Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería e Investigación

versão impressa ISSN 0120-5609

Ing. Investig. vol.36 no.1 Bogotá jan./jun. 2016

https://doi.org/10.15446/ing.investig.v36n1.48104

DOI: http://dx.doi.org/10.15446/ing.investig.v36n1.48104

Software to manage transformers using intelligent electronic device

Software para gestionar transformadores usando dispositivo electrónico inteligente

H. S. Fernandes1, M. B. Moura2, P. C. Guadelupe3, M. Z. Fortes4, and N. C. Fernandes5

1 Henrique Santos Fernandes: Telecommunications Engineer, Fluminense Federal University. Affiliation: Fluminense Federal University, Brazil.

Email: sf.rique@gmail.com.

2 Matheus B. Moura: Telecommunications Engineer, Fluminense Federal University. Affiliation: Fluminense Federal University, Brazil.

Email: santozaw@hotmail.com.

3 Faulo Cesar C. Guadelupe: BSc. System Information, Estácio de Sá University. Affiliation: Fluminense Federal University. Brazil.

Email: guadelupepc@gmail.com.

4 Márcio Zamboti Fortes: Electrical Engineer, Severino Sombra University,. Master in Energy, Itajubá Federal University. Doctorate in Electrical Engineering, São Faulo University. Affiliation: Fluminense Federal University, Brazil.

Email: mzf@vm.uff.br.

5 Natália Castro Fernandes: Electronic and Computation Engineer, Rio de Janeiro Federal University. Master and Doctorate in Electric Engineering, Rio de Janeiro Federal University. Affiliation: Fluminense Federal University, Brazil.

Email: nataliacf@gmail.com.

How to cite: Fernandes, H. s., Moura, M. B., Guadelupe, P. C., Fortes, M. Z., & Fernandes, N. C. (2016). Software to manage transformers using intelligent electronic device. Ingeniería e Investigación, 36(1), 85-89. DOI: http://dx.doi.org/10.15446/ing.investig.v36n1.48104.

ABSTRACT

Power companies usually answer the increase in power demand by building new generation facilities. Nevertheless, an efficient use of energy could reduce and delay the costs of investment in new power plants. This paper shows a software system to manage transformers and evaluate losses when they work with zero loads. This system contributes to reduce the waste of energy with some simple actions such as shutting off an unused transformer or reconnecting disabled equipment based on the customer's demand. It uses real time measurements collected from Intelligent Electronic Devices as a base for software decisions. It also measures and reports the total power saving.

Keywords: Automated Systems, energy management, industry electric utility control, intelligent electronic device.

RESUMEN

Las compañías eléctricas por lo general responden al aumento de la demanda de energía mediante la construcción de nuevas instalaciones de generación. Sin embargo, un uso eficiente de la energía podría reducir y retrasar los gastos de inversión en nuevas centrales eléctricas. En este trabajo se muestra el sistema de software para gestionar transformadores y evaluar las pérdidas cuando trabajan con cero cargas. Este sistema ayuda a reducir la pérdida de energía con acciones simples como: Desenergizar un transformador no utilizado o volver a conectar el equipo con base en la demanda del cliente. Utiliza las mediciones en tiempo real obtenidas de la base de Intelligent Electronic Devices para el software de Decisiones. También mide e informa el ahorro total de energía.

Palabras clave: Sistemas automatizados, gestión de la energía, industria eléctrica control de servicios, dispositivo electrónico inteligente.

Received: December 31st 2014 Accepted: January 5th 2016

Introduction

Energy efficiency becomes a critical element for the environment. This renewed importance is due to growing concerns about global climate changes and energy security as commented by Gillingham and Newell (2009). In this sense, waste of energy is one of the main problems. The use of computer resources to support management teams in identifying opportunities is one of the research areas that can be developed, especially with the Intelligent Electronic Device (IED) technologies. This paper presents an automated system applied in electric transformers contemplating a dedicate software in order to identify opportunities to reduce electric consumption when the equipment has a low load.

Using IEC 61850-based IED's measurements, the system tracks the substation's behavior and reduces operational costs. The IED's can be used in several applications as described by several authors (Buse, et al. 2003) (McDonald, 2003) (Kezunovic, 2007) (Nina, et al. 2013). Some comments about the use of IEC 61850 in substations are presented in Roostaee and others (2011) and Mackiewicz (2006).

The proposed solution collects and processes IED measurements. The service value function is used to get online information from the lEDs such as voltages, currents, frequency, (active, reactive, and apparent) power, power factor, primary and secondary phasors, differential currents, bias current, (current and voltage) symmetrical sequence, pulse counters, measured values and other information of the different parameters, depending on the features provided by the IED manufacturer.

