Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería e Investigación

Print version ISSN 0120-5609

Ing. Investig. vol.37 no.1 Bogotá Jan./Apr. 2017

https://doi.org/10.15446/ing.investig.v37n1.57158

DOI: http://dx.doi.org/10.15446/ing.investig.v37n1.57158

Mechanical characterization of porous asphalt mixes modified with fatty acid amides -FAA-

Caracterización mecánica de mezclas asfálticas porosas modificadas con amidas de ácidos grasos

V. Senior-Arrieta1, and J.E. Córdoba-Maquilón2

1 Ph. D (c) in Civil Engineering. Universidad Nacional de Colombia, Facultad de Minas. Colombia. MSc in Highways and transportation system. E-mail: vseniora@unal.edu.co.

2 Ph. D in Systems Engineering. Universidad Nacional de Colombia, Facultad de Minas. Colombia. Head Department of Civil Engineering in Universidad Nacional de Colombia. E-mail: jecordob@unal.edu.co.

How to cite: Senior-Arrieta, V., and Córdoba-Maquilón, J.E. (2017). Mechanical characterization of porous asphalt mixes with fatty acid amides -FAA-. Ingeniería e Investigación, 37(1), 43-48. DOI: 10.15446/ing.investig.v37n1. 57158.

Received: April 26th 2016 Accepted: January 23rd 2017.

ABSTRACT

Porous asphalt mixes (PAM), conform a special road surface for asphalt pavement structures. They have a distinctive particle size distribution that permits infiltration of the runoff storm water due to its voids content which is about 20 %. Many researchers have conducted studies and concluded that the use of modified asphalts is completely necessary to design PAM. Organic and chemical additives and special procedures such as foamed asphalt and including fibers into the mixture design have enhanced the performance of PAM, during its service life. This paper is based on the mechanical characterization of PAM and how the asphalt binder modified with fatty acid amides, influenced on their behavior and performance. In order to do so, an experimental methodology based on laboratory tests aimed to establish a comparison between porous asphalt mixes, designed and produced with a 60-70 in 1/10 mm penetration at 25 °C neat asphalt binder, and another using modified asphalt with fatty acid amides.

Keywords: Modified asphalt, porous asphalt mixes, hot asphalt mixes, hydroplaning, fatty acid amides, Cantabro test.

RESUMEN

Las mezclas asfálticas porosas (PAM), conforman una superficie de rodadura especial para los pavimentos flexibles. Tienen una granulometría característica, lo cual permite la infiltración de las aguas de escorrentía pluvial, gracias al contenido de vacíos que posee, alrededor del 20 %. Muchos investigadores han realizado estudios que han permitido concluir que el uso de asfaltos modificados es completamente necesario para diseñar las PAM. Aditivos químicos y orgánicos y procesos especiales tales como el de asfalto espumado y la inclusión de fibras en el diseño de la mezcla, han mejorado el comportamiento de las PAM, durante su periodo de servicio. El presente artículo aborda la temática de la caracterización mecánica de mezclas asfálticas porosas (PAM) y hace énfasis en cómo el cemento asfáltico modificado con amidas de ácidos grasos, influye en su comportamiento y desempeño. Esta investigación, basada en una metodología experimental a través de ensayos de laboratorio, estableció una comparación entre las mezclas asfálticas porosas, empleando para su diseño y producción una, con asfalto puro de penetración 60-70 en 1/10 mm a 25 °C y otra, cuyo asfalto está modificado con amidas de ácidos grasos.

Palabras clave: Cemento asfáltico modificado, mezclas asfálticas porosas, mezclas asfálticas en caliente, hidroplaneo, amidas de ácidos grasos, ensayo Cántabro.

