1. Introduction

A big challenge for pavement researchers is to carry out accelerated pavement tests for predicting field performance. These tests help to reduce the uncertainty between design models and analysis techniques that otherwise could only be verified under normal traffic and aging in real time 1. Despite the current popularity of accelerated pavement testing, most studies have focused on mechanical materials response instead of aging effects, although it is an important distress, besides traffic loads, affecting the surface of asphalt pavements and causing a reduction of durability.

Asphalt aging is generally classified as either short or long-term 2)(3)(4)(5. While the former refers to the oxidation and volatilization of the asphalt binder during factory-based fabrication (including storage) and road construction (extension and compaction or laying), the latter is the result of in situ oxidation and hardening of the asphalt binder throughout its service life as pavement.

Aged asphalt cement (AC) generates lower adhesion between the mineral aggregates and the binder (furthering the probability of stripping) and changes in the ductile and fragile behavior of the binder and asphalt mixture (including higher levels of rigidity and viscosity). On some occasions, light AC aging turns out to be desirable on account of the associated increase in rigidity 6. However, this “desirable” aging only applies in cases where aging does not lead to changes in the material’s ductility and fragility under minimal loads. In accordance with 7, the premature failure of asphalt pavements is often attributable to the weak adhesion between the binder and the aggregate particles, due to moisture action, mechanical stress and asphalt aging.

Though aging modifies the asphalt’s characteristics and usually witnesses hardening, AC oxidation has been considered to be the primary cause of hardening and embrittlement (fragility) 8)(9. Excessive hardening frequently results in embrittlement and cracking of the pavement’s asphalt layer, particularly when service life entails exposure to low temperatures 8)(10)(11. In short, the rate of hardening is affected by the asphalt’s chemical composition, light exposure, aggregate properties and environmental conditions (i.e. temperature and humidity) 12)(13)(14)(15.

The first technical study of asphalt aging was carried out in 1903 16. Since then, numerous researchers have studied the influence of this phenomenon on the physical, chemical, mechanical and rheological properties of AC and asphalt mixtures (AM). Laboratory and in situ based studies are more recent 2)(13)(14)(15)(17)(18)(19 and have been mainly focused on durability. However, on a global scale, most of the research on the aging phenomenon has been centered on AC, while there are less studies on asphalt mixtures (AM). Moreover, AC aging studies have been mainly on design procedures while AM aging studies have characterized performance along service life.

Studies on aging can be divided into four categories: a) heating; b) oxidation; c) light-based treatments; and, d) steric hardening. Heating entails subjecting the AC to high-temperature treatments; oxidation tests are performed with high temperatures and high oxidation pressures. For light-based aging, samples are directly exposed to Ultra Violet (UV) or infrared light treatments. Steric hardening refers to asphalt hardening at room temperatures as time elapses 20. Additionally, the most common methods of evaluating AC’s resistance to short (RTOFT) and long-term (PAV) aging are the Rolling Thin Film Oven Test (RTOFT) and the Pressure Aging Vessel (PAV) 21)(22. The aforementioned tests have been used as a material performance characterization in Superpave® method. Other tests, like the “Rolling Microfilm Oven Test” and the “Tilt Oven Durability Test”, have also been employed to test short-term aging. For long-term aging, the “Rotating Cylinder Ageing Test” (RCAT), the “Iowa Durability Test”, the “SHRP-PAV” and the “HiPAT” also appear in the pertinent scientific literature.

About AM aging, temperature treatments like Short Term Aging Oven (STOA) and Long Term Aging Oven (LTOA) according to SHRP -003A have been used to simulate aging phenomena 17. However, evaluation of mechanical properties after laboratory treatments compared to field samples was not the same for all asphalts and asphalt-aggregate combinations 6)(23)(24)(25. Even more, aging did not always produce detrimental effects on AM 24. Additionally, a low-pressure oxidation treatment over AM is an alternative to high temperature aging and has proved to be more appropriate for open-graded mixtures or those with soft grades of asphalt 26.

Based on the above, and considering on one hand the scarcity of literature about accelerated aging of mixtures, and on the other hand, AM’s performance in real life is affected simultaneously by temperature, pressure, humidity and radiation. So, the present study aims to recreate in laboratory environmental conditions for aging AM in order to evaluate the performance to dynamic modulus, permanent deformation and fatigue life. Furthermore, to compare these results with pavement of several years of service extracted from the field.

