Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.37 no.1 Bogotá Jan./Apr. 2017

https://doi.org/10.15446/ing.investig.v37n1.57306

DOI: http://dx.doi.org/10.15446/ing.investig.v37n1.57306

Refined cassava flour in bread making: a review

Harina de yuca refinada en panificación: una revisión

Johanna Aristizábal1, José Alberto García2, and Bernardo Ospina3

1 MSc in Food Development and Innovation. Universitat de Barcelona. Affiliation: Consultant, Corporación CLAYUCA, Colombia. E-mail: j.aristizabal@clayuca.org

2 Specialist on Management of Total Quality and Productivity., Universidad del Valle, Cali. Affiliation: Production and processing technology coordinator, Corporación CLAYUCA, Colombia. E-mail: a.garcia@clayuca.org

3 MSc in International Agricultural Development. University of California at Davis, Ca, USA. Affiliation: Executive Director, Corporación CLAYUCA, Colombia. E-mail: b.ospina@clayuca.org

How to cite: Aristizábal, J., García, A., Ospina, B. (2017). Refined cassava flour in bread making: a review. Ingeniería e Investigación, 37(1), 25-33. DOI: 10.15446/ing.investig.v37n1.57306.

Received: May 5th 2016 Accepted: February 14th 2017.

ABSTRACT

Different studies have developed a variety of breads using cassava flour, with similar characteristics to wheat flour breads. The use of cassava flour in bread making is a convenient alternative for promoting the use of a local crop as well as reducing imports of wheat flour, promoting the production of high quality cassava flour, offering a gluten-free product and developing biofortified and fortified foods. Although the substitution level of cassava flour is limited, in some products, the incorporation of additives or flours from other crops improve the nutritional value and bread making quality of the baked foods. Several limitations have hindered the success of initiatives to promote, in some cassava producing countries, the intensive use cassava flour in bread making. Among these include the costs and efficiency of processing technologies, standards of the quality of cassava flour and lack of favorable policies. Further studies about bioavailability and retention of nutrients on baked foods and evaluation on the effects of processing cassava flour in relation to increasing the resistance starch are required to provide scientific evident for the health benefits of this flour.

Keywords: Cassava flour, composite flour, gluten-free, biofortification, resistant starch.

RESUMEN

Diferentes estudios han permitido desarrollar una variedad de panes utilizando harina de yuca, con características similares a los panes de harina de trigo. El uso de harina de yuca en productos de panificación es una alternativa conveniente para fomentar el uso de un cultivo local, reducir la importación de harina de trigo, promover la producción de harina de yuca de alta calidad, ofrecer un producto libre de gluten y desarrollar alimentos bio-fortificados y fortificados. Aunque el nivel de sustitución de harina de yuca es limitado, en algunos productos, la incorporación de aditivos o harinas de otros cultivos mejora el valor nutricional y la calidad panificable de los productos horneados. Varias limitaciones han impedido el éxito de iniciativas para promover, en algunos países productores de yuca, el uso intensivo de harina de yuca en panificación. Dentro de estas se incluyen costos y eficiencia de tecnologías de procesamiento, estándares de calidad de la harina de yuca y la falta de políticas favorables. Se requieren estudios adicionales sobre bio-disponiblidad y retención de nutrientes en productos horneados y evaluación de los efectos del procesamiento de la harina de yuca en relación a incrementar el almidón resistente para proveer evidencia científica de los beneficios para la salud de esta harina.

Palabras clave: Harina de yuca, harina compuesta, libre de gluten, bio-fortificación, almidón resistente.

Introduction

Colombia is the third largest producer of cassava in Latin America after Brazil and Paraguay. In 2014, Colombia produced 2,1 million tons (MT), as compared with Brazil (23,2 MT) and Paraguay (3,0 MT). (FAO, 2016). Cassava is a staple food in many countries of Africa, Asia, Latin America and the Caribbean. This crop has great social value and cultural identity. Therefore, cassava plays an important role in food security and nutrition being a source of income for producers, processors and trades contributing substantially to poverty alleviation (IFAD & FAO, 2001). Among its main features stand out its great potential for the production of starch, tolerance to drought, its adaptation to difficult ecosystems such as acid soils of low fertility and its great flexibility on planting and harvesting adapting to different growing conditions (Cadavid, 2002). Both its roots and its leaves are suitable for human consumption; the first as a source of carbohydrates and the second as a source of protein, minerals and vitamins, particularly carotene, calcium and phosphorus (IFAD & FAO, 2004). Cassava is mainly grown by small producers, who use it for self-consumption, feed animals and generate income by selling in different markets (UNCTAD, 2015). One of the biggest challenges to the food industry in developing countries is changing processing techniques from traditional to modern ones. This transition depends on the type of food to be processed, consumption habits, supply of raw material and availability of equipment (Falade & Akingbala, 2011 and Ukwuru & Egbonu, 2013).

Cassava flour is one of derivatives from cassava roots whose processing technology is cheaper and easier than cassava starch production besides require less consumption of water and energy and produce smaller quantity of byproducts and waste (Abass et al., 1998). Cassava flour is traditionally obtained from receiving roots which later are washed and/or peeled and after that grated or chipped into slices or chips. These can be dried on concrete floors by the sun, on trays or in artificial dryers (rotatory, trays, fixed bed or flash). The commonest technique applied is drying cassava chips by the sun, which depends on sunny seasons and large spaces. The dried chips are milled and the flour is sieved to obtain refined flour which finally is packaged and stored. The production of cassava flour in Colombia is artisanal and small-scale. However one of the biggest limitations is drying technology (Alonso et al., 2002).

