Introduction

Motivation and objective

In Colombia, according to the National Institute of Roads (INVIAS, 2016) more than 43% and 90% of the roads with and without pavement accordingly, are regular and in poorly condition. Additionally, the tendency of the vehicles in circulation in the last 40 years has been increasing both in magnitude and loads. The annual mobilization growth rate of products from the agriculture sector, manufacture, mining and cattle growth is 5.47%, 14.82%, 19.11% and 4.88%, respectively (MINTRANSPORTE, 2008). This data generates the necessity of road construction with resistance and durable materials for the transit loads and weather effects. The technology of the modified asphalts has been a studied technique and has been utilized in the world as an attempt to modify the physical and chemical properties of asphalt mixtures when they are tested to different loads and environmental conditions. There are different types of additives to modified asphalts in the world (rubber, resins, polymers, nano-particles and others) (Fang et al., 2016; Ashish & Singh, 2018; Cai et al., 2018; Xiao et al., 2018). Specially, it is necessary to know the physical, rheological, and thermal of bitumen properties, because these properties affect the asphalt mixture performance and help to understand the elastic and viscous response of these materials when they are submitted to cyclic shear stresses (Peiliang et al., 2010; Said et al., 2013; Castro et al., 2016; Ashish and Singh, 2018). Bitumen used in this study was neat asphalt cement (AC) 60/70 and it was modified with four non-conventional additives. This AC was chosen because it is the most AC used in Colombia for the fabrication of asphalt mixtures for pavement construction. The four additives used were: two polymers, one natural asphalt and one chemical product. The first one was a granular crumb rubber (GCR), a waste product from scrap tires, the second one was a low density polyethylene (LDPE) from used coffee mixer sticks; the third one was a natural asphalt called Gilsonite (G) and the fourth one was a chemical additive known as Husil. These additives were chosen due to the some mechanical benefits when they were applied in the fabrication of asphalt mixtures, however, about their physical, rheological and thermal characteristics studies are still missing to understand the holistic behavior.

Background

When GCR is used as an asphalt modifier, asphalt mixtures with this modified asphalts had shown: i) more resistant mixes to the fatigue cracking and rutting phenomena (Lougheed et al., 1996; Xiao et al., 2007; Kumar et al. 2010; Hsu et al., 2011; Punith et al., 2011; Kaloush, 2014; Wang et al., 2017; Bakhshi & Arabani, 2018); ii) increases the resistance to the aging and oxidation (Punith et al., 2011; Huang, 2008); iii) increases resistance to low temperature cracks (Huang et al., 2007); iv) less susceptible to the temperature changes (Dong & Tan, 2011); v) increases the resistance due to moisture damage (Dong & Tan, 2011; Punith et al., 2011); vi) better resistance over asphalt porous mixtures (Partl et al., 2010; Punith et al., 2011; 17); vii) decreases the tire/pavement noise (McQuillen et al., 1997; Anderson et al., 2008); viii) generates mixes with less maintenance needs (Lee et al., 2008); ix) helps to diminish the negative environmental impact product of the used tires (Huang et al., 2007); x) good behavior to manufacture recycled mixes (Xiao et al., 2007; Saberi et al., 2017) and warm (Oliveira et al., 2013; Saberi et al., 2017). LDPE is a plastomer (thermopasltic polymer), that contributes with stiffness of the AC (Othman, 2010) producing a better resistance to the permanent deformation (Zoorob & Suparma, 2000; Huang et al., 2007; Al-Hadidy and Tan, 2009; Rondón et al., 2010; Punith & Veeraragavan, 2011; Bagampadde et al., 2013; Castro et al., 2016). However, one disadvantage is production temperatures increases (Fang et al., 2015), due that the viscosity increases. Also, in terms of fatigue resistance authors had reported reductions between 12 to 32% (Fang et al., 2015). The Gilsonite (G) is a type of natural asphalt known in the world because its higher point of softness, low viscosity and stiffness due to its asphaltenes contents (Widyatmoko et al., 2005; Cholewiñska & Iwañski, 2011; Esfeh et al., 2011; Ameri et al., 2011, 2012; Rondón et al., 2016). The former generates a notable increase in the asphalt stiffness when it is used as an additive, leading more resistant mixes in high temperatures sites (Feng et al., 2011, 2011a; Jahanian et al., 2017; Yilmaz & Yamaç, 2017). In addition, some studies had reported an increase of fatigue resistance (Yilmaz et al., 2013), to moisture damage and decrease in asphalt content (Kõk et al., 2012; Babagoli et al., 2015). The less reported additive is the Husil (patent pendent). It is an inorganic chemical additive that acts as a synthetic zeolite. When entering in contact with the asphalt cement in an approximate temperature of 70°C the Husil material makes the asphalt turns into foam, decreasing its viscosity and making easier the work processes and mix compatibility (Rondón et al., 2016a). According to Rondón et al. (2016a, 2017), the Husil allows to reduce the temperature of the mix in approximately 30°C, achieving the increase of the resistance under the monotonic and dynamic loads.

