Introduction

The ACI 308-213 R-13 defines curing of concrete as the process through which the concrete matures and develops its hardening properties over time as a result of the continuous hydration of the cement in the presence of enough water and heat amount (ACI, 2013).

For years, the most widely used curing method has been external curing. It consists in the superficial application of water to the concrete, through a constant exposition at the surface by means of periodic irrigation of water or with the use of materials with good absorption and desorption capacities, such as sawdust and some polymers. In some cases, the elements are completely immersed in a pool of water, as in the case of test specimens and precast elements.

However, in the daily practice, immersing cast structural elements in situ is not an option. In these cases, the periodic application of water or the use of some external agent in order to conserve the moisture are implemented, as is shown in Figure 1.

According to Neville (2010), the main problem that could occur during the external curing is call slow-flow. This effect takes place when the curing water starts circulating into the concrete and the external curing water is evaporated from the concrete. This makes that only the surface of the element and a small internal layer of little thickness and to the surface are cured and not the whole volume of the element, as expected. That is why the thicker the piece is, the higher the volume of uncured concrete will be. Therefore, in order to ensure an efficient surface curing, a permanent sheet of water must be guaranteed on the concrete surface for a long time. This condition is difficult to ensure on large surfaces, in isolated places, in hot climates and in places with water supply problems. Additionally, the lack of awareness in the construction area about the importance of an efficient external curing for the adequate behavior of the concrete makes this process hard to control.

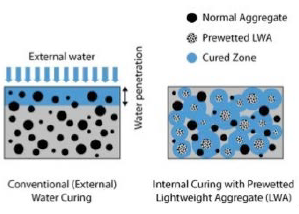

Additionally, the ACI 308R-01 defines internal curing (IC) as the "process where the hydration of cement occurs because of the availability of additional internal water that is not part of the mixing water" (ACI, 2008). According to the Expanded Shale, Clay and Slate Institute (ESCSI), internal curing helps concrete to develop its full potential in a simple, economical and sustainable way. The IC improves hydration, reduces early cracking, reduces chloride penetration and improves durability, all of which extend the service life of the concrete.

In Figure 2, the comparison between the surface curing and the internal curing shows that the former works as a hard shell around concrete elements, while the latter makes uniform hydration of the concrete. Both, superficial and internal, could ensure homogeneous curing within the concrete mass.

According to this, a new paradigm has arisen in response to the deficient external curing practices used in infrastructure works and, especially, facing the difficulty of curing concrete with low w/c ratio. This paradigm is called internal curing of concrete and consists in storing water inside the concrete that is not available during the mixing or in the first hydration stages but is released later for curing. In order to achieve this behavior, saturated lightweight aggregates are used, since they can provide curing water from within the mixture thanks to their absorption and desorption properties.

In Colombia, according to the technical bulletin from March 15th, 2016 issued by the DANE, the use of concrete as construction material amounts to 8 500 m3, which places it as the most widely used construction material in the country. Road infrastructure, warehouse floor slabs, concrete walls, columns and beams are, among others, the civil works with most problems in service and maintenance. The main reason is the lack of curing in the early ages of concrete, which is when the properties of strength and durability that the concrete will have during its service life are developed.

The Colombian Seismic Resistant Code (NSR-10), in its title C, defines lightweight concrete as concrete with lightweight aggregate, that has an equilibrium density between 1 440 and 1 840 kg/m3 (AIS, 2010), as defined also by the NTC 4022 (ICONTEC, 1994) based on the ASTM C567. Likewise, the Colombian technical standard NTC 4045 provides the characteristics that a lightweight aggregate must fulfill to be part of structural concrete (ICONTEC, 1997), based on the American specification ASTM C641.