Introduction

Similarly to hot asphalt mixes (HMA), porous asphalt mixes are made of coarse aggregates, asphalt binder and mineral filler. Its high percentage of air voids (AV), is the main feature. For porous asphalt mixes, the AV is in the ranges from 18 °% to 25 % according to (Alvarez et al., 2014), by contrast, for HMA, the air voids are not greater than 8 %. Porous asphalt mixes come from mainly the 1950, when were registered their first uses in different U.S. states as reported by (Adam et al., 1998). Since then, they have shown remarkable progress in areas such as design, development, performance and maintenance as (Kandhal and Mallick, 1998) noted. The initial objective was to improve the vehicles surface friction conditions, when the rain occurred. According to (Suresha et al., 2010), several agencies worldwide use diverse names in order to refer to these mixtures, some of which include: porous asphalt mixtures (PAM), permeable friction courses (PFC) and Open-graded friction courses (OGFC). Nevertheless, there are subtle differences between them.

On the other hand, Europeans introduced modified asphalts and fibers into the American OGFC concept developed between 1930 and 1970 and significantly improved the performance of those mixtures reported by (King Jr. et al., 2013). According to the literature review (Ruiz et al, 1990), the first application of PAM in Spain was placed in 1980. As a result, laboratory tests carried out at the University of Cantabria, such as abrasion loss using Los Angeles Machine (Cantabria test) and on-site permeability by means permeameter LCS, are still considered to follow as a methodology to design and control the porous asphalt mixtures. Meanwhile, in 1982, France initiated studies for the implementation of a novel modified asphalt binder using asphalt rubber-aggregate blend, as (Sainton, 1990) reported. This asphalt binder showed remarkable rheological properties and proper resistance to aging. After conducting several roughness, drainage and uniformity tests, the PAM with modified asphalt binder showed better performance, in comparison with those using neat asphalt binder. Other countries such as Ireland, Belgium, Switzerland, Germany, Austria, United Kingdom, Australia, France, Denmark and the Netherlands have reported good experiences using PAM, according to NCHRP Report No. 640 (Cooley, 2009).

Afterwards, and regarding a successful experience from some states in U.S. and several European countries, the National Asphalt Technology Center (NCAT) developed a new-generation for the OGFC assessing stripping and raveling. Consequently, they noticed these distresses affected its durability (Mallick et al., 2000). Later, in 2004, ASTM adopted the size distribution particles grading of the new-generation of OGFC as the grading master range for OGFC in one of its standards (ASTM D 7064-08 2013), according to (Suresha et al., 2010).

OGFC gained popularity across the United States, but some diseases related to durability, binder drain down, aging, pore clogging, ice removal, raveling, delamination and stripping became the main concerns, according to the experiences of states in United States using PAM, summarized in a general survey, as (Putman, 2012) noted.

Nowadays, American transport agencies such as FHWA, several states Departments of Transportation (DOT) and European transport agencies persist in assessing different polymers, to modify the asphalt and in turn, enhance the design, production, construction and maintenance of porous asphalt mixes and increase its durability and resistance to raveling according to (Hassan et al., 2000).

Although, the asphalt binder modified with polymers plays a recognizable role in porous asphalt mixture performance and it is widely being used in many American transport agencies in states of U.S., this paper intended to obtain the mechanical characterization of porous asphalt mixes, whose neat asphalt binder is solely modified with fatty acid amides in order to assess the influence of them on the general behavior and performance of PAM. In addition, it is a good way to present the Latin-American experience, using additives to modify the asphalts.

Porous asphalt mixes

Framework

The asphalt mixes are basically a set of coarse aggregates blended with asphalt materials placed in almost horizontal layers. They are responsible for distributing all the vehicles traffic loads until facing the subgrade, throughout the base and subbase layers. They must be resistant and made of high-quality materials to withstand the severity of weather, traffic and erosion.

To conform the first layer, the road surface, a wide variety of asphalt mixes can be used. The porous asphalt mixes are one of them. Primarily, in order to build safer roads. When raining occurs, the road surface designed and placed with PAM, must be able to quickly evacuate the water that falls on it. Otherwise, a thin film of water will be formed and disposed on the road surface irregularities and thus, at high speeds of vehicles, is likely there will be a lack of contact between the tire and the road surface. This phenomenon is known as hydroplaning.

