses in power systems (Acosta-Urrego & Hincapié-Isaza, 2013). However, diagnosis and maintenance activities in electrical systems require a lot of resources and time to be conducted (Capelini, Adami, Martinez, & Parentoni, 2015).

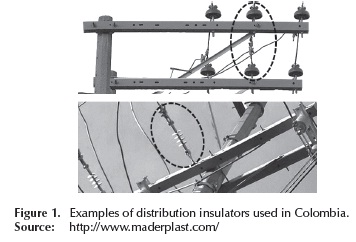

Distribution insulators are used in Colombia and other countries mostly at 11.4, 13.2 and 34.5 kV power distribution systems. Their use is related with rural and urban environments throughout the territory and they can be made of ceramic and non-ceramic (silicone rubber, polymeric materials, glass and resin) materials. An example of ceramic and polymeric insulator applications is shown in Figure 1. Some of these ceramic insulators are approaching more than 15 years in service, while a great quantity of non-ceramic insulators have service exposures of about 3 to 10 years.

One of the most important problems that insulators are subjected to, is degradation by different environmental effects. These effects include ultraviolet exposition, heat, sunlight, humidity, atmospheric pressure and biological degradation caused by microorganisms (biocontamination) in air.

There is evidence supporting the fact that biocontamination on ceramic and polymeric insulators can take place on different zones of the world, particularly in tropical regions (Coowar & Hoole, 1988; Fernando & Gubanski, 2000; Fernando, 1999; Flemming, 1998; Fujii, 2003; Gorur, Montesinos, Roberson, Burnham, & Hill, 2003; McAfee, Heaton, King, & Falster, 1997; Wallstrõm & Karlsson, 2004). However, it is not completely clear how the biological growth can affect the performance of medium and high voltage insulators under high humidity, temperature changes and intensive sun radiation.

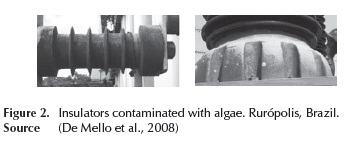

Several studies indicate that microbiological growth is benefited by certain environmental conditions related with tropical climates (De Mello et al., 2008). The alga Chlorella vulgaris is not an exception and its development on insulating materials is reported in different regions (Gorur et al., 2003; S Wallstrõm, 2005). Figure 2 shows growth of algae on medium and high voltage insulators at the Rurópolis substation in Amazonas, Brazil (De Mello et al., 2008).

Due its location (latitudes between 12° N and 4° S and longitudes between 67° and 79° W), Colombia is an equatorial country with temperatures from 0 °C to 40°C, trade winds and humidity above 50 %. These especial conditions make the Chlorella vulgaris growth quite probable along the Colombian territory. However, there are no local studies on the impact of these algae on the electrical performance of different types of insulators. Based on experimental tests, this work presents the electrical response of ceramic and polymeric insulators bio-contaminated with Chlorella vulgaris on their surface.

The rest of the paper is organized as follows: The algae and the insulators used in the biocontamination process, including their technical features, are presented in section 2. Section 3 presents the characteristics of the controlled chamber used to recreate the conditions for the Chlorella vulgaris growth. The biological identification of algae colonies is described in section 4. The reference electrical tests and the laboratory tests on contaminated insulators are presented in sections 5 and 6, respectively. A brief discussion about the results is presented in section 7. Finally, the conclusions of this work are presented in section 8.

Biological contamination process

Objects under test

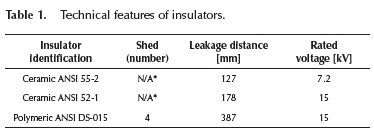

For the biocontamination process mentioned above, single-pin ceramic insulators ANSI 55-2, disc-suspension ceramic insulators ANSI 52-1 and polymeric insulators ANSI DS-015 were selected. Table 1 shows the technical features of insulators. These elements are used in rural and urban distribution systems and they have different rated voltage and different leakage distance.

At the initial stage, all insulators were cleaned to perform electrical reference tests. Prior to this process, each insulator was disinfected and isolated from the environment in order to avoid contact with external agents. Once the insulators were exposed to a biological contamination process, all of them were removed and individually transported. This process prevents insulators from changing their physical conditions before carrying out experimental tests.