Notwithstanding the inclusion of lightweight concrete within national regulations, the use and commercialization of the lightweight aggregate for concrete are limited due to the lack of research that supports its operation, not regarding lightweight concrete but also in the practical field as internal curing agents. Possible use of lightweight aggregates nationwide could take place when a high volume of concrete is used, and it is difficult to ensure a continuous and prolonged supply of water. The use of lightweight aggregates as internal curing aggregate of concrete could be a good alternative to avoid the current wrong practices in the curing stage and as a solution to develop infrastructure in the regions where it is not possible to ensure continuous water supply.

Before using the lightweight aggregates available in the national context as internal curing agents, it is necessary to evaluate their behavior through a partial incorporation into concrete that allow the characterization of their properties in fresh state, its mechanical strength, and the influence on the durability. Subsequently, this also allows the formulation of concrete dosages with lower density than in conventional concrete with the aim to achieve similar properties.

In order to evaluate the benefits of the lightweight aggregate as an internal curing agent, an experimental program was performed. Specimens with a different concrete matrix were tested using two types of lightweight aggregates. Each one was included in the concrete matrix instead of a percentage of the normal weight coarse aggregate. The first lightweight aggregate was calcined clay and the second one was recycled crushed clay bricks (CCB) in the laboratory. An internal curing agent, commercially known as "Better Mix" and supplied by the company Toxement, was also evaluated.

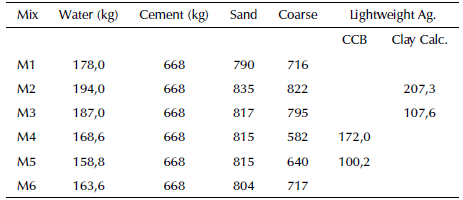

The effects of internal curing were tested in six different concrete mixtures. The first mixture (M1) was a control sample, while the second (M2) and third mixtures (M3) had an addition of calcined clay with a partial replacement of the coarse aggregate in percentages of 15% and 20%, respectively. Likewise, the fourth (M4) and fifth (M5) mixtures contained the same percentage of replacement of the coarse aggregate, but the substitution material was the CCB aggregate. Finally, the performance of the Better Mix curing agent was assessed in the sixth mixture (M6).

Materials and Testing Procedure

Materials

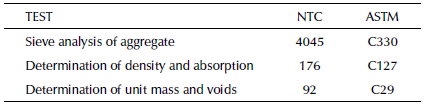

The CCB aggregate was obtained from crushing 11-inch clay blocks, obtained from the external service tests of the Structures Laboratory of the Escuela Colombiana de Ingeniería Julio Garavito, as shown in Figure 3. The selection and characterization tests were carried out according to the standards presented in Table 1.

The characterization of the second lightweight aggregate was carried out in the Soil and Geotechnics Laboratory of Escuela Colombiana de IngenieríaJulio Garavito, following the same characterization standards stipulated in Table 1.

The third internal curing agent was the commercially known "Better Mix" supplied by Toxement, which is a concrete additive that has the property of holding water.

Due to the used w/c ratio (w/c = 0,30), it was necessary to use a Superplasticizer additive. The additive used was "Eucon MR 500", supplied by Toxement. The dosage was calculated according to the recommendations of the manufacturer (1,5 % of cement weight).

Characterization of the materials

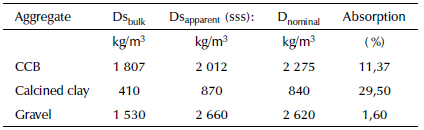

Results of the characterization tests of the aggregates are shown in Table 2.

Mixture design

For the design of the mixtures, the recommendations of the ACI 211.1 were followed (ACI, 1991). In common practice, the internal curing was used to obtain high strength concrete, therefore, a low w/c ratio of 0,30 was chosen.

The amount of cement and the amount of water for all the mixtures was kept fixed and partial replacements of coarse aggregate were made by the two lightweight aggregates previously described. For these replacements, the average density between the stone aggregate and the lightweight aggregate was calculated, in order to find the necessary quantities of each one. For each of the mixtures evaluated, the lightweight aggregates were pre-moistened for 24 hours prior to the preparation of the mixture. Due to this pre-moistened, the incorporated water was discounted from the calculated mix of water.

