Introduction

Currently, research aimed at the use of agronomic techniques that improve productivity in terms of quantity and quality of products has increased (Edgerton, 2009). At the same time, there are ongoing efforts to promote the conservation of natural resources, the protection of soil, and the reduction of environmental impact (Zhao et al., 2018). Recent studies that compare the properties of soil treated with organic and chemical fertilizers have shown the former to improve nitrogen and organic matter contents and increase productivity (Drinkwater and Snapp, 2007; Yang, Su, Wang, and Yang, 2016). The addition of organic supplements such as compost makes it possible to stabilize the soil structure, increase the density of the fertile layer, and maintain a healthy environment (Carrizo, Alesso, Cosentino, and Imhoff, 2015). With the use of biological processes, agricultural residues can be transformed into biofertilizers (Muscolo, Papalia, Settineri, and Mallamaci, 2018) for the development of sustainable agriculture. The speed and degree of degradation of the waste depends on the quality of the materials used and the conditions of the process.

The composting process is a method that involves thermophilic and mesophilic organisms which consume organic matter as a substrate under controlled conditions, thus obtaining a stabilized, mature, deodorized, hygienic, pathogen-free, and plant-seed product, rich in humic substances with ideal properties to improve the soil (Lim, Lee, and Wu, 2016). Composting of lignocellulosic food waste is an alternative for sustainable conversion, as it generates a green product; it can be considered as an effective method to transform organic matter into a potentially safe, stable, and harmless material that can be used as a soil improver, organic biofertilizer, or peatmoss substitute in cultivated soils (Chen et al., 2014).

Several studies indicate that the addition of various materials during compost preparation process can accelerate the process and improve the quality of the product (Gabhane et al, 2012; Makan, 2015). In the composting of organic matter with livestock residues, bagasse is commonly used as a structuring agent. The main purpose is to maintain the appropriate water content in the mixture and promote the formation of porous spaces in the compost mass. This increases oxygen availability and reduces the loss of static pressure in piles with forced aeration (Teixeira, de Matos, and Melo, 2015). The addition of sufficient cane bagasse increases the pH from 3,5 to 5 and can improve the transformation of nutrients from organic waste by controlling pH (Cole, Roberts, Garside, de Nys, and Paul, N. A, 2016). In addition, bagasse can also be used as a carbon source to adjust the carbon/nitrogen (C/N) ratio and improve the availability of nutrients (nitrogen, phosphorus, and potassium) by increasing the content of organic matter and nitrogen in the compost, thus reducing the loss of gaseous nitrogen (Kumar, Verma, Singh, Kumar, U., and Shweta, 2010). In previous studies, the application of cane bagasse in the composting of municipal solid waste improved the quality and shortened the process time required for its stabilization (Mohee et al., 2015). Another study showed that adding 15% sugarcane bagasse and 20% exhausted grape marc during the two-stage method for composting green waste improved the quality of the final product and reduced the compost maturation time to 21 days, compared to the 90-270 days required by the traditional process (Zhang and Sun, 2016). There are several studies in which various agroindustrial wastes have been used for the production of compost: filter mud, vinasse, coffee pulp, citrus, fruit-horticultural waste, etc. (Caballero and Soto, 2019)

Citrus fruits are the most consumed fruits around the world, due to the nutritional value and health benefits resulting from the amount of secondary metabolites they possess (Panwar, Panesar, and Chopra, 2019). Brazil, India, Mexico, Spain, and the United States produce over two-thirds of the world's citrus fruits (Zema, et al., 2018). The Citrus genus includes several important fruits but is dominated by sweet oranges (Citrus sinensis), which can be classified into three groups: common oranges (White or Golden oranges), navel orange, and pigmented or blood orange (Ortiz-Sánchez, Solarte-Toro, Orrego-Alzate, Acosta-Medina, and Cardona-Alzate, 2020; Mamma and Christakopoulos, 2014).

Citrus processing involves the following stages: after the harvest, they are transported to the processing plant, where the waste is removed for later washing. The next steps consist of extracting the juice by squeezing and centrifuging, after which the juice is heated to activate the pectinase enzymes and transferred to the concentrators to add citric acid, enzymes, and vitamin C, in order to obtain the best quality. Finally, the juice is packaged in sterilized containers (Taghizadeh-Alisaraei, Hosseini, Ghobadian, and Motevali, 2017).