We implemented the proposal using the Python language to analyze the economy impact in the power system. The Python language has several different uses as shown in researches developed by Oliphant (2007). We developed a simulator that uses generic consumer's load to evaluate the energy efficiency inside substations.

This paper explains how the software works, and then presents some equations to demonstrate the economy that the software could have made if it was in use. This allows the user to estimate the economy the software brings. Simulation inputs are a generic consumer's load. We present the results of the simulation and a brief discussion about them.

IEC61850 Comments

The IEC 61850 standard provides new ways to get information about the grid state, by using IEDs, which are microprocessor-based controllers used for monitoring of power system equipments such as transformers, capacitors, etc.

The IEC working groups started the development of a common standard for substation communication in 1994, at the same time that IEEE started a similar communication protocol called UCA. In 1997, both of these decided to join efforts and created a common standard for substation communication, called IEC 61850. The scope of the IEC 61850 is to specify the communication in substations. Lopes et al. (2015) comment that IEC 61850 simplifies the design, installation and the maintenance of the system with a significant cost reduction.

The abstract data and object modeling of the IEC 61850 define a method of standardization for power system devices and describe the same pattern to be used with all the IEDs. The standard maps the abstract objects and the services to the Manufacturing Massage Specification (MMS) protocol of ISO 9506-1. According with Mackiewicz (2006), the key features of IEC 61850 include the use of a virtualized model and the naming for all data. Additionally, all object names are standardized and defined in a power system context. In IEC 61850, devices are self described and high-level services are defined. This standard also proposes a configuration language to set the IED parameters.

Among the main benefits brought by IEC 61850 we highlight the reduced costs for installation, commissioning, migration, extension, and integration.

Today's IED s have new features, besides the basic measurements such as frequency, voltage, and current harmonic content, symmetrical sequences, etc. With the use of the IEDs, It is possible to replace the old legacy traditional measurement equipments.

Transformers

Typically, energy efficiency actions are not in transformers. There are several studies in industrial systems such as lighting, air leaks, panels and induction motors, with some examples of research results presented in the references (Andrade et al., 2013), (Fortes et al., 2014), (Ferreira et al., 2015).

Although there are a few kind of transformers, this paper focuses on three-phase power transformers. They present a phase difference between the primary and the secondary winding and can have two basic structure connections, delta and eye. Depending on the configuration in the primary and in the secondary, it will generate different phases angles.

The efficiency of a typical modern power transformer is 97 %, which means that up to 3 % of all electrical power generated is wasted in transformer losses. These losses are far from negligible, and reducing the waste leads to great savings as well as reduced environmental impact. The main losses are in the core and in the cooper.

The core loss is caused by hysteresis of the magnetic material, increasing heat in the system. The copper loss is due to resistance of the primary winding. There are modern techniques (such as thermodynamic models) used to determine the loading limits of transformers and thus better quantify the losses, as shown in Pontes and others (2013).

In order to simplify the problem, in this paper we only consider the zero load loss. This loss occurs in a transformer that is on but has no load at all. The software checks this load and takes action. A complete analysis can be made by inserting the real data of transformers. In other words, to field application, the software should be appropriate to the data (provided by manufacturers) of installed equipment.

Proposed Software System

According to Nudurupati and others (2011), in order to proactively respond to these challenges, management requires up-to-date and accurate performance information on its business. This performance information needs to be integrated, dynamic, accessible and visible to aid fast decision-making in order to promote a proactive management style leading to agility and responsiveness.

The software was designed to collect the information from the IEDs about the load of the transformer and the distribution lines using IEC 61850 messages. The software then processes these measurements and decides the best action to be executed with the transformers connected to the system.

These actions are turning on a disable transformer, shutting off an under used transformer, or doing nothing. The software keeps the transformers in a near optimal functional performance area. This ideal load is achieved because the user configures the software with the best parameter (lower loss per percentage loading) for the group of transformers.

The proposed software system works by getting the current usage from all sectors connected to the transformers bar and gets the maximum current from active transformers. With these measures, the system calculates the actual load of all transformers. If the load is higher than the maximum load, the system turns on a disabled transformer. If the load is lower than a specified threshold, the system shuts off a transformer. To avoid repeatedly turning on and off a transformer, we introduced a hysteresis based on the variable controller. This variable is set by the user and defines how many times the measurement should be above or below the ideal load to turn on/off the transformer. The expert in industrial energy efficiency can adjust these parameters entering variable control limits in the software.