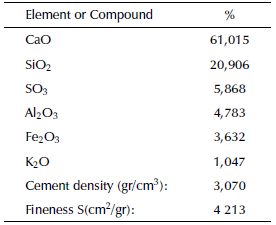

The cement used in this research was supplied by the Argos Company and characterized through the X-ray fluorescence test, in the laboratories of the Universidad Nacional de Colombia. The characterization was done in a solid cement sample in order to obtain its chemical composition, density and fineness. The characterization of the cement is presented in Table 3.

Table 4 shows the dosage of the 6 mixtures evaluated and the dosage per m3 of concrete.

Test specimens

For the development of this research, three different types of specimens were used. Specimens type 1 were 12 slabs of 350 x 250 x 200 mm, whose dimensions were determined in order to extract 6 standard cylinders of 100 mm diameter and 200 mm high from each specimen, by means of a core extraction drill. The extraction set can be observed in Figure 4.

Concrete slabs were used instead of standard cylinders based on the recommendations given in the State-of-the-Art report of RILEM 196-ICC (Klover and Jensen, 2007). The authors suggest that it is necessary to have specimens with greater area and volume than the conventional cylinders, in order to evaluate the internal curing effects. The casting process of this type of specimens consisted in placing two layers of fresh concrete, each one was tamped 20 times with a smooth steel bar of 16 mm in diameter and 600 mm in length. Then, the molds were externally compacted with a rubber mallet in order to diminish the anthills. Subsequently, the edges and the remaining material were leveled.

The compression, modulus of elasticity, ISAT, chlorides and sorptivity tests were performed on the 100 x 200 mm cores extracted from specimens type 1, according to the corresponding ASTM standards. The tests were performed after 28 and 180 days, in order to obtain a representative estimation of the concrete performance at two different ages. 12 specimens were analyzed per mixture at each test date, for a total of 144 cylinders.

In order to evaluate the performance of the concretes, it was necessary to make twin specimens of each mixture. Half of these were preserved in submerged state and the other half were conserved in a room with controlled temperature and humidity at 55 %, and constant temperature of 25 °C. These conditions were hold until the core extraction and test age.

In Figure 5, some specimens type 1 are shown, after the extraction of the cylinders.

Specimens type 2 were prisms with dimensions 150 x 150 x 50 mm and elaborated following the parameters established in the NTC 3494, in order to evaluate the loss of water of the concrete and the influence of the internal curing. The specimens were preserved as specimens type 1: three per each mixture in the controlled-temperature room and three in submerged conditions until the day of the test.

Specimens type 2 were elaborated following the same process described above for specimens type 1.

Finally, specimens type 3 were standard prismatic of 75 x 75 x 250 mm, made for the volumetric variation test, according to the ASTM C157. Six specimens were made from each mixture. three of them were submerged and three were storaged in a room with controlled temperature and humidity, as well as the other specimens. A total of 36 specimens were made.

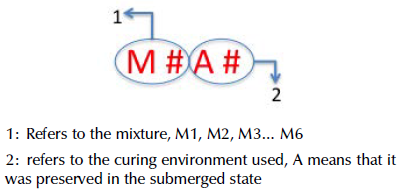

Nomenclature

For the identification of the different specimens, the nomenclature from Figure 6 was used.

Results and discussion

Properties of fresh concrete

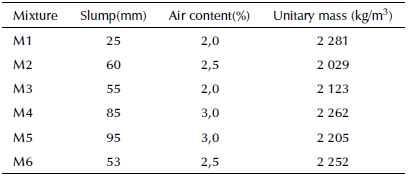

Shows the fresh-state properties recorded for the different mixtures.

As observed in Table 5, the unit mass decreased from Mixture 2 to Mixture 6 in around 1 % and 12%, compared with Mixture 1. This is due to the lower density of the lightweight aggregates used in the mixes compared with the standard one. In large volumes of concrete, this would represent a considerable weight reduction. However, our mixes could not be considered lightweight concrete according to the definition given before. The air content has not appreciable alteration due to the use of lightweight aggregates.