2. Methodology

2.1. Material Characterization

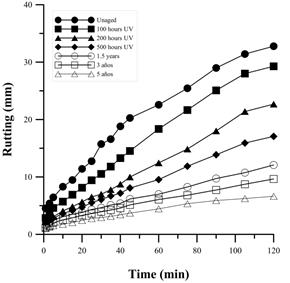

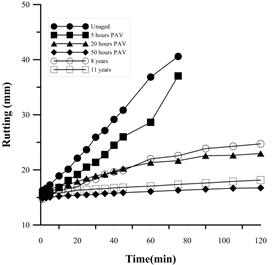

Asphalt cement 80-100, with a penetration range of 1/10 mm (ASTM D-5), was used to make the mixtures. This AC 80-100 was produced by the Colombian Petroleum company ECOPETROL S.A. in the Barrancabermeja (Colombia) factory. The performance grade (PG) of the AC 80-100 is 58-22, which is suitable for use in areas with annual average temperatures below 24°C. Table 1 presents the results of the AC physical characterization. The mineral aggregates used to produce the asphalt mixtures were extracted from the Coello River in the department of Tolima, Colombia. Table 2 shows the physical characterization of the aggregates.

2.2. Asphalt mixture design

Materials used in this study fulfill the requirements set forth by the National Institution of Highways in Colombia (INVIAS by its Spanish acronym) 27. The aggregate’s original granulometry was adjusted to meet the specifications for the production of dense hot mix asphalt with nominal aggregate size of 19 mm called MDC-19 (Table 3). Once aggregate and the asphalt binder was verified AM design was developed according to the Superpave mix design method laid out by the Standard Highway Research Program (SHRP-A-379, 1994), the optimal percentage of AC was determined to be 5.8%.

This type of mixture is the most commonly utilized in Colombia for the surface layers of pavement, which is directly exposed to the environmental factors. Laboratory samples were produced with the same characteristics than field samples. Moreover, materials used for in situ and laboratory-produced pavements were provided by the same asphalt mixture supplier company. Therefore, we were able to guarantee that the mixtures corresponded. Likewise, as transit loads were not taken into consideration, field samples were extracted from parking lot confinement curbs and bicycle paths.

2.3. Experimental stage

Two types of asphalt mixtures samples, slabs and cylinders, were manufactured in the laboratory. Eight slabs of 30 * 30 * 5 cm asphalt mixture were used to perform rutting, four slabs of 30 * 50 * 3 cm to fatigue testing and 30 cylinders 10 cm in diameter and 20 cm thick to develop dynamic modulus test. Slabs were compacted in a Universal Load machine with 600kPa during eight minutes and cylinders were compacted with two different air voids content, 4% and 10% in a gyratory compactor. Five trapezoidal samples for fatigue test were cut from each of the fatigue testing slabs. On the other hand, six slabs were extracted from in-service pavement, three of them for rutting evaluation and the other three for fatigue tests.

2.4. Aging treatments

Four set of samples were used for the aging experiments. The First set corresponded to unaged AM, defined as the control sample. The second set were laboratory - made samples aged in an UV chamber for periods of 100, 200 and 500 hours. Third set corresponded to AM laboratory-made of previously aged asphalt cement by PAV, following ASTM D-6521, for periods of 5, 20, and 50 hours. The fourth set of samples were those extracted from field after 1.5, 3, 5, 8 and 11 years of construction.

2.5. Aging chamber

For the purposes of this study, an UV chamber capable of simulating controlled environmental conditions such as UV radiation, temperature and relative humidity of 99% was constructed. This chamber has eight lamps that emit radiation in a wavelength of 340nm in the UVA range-equivalent to 0.77 W/m2/nm. The chamber employs cycles combining radiation period followed by a condensation one. The former consists in a two hour period in which UV lamps are turned on. During this period, the temperature increases up to 60°C while the UV light affects the samples. Then, it follows a two hour period when the lamps are turned off, the temperature decreases until 50°C and the sample does not receive the UV radiation.

Sample exposure times for this study were between 0 and 500 hours (250 cycles). The 340nm wavelength reflects Bogota’s (Colombia) daily value of 2.2Wh/m2 (28. Hence, daily UVA radiation corresponded to 8.8 KJ/m2 while annual value was 3.2 MJ/m2. As the aging chamber relies on a radiation value of 1.55W/m2 for each cycle (ASTM G 154-06), 500 hours of UV radiation was considered to be similar to UV conditions in Bogota (Colombia) over the course of a year.