Alga Chlorella vulgaris

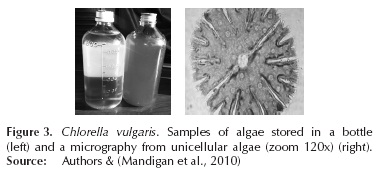

Chlorella vulgaris is a unicellular alga with spherical shape and greenish pigment widely found around the world (Amin & Salman, 2006) but their use in insulation system is not older than 25 years. The insulators made up of these materials are correspondingly called polymeric or composite insulators. Since these materials suffer from the problem of environmental degradation due to organic in nature so this time is not enough to guarantee that they can sustain in environments for long time where biological degradation is fast. So to have a correct fact file of prediction of their behavior over a long time (also called aging. These algae have the ability to carry out a photosynthetic process that allows them to multiply and perform their vital process by obtaining carbon dioxide, water, sunlight and some minerals from the environment. Figure 3 shows an example of Chlorella vulgaris samples and a picture of unicellular alga taken with an electronic microscope (Mandigan, Martinko, Stahl, & Clark, 2010).

Chlorella vulgaris grows easily in locations with high levels of nitrates and phosphates or with direct contact of sunlight. To promote the growth of algae, a mix of sporulation agar and other nutrients, such as nutrient medium, were applied on the surface of insulators. These elements together with controlled environmental conditions are necessary to carry out an adequate biological contamination and promote the microbial colonization process.

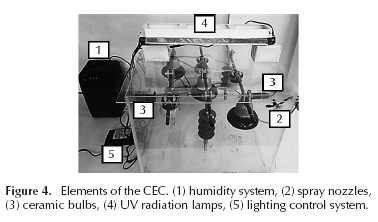

Controlled environment chamber

Reports of biological growth on electric insulators suggest that microbial colonization takes a long time to be visible on the surface of the insulators (Fernando & Gubanski, 2000; Gubanski, Fernando, Pietr, Matula, & Kyaruzi, 2000). Hence, in order to recreate optimal growth conditions and accelerate the colonization process, a controlled environment chamber (CEC) was constructed. Using this chamber it is possible to monitor and control the most important variables that affect the algae growth, such as temperature, relative humidity and solar radiation. Figure 4 shows the elements that compose the CEC and the distribution of insulators inside the chamber.

The CEC recreates the specific conditions for algae growth, keeping the temperature range between 23-28 °C, maintaining the relative humidity between 80-100 % and controlling cycles of 12 hours of light (to represent day and night). In order to achieve this, a microcontroller Arduino Leonardo was used to automate and control the CEC (León et al., 2014). The control system acquires the information from the measurements provided by two dual (temperature-humidity) RHT-03 sensors. Later, these variables are compared with reference values previously established.

Once the variables are evaluated and compared, the mechanism of the high pressure misting, heat emitter and day-light cycle are triggered according to the reference values. Finally, to provide an adequate exposition to the environmental conditions, the insulators are placed inside the chamber in a random position.

Identification of algae colonies

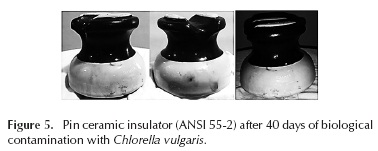

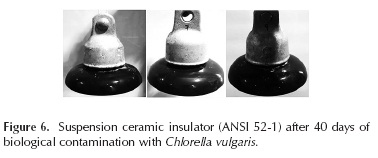

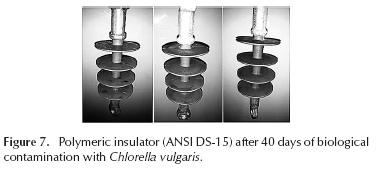

For the biocontamination process three single-pin ceramic insulators ANSI 55-2, three disc-suspension ceramic insulators ANSI 52-1 and three polymeric insulators ANSI DS-015 were randomly selected and placed inside the CEC. Contamination with Chlorella vulgaris was made for a period of 40 days. Figures 5, 6 and Figure 7 show the presence of the microorganism on ceramic insulators ANSI 55-2, ANSI 52-1 and polymeric insulators, respectively.