The lightweight aggregates improved the manageability between 2,2 and 3,8 times compared with the standard sample. It changed from a slump of 25 mm for the standard sample to a range between 55 and 95 mm. This could be attributed to the fact that the mixing water is not absorbed by the aggregates, because these were previously saturated, thus allowing a uniform distribution of water in the mixture. This increase in the manageability for high strength concrete with low w/c ratios represents an advantage for its handling.

Mechanical properties

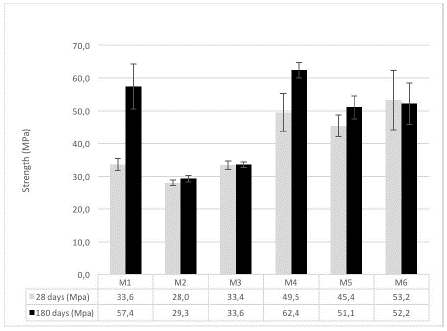

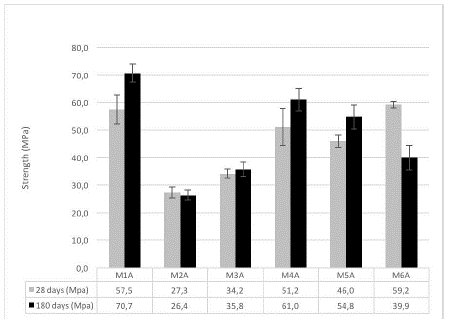

Compressive strength:Figure 7 shows the compressive strength for the samples cured in the controlled temperature room. Figure 8 shows the compressive strength for the pool-cured samples. Both graphics show the results of the average compression strength of the three specimens in the aforementioned test ages.

An increase of the strength resistance from the 28 days to the 180 days was observed in the standard mixture (M1) as well as in the mixes with CCB aggregate (M4, M5), between 26% to 70%, suggesting an increase of the strength at long ages. Mixes with the calcined clay presented just a slight variation smaller at the 4 %, which induced the maximal strength resistance in these mixes within 28 days. The mixture with the superplasticizer (M6) presented a bigger reduction in the strength resistance for the submerged samples, however, it is necessary to increase the number of specimens in this mixture before concluding this behavior. Among all the specimens, the maximal strength at 180 days was for the Mixture 1 in submerged state, as expected, with 71 MPa. The closest strength to this maximal value was observed in the Mixture M4 in the controlled temperature room, only with a reduction of the 11,7%, which suggests the effectiveness of the internal curing. Additionally, comparing this mixture in submerged and non-submerged state did not show a representative variation in the strength, which then allows to infer that the internal curing in this mixture is optimum.

Meanwhile the standard mixture M1 has a strength reduction of almost 20% between the specimens submerged and non-submerged. The specimens cured internally have just a difference between 3 % and 10%, therefore it could be said that the internal curing really occurred, and that its success depends on the dosage and kind of the aggregate.

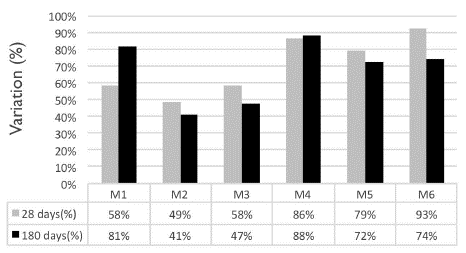

Figure 9 shows the percentage difference between the resistance obtained in the standard mixture in the submerged state and the mixtures conserved in the room with controlled humidity and temperature.

Source: Authors

Figure 9 Variation of the compressive strength in mixtures conserved in the room compared with the standard mixture in submerged state after 28 and 180 days.