Wheat and corn and its flours imports represent a major burden on the economy of importing countries including trade imbalance, overdependence on foreign foods, loss of foreign exchange, food insecurity, as well as displacement of local food, with detrimental effects on the agricultural and technological development of these regions (Ohimain, 2014) . The need for strategic development and use of local resources for producing low cost foods, such as bread and baked foods has been recognized by organizations such as the Food and Agriculture Organization of the United Nations (FAO), the International Center for Tropical Agriculture (CIAT), the International Institute of Tropical Agriculture (IITA) and the Federal Institute for Industrial Research Oshodi (FIIRO). Inclusion of cassava flour as composite for production of foods such as noodles, breakfast cereals, cookies, breads, cakes, pastries, muffins and doughnuts among others could reduce costs and increase the production of these products locally (; Akinlonu, 2011; Falade & Akingbala, 2009 and Oyewole, 2002;). Measures to promote the use of cassava flour in tropical countries, particularly cereals importing countries, remain active however its implementation has not been consolidated. Brazil, in 2001, promoted the incorporation of 10 % of cassava flour in wheat flour in bread making in order to absorb 50 % of the country's cassava production (Rebelo, 2002). Nigeria, in 2003, established a policy to use 10 % of cassava flour in bread making; however, 5 % was used due to shortage of cassava flour. In 2012, the country imposed a tax to imported wheat flour, so bakeries were required to use 20 % cassava flour. In addition, given the importance of cassava in diet Nigeria, proposals have been developed to biofortify cassava and reduce the deficiency of vitamin A which is a common problem in this country (UNCTAD, 2015) .

In this study the contribution of scientific literature on the development of bread making products using cassava flour is analyzed. Three alternatives for the potential use of cassava flour are introduced including the elaboration of gluten-free products, biofortification and fortification of wheat-cassava composite flours, and techniques for increasing resistant starch in cassava flour products. Finally, the main challenges that must be overcome producing countries to achieve the extensive use of cassava flour in bread making are discussed to inspire actions and business models to exploit the comparative advantages of cassava flour in relation to wheat flour, boosting rural development in these regions.

Production of refined cassava flour

In 2001, the Latin American and Caribbean Consortium to Support Cassava Research and Development (CLAYUCA) and the International Center for Tropical Agriculture (CIAT), with support from the Colombian Ministry of Agriculture and Rural Development (MADR) supported the design of a pilot plant to obtain dried cassava chips for animal consumption. This initiative encouraged many industries in Colombia to design systems for drying cassava for both human and animal consumption; however the technologies designed did not have extensive application in the large scale production of cassava flour in Colombia, due to investment costs and operational problems among others (Silva et al., 2002).

In 2006, CLAYUCA developed a research project to establish a pilot plant for continuous production of refined cassava flour titled sponsored by the MARD (García et al., 2006). In this project, a modular pilot plant optimizing previous plant models was designed (Barona & Isaza, 2003) using improved methods of milling and refining. This technology has been recently improved in order to reduce the process time and energy consumption (Gallego & García, 2015).

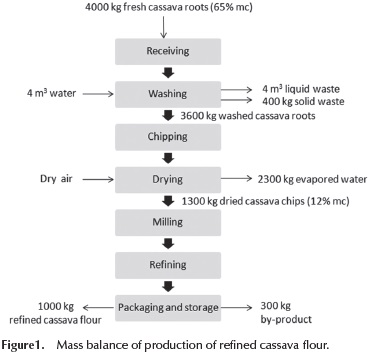

The refined cassava flour production process comprises the steps of receiving, washing, chipping; drying, milling and refining.

- Reception: After harvesting cassava roots are transported to the processing plant. There the cassava is weighed to estimate its dry matter content using the technique of specific gravity (Toro & Cañas, 1983) which is possible also estimate the production yield. Subsequently, the roots are deposited in a feeding hopper which leads to a sand trap which rotates allowing that excess of impurities such as adhered soil, rootlets, and the peduncle are removed.

- Washing: The roots are driven by conveyor belt to a wash machine which consists of a horizontal cylinder with holes. The load on the machine is 200 kg. The roots are washed using water under pressure for about 5 minutes. On average 1 m3 of water is required to wash 1 ton of cassava roots. The combination of water and friction between roots and the drum inner walls removes impurities and the thin outer peel. To improve the microbiological quality of cassava flour, at the end of the washing may be used a disinfectant solution of sodium hypochlorite at 10 ppm washing the roots during 2 minutes.

- Chipping: In this stage the size of cassava roots is reduced to increase the area of heat transfer and accelerate the drying process. The roots are chipped using a machine which has a vertical disc rotating with several fluted trapezoidal blades that turn at 1200 rpm. A typical cassava chip is a rectangular piece of about 0,5 cm2 cross section area and 3 cm lenght, which has moisture content between 58-70 %. The drying time depends on the size of cassava chips.

- Drying: Cassava chips can be dried by sun or using artificial dryers to reduce moisture content (mc) to 10-12 %. Drying is a critical stage; it should be uniform to avoid fermentation problems or microbial contamination of the flour.

- Milling and refining: The dried cassava chips are milled through a hammer mill which has expanded mesh which reduces refine the flour rejecting small materials such as thin outer peel, and fiber pieces. The material that passes through the mesh enters a cylindrical mill-sieve, after which it is sucked by a centrifugal fan that transports the material to a pair of cyclones. The operating conditions of refining can be varied in accordance with the refinement requirements to obtain either refined flour or whole flour.

Subsequently, the refined cassava flour is packed into plastic bags and stored on wooden pallets in a place free of moisture, contamination and insect pests.

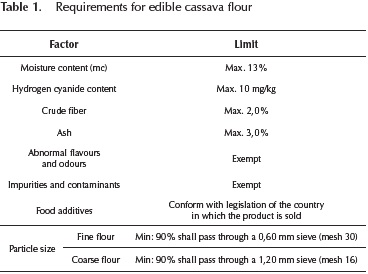

The FAO-WHO commission of the Codex Alimentarius defined the standard for edible cassava flour. Codex Stan 176 (Codex Alimentarius Commission, 1989).

In general, the yield process for obtaining refined cassava flour is:

- 3 kg cassava roots: 1 kg dried cassava chips (12 % mc).

- 1,3 kg dried cassava chips: 1 kg refined cassava flour (12 % mc).

The conversion factor of cassava roots to refined cassava flour depends on the dry matter content of cassava roots as well as of levels of impurities in the raw material and losses occurring in the process.

