Introduction

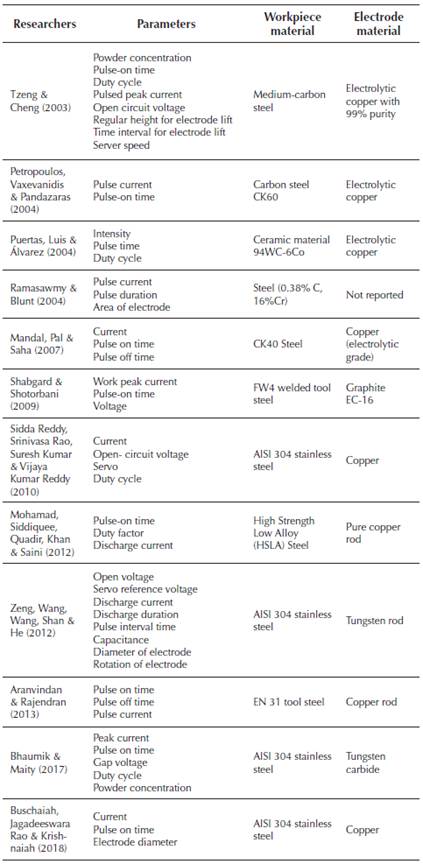

The term nontraditional machining refers to the group of processes that uses other mechanisms to remove materialfrom the workpiece by various techniques involving mechanical, thermal, electrical, chemical energy or combinations of these energies. Electric discharge machining (EDM) is one of the most widely used nontraditional processes. The shape of the finished work surface is produced by a formed electrode tool (Groover, 2013), connected to a DC power supply and placed in a dielectric fluid, a transient spark discharges through the fluid, removing a very small amount of metal from the workpiece surface (Kalpakjian & Schmid, 2014). The relation between EDM machining parameters and surface finish has been investigated. Some EDM machining parameters were studied, which are shown in Table 1, as well as the materials of the workpiece and electrode.

This study used the factorial design 23 in order to analyze the influence of the selected input parameters including, the pulse current, the pulse on time and the pulse off time on the surface finish of stainless steel AISI 304 specimens by using the EDM processes. The relation between the machining parameters and average roughness (Ra) by means of a second order regression model was estimated, which was validated by using the analysis of variance (ANOVA) and calculating the mean absolute percent error (MAPE) technique. Likewise, the level for each input parameter which produces the lowest surface roughness was determined.

Experimentation is a key element in understanding the behavior of physical phenomena, and consists of deliberately changing system variables in order to observe and identify variations. Experimentation is used in two industries: design and improvement of process and products (Montgomery, 2004; Tanco, Viles, Ilzarbe & Álvarez, 2007). The techniques of Design of Experiments (DOE) analyze the individual effects and interactions of various parameters of any given process that is studied. DOE requires relatively few resources and provides information that can be used to model the process behavior and determine the combination of parameters levels that improves the performances (Montgomery, Peck & Vining, 2006; Gutiérrez & de la Vara, 2008).

Surface roughness

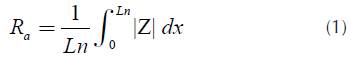

The surface roughness is a parameter used to evaluate the quality of the mechanical parts which predominantly affects its functionality and production costs (Mata-Cabrera, Hanafi, Khamlichi, Jabbouri & Bezzazi, 2013; Schultheiss, Hãgglund, Bushlya, Zhou & Stâhl, 2014). The average roughness (Ra) is the arithmetical mean of the examined roughness value in the machined zone. This is the most used parameter of roughness value due to its practicality, and it can be calculated by using the Equation (1):

where Ln is the evaluation length and Z is the distance between two points of the profile (ASME, 1995).

Method and material

Equipment and material used in the experiments

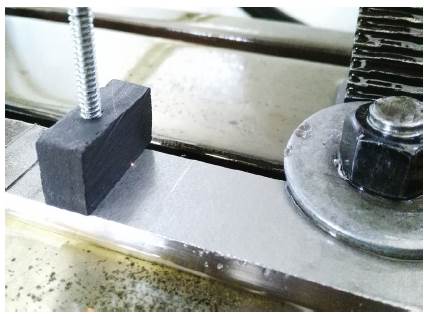

The die-sinking EDM machine of type Surefirst ED-203 was used in to machining of stainless steel workpieces as shows in Figure 1.