This article shows the evaluation of physical, mechanical and thermal properties of the neat and modified AC 60/70 with additives mentioned. Physical characterization includes penetration, softening point, ignition point, flame point, viscosity and ductility. Rheology test were performed in order to obtain performance grade (PG) at high and intermediate temperatures, Multi Stress Creep and Recovery (MSCR) and Linear Amplitude Sweep (LAS) characterization. In addition, thermal properties were obtained through differential scanning calorimetry (DSC) and thermo-gravimetric analysis (TGA).

Materials and Methods

Material characterization

For the four non-conventional additives the following characteristics were considered (Figure 1): a) the GCR from scrap rubber tires, was mechanically grinding to obtain particles less than 6.3mm; b) the low density polyethylene (LDPE) was obtained of waste coffee straws, that were cut in order to pass the sieve No. 4 and were retained in the No. 10; c) the Gilsonite was obtained from a mine localized in the Cesar State (Colombia); d) the Husil was obtained in liquid base.

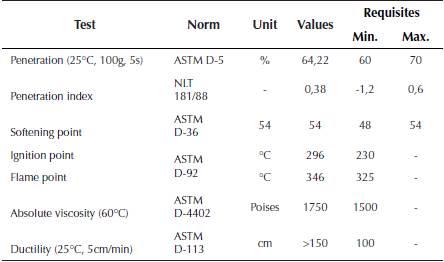

In Table 1, the properties of the AC 60/70 used are presented. It can be observed that the asphalt utilized fulfill the minimum requisites of quality required by INVIAS (2013).

Additive dosage

The additives were added to the asphalt according to literature review. For the GCR, the recommended percentages of inclusion are between 10-20% from the asphalt weight. In the present study, a relation of GCR/CA = 14% was chosen because this was the most utilized percentage in previous Colombian studies (IDU, 2002, 2005). In the case of the LDPE and the Gilsonite, the inclusion percentage were of 5% and 10%, respectively (LDPE/CA = 5% and G/CA = 10%), because in these percentages were reported the best behaviors in asphalt mixtures (Rondón et al., 2010; Rondón et al., 2016; Rondón & Reyes, 2012). Husil were incorporated at 1% according to Rondón et al. (2014, 2016a, 2017). Additive mix temperature with asphalt was 155±5°C because higher temperatures produce loss of lighter chemical components and bitumen and below of this temperature the mixing was difficult. Nevertheless, in the Husil case, it was incorporated at 70°C because at this temperature asphalt starts foaming. The mixing times were 40, 70, 20 and 5 minutes for the LDPE, GCR, G and Husil, respectively, following the recommendations made by studied references.15 samples were manufactured in total (3 samples per CA 60/70 modified and 3 samples for the CA with no modification) for the physical characterization tests, 40 samples (8 samples per each CA 60/70 modified and 3 samples for the CA with no modification) for the rheology test and 10 samples (2 samples per each CA 60/70 modified and 3 samples for the CA with no modification) for the calorimeter and thermal analysis.

