Introduction

In the dairy chain, studies aimed at improving managerial or organizational processes are commonly carried out in the dairy, whose theoretical basis is lean six sigma (LSS). As an example, the study by Powell et al. (2017) focused on the environmental sustainability gains from the use of LSS. Foshchii and Krasnokutska (2021) conducted a study on the feasibility of adopting lean production in a Ukrainian dairy. Finally, Trubetskaya et al. (2023) used the LSS in association with the ISO 5001 standard to optimize the use and consumption of energy in the dairy processing plant. In all these studies, the positive impacts of using LSS in processing plants were observed.

LSS is regarded as the latest generation of improvement methodologies that have a global outreach (Samanta et al., 2023). It is the result of merging lean theory and six sigma theory, which sparked revolutions in administrative strategies and were the object of tireless research throughout the 20th century (Patel and Patel, 2021), and their integration was considered to be essential (Francescatto et al.. , 2023). LSS helps reduce the non-value-added activities, waste, defects, and nonconformities encountered during processes, and it addresses issues related to waste and process flow with a focus on reducing product and process variation (Patel and Patel, 2021).

Considering the flexibility of LSS, Francescatto et al. (2023) highlighted the versatility of its application in different areas, which is noted in the high number of recent articles published on the topic, with a diversity of approaches and foci. However, no field studies have been identified which are applied to dairy producers in order to improve their organizational environment - in this case rural land - using administrative tools that contribute to efficiency gains.

According to the FAO (2021), it is estimated that 895 million people worldwide (14% of the population) depend directly on dairy farming. Thus, studies that promote the improvement of management and processes are necessary because of their socioeconomic impact.

Therefore, the research question of this study is

How can the use of lean six sigma tools provide milking management efficiency in small dairy farms?

To answer this question, our study applied the concepts inherent to LSS theory in Brazilian small-scale estates via the action-research methodology. We chose small-scale dairy producers because milk production in Brazil plays an important social role, as it is typically carried out in family farms and contributes significantly to the retention of rural workers (Casali et al., 2020; Tramontini et al., 2021 ; Tonet et al., 2023). Dairy production in the country involves more than 1,5 million farmer families (IBGE, 2017), with low production scales and diverse strategies, posing challenges to the development of production systems (Bodenmüller Filho et al., 2010; Lima et al., 2023). In all Brazilian municipalities and states (Kuwahara et al., 2018), each rural property has its own characteristics, with a clear availability of resources and decision-making difficulties (Koerich et al., 2019).

Here lies the novelty and contribution of this research: it inserts a theory consolidated in other fields of the industry into this agent of the dairy chain, demonstrating that its applicability brings positive and promising results, especially with small-scale producers, who have a significant role in the economy.

Materials and methods

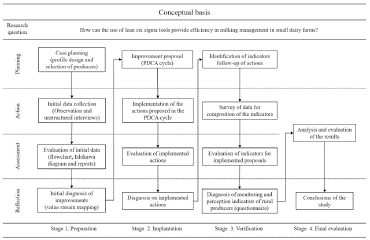

Based on the concepts proposed by Coughlan and Coghlan (2002), this framed within an action-research approach, as it solves a collective problem with the cooperation and participation of those involved, producing knowledge and solving a practical problem. The steps for conducting this research are depicted in Figure 1.

This study was carried out in four small-scale dairy farms, in the municipality of Tupã, São Paulo state, Brazil, at the coordinates 21°56' S, 50°30 W and at a 530 m altitude (Figure 2).

The main production source of the four small-scale farms (PA, PB, PC, and PD) is milk. They have been actively involved in dairy farming for at least 20 years. PA and PC are managed by women and PB and PD by men. The milk produce is collected by dairies located up to 60 km away from the estates.

The farms have a minimum of 15 dairy heads (be it in the lactation process or not) and a history of participation in training together with rural dairy programs. The farmers signed a consent form before the beginning of the research. The phases between data collection and the implementation of the actions took place between September 2018 and December 2019, with a total of 44 visits to the estates.

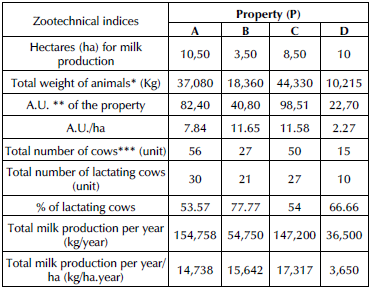

The characteristics of these small-scale producers are shown in Table 1.