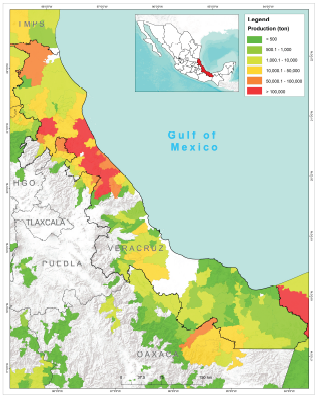

Approximately one-third of citrus fruits are used in the process, which produces between 50 and 60% organic waste. The processed citrus residues have an acidic pH (3-4) and are characterized by having a high quantity of organic matter (95%) and a large amount of water (between 80 and 90%) (Behzad and Keikhosro, 2018). Citrus byproducts include fats, free sugars (glucose, fructose and sucrose), organic acids, polymers (cellulose, hemicellulose and pectin), enzymes (pectinases, phosphatases and peroxidases), flavonoids, essential oils (limolene), and pigments (Boukroufa, Boutekedjiret, Petigny, Rakotomanomana, and Chemat, 2015). Organic acids from processed oranges (malic, malonic, and oxalic), together with other components, represent 1% of the dry weight (Raveh et al., 2020). In citrus fruits, the taste depends mainly on the amount of sugars and organic acids, while volatile components are associated with aroma. Therefore, the residues from citrus processes obtained during the extraction of thejuice contain seeds that are characterized by their high content of oils, where C16 and C18 acids predominate (Bora, Kamle, Mahato, Tiwari, and Kumar, 2020; Joglekar, Pathak, Mandavgane, and Kulkarni, 2019). Veracruz is the main citrus producing state (Table 1 and Figure 1).

Table 1 Citrus production

| Citrus | planted area (ha) | Harvested citrus (t) | Yield (t/ha) |

|---|---|---|---|

| Orange | 167,884 | 2,331,660 | 11,13 |

| Lemon | 46,319 | 658,282 | 12.20 |

| Tangerine | 20,583 | 322,494 | 15,75 |

| Grapefruit | 7,896 | 242,409 | 29,40 |

| Total | 242,682 | 3,554,845 | 18,76 |

Source: SEDARPA, 2019

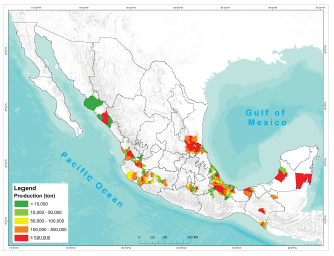

In Mexico, sugarcane production generates more than 2 million jobs, both directly and indirectly, and is carried out in 15 federal states and 227 municipalities (Figure 2). The 2018/19 harvest was conducted in 50 sugar mills. The harvested area was 804 060 ha, producing 57 036 700 t of cane to be ground, with a field yield of 70 936 t/ha, a production of 6 425 919 t, with a factory yield of 11 266%, and an agroindustrial yield of 7 992 t of sugar/ha. Veracruz produces 40% of the total domestic production of cane and sugar (CONADESUCA, 2019).

Among the main byproducts of the sugarcane industrialization process is filter mud, which is formed by the residues that are obtained in the sugarcane juice clarification process during raw sugar production. It is a dark material, consisting of a mixture of fiber, coagulated colloids, wax, albuminoid substances, calcium phosphates, and soil particles. On average, 30 kg are produced for each ton of sugarcane that is ground. It is generally applied on soils next to sugar mills without composting treatment. The filter mud components that stand out are organic matter, calcium, phosphorus, and nitrogen (PROCAÑA, 2019).

Bagasse is the residue of the industrial sugar manufacturing process, the remainder of the sugarcane stalks after the sugary juice they contain is extracted through the mills. Whole bagasse is divided into pith and fiber. Within this context, cane bagasse is a potential fibrous residue for the production of green products that is available in large quantities and has a chemical composition very similar to wood. However, the traditional and most widespread use today is the production of steam by combustion in the boilers of the sugar mill itself. This activity consumes from 50 to 100% of the bagasse that is generated in the process. Bagasse fibers are rigid with irregular, well-defined contours; they are the bearers of the structural elements necessary for the derivatives industry, whose composition is influenced by the agricultural processing conditions of the cane, the type of cut, the collection, and sugar technology (Aguilar, 2010).