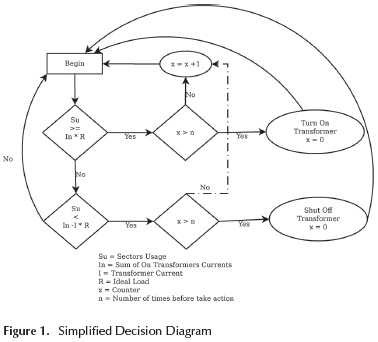

The simplified flowchart to verify whether to turn on or off the transformer is presented in Figure 1. The flowchart idea is to facilitate the identification of when and how long the transformer should be on or off. It also presents the concept of counter to monitor the set-points that will trigger or not the feeding of the equipment within a logic programmed by the specialist.

The system also observes whether the load is too high or too low. In this case, the system bypasses the counter to be more efficient. Additionally, the system shuts off a sector if there is no load available to the transformer in order to increase the lifetime of the equipments.

Expected Power Savings

The software was designed to collect the measurements from the IEDs, calculate the load of the lines and compare them with the load of the transformers, based in some variables defined by the user. The software calculates the energy saving based on the algorithm developed considering the nameplate of equipment and losses declared by the manufacturer. The only information required is a historic of the sectors usage and the type of the transformers.

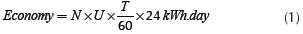

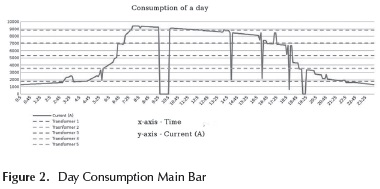

The software also estimates the savings when the system is in use or not, according to Equations (1) and (2). The code was developed through a formula to calculate how much energy can be saved (Equation (1)) with the smart usage of transformers. After that, Equation (2) shows how to calculate the sum of all the periods with different number of turned off transformers.

Where: N - Number of Transformers OFF

U - Transformers usage with zero loads

T - Minutes in off mode (24 hours reference)

As an example, the program can use the transformer efficiency to enhance the best use of energy. According to the flowchart in Figure 1, the program decides whether a transformer should be on or off based on the sector usage, the transformer current, the ideal load, and the chosen hysteresis parameter. Hence, we improve system efficiency based on a simple comparison that allows the decision of when changing the number of transformers on at each moment.

Case Studied

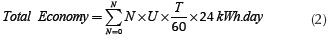

The software can also calculate how much energy could be saved if you had used it. The only information needed is a historical of the sectors usage and the nominal power of the transformers. In this simulation a substation with 5 transformers is used; Figure 2 shows the loads that are being used. This curve is based on an electrical bus of an industrial process that works with heating and cooling period in stages. At times there is a shutdown of heating and cooling systems for temperature equalization in the process.

In this studied case, the software determined that the active power lost due the joule effect when the transformer was unloaded was of 13 kW, and the maximum active power when the transformer was fully loaded was 750 kW; about 95 % of the power nominal of the transformer was considered as an ideal load.

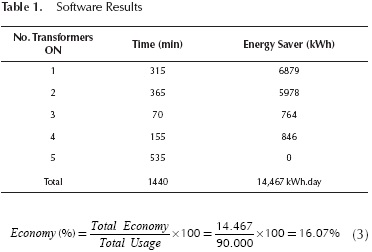

With these adjusted values and the phase currents of each transformer monitored by IEDs, the software will signal (on or off) when there are at least four readings above or below predefined values of charging. For instance, reference loads such as 95, 80, 65 and 50 % of the nominal power can be adjusted. Table 1 shows how much time is each transformer on, and how much energy saved. The value presented is based on the process load curve shown in Figure 2. If all transformers are on, the energy consumed should be 90,000 kWh.day. Hence, the analyst can see how much more efficient the substation can be with the software by using the equation (3).

Conclusions

The python language is used to improve and help the fast development of the software, mainly because the benefits of this language dealing with the files collected from the IEDs. These actions enhance the massive job of collection of the measurements from all the transformers and circuits.

Using the proposed system it is possible to increase the efficiency of a group of transformers, because the system is able to turn them on or off according to the current load of the network. The economy is obtained through the reduction of a transformer working with low or zero-load, because in a normal operation the transformers are never shut down; when the software acts shutting down a transformer it generates an economy in its life cycle and in the waste of energy.

With the adoption of the software, it is possible to increase the time in which a group of transformers works in the better efficiency area, because when the efficiency of the group of equipments starts to reduce, the program shuts-down a sub-used/no load transformer, forcing the rest of the group to work again with better efficiency.

The system is also capable of calculating the zero load time economy and comparing it to the normal use of a group of transformers. Based in this information the system informs the power saved for the period.