Table 1 Zootechnical indices of the four dairy farmer families participating in the study

Source: Authors

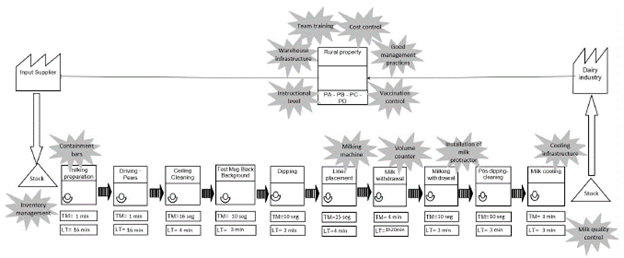

Data collection considered the status of the property and was performed through visits to the estates, using direct observation techniques and unstructured interviews to collect relevant information not available in the environment, which had value for our work and the application of lean tools, i.e., flowcharts, Ishikawa diagrams, value stream mapping, and reporting.

Based on the collected data, an analysis of the current issues with regard to the milking process was carried out, with the subsequent elaboration of a value stream mapping. From this scenario, in partnership with small-scale producers, a corrective action plan was built through the PDCA cycle.

With the planning of corrective actions and the active support of the researchers, the actions to be implemented at the time were defined, considering the situation of each producer, the financial situation of the property, and the time of execution of the action. This stage of the research took place from August to December 2019, with 18 visits to the estates.

As a final stage called post-intervention scenario, a questionnaire with ten questions (Appendix A) was applied, which identified the impact of the interventions on the efficiency of the small-scale producers' management of the milking process, which is addressed in the discussion section.

Results

1 st stage - Problem identification from the process flowchart

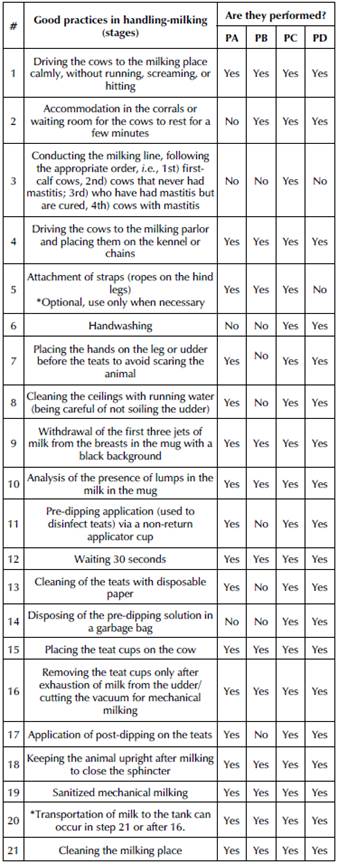

To identify the problems, the ideal flowchart based on Rosa et al. (2014) was employed. From the observation of the milking process, the steps and failures of the milking management process were determined (Table 2).

Table 2 Synthesized flowchart with the results regarding efficient management-milking practices by small-scale producers

Source: Authors

2 nd stage - Elaboration of Ishikawa diagram for problem consolidation

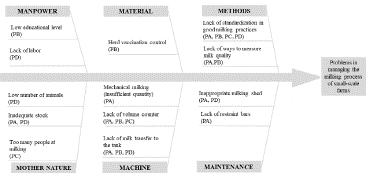

The results of the flow diagram and direct observation allowed using the Ishikawa diagram tool. The Ishikawa fishbone diagram is a tool to discover the roots of a problem and to generate ideas for improvement (Souliotis et al., 2018). The causes are associated with six possible categories, called 6M's, which are machine, manpower, methods, material, maintenance, and mother nature. These are summarized in Figure 3.

Source: Authors

Figure 3 Representation of the Ishikawa diagram for management problems in the milking process of small-scale farms

3 rd stage - Value stream mapping (VSM), highlighting points for improvement

The problems identified in the Ishikawa diagram were the subject of studies and proposals for improvement by the researchers together with the small-scale producers. To this effect, the elaboration of the VSM) allowed to visually represent the problems in the milking process (Figure 4) for the four estates. The VSM is a comprehensive tool for ensuring continuous improvement activities and yields effective results for waste elimination activities, in addition to showing value-and non-value-added tasks (Jamil et al., 2020).

Gray signs represent such problems, and, in the literature, they are described as opportunities for the organization to perform concrete or continuous improvement processes, which are called improvement explosions.

