Introduction

The production of construction and demolition waste (CDW) in the city of Bogotá drastically increases every year, which is becoming a problem for the environment. Therefore, the good use of this material will greatly reduce pollution (Montoya-Villarreal et al., 2016). On the other hand, Bogotá is going through a construction expansion, widening and modernization of urban zones that bring an increase in waterproof areas, creating greater superficial runoff water to evacuate. If the city continues to grow under the traditional concept of evacuating its rainwater with the present system, sooner or later it will not be enough.

Pervious concrete is a special type of highly porous concrete because when it is mixed with little or no fine material at all it allows high volumes of water to pass through into the soil by means of natural filtration (ACI Committee 522, 2010). Therefore, it would address a solution to the production of construction and demolition waste, and it would help to evacuate rainwater. Moreover, by being done with recycled material, it would make it an environmentally friendly product.

In Colombia, Cruz Veloza and Gómez Rodríguez (2013) re-searched the influence of the recycled aggregate of masonry on the behavior of the concrete and found out that the use of this type of aggregates is not a limitation to make concrete. However, it can be used in concrete with high strength ranges and aggressive environments with greater volume of cement, additives or more additions. Beltrán Tobón and Borrego Sánchez (2014) evaluated the influence of RA enhancement with poor cement slurries, concluding that some treatments with cement in this type of aggregates help to the concrete having greater compression strengths.

On the other hand, the pervious concrete investigations in the country have not been very detailed, since the use of this material has only recently been used in Colombia. Moujir and Castañeda (2014) focused on the use of this type of concrete for use in pavements, determining that this concrete contributes to the reduction of surface runoff. In addition, these authors verified that porosity and strength are inversely proportional because a greater void content affects strength.

Some investigations around the world show important advances in pervious concrete development. Chindaprasirt, Hatanaka, Chareerat, Mishima, & Yuasa (2008) cement paste characteristics and porous concrete properties are studied. The results indicate that cement paste characteristics are dependent on the water to cement ratio (W/C) studied the cement paste characteristics and porous concrete properties. First of all, they studied the influence of water to cement ratio (W/C), the incorporation of superplasticizer (SP) and sufficient mixing over the cement paste viscosity. They found that using 0,20-0,25 W/C and 1% of SP the paste obtained has an ideal high viscosity to produce pervious concrete. Furthermore, the authors concluded that a vibration energy of 90 kN-m/m2 is effective in order to produce pervious concrete with 15-25% of void content and strength of 22-39 MPa.

Güneyisi et al. (2016) used coarse aggregate of crushed concrete and natural fine aggregate. In this research, concrete mixes ranging from 0-100% of RA. Concrete with 100% RA had14MPa of compressive strength, and 1MPa of flexural strength. In addition, they report a permeability of 12,5 mm/s. Aamer Rafique Bhutta et al. (2013) developed pervious concrete with the use of crushed concrete as coarse aggregate, obtaining a compressive strength of 10 MPa, a flexural strength of 1,8 MPa and a permeability of 35 mm/s. Finally, Barnhouse and Srubar (2016) made several specimens in which they added to some of them titanium oxide (TiO2) that helped reduce the amount of water and improved the compressive strength with results of 3,4 MPa but obtaining a macro porous concrete with a permeability of 68 mm/s.

Recently, similar to the study carried out in this paper, Zaetang, Sata, Wongsa, & Chindaprasirt (2016) incorporated recycled concrete block aggregate and recycled concrete aggregate in pervious concrete by replacing natural aggregate at the levels of 0%, 20%, 40%, 60%, 80%, and 100%. Compressive strength, density, total void, water permeability, thermal conductivity and surface abrasion resistance of pervious concrete containing the aggregates were studied. They found that recycled concrete aggregate and recycled block aggregate replacement level of 60 % and 40%, respectively, were optimum with a compressive strength of 15,0 and 17,0 MPa compared to 13,4 MPa of pervious concrete containing NA. According to the authors, the improvements were due to the good bonding between the two different types of recycled aggregates and cement paste, and the increased paste content as a result of abrasion and crushing of aggregates particles during mixing.