Porous asphalt mixes are different from porous pavement structures. Firstly, PAM, as it noted before, are road surfaces designed to improve vehicle-circulation while it is raining, avoid the problem of hydroplaning and dislodge the water out the road surface. They are placed on top of completely impermeable asphalt layers. By contrast, porous pavement structures could be defined as multilayer composite sections of coarse aggregates with different particles nominal size and thicknesses allowing the water infiltration in the deeper layers of the pavement. They can be used at parking lots, roads and other paving areas according to (Chen et al., 2013).

The failure of PAM is produced by a lack of cohesion to adequately resist vehicles traffic tangential stresses. It is necessary to provide a proper coarse aggregate interlocking and a stiffer asphalt binder. That is why in Spain, porous asphalt mixes are designed based on porosity and wear resistance criteria, as assessed by the Cantabro test.

Advantages, disadvantages and limitations

Porous asphalt mixes have special features that make their behavior be different from HMA or dense-graded friction courses. Some advantages and restrictions related to their production and performance, according to (Huber, 2000), (Kandhal, 2002) and (Alvarez et al., 2006) statements:

- PAM have a good macrotexture (i.e. road surface irregularities from 0,5 to 50 mm), because of their greater coarse aggregates exposition in road surface, which are able to maintain tire-pavement grip at high speeds.

- They offer a comfortable and quiet driving, reduction of spray and splash by effect of vehicles circulating at high speeds in presence of raining, and improvement of driver visibility on the wet surface.

- Avoid light reflection: By dislodging water out the road surface, they also eliminate the light reflection and significantly improve the driver visibility.

In addition, PAM has several handicaps that must be taken into account to achieve a better performance. Gradual clogging, raveling and stripping, have been historically reported as the main distresses causing durability problems to PAM, as (Alvarez et al., 2014) noted.

For instance, according to (Hamzah et al., 2012), the PAM highest air voids percentage, promotes oxidation and aging phenomena on asphalt. As a result, PAM has a shorter life than dense-graded friction courses (HMA). As reported by (Miró, 2006) it seems that improved driving-quality in presence of rain let the drivers increase the vehicles speed, so that this effect can be compensated.

Fatty acid amides -FAA-

Fatty acid amides are an asphalt viscosity-modifier of low molecular weight, which can increase the road surfaces life expectancy, especially at high temperatures. According to (Rubio et al., 2012), they have been used as asphalt viscosity-modifier in recent years due to crystallization of the wax in particular, obtaining a reduction range for PAM mixing-temperature from 20 °C to 30 °C. By improving the asphalt binder adherence and stiffness within the porous asphalt mixture, ensures a high resistance to permanent deformation by induced traffic and the weather, even when it is placed at low temperatures.

Typically, the amines melting point is between 141 °C and 146 °C. A minimum processing temperature required to achieve a homogeneous modification between FAA and the asphalt binder, brings cost savings to asphalt producers and environmental benefits by reducing energy consumption during mixture production.

Materials and methods

This research is intended to establish a comparison between two types of porous asphalt mixes. The first one, a porous asphalt mixture designed with a neat asphalt binder 6070 in 1/10 mm penetration, and the second one, a porous asphalt mixture designed with modified asphalt at 2 °% by asphalt mass of fatty acid amides. To clarify, the neat asphalt was modified with FAA prior to design the second mixture in the proportion already mentioned. Thus, the only difference between them will be the use of FAA.

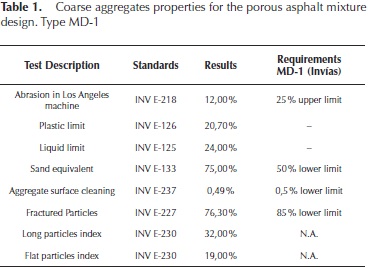

The coarse aggregates characterization used for the two porous asphalt mixes designed, were conducted according to Instituto Nacional de Vías (2013) standards. Table 1 presents the tests and their respective standard, also presents the results for both Porous asphalt mixes designs.

In table 1, the slight difference between the fractured particles percentage results and the target in the required standard, could be attributed to a lack of irregularities or fractures in tested particles mass, without this noticeably affecting the porous asphalt mixture performance. Since the higher the fractured particle percentage, the higher the coarse aggregate-asphalt binder adherence.