The ash of sugarcane bagasse is an inorganic residue that remains after burning it in boilers, whose final temperature is between 700 and 750 °C. It is predominantly composed of silicon, aluminum, calcium, and iron compounds, along with minimal amounts of magnesium, titanium, sodium, and potassium. Although its constituents are oxides, they are represented mostly as a mixture of silicates, oxides, and sulfates with tiny amounts of other elements. Silicates have their origin in slate and clay minerals; iron oxide derives mainly from pyrites, which, when burned, produce ferric oxide and sulphur oxides; whereas calcium and magnesium oxides result from the decomposition of mineral carbonates. Sulfates are formed mostly by the interaction of pyrite mineral carbonates and oxygen.

Ash decomposition varies according to the variety of the cane and age, the type of soil, and the amount of fertilizers. The amount of ash in the bagasse depends largely on the amount of soil, which is a foreign material collected during harvest. The normal amounts of ash in low rainfall conditions are between 2 and 4% of the total bagasse (Andreão, Suleiman, Cordeiro, and Nehdi, 2019). The objective of this research was to model the process of composting byproducts from the orange and sugarcane agroindustries simultaneously in a compost pile, in order to obtain stabilized biofertilizer with suitable parameters for use as a soil improver.

Materials and methods

In this investigation, a univariate experimental design was used for composting orange and cane byproducts through the pile method. The experimental process was conducted in a greenhouse located in the facilities of the Faculty of Biological and Agricultural Sciences of the University of Veracruz, located in Peñuela, Amatlán de los Reyes, Veracruz, México. The experiment was carried out in a greenhouse so that outdoor climatic and environmental conditions would not interfere with the experimental results and variables such as temperature and moisture.

During the composting process, the following materials were used: orange peel, green sugarcane leaves, bagasse, ash, filter mud, sugar mill byproducts, and spent substrate from the production of Pleurotus ostreatus, a highly consumed mushroom in the region. However, the residue from its production has no use and is considered waste or garbage. The moisture of the substrates was determined by gravimetry (Table 2).

Table 2 Byproducts used

| Material | Amount (kg) | Initial moisture (%) | Composition (%) |

|---|---|---|---|

| Orange peel | 89 | 84 | 48,58 |

| Green-sugarcane leaf | 40 | 80 | 21,83 |

| Sugarcane bagasse | 23 | 15 | 12,55 |

| Ash | 6,0 | 12 | 3,28 |

| Sugarcane filter mud | 11,2 | 20 | 6,11 |

| Edible Mushroom spent substrate | 14 | 16 | 7,65 |

| Total | 183,2 | - | 100 |

Source: Authors

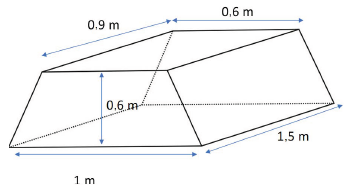

The materials were previously weighed and conditioned for the preparation of the compost pile, which was made in a pyramid arrangement with nine sampling points (Figure 3).

The materials were placed in interspersing layers to keep the moisture of the substrate and the pore space in balance, thus ensuring gas exchange inside the pile. During the experimental process, temperature was monitored manually using a Tel-Tru thermometer for composts at nine points: three on the surface, three in the center, and three at the base corresponding to the treatments. The pH in the substrate was determined once a week using a Hanna Instruments HI2209-01 pH meter. The pile was irrigated weekly during the turning process.

At the end of the process, nutrient and micronutrient compositions were analyzed and compared with regional biofertilizers: filter mud and compost (filter mud 75%, and bagasse 25%) from a sugar mill based on the Official Mexican Standards NMX-AA-025-1984 and NOM-021-SEMARNAT- 2000.

Results and Discussion

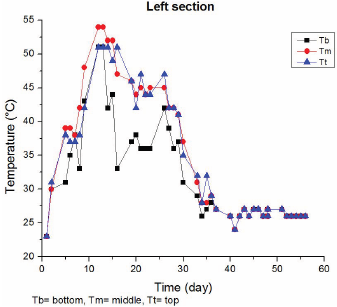

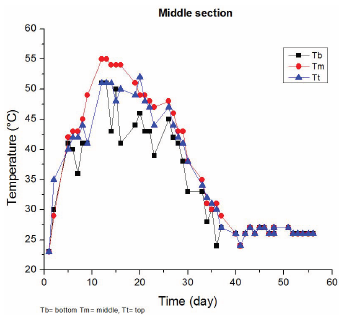

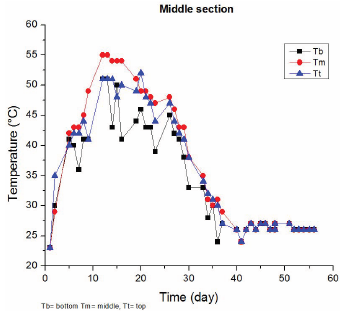

During the composting process, various changes in the substrate structure were observed: fungi growth and yeasts, complete degradation of the components (which became humus), temperature increase, dehydration, etc. It is important to note that, in this research, the growth of microorganisms on the surface of the substrate was not quantified; it was only observed qualitatively and was correlated with the increase in temperature inside it. The evolution of temperature in the different sampling sections is presented in Figures 4, 5, and 6.