In this context, this paper presents results of a pervious concrete using coarse aggregate commercially purchased as brick ceramic aggregate (RA1) and crushed concrete aggregate (RA2) from the city of Bogotá. These concrete mixes have been tested for density, void content, compressive and flexural strength and permeability.

Materials and methods

The methodology of this research began with the characterization of the natural aggregate (NA) and RA; then, the mixing process was defined along with the manufacturing process. Once these processes were defined, the mix design was chosen. Three types of concrete mixes with different W/C ratios were done: 0,28, 0,30, and 0,34 in order to select the best W/C ratio. Finally, pervious concrete was mixed with different levels of substitution of RA: 100% RA1 and 0% RA2, 75% RA1 - 25% RA2, 50% RA1 - 50% RA2, 25% RA1 - 75% RA2 and 0% RA1 - 100% RA2; and a control with 100% of natural aggregate NA.

Materials

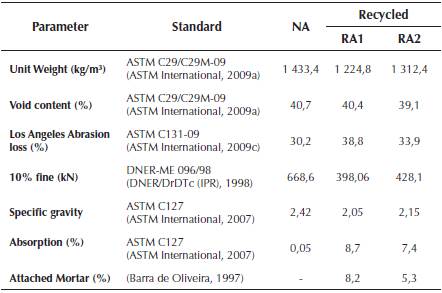

To develop the pervious concrete mixes, Portland cement, with high early strength (HE by ASTM C1157) and with a specific gravity of 2,99, was used. For the validation of the W/C ratio, only the sizes maximum on the 1/2 "and 3/8" sieves were used. The properties of the aggregate are summarized in Table 1.

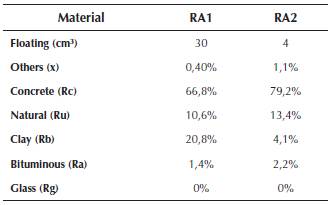

For RA1 and RA2, demolition materials were acquired in a debris deposit in the city of Bogotá. The material was classified with the test UNE-EN-933-1 (AENOR, 2009) and the results are in Table 2, which shows that RA1 contains 66.8% of concrete and 20.8% of clay, while RA2 contains 79.2% of concrete and 4.2% of clay.

In addition, a high-range water-reducing hyperplasticizer additive was used, based on polycarboxilic ethers modified in a 0,3% of the weight of the cement.

Mixing process of concrete

Prior to mixing, the aggregates were oven dried a day earlier, for 24 hours, in order to mitigate the effects of the moisture retained by the materials. The mixing process was carried out as follows:

Mix during 1 minute the whole aggregate with the water corresponding to its absorption, and leave at rest (1 minute more). (It is foreseeable that 100% absorption of aggregates is not covered, however this is done thinking of an industrial process).

Then add 5% of the weight of the cement (1 minute) and let it rest.

Remaining cement with water and additive (3 minutes)

Leave the mixture to stand (1 minute).

Mix again (2 minutes).

A compaction process was defined in the elaboration of the cylinders and beams to have a smaller variability in the results. The process is the following:

Fill the mold halfway and leave it on the vibration table (5 seconds).

With the Marshall hammer, compact it with 5 strokes

The same procedure is performed for the next layer

Weigh the mold again to verify that the amount of concrete being used is the same in all specimens.

The estimation of vibration energy used is 27 kN-m/m2.

The mix process reported in "Report of Pervious Concrete" 522R-10 (ACI Committee 522, 2010) was used.

Definition of the W/C ratio

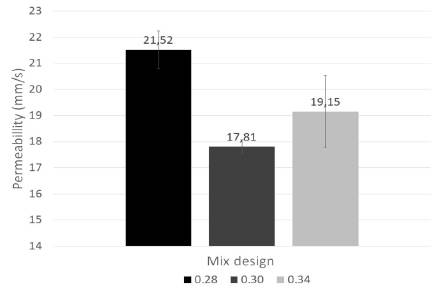

Three W/C ratios were used: 0,28, 0,30 and 0,34. It was determined that 0,28 was the best, because the concrete paste is distributed in the sample in a more homogeneous way (Figures 1 and 2).