It is observed that the samples with crushed clay bricks (M2 and M3) achieved a compression resistance equivalent to 88 % of the externally cured standard mixture after 180 days. In addition, M2 and M3 presented a similar strength in the cylinders conserved in the room with controlled humidity and temperature to those preserved in the submerged state, thus proving the properties of crushed clay bricks as curating agent.

The mixes with calcined clay, M2 and M3, obtained the greatest reduction in compressive strength. The internally cured samples achieved only 41 % of the resistance achieved by the standard sample.

From the foregoing, it could be observed that the compressive strength of mixtures with lightweight aggregates depended fundamentally on two factors: the percentage of coarse aggregate substituted by lightweight aggregate and the type of lightweight aggregate used. Comparing the behavior obtained for the concretes with lightweight aggregate of calcined clay against concrete with CCB aggregate in equal replacement percentages, a variation of the resistance is observed up to 49 %, where the CCB mixes obtained the higher strength. In addition, all mixtures with lightweight aggregates, the ones in the room as well as the ones in the submerged state, had lower compressive strength than the standard mix. This result agrees with the conclusions of Shafigh, Jumaat, Mahmud and Hamid (2012) regarding the reduction of resistance in mixtures with lightweight aggregates.

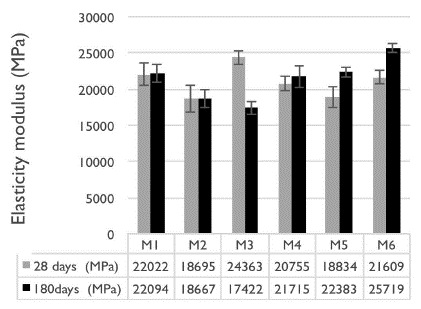

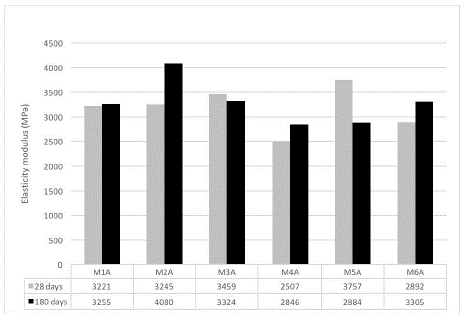

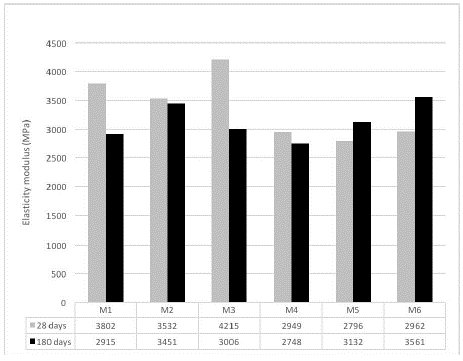

Modulus of elasticity: The procedure followed to evaluate this property was as specified in the ASTM C469 standard (2014). Figure 10 shows the average moduli of elasticity for the samples preserved in the room with controlled humidity and temperature.

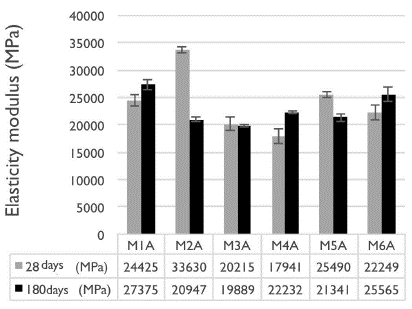

Figure 11 shows the average modulus of elasticity for the samples in submerged state. It shows that the standard mixture obtained the largest modulus of elasticity (27 375 MPa), after 180 days. The modulus of the mixture with the curative agent preserved in the room with controlled humidity and temperature was the closest to the standard sample after 180 days (25 565 MPa), while the sample with the lowest elasticity modulus corresponded to the mixture with 15% replacement of the coarse aggregate with calcined clay after 180 days (19 889 MPa).