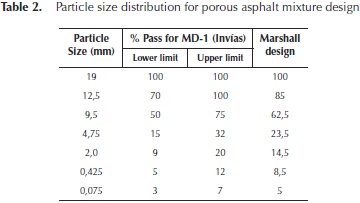

It has furthermore been determined the job formula from particle size distribution and the optimum asphalt content. Three asphalt content percentages for each single porous asphalt mixture designed: 4,5 %, 5,0 % and 5,5 %. Table 2 presents the particle size distribution type MD-1 (i.e. porous asphalt mix type 1), whose nominal maximum size is 19,0 mm:

For samples preparation, Marshall Method was employed. Both asphalt binder and coarse aggregates (in this case, asphalt binder includes neat asphalt binder as well as the modified asphalt binder with FAA) are heated in the range from 144 °C to 149 °C, to achieve the proper viscosity which satisfied an adequate coarse aggregates coating, without causing asphalt binder drain down. Once heated, they are mixed and put inside the molds in order to compact with 50 hammer blows by each face. The compaction temperature is in the range from 136 °C to 140 °C. The temperature was controlled during the whole process.

Results and discussion

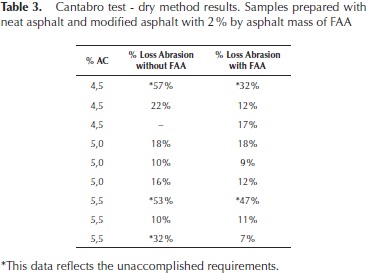

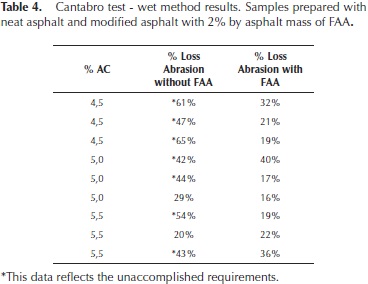

To assess the PAM mechanical characterization, some tests had to be carried out and evaluated with the following criteria: the losses abrasion in Los Angeles machine, without steel balls and after experiencing 300 revolutions, by dry wear shall not be greater than 25 % and by wet wear, after to process water immersion for twenty-four hours at 60 °C, shall not exceed of 40 %.

Cantabro test directly assesses cohesion or interlocking, as well as resistance to the disintegration of these mixes. So, it is possible to indirectly evaluate the ability of the modified asphalt with fatty acid amides to increase the resistance to the disintegration of the porous asphalt mixes or, in other words, to maintain the cohesion of the mixes, in presence of water. Tables 3 and 4 present respectively the results of Cantabro test for both dry and wet methods, for two groups of porous asphalt mixes already described in this section.

The results displayed above clearly show that, porous asphalt mixture including an asphalt modified with 2 % by asphalt mass of FAA, had a better performance to the wear action after experiencing 300 revolutions in Los Angeles machine under wet method. Undoubtedly, this kind of modification significantly contributed to provide a more cohesive mixture and, in turn a stronger internal structure.

Some scattered results in tables 3 and 4 somehow obey to samples manipulation during the whole process, starting at mixture extraction out the mold, then in Los Angeles machine and recording the test specimen initial and final weights. Also, the results are influenced by the compaction temperature. The lower the compaction temperature, the higher the asphalt binder viscosity will be. It directly affects the coarse aggregates coating and in turn, the mixture cohesion.

The job formulas for both porous asphalt mixes designed were set by checking all the requirements provided by Invías standards related to: air voids content, permeability rate, water damage and loss abrasion in Los Angeles machine dry and wet methods. These tests were conducted in order to check the requirements, but the results are not reported in this paper. In consequence, two optimum asphalt contents were obtained: 5,0 % for a porous asphalt mixture using neat asphalt binder, and 4,7 % for a porous asphalt mixture, using modified asphalt with 2 % by asphalt mass of fatty acid amides -FAA-.