From a single observation, it was determined that the biologically contaminated insulators were covered with dense green patches. Pin-ceramic and polymeric insulators present green algae zones that contrast with the grey color of their surfaces. In the case of suspension ceramic insulators, the dark color of their varnishes reduce the visibility of Chlorella vulgaris colonies. Under microscopic visualization, Chlorella vulgaris was found as a major biological component covering the surface of all contaminated insulators. The algae cells have a spherical shape and vary about 2 to 10 ijm in diameter.

From the microbiological test, besides the existence of Chlorella vulgaris the presence of fungal mycelia and mold Penicillum Sp. was also noticed. This may suggest that the samples were accidentally contaminated due to the presence of other microorganisms in the air (around the chamber) during the process of the algae implantation. With respect to the degradation of insulator materials, microscopic test were performed after the electrical tests. The results show that the presence of Chlorella vulgaris on the surface of the insulators does not change the physical composition of the ceramic and polymeric materials.

Laboratory tests before biocontamination

Electrical tests were developed in the High Voltage Laboratory (LAT-UD) at Universidad Distrital Francisco José de Caldas in Bogotá, Colombia. Dry flashover voltage (FOV), wet flashover voltage (WFOV) and leakage current (LC) tests at low frequency were taken in order to analyze the influence of Chlorella vulgaris growth on the electrical performance of the insulators.

Setup of the laboratory tests

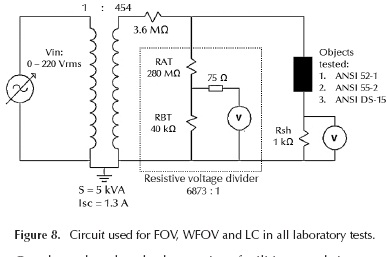

The procedure used to develop the electrical tests is defined by the Colombian national standard NTC 1285 (Instituto Colombiano de Normas Técnicas - ICONTEC, 2002). The test circuit used in LAT-UD to measure the FOV, WFOV and LC in all insulators is shown in Figure 8.

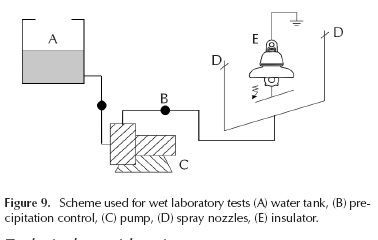

On the other hand, the testing facilities used in wet conditions are the same used in dry conditions. However, the standard NTC 1258 requires the inclusion of a uniform spray on the insulators surface in order to realize the wet tests. Figure 9 shows the scheme to produce the artificial spray at LAT-UD. In this case, a Monsoon RS400 unit was used as artificial spray system. This system is composed by a pump and a water tank with capacity of 9.5 liters. Finally, the output of the system is composed by two nozzles that have variable pressure and adjustable direction.

According to NTC 1258 the artificial spray should be directed in a downward form, so that when it hits the surface of the insulator an angle of 45° must be formed. In addition to this, the vertical precipitation rate is defined in 5mm per minute, the water temperature should be similar to environmental temperature and the water used during tests should have a resistivity between 151 and 205 [Ω-m].

Technical considerations

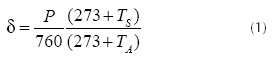

Due to the geographical location of Bogotá, Colombia (4 ° 36'N, 74 ° 5' W y 2.640 m.a.s.l.) and its average weather conditions (temperature: 14 °C, relative humidity: 70 % and atmospheric pressure: 564 mm-Hg), environmental corrections were applied for all measurements according to the standard NTC 1285. Thus, the air density factor (5) for the atmospheric conditions of Bogota was estimated for each test using Equation (1).

Where, P is the atmospheric pressure in mm-Hg, T is the standard temperature in °C (defined as 20°C according to the technical standard) and TA is the environmental temperature. These parameters were measured during each test and the factor δ was calculated in order to determine the flashover voltage (Vb) applying Equation (2).

Where V is the flashover voltage provided by the manufacturer of each insulator. During the dry and wet tests, five measurements (samples) were taken for each insulator and the average value was estimated. It is important to notice that this procedure was applied for all tests. Additionally, it made sure that the time between consecutive tests was greater than 15 seconds and less than 5 minutes, and that the variation of measured values between samples did not exceed +/- 5 °%.