Mix proportions

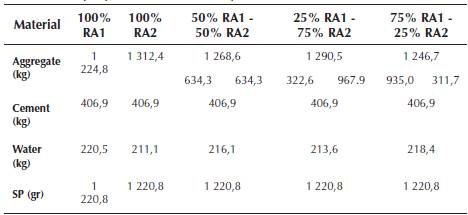

Pervious concrete was mixed with entry parameters of 10% of void content and 0,28 of W/C ratio with two types of recycle aggregate, RA1 AND RA2, in different proportions (Table 3). One control with 100% NA was used.

Testing methods

Compressive and flexural strength were evaluated according to ASTM C39 (ASTM International, 2009b) and ASTM C78 (ASTM International, 2002), respectively.

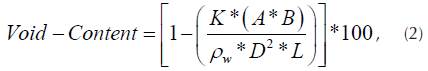

ASTM C1754 (ASTM International, 2012) was followed to calculate the density and the void content of pervious concrete.

here K is equal to 1 273 240 (mm3kg/m3) in SI units, A is the dry mass (g), D is the average diameter (mm) and L is the average length of the specimen (mm).

where B is the submerged mass of the specimen(g) and is the density of water at temperature of the water bath (kg/rm3).

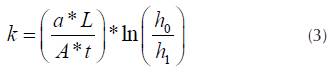

The permeability was evaluated with a permeability device (see Figures 3 and 4). The goal of this device is to measure the flow of certain volume of water through a test specimen of pervious concrete, within a certain time limit. The formula is based on a law proposed by Darcy, as follows:

Where k, a, L, A, t, h 0 , h 1 are the coefficient of permeability (mm/s), the cross-sectional area of the pipe (mm2), the length of the specimen (mm), the cross-sectional area of the specimen (mm2), the time taken for the head to fall from h0 to h1 (s), initial water head (mm) and final water head (mm), respectively. This device consists in different elements as shown in Figure 4

Results and discussion

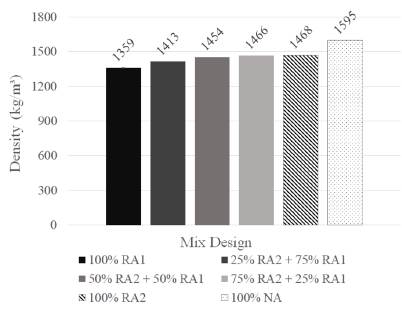

Density

The density of hardened pervious concrete versus recycled aggregate in different percentages is shown in Figure 5. The range of results varies between 1 360 and 1 469 kg/m3 and the control sample with NA has an average of 1595 kg/m3. The tendency of the observed density shows a proportional increase to the increase of RA2. This is because RA1 has less specific gravity than the RA2. Likewise, this behavior is seen in the density of the control simple. Besides, the NA has more round particles, therefore, the compaction is favored, which contributes to obtaining greater densities.

It was noted that pervious concrete with RA, against NA, decreased by 15% with RA1, and by 8% with RA2. While in the void content there was an increase of 8% with RA1, and of 3% with RA2 against NA.

Cosic et al. (2015) reported densities of pervious concrete with natural aggregate that vary between 2 075 and 2 443 kg/m3. This concrete shows greater density because a natural coarse aggregate was used, as well as fine aggregate such as: sand, dolomite and steel slag in different proportions. Güneyisi et al (2016) found densities of pervious concrete with RA that vary between 1 781 and 1 976 kg/m3. This is because the recycled material has greater specific gravities than the ones used in this study. Sriravindrarajah, Wang and Ervin (2012) found similar results because they used recycled aggregates with the same size as the ones used in this study.

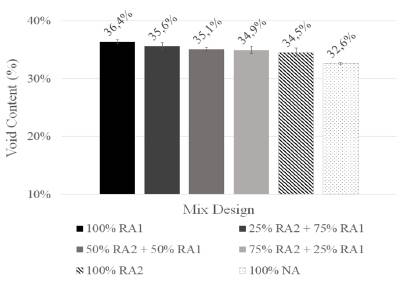

Void content

Figure 6 shown void content of pervious concrete versus the recycled aggregate in different percentages. The results of the void content do not change considerably among the different recycled aggregate mixes because the void content is an entry parameter for all mixes in mix design (ACI Committee 522, 2010). However, it is shown that the control mix has less void content due to the round nature of its particles, thus favoring compaction.