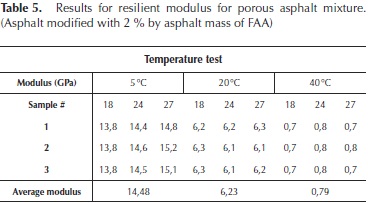

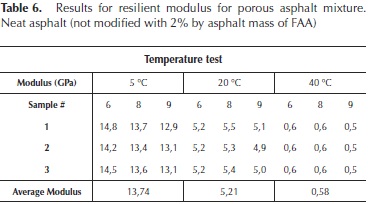

Afterwards, each one of the porous asphalt mixes designed with job formulas as noted before, were assessed by their mechanical characterization. The resilient modulus test was conducted at Corasfaltos laboratory in Piedecuesta, Santander (Colombia). Tables 5 and 6, present the resilient modulus results carried out under the following conditions: three different temperatures (i.e. 5 °C, 20 °C y 40 °C) and a frequency of 10 Hz (i.e. about a service speed of 60 km/h).

Porous asphalt mixture using fatty acid amides in 2 % by asphalt mass, showed a higher resilient modulus value than unmodified porous asphalt mixture, an important design criterion. A resilient modulus approximately equal to 7 GPa could be easily compared with the structural ability of the conventional HMA. Despite of, some authors define to these porous asphalt mixes as thin layers without structural capability, the resilient modulus found is a clear evidence that this sentence could be refused.

Regarding aforementioned, a recent research (Moriyoshi et al., 2014) showed a comparison between HMA and PMA performances after seven years placed, assessing properties such as rutting using the TRRL wheel tracking test and a contact pressure equal to 0,54 MPa. They found that rut depth for PAM was less than HMA, it is, 1 mm and 6 mm, respectively. Consequently, a rut depth greater not only affects the vehicle user's comfort, but as well change the concept of PAM low structural capability in something not completely true.

Conclusions

Laboratory tests were conducted to assess two types porous asphalt mixes. The first one, with a neat asphalt bonder and the second one with modified asphalt at 2 % by asphalt mass of fatty acid amides. Cantabro test was performed on samples under dry and wet conditions, revealing that fatty acid amides contributed to the porous asphalt mixture designed with greater cohesion, which is its major distress, due to their permanent contact with water, and this is consistent with the low mass loss obtained.

By comparison, the porous asphalt mixture designed with neat asphalt 60-70 in 1/10 mm penetration, did not accomplish with the minimum loss requirements for none of the three percentages tested (4,5 %, 5,0 % and 5,5 %). Meanwhile, the porous asphalt mixture designed at 2 % by asphalt mass of fatty acid amides, reflected satisfactory results in Cantabro test under dry and wet methods and also showed better results for mass loss percentage under wet conditions: which is the most critical situation.

One important consideration made in this research was the fact of no including cellulose fibers into the design of a porous asphalt mixture. Many American transport agencies have highlighted the use of fibers in order to improve the mixture cohesion. Nonetheless, this project intended to solely assess a neat asphalt binder 60-70 in 1/10 mm. penetration, modified with fatty acid amides -FAA-, and how influenced the PAM mechanical behavior.

In this way, it is possible confirm that FAA is a good modifier for porous asphalt mixes, since it gave them greater cohesion.

References

Kandhal, P.S., Mallick, R.B. (1998). Report 98-07 Open-Graded Friction Course: State of the Practice. Transportation Research Circular E-C005. Washington, D.C. [ Links ]

Alvarez, A.E., Martin A.E., Estakhri C.K., Button J.W., Glover C.J., Jung, S.H. (2006). Technical Report: Synthesis of Current Practice on the Design, Construction, and Maintenance of Porous Friction Courses. Texas Transportation Institute Report No. FHWA/TxDOT Report 0-5262-1. [ Links ]

Alvarez-Lugo, A.E., Reyes-Ortiz, O.J., Miró, R. (2014). A Review of the Characterization and Evaluation of Permeable Friction Course Mixtures. Revista chilena de Ingenieria, 22(4), 469-482. [ Links ]

ASTM D 7064-08. (2013). Standard Practice for Open-Graded Friction Course (OGFC) Mix Design. Annual Book of American Society for Testing materials ASTM Standards (Rea-pproved 2013), 1-7. [ Links ]