Cassava flour in baked food

One of the most popular uses of cassava flour in the world is in the manufacturing of baked products such as bread, cakes and pastries (Shittu et al., 2008). Cassava flour as raw material for the bakery and pastry industry, as a substitute for wheat flour, can be used in the elaboration of products such as thickeners, dehydrated soups, noodles, extruded products, seasonings, breaded, baby food, sweets and processed meat (Adebayo et al., 2010; Balagopalan et al., 1988; Day et al., 1996 and Fernández et al., 1992;).

A number of studies have been conducted to use cassava flour in bread making. Most of the studies revealed that wheat flour can be replaced by 5 to 10 % cassava flour without significant effects on processing and the quality of bread (Dendy et al., 1972; Giacco & Appolonia, 1977; Almazan, 1990; Defloor, 1995 and Eddy et al., 2007). Substitutions of up to 30 % have been made to obtain acceptable breads (Defloor et al, 1993 and Jensen et al., 2015). Some factors that influence the quality of bread made with wheat-cassava composite have been studied such as the type of variety of cassava (Eggleston et al., 1993; Eduardo et al., 2013; Eriksson et al., 2014; IIT, 1986a; Henao & Aristizábal, 2009 and Shittu et al., 2007b), maturity of cassava of a same variety (IIT, 1986b and Defloor et al., 1994, 1995), the time and temperature of baking (Shittu et al., 2007a) and absence of fertilizer on cassava roots (Shittu et al., 2008). Akingbala et al. (2011) evaluated the effect of the maturity of the cassava root and shelf life of cassava roots and flour on the physico-chemical and sensory characteristics of cookies made with cassava flour. Studies have shown that cassava flour absorb a larger amount of water than wheat flour (Defloor et al., 1993; Eduardo et al., 2013). Henao & Aristizábal (2009) found that using 10 % of cassava flour the dough yield increased by 1,4%.

On the production of cookies, cassava flour can replace wheat flour in percentages of 20 % (Mlingi et al., 1998), 30 % (Abass et al., 1998; Oyewole, 2002 and Falola et al., 2011) 40 % (Eggleston et al., 1992 and Onwuka & Bokanga, 1994) and 100 % (Onabolu & Bokanga, 1998 and Oyewole et al., 1996) with overall acceptability in terms of color, texture, crunchiness and flavor. Cassava flour substitutions from 30 to 100 % has been evaluated in the production of cakes; as the proportion of cassava was increased, the firmness, chewing, and cohesiveness decreased, tendency that was remained in the time (Cueto et al., 2011). Rangel et al. (2008) made cakes using 20 % of cassava flour obtaining an acceptable product but with a lower specific volume.

Although cassava flour can replace wheat flour at levels above 20 %, additives such as emulsifiers, enzymes, hydrocolloids and gums, lipids and proteins may be required to improve the quality of bread and increase the nutritional value (Houben et al., 2012). However, using these additives may increase the cost of production of bread (Ohimain, 2014). Eduardo et al. (2013) evaluated the addition of pectin (1-3 %) together with a 40 % substitution of cassava flour resulting in a reduced crumb firmness of bread. Using 30 % cassava substitution Khalil et al. (2000) achieved acceptable breads using malt while Owuamanam (2007) carried out a pre-treatment of cassava roots with citric acid solution before milling into flour. The addition of xanthan gum (Shittu et al., 2009; Gambus et al., 2007), and agar-agar (Alvarenga et al., 2011) have been investigated to improve the functional properties of gluten-free breads. Moreover, substitutions of 100 % cassava flour using egg white and extra virgin olive oil have been done (Pasqualone et al., 2010).

Biofortification and fortification of wheat-cassava composite flours

The most conventional strategies used to address micronutrient malnutrition are supplementation, food fortification and biofortification (Berti et al., 2014). Fortification is the addition of one or more nutrients to a staple food in order to improve its quality. On the other hand, biofortification is the process of increasing the content and/or bioavailability of essential nutrients in crops during plant growth through genetic and agronomic pathways (López, 2015).

Diverse mixtures can be designed and more nutritious products can be developed for local markets (Noorfarahzilah et al., 2014). There are some varieties of cassava with high content in carotenoids, making these varieties a source of pro vitamin A. The total content of (3-carotene can reach about 5 u.g/g in yellow pulp cassava roots (Aniedu & Omodamiro, 2012 and Kimura et al.. 2007). Oven-drying of cassava roots rich in ( - carotenes retained high content of ( -carotene (71,9 %) compared to drying shadow drying (59,2 %) and boiling (55,7 %). In addition, storage of cassava flour and chips in plastic bags using vacuum resulted in higher losses without application of vacuum. There is higher retention of ( -carotene in cassava chips than cassava flour (Chávez et al., 2007). The Harvesplus program lead the project "Combating hidden hunger in Latin-America: biofortified crops containing improved vitamin A, essential minerals and high quality protein" which increased the beta-carotene content of cassava roots making this crop more nutritious, contributing to the reduction of nutritional deficiencies of low income population in Colombia, Brazil and Nicaragua by developing food products such as soups, biscuits, breads, cakes, noodles and baby food (Ospina et al., 2009).