The void content of the mixes is greater than the one reported in the literature because of the low densities obtained due to the absence of fine aggregates, the use of only two sizes of aggregates, and mainly the low energy of vibration that was used. Chindaprasirt et al. (2008) concluded that vibration energy of 90 kN-m/m2 is effective in order to produce pervious concrete with 15-25% of void con-tent. With W/C ratios similar to those used in this study, Solminihac et al. (2007) obtained total voids of pervious concrete with natural aggregate between 24% and 29%, because they used a different mix design, and aggregates used were of different sizes, giving a better graded mix favoring the filling of the voids. Whereas Wang et al. (2006) have results between 25-34%, obtaining similar values to those shown in Figure 6, because their mix design parameters are comparable.

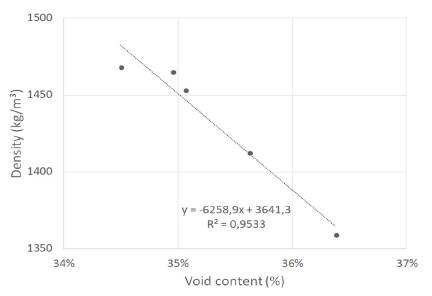

As expected, void content and density of pervious concrete are directly linearly related (see Figure 7), with very good degree of fit (R2 = 0,95). However, Güneyisi et al. (2016) obtained a lineal relation R2 = 0,79. This shows that mixtures in this paper have a more homogeneous distribution of cement paste.

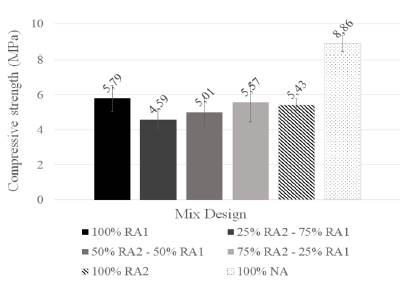

Compressive strength

Figure 8 shows compressive strength of pervious concrete in relation to each substitution level. The compressive resistance values of pervious concrete with recycled aggregate were affected by 40% against the concrete with NA. However, in the substitution mix of 100% RA, there was less compressive strength by 35%, since the RA1 improved its strength by absorbing cement paste during the mixing process.

This strength is directly related to the amount of cement paste in the mixture. A greater amount of cement paste implies reduction in permeability and an increase in compressive strength. The compressive strength of pervious concrete is affected by the use of RA in comparison to NA. This is due to the fact that the properties of the NA are better against RA (Table 1). According to Güneyisi et al. (2016), this strength can also be affected by the poor adherence in the interfacial transition zone (ITZ), a weathered zone between the concrete paste on the original aggregate and the new concrete paste.

As expected, the pervious concrete with NA has greater compressive strength than the mixes with RA. As seen in Figure 8, there is not a clear influence with the different types of RA. Compressive strength of 100% RA1 was greater than RA2. However, RA2 showed greater strength that RA1 (Test 10% fine). That is because the aggregates were dried in an oven, and since RA1 has greater absorption, it absorbs the cement paste, improving its strength by 8,25%.

Lasso-Aguirre and Misle-Rodríguez (2012) found a compressive strength at 28 days of 4,85 MPa with a recycled aggregate in Bogotá, very similar to the ones reported in this research. On the other hand, Aamer Rafique Bhutta (2013) and Sriravindrarajah et al. (2012) show a strength of pervious concrete with crushed concrete recycle aggregate of 6 MPa and 4,48-6,96 MPa, respectively. Both results agree with this research. Finally, according to ACI (ACI Committee 522, 2010), compressive strength can vary between 3,5 and 28 MPa depending on the use. So, results presents here are within the normal specifications.

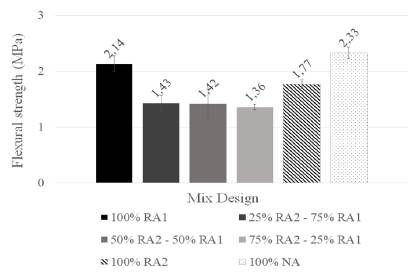

Flexural strength

Figure 9 shows flexural strength. The use of RA reduces the flexural strength by 35%. However, in a mixture with 100% RA1 there is a better performance with a reduction of only 8% in relation to mix with NA. This is due to the high aggregate absorption since it improves its properties by absorbing the cement paste during the mixing process. In this context, Güneyisi et al. (2016) obtained flexural strength between 1 MPa with RA and 1,3 MPa with NA, whose results fit reasonably well with those obtained in this research.