By alternating between the two phases in the chamber, it was possible to simulate the actual exposure faced by the material in the field 29, as during the day the material is subjected to UVA exposure (lamps turned on) while the night would be considered as a “rest” period (lamps turned off), which determine the physicochemical changes undergone by the material. Moreover, to undergone that only the top side of the samples in the laboratory were UV irradiated, as occurs in field conditions, we made sure each cylinder’s shafts and each slab’s edges were isolated with flexible polycarbonate.

2.6. Performance evaluation

Unaged, UV and PAV aged, and field samples were evaluated with three dynamic tests: dynamic modulus, resistance to permanent deformation and trapezoidal fatigue. In the case of the dynamic modulus, the axial sinusoidal load method proposed by ASTM D 3497-03 was used. For these purposes, measurements were done at temperatures of 5, 25 and 40 °C and at frequencies of 1, 4 and 16 Hz. Master curves for these samples were adjusted at 25 °C, using CAM model 30.

Rutting tests were based on the French standard NLT 173 - 84, for which four slabs from UV and four from PAV were arranged in a chamber at 60 °C one at a time. A weighted wheel was passed over the slab surface at a normalized contact pressure of 900 ± 25 kN/m² (9 ± 0.25 kgf/cm²). Fatigue resistance tests were carried out based on the Central Laboratory of Bridges and Roads (LCPC according to its French acronym) method, which is a strain-controlled test and entails the application of sinusoidal load to trapezoidal samples supported at each extreme. Field slabs of 1.5, 3 and 5 years were used to evaluate rutting while 8 and 11 year slabs were used to valuate fatigue life.

3. Results and discussion

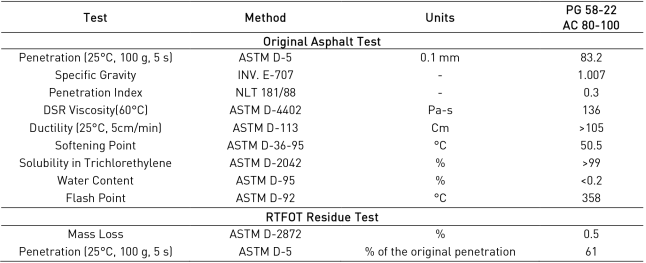

Asphalt mixtures exhibited enhanced resistance to permanent deformation when exposing time in the UV chamber increased (Figure 1). After 100, 200 and 500 hours in the UV chamber, the mixtures displayed lower levels of permanent deformation when compared to unaged samples (10.7, 30.8 and 47.9%, respectively). Similarly, the field mixture experienced an increase in rutting resistance with higher environmental exposure. For 1.5, 3 and 5 years of exposure, permanent deformation was even smaller (63.1%, 70.6 % and 79.8%, respectively), probably due to the increased rigidity. By virtue of regression analyses, it can be stated that 750, 900 and 1250 hours of exposure in the UV chamber would be an approximately represent aging undergone by material in situ at 1.5, 3 and 5 years, respectively.

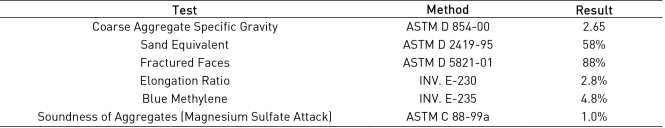

Data for the 20- and 50-hour PAV aging periods proved to be quite close to that observed for 8 and 11 years of field aging, respectively as shown in Figure 2.

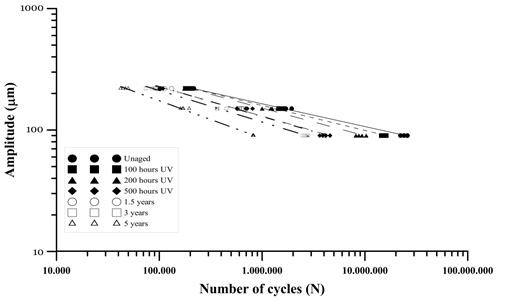

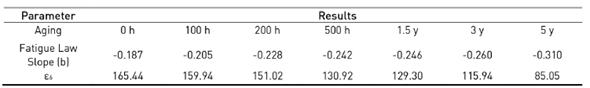

The fatigue life of AM diminished as sample age increased (see Figure 3). This phenomenon can be due to samples reduced their resistance as stiffness increased which has been widely reported in the literature 31)(32)(33)(34. Moreover, fatigue tests for mixtures aged for 500 hours in the UV chamber displayed fatigue life and resistance close to that displayed by the 1.5 years in situ. Hence, 700 and 1075 hours of exposure in the UV chamber represented 3 and 5 years of in situ aging, respectively.