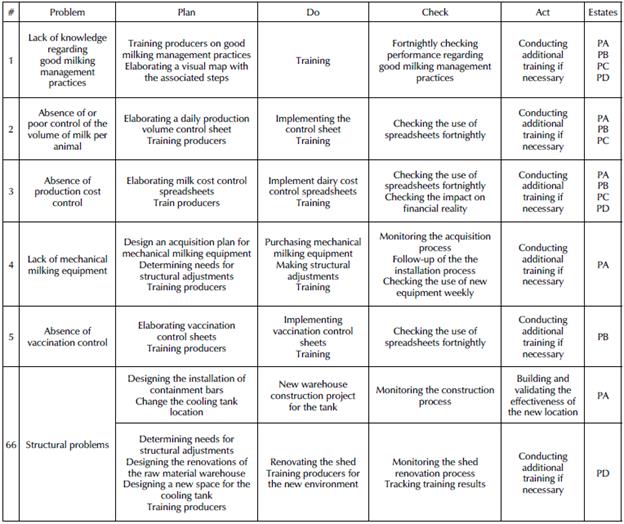

4 th stage - Preparation of the action plan through the PDCA cycle

The proposals for improvements were presented and discussed with the producers, where, out of the 13 problems previously identified, six showed a feasible solution. Constraints, including high investments, execution times, and the decision of producers meant that other issues were not the target of the study at the time. Through the PDCA cycle, actions on viable improvements were determined (Table 3). The PDCA cycle is characterized by a focus on continuous improvement regarding products and processes, through gradual changes that are carried out in four phases and drive the development of the company (Silva et al., 2017).

5 th stage - Implementing the action plan

Once the planning of measures had been performed through the PDCA cycle, the project was implemented. Each improvement is detailed in sequence.

Improvement 1 - Insufficient knowledge of efficient milking management practices

The milking process is a fundamental step for obtaining high-quality dairy products, and factors related to animal hygiene, milking equipment, and milkers lead to milk contamination (Simões et al., 2017). Furthermore, the implementation of good practices allows producers to comply with Brazilian regulations, meeting international hygiene, economic, social, and environmental requirements in favor of the productive chain (MAPA, 2018). Therefore, it was decided to initiate the improvements through training in connection with this process. To this effect, the manual of good milking management practices developed by Rosa et al. (2014) was used.

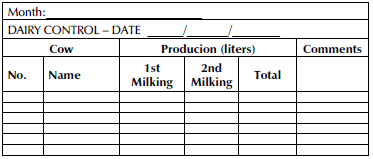

Improvement 2 - Absence of or low control of the volume of milk per animal

In this study, the absence of or low control of the volume produced per animal was mapped for three of the studied estates, which was an unclear problem and was solved by creating a control table (Appendix B).

Through the exposure of producers to difficulties in managing daily control, weekly control was employed to compare productive relationships (constant or with positive and/or negative oscillations) within milking. The need to note the number of dry cows was highlighted because it is important to periodically monitor the entry and exit of cows in this cycle.

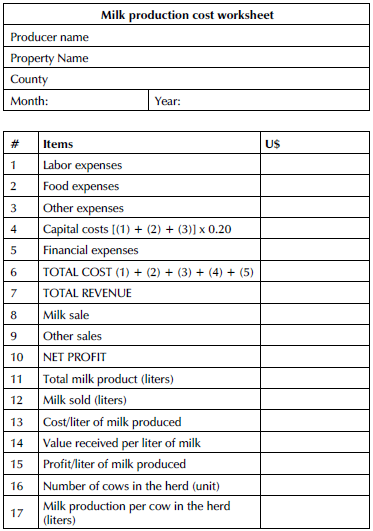

Improvement 3 - Insufficient production cost control

As a common factor in all the studied small-scale dairy farms, insufficient knowledge of the production costs and profit margins has become a deficiency and a recurring problem for dairy farming in Brazil, as highlighted by the 2018 IFCN study. This creates problems in terms of the competitiveness of the Brazilian milk market.

Supported by a technical worksheet, i.e., a table for calculating the cost of milk production in Embrapa's family farming (Appendix C) elaborated by Tupy et al. (2002), as well as by the collection of information from the small-scale producers, the production costs and the profitability of milk culture were measured.

Improvement 4 - Insufficient equipment for mechanical milking

One of the dairy farms (PA) had a problem with the agility of milk extraction due to the high number of animals and the idleness of professionals during the period of milk extraction. Thus, the need to acquire mechanized milking and improve the milking environment was identified. Mechanized milking was budgeted, and a purchase for U$ 550,001 was carried out.