Experimental Phase

To achieve the objectives in the present study, they were three types of test to the asphalts: physical characterization, rheology and thermal. The physical characterization test were penetration, ductility, softening point, ignition and flame point, absolute viscosity at 60°C, short term aging in thin film oven - RTFOT and long term aging in the pressure aging vessel - PAV. They were performed following ASTM standards presented in Table 1. The rheological characterization test was performed using a dynamic shear rheometer (DSR AR2000 ex TA Instruments). The first step for the rheological characterization was finding the performance grade (PG) of the different CA (neat and modified) under high and intermediate temperatures, because Colombia is a tropical weather country. For non-aging tests and aged in RTFOT were used geometries of 25mm, and for aged samples in RTOFT+PAV were used geometries of 8mm, following AASHTO T 315-05. The obtained parameters were the complex moduli (G*) and the phase angles (δ). The second step was the execution of the Multi Stress Creep and Recovery test (MSCR) AASHTO D7450-10a with samples of 25 mm and previously aged by RTFO. The obtained parameters of the test were the result of permanent deformation when applied one unit of stress and the Jnr (non-recoverable creep compliance). The third step consisted in the tolerance estimation of the damage running the linear amplitude sweep (LAS) test, following AASHTO-TP-101. For the execution of this test, samples of 8mm from the aged asphalts in RTFOT+PAV were prepared. This test was performed to evaluate the capacity that has the asphalts to resist cracks when they are under cyclic share loads at crescent amplitudes. The test procedure consists of two stages, the first one a) Frequency sweep: used to solve the rheological properties, through the one stress application over a range of frequency and b) amplitude sweep: used to solve the traffic amount expected, through the incremental application of a linear load under a frequency. The test was running at the intermediate temperature obtained in performance grade (PG) classification. Finally, the thermal characterization was carrying out through TGA and DSC following ASTM C 351 and ASTM E914 respectively. On one hand, thermogravimetric (TGA) test is based on measuring the percentage weight variation respected to temperature variation as a function of time. Through this, it can be seen material oxidation processes, vaporization reactions and decomposition due to the progressive increase of temperature. On the other hand, the differential scanning calorimetry (DSC) is a technique that allows to show the glassy transitions that can be reach due to the work change of the material from a fragile phase to ductile one, and can be of greater importance to see transitions (as crystallization processes and fusion points, considered as the low area under the curve of the more stand put peaks graphically represented) and to resolve the work temperature of the additives to implement.

Analysis and Results

Physical Characterization

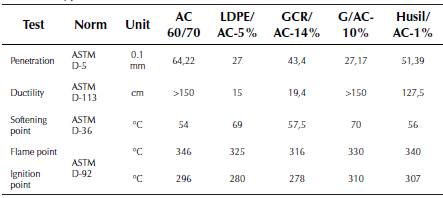

Table 2 shows the results of the characterization tests performed to the asphalts. Based on these results, it supports that the additives increase the stiffness of the asphalt (decreasing the penetration and increasing the softening point). In addition, a decrease in the ductility parameter was observed, because the additives change the molecular structure of the neat asphalt, changing its uniformity, resulting in a micro-structural distance allowing the material to break easily when this is stretched or tensed in the test. However, this decrease does not imply that the modified asphalts be less ductile than the original when they are put down thru processes of mechanical loads. As an additional result, the Gilsonite and the Husil are additives that increase ignition temperature.