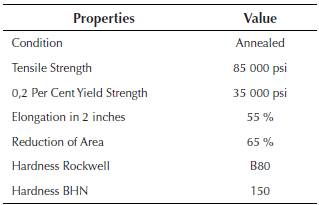

In the study, AISI 304 stainless steel was selected as the workpiece material, the specimens were made with dimensions of 100 mm x 25 mm x 6,35 mm. This steel is frequently used for chemical and food processing equipment; brewing equipment; cryogenic vessels; gutters; downspouts; flashings (Oberg, Jones, Horton & Ryffel, 2008). Its main properties are displayed in Table 2.

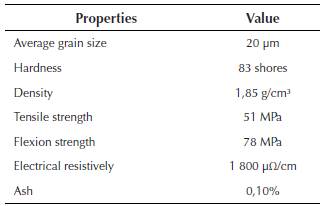

Graphite is one of the most used electrode material for EDM applications, because of its good thermal and electric properties (Klocke, Schwade, Klink & Veselovac, 2013). The experiments in this study were conducted using grade GSP-70 graphite electrodes, they were made with dimensions of 30 mm x 10 mm x 13 mm, and a new electrode was used in each replica of the experimental design. The grade GSP-70 graphite is an isotropic fine grain material with high purity and density levels, and as such is an ideal element to use with tasks involving EDM. Table 3 displays the most significant properties of the used electrodes material.

Figure 2 shows the workpiece and electrode materials used in this investigation.

Design of experiments

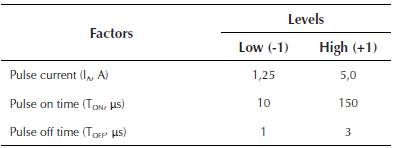

The two-level factorial design was used in this study with the three parameters concerned: the pulse current (IA, A), the pulse on time (TON, |js) and the pulse off time (TOFF, μs). Therefore, a two-level factorial design with three factors (23) was selected consistent with eight combinations for the factor levels, producing two replicas for each combination. The low and high levels for each factor were codified as -1 and +1, respectively.

Table 4 displays the used factors of this work with their levels, which are established on the used electric-discharge machine.

Analysis of surface roughness

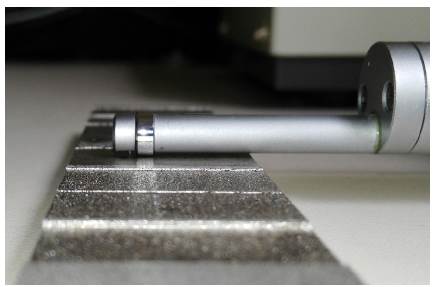

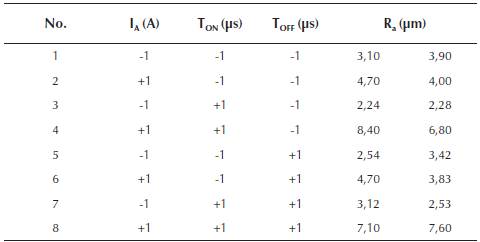

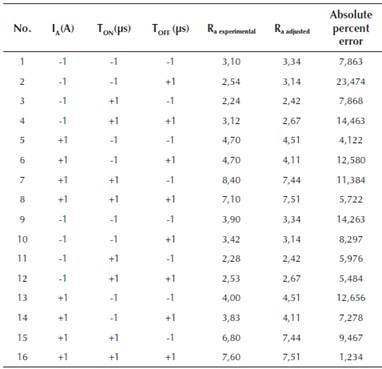

The machined surfaces were produced for each combination of levels of IA, TON and TOFF, and then based on the factors values established in the factorial design. The average roughness (Ra, pm) of the machined surfaces was measured by using the Mitutoyo SJ-402 series 178 profilometer, as shown in Figure 3. The results of the experiment of design 23 technique mentioned in this study are displayed in Table 5.