The variation of the elasticity modulus was different for all mixtures. In the case of the standard mixture in submerged state, and the samples with 25 %, replacement of the coarse aggregate by CCB in the room (M4), there was no variation in the modulus of elasticity after 180 days regarding the modulus obtained after 28 days. Meanwhile, all the other samples showed a variation between 10% and 40%, which is attributed to the difference in the composition of each mixture.

The only mixture with a decreasing modulus of elasticity was mixture M3 with a decrease of 29 %, which suggests the need of additional tests to determine the reason for this decrease.

Figure 12 and Figure 13 show the relation between the compressive strength and the modulus of elasticity, according to the following equation:

As observed in the figures, the relation constant between the modulus of elasticity and the f c is different for every mixture and curing environment. The M2A had a K value of 4 080, whereas the other mixtures had a K value lower than 3 500. Compared with the values defined by the NSR-10 for concretes with a unit mass between 1 440 and 2 460 kg/m3, the closer constant corresponds to the one defined for sedimentary aggregates with a K value of 3 600 (AIS, 2010).

Source: Authors

Figure 12 Relation of the modulus of elasticity and the f c in the samples preserved in the room.

Durability properties of the concrete compressive strength

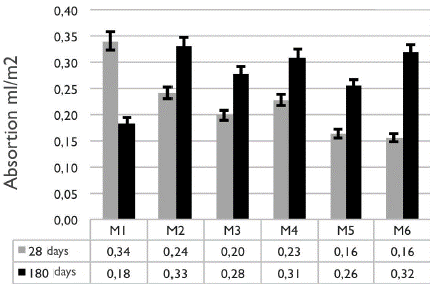

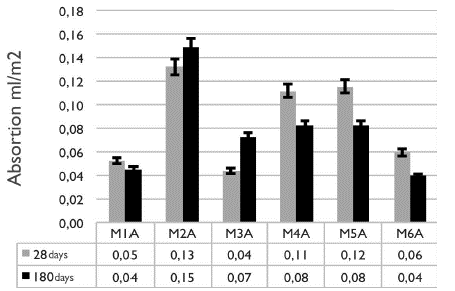

ISAT- Initial surface absorption test: this test was carried out following the guidelines described in the English standard BS-1881 part 5: Testing concrete.

For the ISAT, data were taken after 10, 30 and 60 minutes per sample, according to the aforementioned standard. Results are presented after 10 minutes, because the trend observed at that time was constant for the rest of the measurement. However, for the following reading time values, the absorption values were lower due to the corresponding pore saturation.

Figure 14 and Figure 15 show the results obtained from water absorption for each of the concrete samples, measured at 10 minutes.

Mixtures with light internal curing aggregates had an increase in the initial water absorption rate between 26% and 36% after 180 days. This can be attributed to the porous nature of the lightweight aggregates. The samples of the standard specimen preserved in the room with controlled humidity and temperature achieved an absorption decrease of 84%.

It is concluded that concretes with lightweight aggregates obtained a greater absorption than the externally cured standard sample, which confirms the conclusions made by Castro, Keiser, Golias and Weiss (2011). However, it is worth clarifying that external curing was performed under ideal laboratory conditions where the samples were saturated until the day of the test and that those conditions are not reproducible in practical cases.

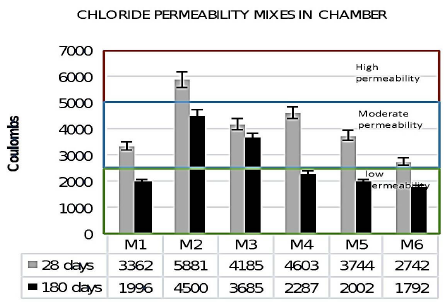

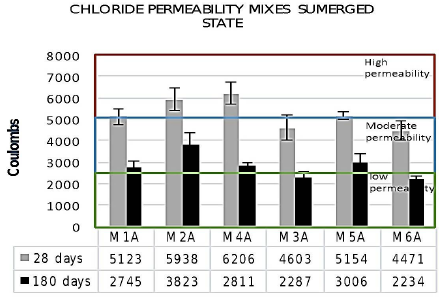

Chloride penetration: this test, as defined by the ASTM C1202-12 standard (2012), allows the determination of the electrical conductivity of the concrete to provide a quick indication of its resistance to chloride ion penetration. Figure 16 and Figure 17 show the current flowing through the test specimens for each of the mixtures after 28 and 180 days. In summary, a lower penetration of chlorides was obtained in the mixtures conserved in the room, which achieved a reduction of 34% after 180 days, regarding the penetration obtained after 28 days.