Rheological Characterization

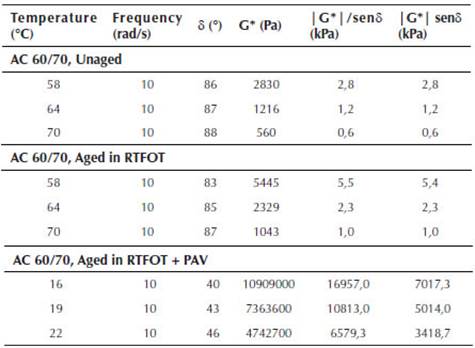

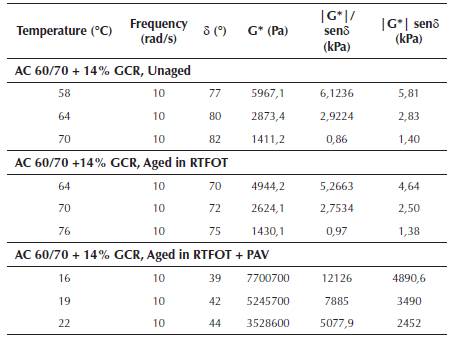

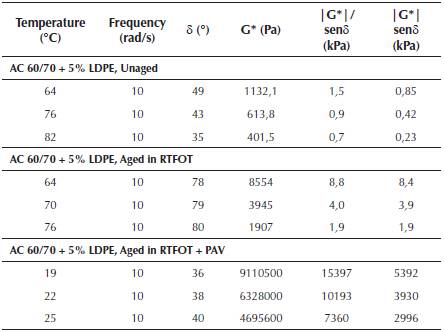

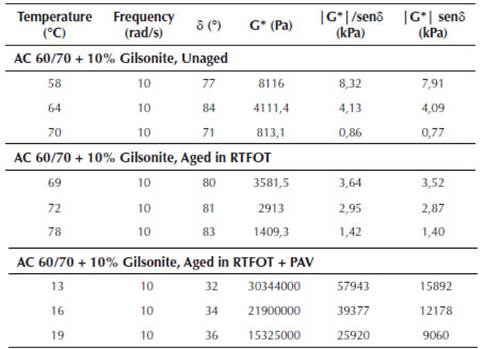

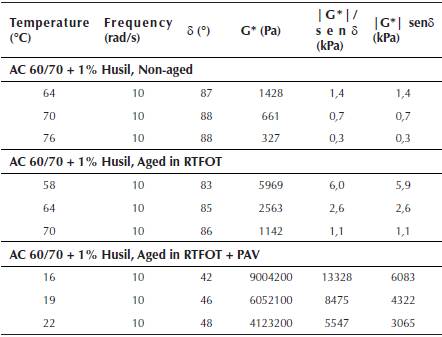

The performance grade PG at higher temperatures of the asphalts was obtained as a result of: i) for non-aging asphalt, kPa, ii) for aging asphalt in RTFOT, kPa and iii) for aging asphalt in RTFOT+PAV, kPa. In Tables 3 to 7 the obtained parameters are presented from the rheology test using the DSR.

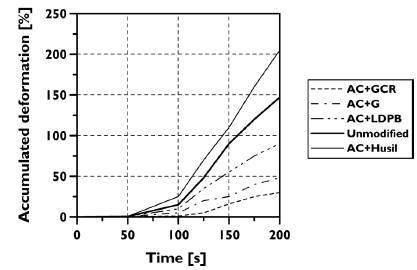

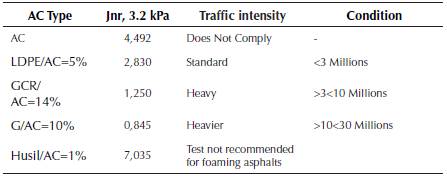

The first part of rheological analysis was the PG classification. In Table 3, it is observed a high temperature PG of 64°C and intermediate temperatures of 22°C, PG64 (22), typical of a conventional AC 60/70. For the GCR/AC = 14% (Table 4), LDPE/AC = 5% (Table 5), G/AC = 10% (Table 6) and Husil/AC = 1% (Table 7), the obtained PG in higher and intermediate service temperatures were of 70(16), 70(19), 76(19) y 64(16), respectively. It was reported in general terms a significant increase on resistance to permanent deformation at higher temperature climates when the asphalt is modified with GCR, LDPE and G. For the modified asphalt with Husil case, this property is did not present any changes. In addition, it was observed that additives enhance fatigue cracking resistance due to |G*| sind in all cases accomplished values to get intermediate temperatures less than 22°C. In the second part of the rheology analysis, MSCR tests were performed on samples previously aged by RTFOT and were ran at higher temperatures obtained by the PG. MSCR analyze the reliance of the asphalt behavior at two different stress levels (0,1 and 3,2 kPa), evaluating either the elastic memory or the accumulate deformations that can be reach to resist after 20 load and unload cycles (creep associate processes). So, as a result, the Jnr parameter that can be defined as the relation between the non-recovery deformation due to the applied stresses, and it means when this parameter decrease, the condition of expected traffic will be higher to support permanent deformations. Accumulated deformation and Jnr parameters were calculated following the guidelines of the AASHTO-D7405-10a. In Figure 2 it can be observe the accumulate deformation percentage against the time accumulation thru the MSCR technique. After 20 load cycles, the modified asphalt with GCR, LDPE and G develops higher resistance to deformation in comparison with the asphalt AC 60/70. For the AC+Husil case, this modified asphalt developed a higher accumulation of the deformation due to the higher test temperatures (close to 70°C), the additive tends to becoming foam, decreasing the viscosity and hence stiffness.

According to Table 8, the unmodified AC and AC+Husil did not achieve the parameters for a traffic intensity, because it exceeds the higher value of Jnr of 4. In the un-modified asphalt case, this response was achieved because is a material with less elastic memory and did not present a recovery from the deformation for several cycles of rapid load. For the AC+Husil case, this response could be reach due to the additive at high temperature tends foam the asphalt and undergone a rapidly decrease in viscosity and stiffness. For this reason, this test is not appropriate to characterize the resistance to the permanent deformation of this type of modified asphalt. On the contrary, the modified asphalts that present favorable conditions under this test were AC+G, AC+CGR and the AC+LDPE. This is due to they are thermoplastic polymers (recycled polymers can be subdued to high service temperatures without degrading their properties) of elastic types (in charge and discharge processes tends to recover their form) as the GCR, and plastic types (materials that make the asphalt stiff) as the LDPE and G.