Results of the reference laboratory tests

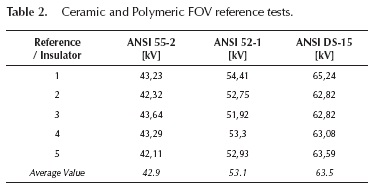

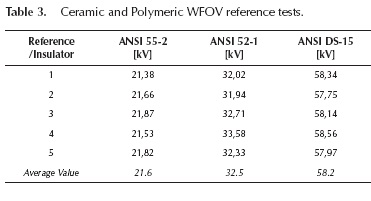

Reference tests (before biological contamination) were conducted to a set of ANSI 55-2, ANSI 52-1 and ANSI DS-015 insulators (5 pieces for each reference). Results of FOV and WFOV for all insulators are show in Table 2 and Table 3. Results presented in Table 2 show that FOV average values of ceramic ANSI 55-2 insulators were close to 42.9 kV, ANSI 52-1 were close to 53. 1 kV and polymeric insulators were close to 63.5kV

On the other hand, average results presented in Table 3 shown that the WFOV value for ANSI 55-2 is 21.6 kV, while for ANSI 52-1 insulators it is 32.5 kV and for polymeric insulator ANSI DS-15 the average value is 58.2 kV. In general terms, for ceramic insulators the WFOV values are at least 35 % lower than FOV ones. This difference is lower for polymeric insulators with differences up to 9 %.

Laboratory tests on contaminated insulators

Flash over voltage tests

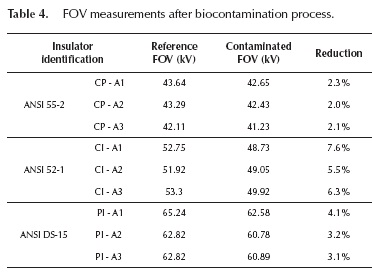

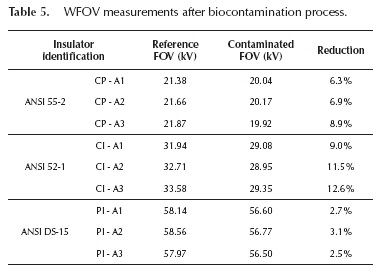

After the biocontamination period, the insulators were extracted from the CEC and shipped to be tested in LAT-UD. Tests realized to contaminated insulators had the same standard procedure that the reference tests. However, the results were different from reference values due to the change in the electrical response of insulators. Table 4 and Table 5 show the FOV and WFOV measurements of insulators contaminated with Chlorella vulgaris. In order to facilitate a comparative analysis each contaminated sample was designated with a code (A1, A2 and A3).

As evidenced in Table 4, FOV values of the biologically contaminated ceramic ANSI 55-2 insulator were reduced by less than 3 % in comparison to with the reference ones. In the case of ANSI 52-1, insulators FOV values were reduced between 6 °% and 8 °%. Finally, for polymeric insulators the average reduction of FOV value was 3.5 °%.

From results presented in Table 5, it can be observed that for ANSI 52-1 and ANSI 55-2 ceramic insulators contaminated with Chlorella vulgaris the WFOV present an average reduction of 11 °% and 8 °%, respectively. In the case of ANSI DS-15 the WFOV values were reduced up to 3 % on average. From these results it is possible to conclude that ceramic insulators have greater reductions in FOV and WFOV than polymeric insulators.