Results and discussion

Regression model

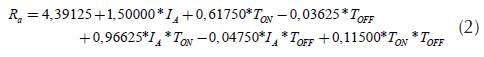

The second order model related to the average roughness (Ra) and machining parameters (IA, TON and TOFF) generated in terms of the levels codified of the aforementioned parameters is displayed in Equation (2).

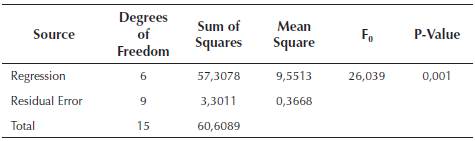

Table 6 shows the ANOVA results produced to check the adequacy of the second order. It can be noted that the P-value is less than α = 0,05, which means that the model possesses a confidence level of 95%, that represents the relationship between average roughness (Ra) and machining parameters (IA, TON and TOFF).

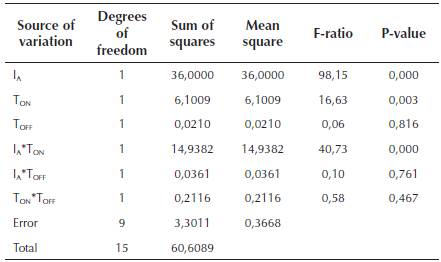

In Table 7, the ANOVA analysis for the individual model coefficients is displayed. It can be noted that there are three parameters with P-value inferior to α = 0,05, meaning that these are indications of a confidence level of 95%. These significant parameters are: the pulse current (IA), the pulse on time (TON) and the interaction between them.

In addition to this, the coefficient of determination R2 = 94,55% obtained through the ANOVA technique explains the amount of reduction in the Ra variability obtained by using the machining parameters (IA, TON and TOFF) in the model.

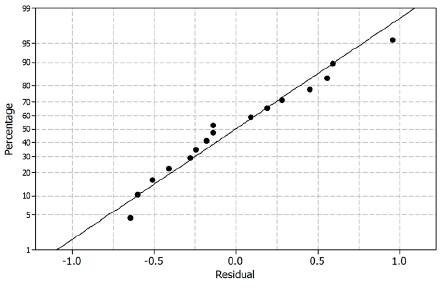

On the other hand, it can be observed in Figure 4 that the residues from average roughness are in line with normal distribution and the second order regression model has extracted all the information available from the experiment data.

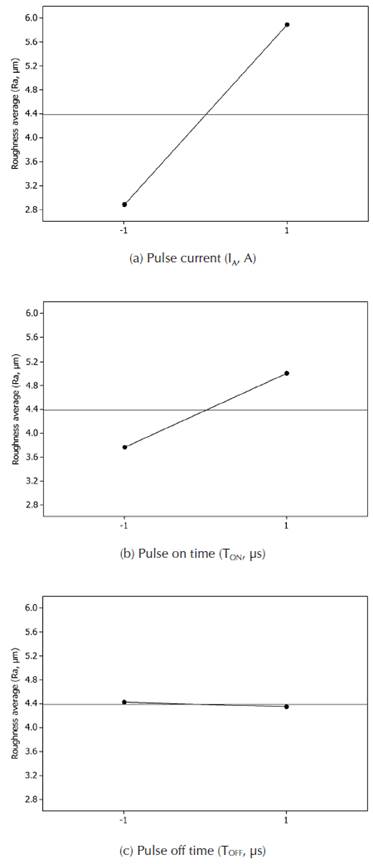

Main effects

Figure 5 displays the graphical representations of the main effects of the resulting average roughness (Ra) and the parameters of the experimental design (IA, TON and TOFF). Figure 5a shows that the levels of pulse current (IA) significantly influence the obtained average roughness (Ra) values, and as increased the pulse current, the average roughness increased. In Figure 5b, it can be observed that the average roughness increases as the pulse on time (TON) increases, meaning that the pulse current can significantly affect average roughness values. Figure 5c shows that the pulse off time does not affect the average roughness (Ra), as there is no significant variation between the mean data for each parameter level.