Biscuits and cakes made from mixtures of cassava/soy flour in 50/50 proportion had high scores in sensory evaluation in all evaluated attributes: color, texture, flavor and overall acceptability (Akubor & Ukwuru, 2003). Akinwande et al. (2008) made biscuits with cassava flour using a substitution of 40 % soy flour incorporating ginger powder as flavor agent which masked the taste of soy. Cakes made with soy/ cassava/wheat flour in the ratio 20:30:50 % respectively were comparable to cakes made with 100 % wheat flour in terms of quality and acceptability for color, flavor, soft-mouth and texture (Ugwuona et al., 2012). The inclusion of soy flour produces a significant emulsifying activity and increases the water absorption capacity, as well as contributing to increase protein content. In addition, due to the high water absorption capacity of soy proteins and its interactions with amylopectin may slow down the process of retrogradation of breads (Olaoye et al., 2006). Cassava flour may be replaced by up to 30 % with pumpkin seed flour to produce cookies without affecting the sensory qualities and increasing its nutritional value (Falola et al., 2011). Polonium et al. (2012) produced a cake with cassava flour, 2 % Spirulina platensis and 4 % cassava fiber, enriched with chocolate, as a school meal. Acceptability trials were carried out with students at a public school in Brazil revealing an acceptability index of 98,8 %. Ogunjobi & Ogunwolu (2010) developed cassava flour biscuits using cashew powder by up to 20 %, as a source of vitamin C, protein and fiber. Jishua et al. (2010) produced muffins and cookies from cassava-based composite flour incorporating a mix of cereals/pulses and additives with fiber to increase the protein content by 4,5-5,6 % (<1,0 % in cassava flour). Other fortification sources include bovine plasma (Benítez et al., 2008) and beans (Graham & Archbold, 1984; Cabal et al., 2014; Chilungo, 2013). The increase of fiber in wheat-cassava flour composite has been evaluated (Jishua & Padmaja, 2008). Biscuits with cassava/cowpea flour in proportion 80/20 and wheat/cassava/cowpea flour in the ratio 35/35/30 did not have significant differences in comparison to wheat flour control (Olapade & Adeyemo, 2014).

Cassava products contain different amounts of resistant starch (RS). In cassava flour the resistant starch levels vary between 0,19 to 2,21 % which depends on the cassava variety and the processing method (Buzati-& Leonel Pereira, 2014). The amount of resistant starch in foods can be modified by processing techniques. Certain types of processing, such as sterilization, drying in ovens, or drying at high temperatures increase the level of resistant starch (Sajilata et al., 2006; Pereira, 2007; Walter et al., 2005). The RS has similar properties to soluble fiber and evidence suggests that it has physiological benefits that contribute to the health of the gastrointestinal tract and the metabolic system in humans, as well as providing fewer calories and reduced glycemic load (Nugent, 2005). The characteristics of different types of resistant starch reflect the processing effect, the starch granule characteristics and the starch structure gelatinization (Hallstrom et al., 2011). High amylose starches tend to be more resistant to digestion (Sharma et al., 2008). Hamaker et al. (1991) evaluated the effect of dietary fiber and resistant starch present in cassava flour on the fecal composition of pre-school children. They determined that a portion of the RS was fermented in the large intestines and the fiber cassava produced an increase in the fecal bulk volume due to its high water-holding capacity. Korus et al. (2009) incorporated tapioca resistant starch (20 %) in bakery products causing a decrease of starch gelatinization which was manifested by an increase of pasting temperature (76,8 °C) comparing with control (83,8°C) and decrease of the maximum viscosity (42,5 BU) while control was 81,5 BU. It was attributed to the rising amounts of dietary fiber, which acts as a neutral filler and dilutes starch lowering the viscosity. These changes were accompanied by reduction of the crumb initial hardness and besides by slower aging of bread. Gluten-free products tend to faster aging because the lack of gluten network as well as water migrates faster from crumb to the crust (Gallagher et al., 2003).

Challenges to overcome for the widespread use of cassava flour in baked food

Despite considerable research done for many countries about using wheat-cassava composite flour in bread making there has been little impact in the market due to mainly high production costs, operational problems and quality of cassava flour. In the case of Nigeria, the largest producer of cassava in the world, the reasons for the failure of many initiatives to promote the use of cassava flour in bread making include: insufficient policy incentives; lack of favorable policies; low wheat flour prices relative to those of cassava flour; unreliable supply of and low demand for cassava flour; lack of market access; poor logistics; high cost of transportation and poor conditions of roads; dependence on weather for drying; lack of working capital (Ohimain, 2014). Other reasons that can be included are lack of willingness by the flour millers to comply with government policy; strong consumer preference for 100 % wheat bread; lack of knowledge regarding the advantages of wheat-cassava bread (CIAT, 1998). In Nigeria, quality cassava flour is another common problem by the presence of impurities such as sand, foul odor and color problems, as well as high moisture content which generate significant variation in physico-chemical and functional properties of cassava flour (Adebowale et al., 2011). Generally, cassava flour obtained by hand peeled of cassava roots has a yellow coloration and presence of odor as well as high microbial load which accelerates the bacterial fermentation (Sanni et al., 2009). When cassava flour is obtained by drying cassava pulp, obtained by pulping the roots, previous dehydration is critical to prevent fermentation problems. This method limits the release of hydrocyanic acid due to its reduced area of heat transfer compared to chipped roots (Kolawole et al., 2012). However, drying cassava chips by sun has limitations not only for dependence on weather and space (intensive, scarce, expansive and seasonal) but also poor microbiological quality (Abass et al., 1998). If rotary or flash dryers are used the main problems encountered include high cost of production, ensuring high efficiency equipment, frequent breakdowns, lack of spare parts and excessive consumption of fuel and electricity, etc. (Ohimain, 2014). Because of the problems presented in the operations and maintenance of artificial dryers, other drying systems have been considered such as solar dryers, and use of fresh cassava roots or chips instead of cassava flour for the preparation of bread (Falade & Akingbala, 2009). Unless these challenges be effectively mitigated, current efforts in research and promotion of use of cassava flour in bread making cannot be successful.

Conclusions

There is enough scientific evidence that shows the effectiveness of using cassava flour to elaborate different kind of breads. The potential benefits of using cassava flour in bread making include reduction of dependence on wheat and wheat flour imports, foreign exchange savings, increase farming incomes, reduction food insecurity and boost of rural development by promoting cassava production. It is a fact that to achieve these goals is fundamental to promote policies to use cassava flour in the milling sector, doing association among cassava producers and processors, designing efficient processing technologies, and assuring quality standards, continuous supply and meet the needs of consumers.

Although the inclusion of cassava flour in baked products has limitations, it is possible increase the substitution level by incorporating additives and flour from other crops which improve the nutritional value and bread making quality. Strategies such as fortification or biofortification of staple foods increase the content of essential nutrients as well as address micronutrient malnutrition of low income population. In addition, baked products made out cassava flour offering food alternatives to celiac people who claim products gluten-free.