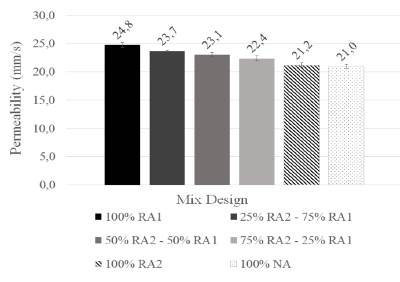

Permeability

Figure 10 shows permeability coefficients obtained through Darcy's Law. These results depend mainly on the type of aggregate. For example, NA has greater compaction, so permeability is reduced. Other factors that influence permeability are density and the void content. While a greater density implies a lower permeability, a greater void content implies greater permeability. As a result, mechanical properties are affected.

Also, Figure 10 shows a permeability variation of 15% between 100% RA1 and 100% RA2.

Barnhouse and Srubar (2016) obtained permeability of a macro porous concrete with recycled aggregate between 55 and 80 mm/s. However, the average compressive strength is 3,5 MPa, confirming the lineal relation between permeability and compressive strength observed in this study. Moreover, Aamer Rafique Bhutta et al. (2013) obtained a permeability between 25 and 45 mm/s in concrete with recycled aggregate of crushed concrete and compressive strengths that are also in agreement with this study.

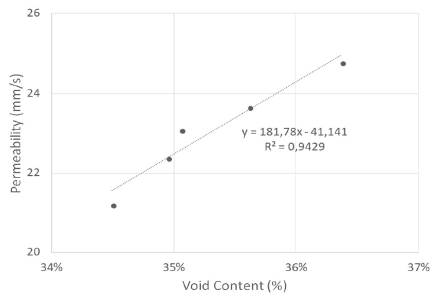

Permeability should also present a lineal relation with void content. A greater void content would mean greater permeability. Different authors have found that such lineal relation is of R2 = 0,79 (Güneyisi et al., 2016) and of R2 = 0,98 (Aamer Rafique Bhutta et al., 2013).

As expected, there is a good lineal relation between permeability and void content of pervious concrete, as shown in Figure 11, obtaining a value of R2 = 0,94.

Conclusions

This paper shows the influence of incorporating two different types recycled aggregates, brick ceramic aggregate (RA1) and crushed concrete aggregate (RA2) from construction and demolition waste (CDW), from the city of Bogotá, on the performance of pervious concrete under compression and flexural strength. The substitution of RA in the production of pervious concrete is outlined, taking into account five substitution levels. The pervious concrete mixes were submitted, 28 days later, to density tests, void content, compression and flexural strength and permeability.

Increasing the content of recycled aggregate resulted in a reduction to compressive strength due to recycled aggregate shows lower resistances (resistance to degradation and 10% fine) against the natural aggregate.

The compression strength results obtained in this study were found within the permitted interval for pervious concrete (ACI Committee 522, 2010). However, vibration energy (27 kN-m/m2) used in this study is too low compare to the value proposed by Chindaprasirt et al. (2008). This affect considerably density, void content and the mechanicals properties of the pervious concrete.

The characteristic permeability of pervious concrete was more than the reported range by ACI (ACI Committee 522, 2010), so it could be considered as a macro porous concrete (Barnhouse & Srubar, 2016). The pervious concrete mix with RA1 had a higher permeability coefficient, exceeding by 15% the NA mix, while with RA2 increases by 1%. It should be noted that the type of RA does significantly affect the measured time for the volume of water passing through, that was only 0,4 seconds.

According to the results found in this research, the characterized RA can be used to produce pervious concrete, since they comply with the ranges presented by ACI (ACI Committee 522, 2010), reaching compression and flexural strength of up to 5,79 MPa and 2,14 MPa, respectively, and a permeability of 24,79 mm/s.