Leakage current tests

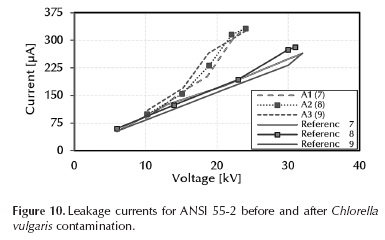

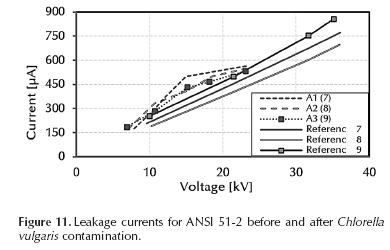

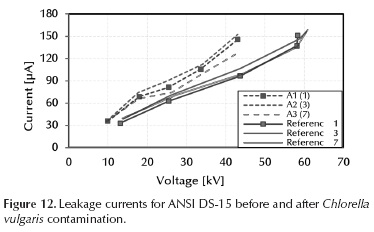

For LC measurements, a set of voltages between 5kV and the 75 %% of the FOV were applied. A shunt resistor of 1kΩ was used to get the current that flows to earth using the Ohm's law and the voltage across the shunt. To analyze the behavior of leakage currents each insulator was distinguished by a different number. Figures 10, 11 and Figure 12 show the leakage current curves (before and after contamination) of suspension ceramic, pin ceramic and polymeric insulators, respectively. In all cases, the solid lines represent the reference values and dotted lines are related with biocontamination tests.

Experimental tests show that ANSI 55-2 insulators contaminated with algae have higher leakage currents (at same voltage) compared to reference tests. In the case of bio-contaminated insulators, they reached values close to 350 µA with an applied voltage of 24 kV, while for clean insulators the leakage current reached 260 µA when 30 kV was applied.

In the range between 8 and 24 kV the leakage currents in suspension ceramic insulators (ANSI 52-1) contaminated with Chlorella vulgaris show slight changes with respect to currents obtained with the reference group, reaching maximum values of 520 µA. However, the applied voltages during biocontamination tests (before multiple discharges generation) are less than the voltages achieved in reference tests. This value was reduced in 30 % with respect to reference tests where clean insulators achieved voltages up to 36 kV.

Finally, for polymeric insulators the maximum values of leakage currents are near to 150 µA, in both, clean and contaminated insulators. However, the applied voltages during test with contaminated samples were close to 42 kV in comparison to the 60 kV achieved in reference tests.

Discussion

The results presented in this paper about the electrical performance of insulators contaminated with Chlorella vulgaris have revealed that algae can grow on ceramic and polymeric materials, independently of the form or constitution of the insulators. On the other hand, there is evidence that Chlorella vulgaris contamination on ceramic insulators (ANSI 55-2, ANSI 52-1) and polymeric insulators (ANSI DS-15) leads to a reduction of dry and wet flashover voltages. Furthermore, the leakage current tests show an increase of the surface conductivity of the contaminated insulators with respect to the reference tests (clean insulators).

During electrical tests, the surface current through the insulators reduced the humidity in the surface and destroyed the biological colonies of Chlorella vulgaris, but did not produce changes in the materials of the insulators. Because the development of algae colonies on electrical insulators under natural conditions can extend from months to years and the microorganisms do not penetrate into the materials, the probability that contamination by Chlorella vulgaris produces a physical deterioration of the insulators is small.

Taking into account the factors mentioned above and based in the fact that the Chlorella vulgaris growth can affect the electrical performance of distribution insulators in a long-term, it is possible that the risk of insulator flashover under conditions of high humidity, high temperature and intensive sun radiation may increase if maintenance is not performed periodically.

Conclusions

In this study, after forty days of Chlorella vulgaris exposition, single-pin ceramic (ANSI 55-2), disc-suspension ceramic (ANSI 52-1) and polymeric (ANSI DS-015) insulators has revealed that algae can grow in its surface and affect the electrical performance of this protection elements. Moreover, when comparing the reference tests with insulators under biological contamination it was demonstrated that microbial colonization affects the electrical performance of medium voltage insulators. In all cases, the changes in the electrical performance of insulators reduce their flashover voltages (under dry and wet conditions) up to 12 %0 and increase their leakage currents up to 80 %.

After laboratory tests, it was observed that the presence of Chlorella vulgaris affects the wet flashover voltage of ceramic ANSI 52-1 insulators in greater amount, with an average reduction of 11.6 %. However, in the case of leakage currents the insulators that suffer the most due to algae growth are single-pin ANSI 55-2 and polymeric ANSI DS-15 insulators with an increase of 80 %o and 60 %o, respectively.

Due to the fact that algae can grow under high humidity, high temperature and intensive sun radiation, which are prevalent conditions in some regions of Colombia, the Chlorella vulgaris contamination on ceramic and polymeric surfaces may increase the risk of insulators flashover in a long-term. However, to prevent this condition the algae can be avoided with a preventive maintenance on insulators and the use of new materials with resistance to this microbiological growth.