A tendency towards growth in the fatigue law’s slope was observed (Table 4). We found that aging increased fatigue law's slope 1.3, 1.4 and 1.7 for 1.5, 3 and 5 years from the control mixture, respectively. Additionally, it seems that b and ε 6 for 500h UV treatment is quite close to 1.5 years in the field (Table 4). Thus, environmental aging and UV radiation in laboratory can be considered as a good predictor of fatigue life.

Table 4 Fatigue law’s slope (b) and deformation at a million load cycles (ε 6 ) for the MDC-19 mixtures evaluated at different stages of aging in the UV chamber and in the field

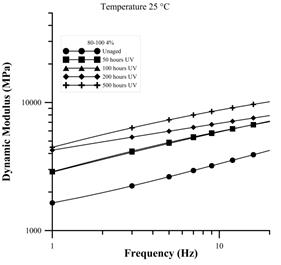

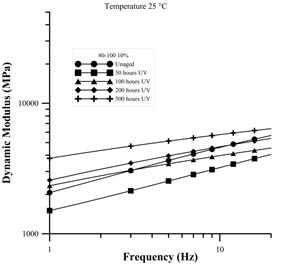

In the case of the dynamic moduli, their growth correlates to higher exposure time (Figures 4 and 5). For all AM, higher complex modulus was observed as aging time increased, independently of air void content However, after 100 hours of UV treatment, the “open” mixtures modulus (10% voids) declined, probably due to the softening caused by the reaction among AC fractions and UV radiation. As UV radiation possesses enough energy to break up the AC molecular bonds, the aging process affects the SARA fractions. The molecular break up due to the UV radiation transforms the SARA fractions and varies their proportions, as asphaltenes and resins increase. The higher proportion of resins means that asphalts become more ductile and, as a result, the material softens 12.

Whereas under 500 hours of UV aging mixtures with 4% air void content increased their stiffness up to 2.8 times of their initial modulus at 10 Hz and 25 degrees Celsius, the modulus’ index of mixtures with 10% air void content increased 1.3 times more than its initial one in spite of being under the same frequency and temperature treatment. Similar results were reported by 24)(35; however, these studies only reported twofold increases on dense asphalt mixtures.

Researchers have been developed important studies regarding performance of aged asphalts and asphalt mixtures. Regarding asphalt mixtures, few studies have considered Long Term Aging and they have only assessed from 1 to 10 days of aging temperature treatments 24)(35)(36. In contrast, this study analyzed up to 100, 200 and 500 hours which corresponded to 4, 8 and 20 days of treatments. In addition, scarce literature has been found on accelerated aging of mixtures; thus, this research contributes to this type of testing. Moreover, this research has made important efforts in the manufacturing and sample extraction. Finally, the UV chamber was a valuable asset as it allowed to combine all variables simultaneously, imitating real conditions.

4. Conclusions

This wide-ranging experimental research on the influence of UV chamber aging on the performance of asphalt mixtures commonly used in Colombian pavements, with performance measured in terms of dynamic moduli, permanent deformation and trapezoidal fatigue provided evidence on the role played by environmental factors on the asphalt mixture’s physical characteristics.

This study demonstrated that aging is not a negligible effect, as environmental variables exhibited an important effect on aging of asphalt mixtures that were not subjected to traffic loads. In that way, environmental aging and UV radiation reduced the fatigue life of asphalt mixtures. The fatigue law’s slope was reduced up to 33% in the first 18 months of service life, and up to 42% during the first five years. Also, permanent deformation was reduced with service life. This reduction can reach 80% within a period of five years.

When neat asphalt was aged in the PAV, performance proved to be the same as SHRP. Thus, 20 hours of PAV aging reflected 8 years of service life approximately. However, the PAV test did not sufficiently resemble local environmental conditions to merit recognition as an indicator of aging in asphalt mixtures.

The UV chamber built for this project enabled the recreation of the effects of aging faced by asphalt mixtures in the field-especially throughout the early stages of aging-and allowed parallels to be drawn between UV chamber exposure time and field exposure time. It is necessary to mention that this is one of the first approach reported to analyze behavior of asphalt mixtures under effects of combined external agents like temperature, ultraviolet radiation and moisture in controlled conditions.

5. Acknowledgments

The authors would like to thank the Pontificia Universidad Javeriana for its support of this project (Project 4686). The authors would also like to acknowledge the valuable contributions of Concrescol S.A., the source of the materials used. Last but not least, the authors are grateful to Joseph Wager and Angela Parrado for their help in matters of English syntax.