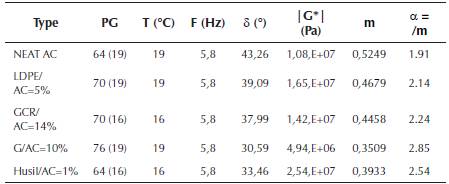

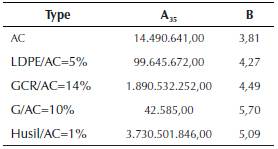

Table 9 shows the results of the LAS tests (a) Sweep frequency for the different AC (neat and modified), test run at intermediate temperature obtained from the performance grade PG (AASHTP-TP-101).

Table 9 shows that the AC 60/70 modifies with Husil has higher levels of stiffness and elasticity, due to the consistency with the specification of the test AASHTO-TP-101, the dynamic module |G*| represents the resistance that the AC have to deform by repeatedly shear stresses, and the phase angle d the elastic behavior (d = 0° totally elastic behavior and d = 90°purelly viscous). Following the guidelines of the test specification, it was determined the parameters A35 and B for the damage analysis. The parameter represents the material properties against the accumulated damage and B the material sensitiveness against any change of the applied loads (see Table 10).

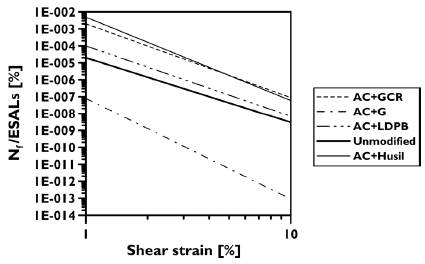

The A35 parameter can be considered as the life fatigue of the AC under a discharge of crackling of 1% and the parameter B as the resultant straight slope, which represents the change rate of the fatigue life material. According to this, the modified AC with Husil and GCR presents the higher resistance levels to repetitive loads of crackling. In Figure 3 it is shown the correspondent values of the normalized parameter for 1 million equivalent axes (ESALs) for different levels of deformation.

The log-log graphic of Figure 3, represent the fatigue life of the materials against the shear deformation at intermediate temperatures. It can be observed in the Figure, that the AC+Husil, AC+GCR and AC+LDPE presents a better behavior with this type of damage mechanism in comparison to control AC asphalt, whilst the AC+Gisonite, that is a more rigid material, can develop a fragile behavior at intermediate service temperatures.

Thermal characterization

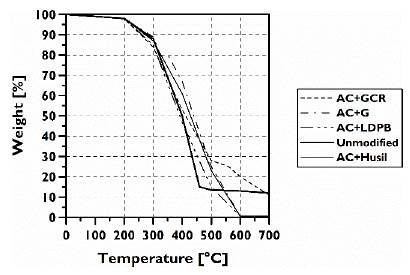

In Figure 4 can be observed the studied asphalt thermographic characterization. It was calculated the mass loss of the asphalts in temperatures between 25°C (average ambient temperatures) and 165°C (average temperature in the laboratory). It was reported the following results of mass loss: a) 1,5% for the non-modified AC, b) Insignificant before 200°C for the GCR/AC = 14%, c) insignificant before 180° for the LDPE/AC = 5%, d) insignificant before 50°C for the G/AC = 10% and e) 2% for the Husil/AC = 1% (this magnitude is due to that above 70°C the additive turns the asphalt into foam). However, it was obtained a mass loss between 165°C and 360°C (higher temperatures than the ones used in the laboratory and lower than the ignition point of each sample) of: a) 34% for the unmodified AC, b) 18% for the Husil/AC = 1%, c) 20% for the GCR/AC =14%, d) 19,203% for the LDPE/AC = 5%, and e) 19.5% for the G/AC = 10%.