Further research is necessary to determinate the bioavailability and retention of nutrients in fortified and biofortified products after bread making process and evaluate the effects of processing techniques and storage on the increase of resistant starch in cassava flour in order to assess its health benefits.

References

Abass, A. Onabolu, A.O. & Bokanga, M. (1998). Impact of the high quality cassava flour technology in Nigeria. In Akoroda, M. O. & Ngve, J. M. (Eds). Root crops in the 21th century. Proceedings of the 7th Triennial Symposium of the International Society for Tropical Root Crops Africa Branch (ISTRC- AB). Cotonou, Benin, 11-17 October. Benin: Center International des Conferences. [ Links ]

Adebayo, K., Abayomi, L., Abass, A., Dziedzoave, N.T., Forsythe, L., Hillocks, R.J., Gensi, R., Gibson, R. W., Graffham, A.J., Ilona, P., Kleih, U.K., Lamboll, R.I., Mahende, G. , Martin, A.M., Onumah, G.E., Orr, A.W., Posthumus, H., Sanni, L.O., Sandifolo, V. & Westby, A. (2010). Sustainable Inclusion of Smallholders in the Emerging High Quality Cassava Flour Value Chains in Africa: Challenges for Agricultural Extension Services. J. Agric. Ext., 14(1):1-10. [ Links ]

Adebowale, A.A., Sanni, S.A. &. Koleoso, Y.S. (2011). Chemical and functional qualities of high quality cassava flour from different SMEs in Nigeria. African Journal of Root and Tuber Crops, 9(1), 11-16. [ Links ]

Akingbala, J.O., Falade, K.O. & Ogunjobi, M.A. (2011). The effect of root maturity, pre-process holding and flour storage on quality of cassava biscuits. Food and Bioprocess Technology, 4(3), 451-57. [ Links ]

Akinlonu, E.O. (2011). Nutritional and sensory qualities of novel dishes from cassava. Dissertation submitted to the Department of Nutrition and Dietetics. University of Agriculture, Abeokuta, Africa. [ Links ]

Akinwande, B.A., Ade-Omowaye, B.I.O., Olaniyan, S.A. & Akintaro, O.O. (2008). Quality evaluation of ginger-flavoured soy-cassava biscuit. Nutrition & Food Science, 38(5), 473-81. [ Links ]

Akubor, P.I. & Ukwuru, M.U. (2003). Functional properties and biscuit making potential of soybean and cassava flour blends. Plant Food Hum Nutr, 58(3), 1-12. [ Links ]

Almazan, A.M. (1990). Effect of cassava flour variety and concentration on bread loaf quality. Cereal Chemistry, 67, 97-99. [ Links ]

Alonso, L., Ospina, B. & Best, R. (2002). Secamiento de trozos de yuca en bandejas inclinadas. En Ceballos, H. & Ospina, B. La yuca en el tercer milenio. Sistemas modernos de producción, procesamiento, utilización y comercialización. Cali, Colombia: CIAT, 433-43. [ Links ]

Alvarenga, N.B., Cebola-Lidon, F., Belga, E., Motrena, P., Guerreiro, S., Carvalho, M.J., & Canada, J. (2011). Characterization of Gluten-free Bread Prepared from Maize, Rice and Tapioca Flours using the Hydrocolloid Seaweed Agar-Agar. Recent Res. Sci. Technol, 3(8), 64-68. [ Links ]

Aniedu, C. & Omodamiro, R.M. (2012). Use of newly bred P- carotene cassava in production of value-added products. Implication for food security in Nigeria. Glo. J. Sci. Fron. Res., 12, 11- 16. [ Links ]

Balagopalan, C., Padmaja, G., Nanda, S.K. & Moorthy, S.N. (1988). Cassava nutrition and toxicity. In Hillocks, R.J., Trsh, J.M. & Belloti, A.C. (Eds). Cassava in Food, Feed and Industry. Florida, USA: Boca Raton, CRC Press, 13-36. [ Links ]

Barona, S. M. & Isaza, L. E. (2003). Estudios para el desarrollo de un proceso de extracción de almidón a partir de trozos secos de yuca (Manihot esculenta Crantz) con mínima utilización de agua. Tesis de grado Ingeniería Agrícola. Universidad del Valle, Cali, Colombia. [ Links ]

Benítez, B., Archile, A., Rangel, L., Ferrer, K., Barboza, Y. & Márquez, E. (2008). Composición proximal, evaluación microbiológica y sensorial de una galleta formulada a base de harina de yuca y plasma de bovino. Interciencia, 33(1), 61-65. [ Links ]

Berti, C., Faber, M. & Smuts, C. M. (2014). Prevention and control of micronutrient deficiencies in developing countries: current perspectives. Nutrition and Dietary Supplements, 6, 41-57. [ Links ]

Buzati-Pereira, B.L. & Leonel, M. (2014). Resistant starch in cassava products. Food Sci. Technol, Campinas, 34(2): 298-02. [ Links ]

Cabal, D. C., Melo, A., Lissbrant, S., Gallego, S., Hechavarría, M. & Tofiño, A. (2014). Highly nutritional cookies based on a novel bean-cassava-wheat flour mix formulation. Agronomía Colombiana, 32(3), 407-16. [ Links ]

Cadavid, L.F. (2002). Suelo y fertilización para la yuca. En Ceballos, H. & Ospina, B. La yuca en el tercer milenio. Sistemas modernos de producción, procesamiento, utilización y comercialización. Cali, Colombia: CIAT, 104-25. [ Links ]

Chávez, A.L., Sánchez, T., Rodriguez-Amaya, D.B., Nestel, P., Tohme, J. & Ishitani, M. (2007). Retention of carotenoids in cassava roots submitted to different processing methods. Journal of the Science of Food and Agriculture, 87, 388-93. [ Links ]

Chilungo, S. (2013). Physicochemical properties and baking qualities of baked wheat products supplemented with cassava and pigeon pea flours. Thesis of master Food Science. Michigan State University, Michigan, USA. [ Links ]