Figures 4,5, and6show that, at the beginning of the composting process, the substrate temperature was equal to that of the environment. However, once the metabolic process of the mesophilic microorganisms had begun, the necessary conditions were created so that different groups of bacteria, yeasts, and fungi developed, producing an increased temperature in the substrate as a result of metabolic activity (Cai et al., 2013).

A technology commonly used to manage organic waste is biological composting, which stabilizes organic matter to a humus with almost no odor or pathogens and can be applied beneficially to the soil (Nwanze and Clark, 2019). During this process, bacteria, actinomycetes, fungi, molds, and yeasts oxidize long and short chain fatty acids, paper products, and other contaminants, thus producing heat, which leads to a reduction in waste due to microbial conversion and the evaporation of water (Tuomela, Vikman, Hatakka, and Itavaara, 2000). Protozoa help to consume bacteria and fungi, while rotifers control the growth of bacteria and protozoa, which minimizes the health risks associated with pathogens (Haug, 1993). The main aim of composting is to maximize conversion of organic material. Therefore, water is added to the process when the organic matrix reaches a certain dryness in order to preserve moisture for optimal microbial activity and maximum organic conversion. As a consequence, long residence times of around 50 days are required (Cai et al., 2013). The factors affecting the composting process are temperature, the initial C/N ratio, aeration, porosity, moisture content, and pH (Shafawati and Siddiquee, 2013). These parameters are regulated and controlled to provide an optimal environment for the development of microorganisms that degrade organic matter (López et al., 2015).

The composting process can be divided into three phases: the initial activation phase, a thermophilic phase, and a mesophilic or maturation phase (Chowdhury, Akratos, Vayenas, and Pavlou, 2013). Most of the degradation of organic waste occurs during the thermophilic phase. In this phase, microorganisms degrade readily available compounds in organic waste. In general, a high microbial activity translates into a high degradation of organic waste (Fourti, 2013). It is characterized by the high temperature in the composting pile due to the heat released by microbial catabolism (Singh and Kalamdhad, 2014). The high temperature reached at this stage is also crucial for pathogen reduction and disinfection. Temperatures above 55 °C are required to eliminate pathogens in organic waste (Tian et al., 2012).

The maximum temperature in the three sections of the pile was 55 °C on average, which was obtained on the 15th day of the process. In piles with a greater volume of material, the temperature could reach 70 °C during the degradation of animal manure (Tang, Yu, Liu, Xu, and Shen, 2011) and green waste (Cáceres, Coromina, Malmska, and Marfa, 2015). The end of the thermophilic phase and the beginning of the maturation phase were indicated by temperature decrease in the composting pile. As organic waste stabilizes, the temperature will continue to decrease to room temperature (Sánchez, Serramiá, Civantos, Fernández, and Roig, 2010), which also marks the depletion of the degradable organic fraction in the waste (Ravindran and Sekaran, 2010).

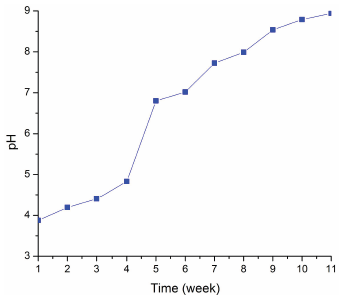

Figure 7 presents the evolution of pH in the compost pile. This parameter is an indicator of the aeration process, since, in anaerobic conditions, organic acids are produced which would cause the pH to decrease. The components present in the substrate of the tested pile determined the bioprocess that occurred, given that, when the content of lignocellulose-rich materials (cane bagasse) is predominant, the degradation process is lower in relation to the amount of organic matter and the C/N ratio obtained at the end of the process.

The composting process was performed under aerobic conditions (Figure 6). The initial pH of the employed substrate was 3,5 and, at the end of the process (11 weeks), it was 9,1. The aeration process contributed to raising the pH of the substrate, thus preventing the generation of organic acids due to the growth of anaerobic microorganisms, although ash and filter mud contributed to its alkalinization.