We implemented the proposed system and developed a simulator to evaluate the results. Based on the simulation results, we conclude that a substation controlled by the program is more efficient than a standard mode operation. The results in the evaluated scenario show an economy of 16 % against the normal use of the transformers. The software proves to be a better choice in scenarios with peaks of usage; when the load was analyzed, it was discovered that during a good part of the day the transformers work with a low load. Hence, the software proves to be very useful and generate a good economy.

This is one more example that proves that a computational solution can help industries or other companies to reduce energy costs and, consequently, reduce the final product cost or increase its profit. This procedure can be adopted in companies that only operate during the week (Monday to Friday).

References

Andrade, J.A.B., Lima, G.B.A., Fortes, M.Z. (2013). As atividades da Manutenção como Ferramenta de Eficiência Energética. 28° Congresso Brasileiro de Manutenção (in portuguese). DOI: 10.13140/RG.2.1.4486.8007. [ Links ]

Buse, D.P., Sun, P., Wu, Q.H., Fitch, J. (2003). Agent-based substation Automation. IEEE Power and Energy Magazine, Vol.1 No.2, 50-55. DOI: 10.1109/MPAE.2003. 1 192026. [ Links ]

Ferreira, U.M., Fortes, M.Z., Dias, B.H., Maciel, R.S. (2015). Thermography as a Tool in Electric Panel Maintenance. IEEE Latin America Transactions, Vol. 13, No. 9, 3005-3009, 2015. DOI: 10.1109/TLA.2015.7350052. [ Links ]

Fortes, M.Z., Brandão, G.P., Dias, B.H., Albuquerque, C.J.M. (2014). Software support for evaluation of energy losses by leaks. IEEE Potentials, Vol. 33, No. 2, 26-31, 2014. DOI: 10.1109/MPOT.2013.2279178. [ Links ]

Gillingham, K.P.K., Newell, R.G. (2009) Energy efficiency economics and policy. Annual Review of Resource Economics, Vol.1, 597-620. DOI:10.1146/annurev.resource. 102308.124234. [ Links ]

Kezunovic, M. (2007). The next generation of monitoring and control systems using synchronized sampling technology and multifunctional IED's. 40th Annual Hawaii International Conference on System Sciences, 117. DOI: 10.1109/HICSS.2007.550. [ Links ]

Lopes, Y., Muchaluat-Saade, D.C., Fernandes, N.C., Fortes, M.Z. (2015). Geese: A traffic generator for performance and security evaluation of IEC 61850 networks. 2015 IEEE 24th International Symposium on Industrial Electronics (ISIE), 687-692. DOI: 10.1109/ISIE.2015.7281552. [ Links ]

McDonald, J.D. (2003). Substation automation, IED integration and availability of information. IEEE Power and Energy Magazine, Vol.1, No.2, 22-31 DOI: 10.1109/ MPAE.2003.1192023. [ Links ]

Mackiewicz, R.E. (2006). Overview of IEC 61850 and Benefits. IEEE PES 2005/2006 Transmission and Distribution Conference and Exhibition, 376-383. DOI: 10.1109/TDC.2006. 1668522. [ Links ]

Nina, D.L.F., Fonseca Neto, J.V., Ferrreira, E.F.M., Santos, A.M. (2013). Hybrid Support System for Decision Making based on MLP-ANN, IED and SCADA for Disturbance Analysis of Electrical Power Distribution Transformers. 15th International Conference on Computer Modeling and Simulation (UKSim),12-20, 2013. DOI: 10.1109/UKSim.2013.147. [ Links ]

Nudurupati, S.S., Bititci, U.S., Kumar, V., Chan, F.T.S. (2011). State of the art literature review on performance measurement. Computers & Industrial Engineering, Vol.60, No.2, 279-290. DOI: 10.1016/j.cie.2010.11.010. [ Links ]

Oliphant, T.E., Python for Scientific Computing. (2007). Journal Computing in Science and Engineering, Vol.9, No.3, 10-20. DOI: 10.1109/MCSE.2007.58. [ Links ]

Pontes, C.E.V, Costa, S.F., Costa, M.C., Henriques, H.O., Aires, J.C.O., Fortes, M.Z. (2013). Thermodynamic Models and Three-Dimensional Analysis for Loading Transformers Limits Determination. IEEE Latin America Transactions, vol.11, No. 5, 1225-1231. DOI:10.1109/TLA.2013 .6684397. [ Links ]

Roostaee, S., Hooshmand, R., Ataei, M. (2011). Substation automation system using IEC 61850. 5th International Power Engineering and Optimization Conference (PEOCO), 393-397. DOI: 10.1109/PEOCO.2011. 5970443. [ Links ]