CIAT (1998). Producción y mercadeo de harina de yuca para el consumo humano. Fase de planta piloto. Cali, Colombia: Centro Internacional de Agricultura Tropical, Programas de Desarrollo Rural Integrado, Universidad del Valle. [ Links ]

Codex Alimentarius Commission(1989). Codex standard for edible cassava flour. Codex Stan 176-1989. Retrieved from http://www.codexalimentarius.org/standards/list-standards/es/?no_cache=1. [ Links ]

Cueto, D., Pérez, E., Borneo, R. & Ribotta, P. (2011). Efecto de la adición de harina de yuca (Manihot esculenta Crantz) sobre las características sensoriales, reológicas y físicas de tortas y panquecas. Rev. Fac. Agron. (UCV), 37(2), 64-74. [ Links ]

Day, G., Graffham, J. A. & Amoako M (1996). Market potential for cassava based flours and starches in Ghana. NRI Report. Chatham United Kingdom: Natural Resources Institute. [ Links ]

Defloor, I. (1995). Factors governing the breadmaking potential of cassava (Manihot Esculenta Crantz) flour. Faculteit landbouwkundige en toegepaste biologische wetenscha-ppen. Belgica: Kathoieke Universiteit te Leuven, Belgica. [ Links ]

Defloor, I., De Geest, C., Schellekens, M., Martens, A. & Delcour, J.A. (1994). Impact of genotype and crop age on the bread making and physiochemical properties of flour produced from cassava (Manihot esculenta Crantz) planted in the dry season. J. Sci. Food Agric., 66, 193-02. [ Links ]

Defloor, I., Leijskens, R., Bokanga, M. & Delcour, J.A. (1995). Impact of genotype, crop age and planting season on the breadmaking and gelatinization properties of flour produced from cassava (Manihot esculenta Crantz). J. Sci. Food Agric., 68, 167-74. [ Links ]

Defloor, I., Nys, M. & Delcour, J.A. (1993). Wheat starch, cassava starch, and cassava flour impairment of the breadmaking potential of wheat flour. Cereal Chem. 78, 525-30. [ Links ]

Dendy, D.A., James, A.W. & Clarke. P.A. (1972). Work of the tropical products institute, on the use of non wheat flours in breadmaking. Cereal chemistry, 42, 3-6. [ Links ]

Eddy, N.O., Udofia, P.G. & Eyo, D. (2007). Sensory evaluation of wheat/cassava composite bread and effect of label information on acceptance and preference. African Journal of Biotechnology, 6(20), 2415-18. [ Links ]

Eduardo, M., Svanberg, U., Oliveira, J. & Ahrné, L. (2013). Effect of cassava flour characteristics on properties of cassava-wheat-maize composite bread types. International Journal of Food Science, 1-10 [ Links ]

Eggleston, G., Omoaka, G.P. & Arowoshegbe, A.U. (1993). Flour, starch and composite bread making quality of various cassava clones. J. Sci. Food Agric., 62, 49-59. [ Links ]

Eggleston, G., Onwaka, P.E. & Ihedioha, O.D. (1992). Development and evaluation of products from cassava flour as a new alternatives to wheat bread. Journal of the Science of Food and Agriculture 59, 377-85. [ Links ]

Eriksson, E., Koch, K., Tortoe, C., Akonor, P. T. & Oduro-Ye-boah, C. (2014). Evaluation of the physical and sensory characteristics of bread produced from three varieties of cassava and wheat composite flours. Food and Public Health, 4(5), 214-22. [ Links ]

Falade, K. O. & Akingbala, J. O. (2009). Improved nutrition and national development through the utilization of cassava. In Robertson, G .L. & Lupien, J. R. (Eds). Using Food Science and Technology to Improve Nutrition and Promote National Development. International Union of Food Science & Technology. [ Links ]

Falade, K.O & Akingbala, J.O. (2011). Utilization of cassava. Food Reviews International, 27, 51-83. [ Links ]

Falola, A.O., Olatidoye, O.P., Balogun, I.O. & Opeifa, A.O. (2011). Quality characteristics of cookies produced from composite flours of cassava and Cucurbita mixta seed. J. Agric. Vet. Sci., 3, 1-12. [ Links ]

FAO (2016). Food and Agriculture Organization of the United Nations Statistics Division (FAOSTAT). Download data. Crops. Retrieved from http://www.fao.org/faostat/en/#data/QC. [ Links ]

Fernández, A., Vélez, C., De Stouvenel, A., Gómez, A., Wheatley, C., Ostertag, C. & Alonso, L. (1992). La producción y uso de la harina de yuca para consumo humano. En: Scott, G. , Herrera, H., Espinola, N., Daza, M., Fonseca, C., Fano, H. & Benavides, M. Desarrollo de productos de raíces y tubérculos. Vol. II. América Latina. Lima, Peru: CIP, Villa Nueva, Guatemal: ICTA, 251-62. [ Links ]

Gallagher, E., Gormley, T.R. & Arendt, E.K. (2004). Recent advances in the formulation of gluten-free cereal based products. Trends Food Sci. Tech., 15, 143-52. [ Links ]

Gallego, S. & García, J.A. (2015). Producción y usos de harina refinada de yuca. Palmira, Colombia: Convenio OEI/ SENA/ CLAYUCA/ Fundación Promotora del Canal del Dique. 61 p. [ Links ]

Gambus, H., Sikora, M. & Ziobro, R. (2007). The effect of composition of hydrocolloids on properties of gluten-free bread. Acta Sci. Pol., Technol. Aliment., 6(3), 61-74. [ Links ]

García, J.A., Gallego, S. & Alonso, L. (2006). Establecimiento de una planta piloto para la producción continua de harina refinada de yuca. En Informe de proyecto. Palmira, Colombia: CLAYUCA. [ Links ]

Giacco, C.F. & Appolonia, B.L. (1977). Baking studies with cassava and yam rheological and baking studies of tuber-wheat flour blends. Cereal chemistry, 55(4), 423-35. [ Links ]