Table 3 presents the results obtained from the physicochemical analysis of the final product with regional composts used as a control.

Table 3 Physicochemical analysis of the compost obtained

| Variable | Unity | Filter Mud (control) | Filter mud compost (control) | Cane- Orange waste |

|---|---|---|---|---|

| Moisture | (%) | 47,565 | 44,468 | 50,067 |

| pH | 7,790 | 6,062 | 9,113 | |

| Electric conductivity | dS m-1 | 1,624 | 1,878 | 5,340 |

| Ash | (%) | 50,775 | 42,303 | 34,540 |

| Organic matter | (%) | 49,225 | 55,457 | 65,460 |

| Total carbon | (%) | 28,553 | 33,953 | 37,970 |

| Total nitrogen | (%) | 0,969 | 1,890 | 1,407 |

| C/N ratio | 33 | 18,445 | 27,517 | |

| Calcium (CaO) | (%) | 6,544 | 5,075 | 4,689 |

| Magnesium (MgO) | (%) | 0,898 | 0,696 | 0,842 |

| Sodium (Na2O) | (%) | 0,051 | 0,026 | 0,087 |

| Potassium (K2O) | (%) | 0,537 | 0,487 | 2,079 |

| Phosphorus (P2O5) | (%) | 4,713 | 2,920 | 1,786 |

| Iron (Fe) | (%) | 0,621 | 0,854 | 0,164 |

| Copper (Cu) | (%) | 0,006 | 0,028 | 0,002 |

| Zinc (Zn) | (%) | 0,026 | 0,073 | 0,010 |

| Manganese (Mn) | (%) | 0,259 | 0,285 | 0,051 |

Source: Authors

The C/N ratio indicates that there is available nitrogen, and that the organic matter present in the humus will continue to decompose once it is incorporated as a substrate for plant growth. The results obtained show that the final product has the organic matter and macro and micronutrients necessary for its use as a soil improver. However, it is advisable to take into account the mechanism of its use and agronomic and economic evaluation in plantation, perennial, vegetable, and ornamental crops, as well as to evaluate the availability of byproducts throughout the agricultural year and the production costs for their industrial scale-up in sugar mills.

The importance of the valuation of citrus residues focuses on the potential of bioeconomy with conventional and sustainable technologies and public policies applied by stakeholders. Otherwise, the environmental impact caused by these byproducts of the citrus processing agroindustry makes it necessary to search for productive alternatives to establish value chains and bioproducts through integrated technological schemes such as citrus biorefining (Satari and Karimi, 2018). The main environmental issue with processed citrus residues is their high degree of fermentation due to their carbohydrate content, which can accelerate the degradation process (Lin et al., 2013). Traditionally, processed citrus residues are incinerated or deposited in landfills. However, this is insufficient and problematic in terms of environmental impact, the energy cost to eliminate moisture content (if they are subjected to incineration), and the economic cost involved in its transport to landfills (Wei et al., 2017). Only a part of the processed waste is used as a supplement for animal feed, although it has the disadvantage of containing a low level of protein, despite its organic matter content.

This situation prevails in a significant number of countries in the Americas and Asia, so it is possible to obtain value-added derivatives of processed citrus residues which can be used as an energy source, for example, by fermentation and biodrying. In addition, bioproducts can be obtained by means of physicochemical, biotechnological, or combined treatments.

Conclusions

The incorporation of citrus and green sugarcane byproducts favors the process of conventional composting byproducts such as bagasse, filter mud, and ash, which can take more than 90 days to show signs of degradation. Considering the current situation of the country, acid soils, highly degraded by monocultures and waste burning and the technological, social, and economic conditions of citrus and sugarcane producers, as well as processing plants, composting is a viable option to valorize the byproducts obtained from these agroindustries. The pile composting method can be effectively applied, and it lasts from 3 to 4 months depending on the type of structuring agent used as bagasse and the composition of the residues. On the other hand, the final product has ideal characteristics to be used as a soil improver in the fields or to be marketed as a peat moss or compost substitute of coffee pulp and filter mud. This is because the pH (9,1), C/N ratio (27,5), organic matter (65,5%), carbon (38%) and macro- and microelements show improved characteristics in relation to the regional compost or filter mud from sugar mill, given that the product converts residues into biofertilizer for use in food production and minimizes environmental pollution.