Samples with internally cured calcined clay recorded a greater passage of Coulombs ranging from 34 % to 64 % at 180 days compared with the mixture preserved in the room. The mixtures with CCB registered a reduction in the passage of Coulombs between 17% and 27% after 180 days, compared with the sample preserved in the camera. The mixture with the curing agent recorded the smallest Coulombs passage among all the samples evaluated and it had a 35 % lower step at 180 days than the externally cured standard sample.

Except for the internally cured sample 2 (M2), all the mixtures recorded a moderate and low passage, thus indicating an acceptable chloride migration. At the age of 180 days, a transcendental reduction occurred in the passage of Coulombs, changing the categorization of moderate to low in all the evaluated mixtures, which agrees with what was found by Dayalan and Buellah (2014).

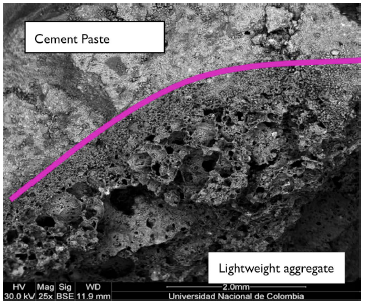

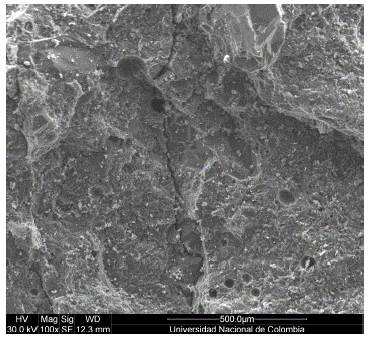

Microscopy: the main objective of this test was to observe the interaction between the aggregates and the cement paste within the concrete matrix. The microscopy test was performed in mixtures M3 and M6.

In Figure 18 and Figure 19, the interaction between the aggregate and the cement paste can be observed. There is a noticeable change of tone between the cement paste and the lightweight aggregate. It can be concluded that the darkest shade is the superficial part of the lightweight aggregate and the clear part corresponds to the cement paste, where there are signs of perimeter humidity, which indicates the expulsion of the internal curing water.

Figure 19, which belongs to sample 6, shows small elongated spots distributed around the entire cement paste, which correspond to the curing compound from Toxement.

Conclusions

The crushed clay bricks in partial replacement of 25 % of coarse aggregate, presented the best behavior in the different tests carried out and surpassed the sustainability point of view. This can represent a benefit, given that waste of the clay units is generated in buildings, due to its fragility, and it can become an economic option when used as a lightweight aggregate for the internal curing of the concrete; thus, decreasing the environmental impact. Nevertheless, the optimal replacement percentage should be proved for each concrete mix, through probe mixes.

Calcined clay does not have good behavior in the tested conditions, the mechanical and durability characteristics were always reduced compared with the standard mix. The authors suggest additional research with different densifications and different aggregate granulometry in order to obtain further conclusions.

In all the internally cured mixtures, there was a reduction in the strength resistance. This is contrary to the conclusion given by Saffar, Saad and Tayeh (2019), where the authors state that the internal curing should increase the strength resistance. However, their conclusion is based on experimentation with fine aggregates.

The Better Mix curing agent had a good behavior in all the tests evaluated, but also had a reduction in the strength of 32% in submerged conditions. This suggests a limitation in its use for external members. It is also recommended further research with different humidity conditions.