Chen, J.S., Chen, S.F., Liao, M.C. (2015). Laboratory and Field Evaluation of Porous Asphalt Concrete. Asian Transport Studies, 3(3), 298-311. [ Links ]

Cooley L.A., Brumfield, J.W., Mallick, R.B., Mogawer, W.S., Partl, M., Pulikakos, L., Gary, H. (2009). NCHRP Report 640: Construction and Maintenance Practices for Permeable Friction Courses. Transportation Research Board, (22). [ Links ]

Hamzah, M.O., Hasan, M.R., Van De Ven, M., Yahaya, A.S. (2012). The Effects of Initial Conditioning and Ambient Temperatures on Abrasion Loss and Temperature change of Porous Asphalt. Construction and Building Materials, (29), 108-113. [ Links ]

Hassan, H., Al-Oraimi, S., Taha, R. (2005). Evaluation of Open-Graded Friction Course Mixtures Containing Cellulose Fibers and Styrene Butadiene Rubber Polymer. Journal of Materials in Civil Engineering, 17(4), 416-422. [ Links ]

Huber, G. (2000). NCHRP Synthesis 284: Performance Survey on Open-Graded Friction Course Mixes. Transportation Research Board Washington, D.C.: Federal Highway Administration. [ Links ]

Instituto Nacional de Vías. (2013). Instituto Nacional de Vías Especificaciones Generales de Construcción de Carreteras y normas de ensayo para materiales de carreteras. Artículo 453: Mezcla drenante. Bogotá, D.C. [ Links ]

Kandhal, P.S., Mallick, R.B. (1998). Report 98-07 Open-Graded Asphalt Friction Course: State of the Practice. National Center for Asphalt Technology. [ Links ]

Kandhal, P.S. (2002). Design, Construction and Maintenance of Open-Graded Aphalt Friction Courses. National Aphalt Pavement Association Information Series 115. [ Links ]

King J., Bill, W., Kabir, M.S., Cooper, S.B., Abadie, C. (2013). Report FHWA/LA.13/513 Evaluation of Open-Graded Friction Course (OGFC). Transportation Research Center (LTRC). [ Links ]

Mallick, R.B., Kandhal, P.S., Cooley, A.J., Watson, D.E. (2000). Report 00-01 Design, Construction, and Performance of New-Generation Open-Graded Friction Courses. National Center for Asphalt Technology. [ Links ]

Miró, R. (2006). Nuevas mezclas para capas de rodadura y su influencia en el confort (ruido) y la Seguridad. Centro Politécnico Superior - Universidad Politécnica de Cataluña. [ Links ]

Moriyoshi, A., Jin, T., Nakai, T., Ishikawa, H., Tokumitsu, K., Kasahara, A. (2014). Construction and Pavement properties after seven years in Porous Asphalt with long life. Construction and Building Materials, 50, 401-413. [ Links ]

Putman, B.J. (2012). Report No. FHWA-SC-12-04 Evaluation of Open -Graded Friction Courses: Construction, Maintenance, and Performance. South Carolina Department of Transportation in Cooperation with FHWA. [ Links ]

Rubio, M.C., Martínez, G., Baena, L., Moreno, F. (2012). Warm Mix Asphalt: An Overview. Journal of Cleaner Production, (24), 76-84. [ Links ]

Ruiz, A., Alberola, R., Perez, F., Sánchez, B. (1990). Porous Asphalt Mixtures in Spain. Transportation Research Board Record, (1265), 87-64. [ Links ]

Sainton, A. (1990). Advantages of asphalt rubber binder for porous asphalt concrete. Transportation Research Board Record, (1265), 69-81. [ Links ]

Suresha, S.N., Varghese, G., Ravi, U. (2010). Effect of aggregate gradations on properties of Porous Friction Course Mixes. Materials and Structures, 43(6), 789-801. [ Links ]

Suresha, S.N., Varghese, G., Ravi, U. (2010). Laboratory and theoretical evaluation of clogging behaviour of Porous Friction Course Mixes. International Journal of Pavement Engineering, 11(1), 61-70. [ Links ]