Graham, H.D. & Archbold, C. A. (1984). Enrichment of cassava products with soybean, peanut and whey protein. content and acceptance. Carib. J. Sci., 18, 1-4. [ Links ]

Hallstrom, E., Sestili, F., Lafiandra D., Bjorck, I. & Õstman, E. (2011). A novel wheat variety with elevated content of amylose increases resistant starch formation and may beneficially influence glycaemia in healthy subjects. Food & Nutrition Research, 55, 7074-DOI: 10.3402/fnr.v55i0.7074. [ Links ]

Hamaker, B. R., Rivera, K., Morales, E. & Graham, G. G. (1991). Effect of dietary fiber and starch on fecal composition in preschool children consuming maize, amaranth, or cassava flours. Journal of Pediatric Gastroenterology and Nutrition, 13, 59-66. [ Links ]

Henao, S. & Aristizábal, J. (2009). Influencia de la variedad de yuca y nivel de sustitución de harinas compuestas sobre el comportamiento reológico en panificación. Ingeniería e Investigación, 29(1), 39-46. [ Links ]

Houben, A., Hochstotter, A. & Becker, T. (2012). Possibilities to increase the quality in gluten-free bread production: an overview. Eur. Food Res. Technol., 235, 195-08. [ Links ]

IFAD & FAO. (2001). The global cassava development strategy and implementation plan Vol 1. Proceedings of the validation forum on the global cassava development strategy. Roma: International Fund for Agricultural Development, Food and Agriculture Organization of the United Nations. [ Links ]

IFAD & FAO. (2004). Global cassava market study. Business opportunities for the use of cassava. Proceedings of the validation forum on the global cassava development strategy. Vol 6. Roma: International Fund for Agricultural Development (IFAD), Food and Agriculture Organization of the United Nations (FAO). [ Links ]

IIT (1986a). Evaluación paramétrica del pan elaborado con harina de yuca en panaderías comerciales de Bogotá (estudios para el auditaje a panaderías y aceptabilidad del pan). Bogotá, Colombia: Instituto de Investigaciones Tecnológicas. [ Links ]

IIT (1986b). Evaluación técnico-funcional de la harina de yuca, variedad MCOL 22-15. Bogotá, Colombia: Instituto de Investigaciones Tecnológicas. [ Links ]

Jensen, S., Skibsted, L.H., Kidmose, U. & Thybo, A.K. (2015). Addition of cassava flours in bread-making: Sensory and textural evaluation. LWT. Food Science and Technology, 60 (1 ), 292-99. [ Links ]

Jishua, S. & Padmaja, G. (2008). Dietary fiber enhancement in cassava based composite flours through fortification. J. Root Cro., 34, 26-33. [ Links ]

Jishua, S., Padmaja, G., & Sajeev, M.S. (2010). Nutritional and textural studies on dietary fiber-enriched muffins and biscuits from cassava-based composite flours. Journal of Food Quality, 33, 79- 99. [ Links ]

Khalil, A.H., Mansour, E.H., & Dawood, F.M. (2000). Influence of malt on rheological and baking properties of wheat-cassava composite flours. Lebensmittel Wissenchaf und Technologie, 33, 159-64. [ Links ]

Kimura, M., Kobori, C.N., Rodriguez-Amaya, D.B., & Nestel, P. (2007). Screening and HPLC methods for carotenoids in sweet potato, cassava and maize for plant breeding trials. Food Chemistry, 100, 1734-46. [ Links ]

Kolawole, O.P., Agbetoye, L.A.S., Ogunlowo, A.S. & Samuel, T.M. (2012). Effect of speed and back pressure on the performance of screw press in dewatering of cassava mash. Green. J. Sci. Eng. Technolo. Res., 2, 17-23. [ Links ]

Korus, J., Witczak, M., Ziobro, R. & Juszczak, L. (2009). The impact of resistant starch on characteristics of gluten-free dough and bread. Food Hydrocolloids, 23, 988-95. [ Links ]

Mlingi, N., Mtunda, K., Ndunguru, G.T., Kiriwagglu, A. & Mahungu, N. M. (1998). Promotion of cassava utilization for improvement of food security and income generation in Tanzania: Viability of processing cassava flour for biscuit production in Dares Salaam. In Akoroda, M.O. & Ngeve, J. M. (Eds). Root Crop in the 21th century. Proceeding of the 7th Triennial Symposium of the International Society for Tropical Root Crops- African Branch (ISTRC-AB). Cotonou, 11-17 October. Benin: Centre International des Conferences. [ Links ]

Noorfarahzilah, M., Lee, J. S., Sharifudin, M. S., Mohd Fadzelly, A.B. & Hasmadi, M. (2014). Applications of composite flour in development of food products. International Food Research Journal, 21 (6), 2061-74. [ Links ]

Nugent, A.P. (2005). Health properties of resistant starch. British Nutrition Foundation Nutrition Bulletin, 30(1), 27-54. [ Links ]

Lopez, J. (2015). Tackling Hidden Hunger. Putting Diet Diversification at the Centre. Penang, Malaysia: TWN. 75 p. [ Links ]

Ogunjobi, M.A.K. & Ogunwolu, S.O. (2010). Physicochemical and sensory properties of cassava flour biscuits supplemented with cashew apple powder. Journal of Food Technology, 8(1), 24-29. [ Links ]

Ohimain, E.I. (2014). The prospects and challenges of cassava inclusion in wheat bread policy in Nigeria. International Journal of Science, Technology and Society, 2(1), 6-17 [ Links ]

Olaoye, O.A., Onilude, A.A. & Idowu, O.A. (2006). Quality characteristics of bread produced from composite flour of wheat, plantain and soybeans. Afr. J. Biotechnol, 5, 1102-06. [ Links ]

Olapade, A.A. & Adeyemo, A.M. (2014). Evaluation of cookies produced from blends of wheat, cassava and cowpea flours. International Journal of Food Studies, 3, 175-85. [ Links ]