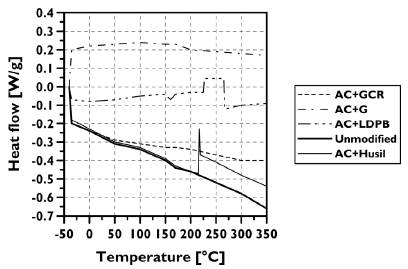

This shows that the modified AC with GCR, G and LDPE are more stable in temperature ranges of 25-165°C in comparison to the unmodified AC. That means that these additives can contribute less susceptibility to the AC in oxidation processes by environmental exposition and less aging in the long term. However, the Husil process is different. This undergone higher mass loss before reaching the general mixing temperature, and is due to that in above temperatures of 70°C the additive turns the asphalt into foam according to the reported results in the thermogravimetric analysis. However, the modified AC with this additive after reaching mixing temperatures in the laboratory (higher than 135°C), develops less mass loss. The second analysis implemented, was the differential scanning calorimetry (DSC). The glassy transition (behavioral step from ductile to fragile or vice versa) of the materials can be achieved when in the obtained graphic from the test, shows changes of slopes and peaks. In Figure 5, it can be observed: a) the non-modified CA shows a glassy transition (Tg) in 15,46°C. This temperature is associated to the decreasing continued slope change. b) The LDPE/AC = 5% present a Tg = 37,5°C, and a concave down peak and finally a crystallization temperature (Tc) of 262.5°C in exothermic conditions (heat flow <0). C) G/AC = 10% does not present Tg, Tc and Tm, however, presents an absorption heat process of 0.225 W/g followed by a heat liberation process until it reaches to a decomposition point of rubber grain of 250°C followed by an increase of heat absorption. d) Husil/AC = 1% presents a Tg = 25°C followed by a Tc = 212,5°C endothermic related to the linear peak and subsequent to this, a similar behavior of the unmodified AC.

For high services temperatures, the PG increases when the GCR, LDPE and Gilsonite are used. Additionally, with these additives, the results in the MSCR test was to increase the resistance to the permanent deformations, making believe that can be used in weathers were the asphalt mixtures needs to resist phenomena associated to rutting under cyclic loads. With the Husil, however, these rheology tests cannot produce enough information of the resistance to the permanent deformations, because at high temperatures, the asphalt turns into foam. The additive that generated the higher asphalt stiffness, and because of that, the higher resistant to the permanent deformation phenomena was the Gilsonite. However, based in the reported results in the LAS test this material can present a high fragility in intermediate and low temperatures (temperatures less than 19°C) and hence can produce cracks.

These results show a fragile behavior of the un-modified AC in lower temperatures of the glassy transition temperature (25.46°C) and a movement for the PEBD inclusion of 37.5°C, GCR of 31,25°C and Husil of 25°C. Meaning, that with the additives, there is a movement from the fragile to ductile behavior, to higher temperatures, making the modified AC presents a fragile behavior in lower temperatures of 37,5°C for the LDPE, GCR of 31,25°C and Husil of 25°C. On the other hand, the results of the inclusion for the Gilsonite showed a high-energy absorption process in comparison to the others. In addition, does not present Tg, Tc, Tm points, due to that is not a polymer capable of forming a crystalline structure generating a higher stability and hardness.

Conclusions

As conclusions of the study, it can be reported:

The additives increase the PG performance grade in intermediate service temperatures. The previously is an indicator of a more resistant asphalt to cracks by fatigue associated to premature aging and changes from ductile to fragile behavior in the asphalt.

Based on the characterization tests, the general tendency of the additives was to increase stiffness on the asphalt.

Based in the results of the LAS test, is reported that when the asphalt is modified with Husil, GCR and LDPE can increase the fatigue resistance of the asphalt, decreasing the possibility of generating micro-cracks in places of intermediate temperatures.

As it is shown in the TGA technique, the modified asphalts are more stable when they are submitted to increasing temperatures. When they reach temperatures close to the mix and compaction temperatures (higher than 135°C), the modified asphalts undergone a minor mass loss in comparison to the conventional asphalt, and this can be associated with less oxidation, loss of chemical components, and as a result, a higher aging resistance.

According to the reported results of the DSC, the implementation of any additive would make that the AC 60/70 can be more resistance to develop fragility under low temperature of service. In average, in the modified asphalts, it can be expected that this fragility can be achieved approximately at 31,25°C, while the conventional asphalt can be achieve at 15,46°C.

Based on characterization and rheological tests, the best behavior (permanent deformation and fatigue resistance) was obtained when control asphalt AC was modified with LDPE. This polymeric waste material increased the asphalt stiffness, the PG at high temperatures and enhanced fatigue cracking resistance (based in LAS test results and PG at intermediate temperatures). Besides, it showed a more stable behavior in comparison to the unmodified AC in TGA test and it showed a greater Tg in DSC test.