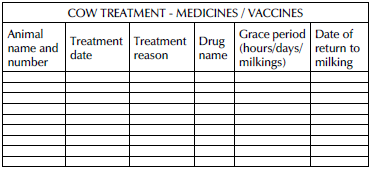

Improvement 5 - Absence of vaccination control

The inappropriate use of drugs to control diseases is a problem that affects dairy farmers in various locations, and it has been the subject of studies from different perspectives (Sabapara et al., 2012; Krömker and Leimbach, 2017; Madkar et al. 2020). The high cost of veterinary drugs, the inadequate knowledge of the disease and its control, and the unavailability of veterinarians (Madkar et al., 2020) are reasons that sometimes lead small-scale dairy producers to apply uncontrolled medication to their animals.

A vaccination and medication control spreadsheet (Appendix D) and the training of small-scale producers on its correct use were the methods used to solve this problem, which, although simple, have a significant impact on the dairy culture.

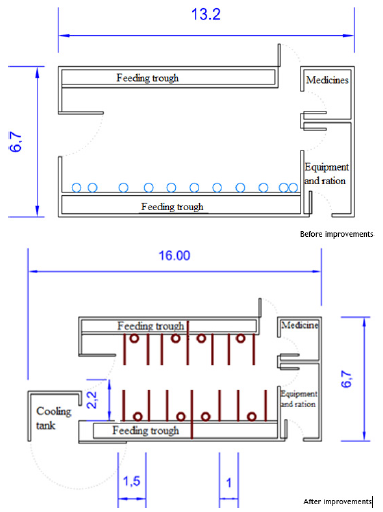

Improvement 6 - Infrastructure issues

The inadequate structural aspects of the PA's milking shed led to small improvements (known as kaizens in lean thinking), given the absence of containment bars in the milking environment and long-distance restrictions to be covered in order to dump the milk next to the cooling tank, which could result in sanitary and logistical losses for the producer. For this producer, the adaptation of the cooling tank had several advantages, as a milking system was also installed (improvement 4). The study of the producer's milking area entailed structural adjustments (Figure 5), including the construction of containment bars and an attached area for the installation of the cooling tank.

PD needed major changes (called kaikaku improvements) to meet the requirements of the legislation in terms of the storage of raw material and the transfer of milk from the collection point to the cooler, as well as the general conservation of its infrastructure. To this effect, some improvements were proposed, including the establishment of a large and increased space for the storage of feed and other related equipment, the creation of a separate environment close to the milking environment to house the cooling tank, and the organization of tools and medicines associated with milk culture (5S technique). Such improvements were budgeted at U$ 5 000,00 and carried out by a contractor.

Discussion

According to FAO and IFD (2013), milk production systems worldwide must combine profitability with the responsibility to protect human and animal health and well-being, the environment, and productive and economic relationships. Milk producers, as the primary producers in the supply chain, must have the opportunity to add value to milk by adopting methods that meet the sanitary demands of the government, processing industries, and consumers (FAO and IDF, 2013). As shown in this study, these requirements can be fulfilled through lean production and its associated tools, which provide added value to the milk product. In this regard, Satolo et al. (2017) stressed that, in an agro-industrial production environment, as in other productive sectors, lean production tools should be selected according to organizational needs.

This study focused on the milking process. The use of the steps in the Guide to Good Milking Management Practices (Rosa et al., 2014) for the detection of problems and the subsequent training of small producers yielded positive results from the perspective of the latter. For these producers, the flowchart and the Ishikawa diagram allowed for a correct analysis of the milking process and the identification of improvements since, according to producer A, "among many identified problems, mainly structural ones are consistent with reality," which confirms producer C's point of view: "yes, these problems are faithfully consistent with our daily lives".

Simões et al. (2015) argued that the use of best management practices reduces the presence of microorganisms, improves the health of animals' mammary glands, and, in conjunction with good processing practices, leads to a better nutritional quality for consumers, reducing the risks associated with raw milk and its products (Fagnani et al., 2021), which, for Züge (2015), ensurs that ownership will continue or become viable under the economic, social, and environmental triad.

Good results were obtained regarding the control of the volume of milk per animal (improvement 2), which is necessary for a productive dairy culture, especially for small-scale producers. Over time, the use of production data becomes an important means for decision-making. The generated data can be used in predictions, automated decisions, models trained from data, or any type of data visualization that provides insights (Bichler et al., 2017).

For dairy producers, controlling the volume of milk per animal allows estimating the future production, and, by setting the correct concentrate volume, over- or underfeeding is avoided, thus meeting the animal's needs, which results in a better production efficiency and reduced feed costs.

Knowing the volume of milk produced can also favor the reproduction of individuals with greater productive potential, helping genetically improve the herd and discarding the less productive animals.

In this regard, which underscores the importance of data control and knowledge, Vicario and Coleman (2020) stated that, if companies cannot manage and process the data to their advantage, they will be outperformed by competitors.