References

Acosta-Urrego, C. A., & Hincapié-Isaza, R. A. (2013). Identificación de pérdidas técnicas en redes de baja tensión con sistemas de puesta a tierra. DYNA, 80(181), 40-50. [ Links ]

Amin, M., & Salman, M. (2006). Aging of polymeric insulators (an overview). Reviews on Advanced Materials Science, 13(2), 93-116. [ Links ]

Capelini, R. M., Adami, J. F., Martinez, M. L. B., & Parentoni, M. F. C. (2015). Development of a system for detecting and locating damaged insulator strings with signals collected at substations. Ingeniería e Investigación, 35(1), 43-48. DOI: 10.15446/ing.investig.v35n1.41832. [ Links ]

Coowar, F., & Hoole, P. R. (1988). Discharge characteristics of alga-contaminated string insulators in the tropics. Electric Power Systems Research, 15(3), 215-218. DOI: 10.1016/0378-7796(88)90026-0. [ Links ]

De Mello, D. R., Maria, J., Angelini, G., Roberto, F., França, R., Carriço, A. R., ... Lobato, I. (2008). Research about the insulation performance of insulators due to slimes mitigation occurrence. In 2008 International Conference on High Voltage Engineering and Application, ICHVE 2008 (pp. 109-112). Chongqing. DOI: 10.1109/ICHVE.2008.4773885. [ Links ]

Fernando, M. A. (1999). Performance of non-ceramic insulators in tropical environments. (Doctoral thesis), Chalmers University of Technology. [ Links ]

Fernando, M. A., & Gubanski, S. M. (2000). Performance of nonceramic insulators under tropical field conditions. IEEE Transactions on Power Delivery, 15(1), 355-360. DOI: 10.1109/61.847273. [ Links ]

Flemming, H. C. (1998). Relevance of biofilms for the biodeterioration of surfaces of polymeric materials. Polymer Degradation and Stability, 59(1-3), 309-315. DOI: 10.1016/S0141-3910(97)00189-4. [ Links ]

Fujii, O. (2003). Investigation on contamination performance of polymer insulators deposited with algae. In XIIIth International Symposium on High Voltage Engineering 2003 (pp. 60-63). Delft, Netherlands. [ Links ]

Gorur, R. S., Montesinos, J., Roberson, R., Burnham, J., & Hill, R. (2003). Mold growth on nonceramic insulators and its impact on electrical performance. IEEE Transactions on Power Delivery, 18(2), 559-563. DOI: 10.1109/TPWRD.2003.809681. [ Links ]

Gubanski, S. M., Fernando, M. a. R. M., Pietr, S. J., Matula, J., & Kyaruzi, A. (2000). Effects of biological contamination on insulator performance. In 6th International Conference on Properties and Applications of Dielectric Materials (Vol. 2, pp. 797-801). Xian, China. DOI: 10.1109/icpadm.2000.876350. [ Links ]

Instituto Colombiano de Normas Técnicas - ICONTEC. NTC 1285 - Método de ensayo para aisladores de potencia electrica (2002). [ Links ]

Mandigan, M., Martinko, J., Stahl, D., & Clark, D. (2010). Brock Biology of Microorganisms (13th Ed.). San Francisco, USA: Benjamin Cummings. [ Links ]

McAfee, R. D., Heaton, R. D., King, J. M., & Falster, A. U. (1997). A study of biological contaminants on high voltage porcelain insulators, I. Electric Power Systems Research, 42(1), 35-39. DOI: 10.1016/S0378-7796(96)01174-1. [ Links ]

Sierra, E., Lajes, S., Filiberto, Y., & Barrios, F. (2013). Modelo difuso para la determinación del período de mantenimiento de redes eléctricas, a partir de los datos del celaje. DYNA, 80(181), 31-39. [ Links ]

Wallstrõm, S. (2005). Biofilms on Silicone Rubber for Materials Outdoor High Voltage Insulation. KTH Fibre and Polymer Technology, (79). [ Links ]

Wallstrõm, S., & Karlsson, S. (2004). Biofilms on silicone rubber insulators; microbial composition and diagnostics of removal by use of ESEM/EDS. Polymer Degradation and Stability, 85(2), 841-846. DOI: 10.1016/j.polymdegradstab.2004.02.014. [ Links ]