Onabolu, A. & Bokanga, M (1998). The promotion of cassava as a commodity for the food industry: A case study in Nigeria. Presented at the CFC workshop on local processing and vertical diversification of cassava in Southern and Eastern Africa, 15-19 June: Mukono, Uganda. [ Links ]

Onabolu, A., Abass, A., & Bokanga, M. (1998). New food products from cassava. Ibadan, Nigeria: IITA. [ Links ]

Onwuka, D. E. & Bokanga, M. (1994). Cassava in the production of bread and bakery products. Proceeding of the 5th Symposium of the international Society for Tropical Root Crops- African Branch (ISTR-AC), 340-42. [ Links ]

Ospina, B., Nutti, M., Gallego, S., Carvalho, J. L., Ascheri, J. L. (2009). Fichas técnicas: Productos alimenticios. In: Proc of an international course on "Tecnologías para la elaboración de productos alimenticios a partir de cultivos con alto contenido nutricional", Palmira, Colombia: CLAYUCA, Empresa Brasileira de Pesquisa Agropecuária. 115 p. [ Links ]

Owuamanam, C.I. (2007). Quality of bread from wheat/cassava flour composite as affected by strength and steeping duration of cassava in citric acid. Nature and Science, 5 (4), 24-28. [ Links ]

Oyewole, O.B. (2002). The powers at the roots: Food and its Microbials Allies. 15th Inaugural lecture University of Agriculture, Abeokuta, Nigeria. [ Links ]

Oyewole, O.B., Sanni, L.O. & Ogunjobi, M.A. (1996). Production of biscuits using cassava flour. Nig. Food J., 14, 24-29. [ Links ]

Pasqualone, A., Caponio, F., Summo, C., Paradiso, V. M., Bot-tega, G. & Pagani, M. A. (2010). Gluten-free bread making trials from cassava (Manihot Esculenta Crantz) flour and sensory evaluation of the final product. International Journal of Food Properties, 13, 562-73. [ Links ]

Pereira, K. D. (2007). Amido resistente, a última geração no controle de energia e digestão saudável. Ciência e Tecnologia de Alimentos, 27(1), 88-92. [ Links ]

Polonio, M.F., Monteiro de Carvalho, J.C., Pereira, K. & Godoy, E.D. (2012). Development of cassava cake enriched with its own bran and Spirulina platensis. Acta Scientiarum. Technology Maringá, 34(4), 465-72. [ Links ]

Rangel, C. N., Watanabe, E., Carvalho, J. L. V., Nutti, M. R., & Silva, E. M. M. (2008). Development of Cake and Bread Formulations Using Cassava (Manihot esculenta L.) and Sweet Potato (Ipomoea batatas L.) Flours: An Application for Biofortified Crops. Shanghai, China: Paper presented at the 14th World Congress of Food Science and Technology. [ Links ]

Sajilata, M. G., Singhal, R. S. & Kulkarni, P. R. (2006). Resistant starch - A review. Compr Rev Food Sci Food Saf., 5, 1-17. [ Links ]

Sanni, L. O., Onadipe, O. O., Ilona, P., Mussagy, M. D., Abass, A. & Dixon, A. G. (2009). Successes and challenges of cassava enterprises in West Africa: a case study of Nigeria, Benin, and Sierra Leone. Ibadan, Nigeria: Instituto Internacional de Agricultura Tropical, 1-25 [ Links ]

Sharma, A., Yadav, B.S. & Ritika, B. Y. (2008). Resistant starch: physiological roles and food applications. Food Rev Int., 24, 193-34. [ Links ]

Shittu, T. A., Aminu, R. A. & Abulude, E. O. (2009). Functional effects of xanthan gum on composite cassava-wheat dough and bread. Food Hydrocolloids, 23(8), 2254-60. [ Links ]

Shittu, T. A., Dixon, A., Awonorin, S. O., Sanni, L. O. & Mazi-ya-Dixon, B. (2008). Bread from composite cassava-wheat flour. II: Effect of cassava genotype and nitrogen fertilizer on bread quality. Food Res. Int., 41 , 569-78. [ Links ]

Shittu, T. A., Raji, A. O. and Sanni, L. O. (2007a). Bread from composite cassava-wheat flour: I. Effect of baking time and temperature on some physical properties of bread loaf. Food Research International, 40, 280-90. [ Links ]

Shittu, T. A., Sanni, L. O., Awonorin, S. O., Maziya-Dixon, B. & Dixon, A. (2007b). Effect of genotype on the flour making properties of some CMD-resistant varieties of cassava. Food chem, 101, 1634-43. [ Links ]

Silva, E., Ospina, B. & Alonso, L. (2002). Obtención industrial de harina de yuca por sistemas continuos. En Ceballos, H. & Ospina, B. La yuca en el tercer milenio. Sistemas modernos de producción, procesamiento, utilización y comercialización. Cali, Colombia: CIAT, 297-01. [ Links ]

Toro, J.C. & Cañas, A. (1983). Determinación del contenido de material seca y almidón en yuca por el sistema de gravedad específica. En: Domínguez, C.E. Yuca: investigación, producción y utilización. Cali, Colombia: PNUD-CIAT, 567-75. [ Links ]

Ugwuona, F.U., Ogara, J. I., & Awogbenja, M.D. (2012). Chemical and sensory quality of cakes formulated with wheat, soybean and cassava flours. Indian J.L.Sci., 1(2), 1-6. [ Links ]

Ukwuru, M.U. & Egbonu, S.E. (2013). Recent development in cassava-based products research. Acad. J. Food. Res., 1 (1), 1-13. [ Links ]

UNCTAD (2015). Infocomm Commodity Profile Cassava. United Nations Conference on Trade and Development. Recuperado Retrieved from http://www.unctad.info/en/Info-comm/AACP-Products/COMMODIRY-PROFILE---Cassava/. [ Links ]

Walter, M., Silva, L.P. & Emanuelli, T. (2005). Amido resistente: características físico-químicas, propriedades fisiológicas e metodologias de quantificação. Ciência Rural, 35(4), 974-80. [ Links ]