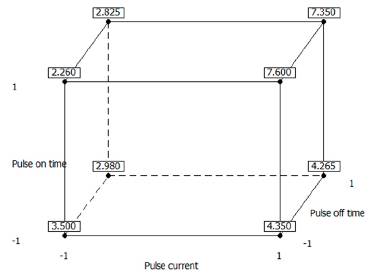

Cube plot

The cube plot in Figure 6 shows that the lowest average figure for average roughness is 2,260 pm between the eight combinations of levels for the experiment parameters, obtained with levels -1(1,25 A), +1 (10 ps) and -1 (1 ps) for IA, TON and TOFF, respectively. The highest Ra value is 7,600 pm, obtained through a combination of 1, 1 and -1, which corresponds to IA of 5,0 A, TON of 150 ps and TOFF of 1 ps.

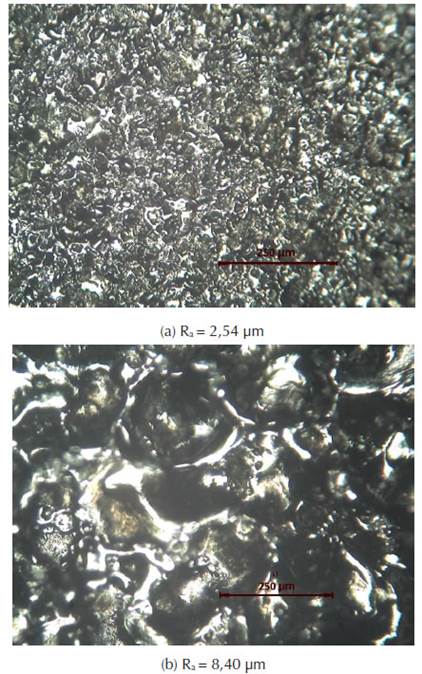

Figure 7 displays the differences between the surface finishes values obtained under different machining conditions. Figure 7a shows a surface roughness micrograph of 2,54 pm value machined using a pulse current (IA) of 1,25 A, a pulse on time (TON) of 10 ps and a pulse off time (TOFF) of 3 ps. Likewise, Figure 7b displays a surface finish micrograph with a value of 8,40 pm obtained using a pulse current (IA) of 5,00 ps, a pulse on time (TON) of 150 ps and a pulse off time (TOFF) of 1 ps.

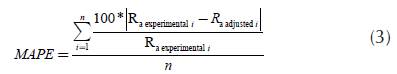

Mean absolute percent error

The mean absolute percent error (MAPE) is the average of the absolute differences between the adjusted and experimental R values, expressed as a percent of experimental values (Heizer & Render, 2011) and is computed with using the Equation (3):

Table 8 shows the absolute percent errors computed. The sum of percent errors is 152,131%, therefore, the value of MAPE is 9,508%. MAPE expresses the error as a percent of the experimental values, undistorted by a single large value.

Conclusions

The following conclusions are obtained based on the experiment results, the ANOVA technique, the second order regression model and the tests conducted for the present work:

- The factorial design 23 used in this study is an effective tool to study the influence of machining parameters on the surface roughness of AISI 304 stainless steel, produced by using of electrical discharge machining.

- The pulse current (IA) and pulse on time (TON) are the most significant parameters, obtained with a confidence level of 95% on EDM machining of AISI 304 stainless steel.

- The surface roughness of the AISI 304 stainless steel wor-kpieces decreased with a using of low pulse current (IA) and a low pulse on time (TON). It is recommended that the electrical discharge machining of AISI 304 stainless steel be performed with a pulse current (IA) of 1,25 A, a pulse on time (TON) of 10 ps and a pulse off time (TOFF) of 3 ps, in order to obtain lower levels of surface roughness values.

- The normal probability plot shows that the residuals follow a straight line, which implies that the residuals are distributed normally, therefore the adequacy of the regression model is validated.

- The value of MAPE obtained is 9,508%, which is perhaps the easiest measure to interpret, because expresses a percent of experimental values.