In the same context, improvement 3 was applied, which deals with cost control.

The cost control table was implemented in 50% of the producers, as the other participants declared they had it under control. The knowledge of the expenses and income of a company is the basis for its economic sustainability (Nifä and Stefea, 2014), and it is no different for a small rural enterprise. In this way, the knowledge acquired from improvement 3 allows producers to measure the technical-economic performance of their production in the future, as well as to diagnose the cost of the dietary supplementation method and compare the costs of other dairy producers.

For the small-scale producers participating in this study, the calculated cost of milk production identified an average profit margin of USD 0,044 per liter, a value of USD 0,025 compared to national studies (IEA, 2018), and USD 0,074 compared to international studies (IFCN, 2018).

In addition, detailing the production expenses allows planning for future improvement actions. The costs related to cattle feed are worth noting, which were 67,5%, a rate higher than that identified by Gabler et al. (2000) (60%).

This point confirms the studies by Lopes and Lopes (1999), which, two decades ago, underlined the importance of electronic tables or field notebooks as an essential means of controlling financial costs, given that they facilitate the grouping of expenditure and help milk quality extension teams and producers to make future decisions (Paixão et al., 2017).

The use of control sheets also brought benefits along with improvement 5, by allowing an effective management in controlling the vaccination of cattle. Vaccination is the most efficient and cost-effective strategy for preventing the appearance of clinical cases in herds (Groenendaal et al., 2015), and it may or may not be mandatory. For producers, these measures should be regarded as a form of investment, as the incidence of diseases sometimes causes economic losses greater than prevention (Grunitzky et al., 2020) and can compromise their production. Van Schaik et al. (1996) indicated that vaccination, in addition to the improvement of the clinical signs of dairy cattle, brought financial benefits 9,5 times higher than the cost of vaccination. Management procedures for the vaccination of dairy cattle, in turn, must be done safely and without causing stress or suffering to the animals; the lack of knowledge and information, according to Madkar et al. (2020), can affect the growth, production, and reproduction performance of dairy animals, as well as the milk quality.

Improvements in physical facilities and equipment took place in two phases of the study. In improvement 4, mechanical milking was installed. According to Hansen and Strte (2020), milking systems have gained popularity in medium-sized or family-owned dairy farms, as they allow for flexible working hours, in addition to improving production efficiency and increasing business sustainability. Paliy (2017) highlighted that mechanical milking contributes to the efficiency of the milking process through conditional stimulation and the unconditional reflexes of dairy cows, contributing to improving the yield per animal per hour of production according to Hogeveen and Ouweltjes (2003).

As for improvement 6, changes were made to the infrastructure of the milking shed, which has a direct impact on animal welfare. It is noteworthy that improvements in infrastructure do not lead to high investment. Sometimes, with low investments, important issues are addressed, providing efficiency to the production process. According to Grunitzky et al. (2020), concerns about the use of rational management in production systems have been neglected for a long time, and this has happened in in Brazil. However, this aspect should be put in a prominent position due to the growing consumer demand for quality products that come from systems that value animals' quality of life. The arrangement of facilities in a dairy farm, especially within the milking parlor, has a direct impact on the production, on animal welfare, and on the longevity of animals within the production process.

Finally, it is noteworthy that the improvements have resulted in positive returns for small-scale producers, namely improved milk quality, which has led to a USD 0,06 increase in the amount paid to PC. Furthermore, the producers involved have reported that improvements are necessary to maintain the dairy activity in the estates, and that "the learning relationship with the university is important to us, although there is an exchange relationship, the product always wins with your support on this scale" (PC). At this point, it is possible to observe the producers' awareness of the importance of science, and that proximity to the university promotes the advancement of culture.

Conclusion

The use of LSS tools has proved to be extremely valuable in identifying problems and proposing and implementing improvements in milking management by small-scale dairy farms. In this study, the implementation of improvements generated gains for producers in different aspects: (i) management: the implementation of control spreadsheets allowed the producers to be aware of their dairy farm and make decisions, highlighting actions related to feed costs; (ii) the milking environment: structural improvements and the installation of equipment provided quality to animal welfare while also allowing rural producers to carry out their daily activities; and (iii) financial, i.e.. the improvement in the price paid per liter of milk delivered. The implementation of improvements associated with the return of producers showed that, through interdisciplinarity, i.e., the interconnection of different areas of knowledge, positive solutions to different types of problems can be achieved. Thus, this article creates a legacy for the milk production chain, with a study that can be replicated in different Brazilian and world realities, revealing a means of implementing a solution to problems that affect the main process of obtaining raw milk.