Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Agronomía Colombiana

versão impressa ISSN 0120-9965

Agron. colomb. v.29 n.3 Bogotá set./dez. 2011

CROP PHYSIOLOGY

Effect of aluminized screens on greenhouse tomato (Solanum lycopersicum L.) production systems at the high tropical conditions

Efecto del uso de pantallas aluminizadas sobre la producción de tomate (Solanum lycopersicum L.) bajo invernadero en el trópico alto andino

Rodrigo Gil1,3, Nadia Yurani Luque2 and Carlos Ricardo Bojacá1

1Department of Basic Sciences, Faculty of Naturals Sciences and Engineering, Universidad de Bogotá Jorge Tadeo Lozano. Bogota (Colombia).2Center for Bio-Systems, Faculty of Sciences Naturales and Engineering, Universidad de Bogotá Jorge Tadeo Lozano. Chía (Colombia).

3Corresponding author. rodrigo.gil@utadeo.edu.co Received for publication: 12 March, 2010. Accepted for publication: 2 November, 2011.

ABSTRACT

Currently, Colombia has 3,390 ha cultivated with tomato under greenhouse conditions characterized by their low level of climate control. In areas where low night temperatures limit tomato production, we evaluated the effect of aluminized screensm-2 on the production of the crop. This work was conducted in two greenhouses planted with tomato in Susa and Chía (Cundinamarca). Each greenhouse was divided in two sections, one half covered with the screen and the other not. Screens at both locations were closed between 5:00 pm and 6:00 am. Inside each greenhouse section, temperature (T, °C) and relative humidity (HR, %) were recorded during the production cycle, as well as the external climate conditions. The effect of aluminized screens on tomato production was compared against the simulation output of the tomato potential growth model "Tomgro". In both locations the covered section with the screen yielded the highest temperatures during the night. At Chia, the night temperature increase due to the screen effect was 1.5±0.10°C, while in Susa the temperature increase was 1.1±0.1°C. Recorded yield under the screened sections showed increments of 6.6% (Chia) and 3.3% (Susa). Simulation results suggest that yield increments of about 15.7 and 13.6% are achievable under potential conditions in Chia and Susa, respectively. The use of thermal screens during night hours helps to retain heat, which in turn is reflected in production increments.

Key words: climate control, Tomgro, heat loss, protected horticulture, night temperature.

RESUMEN

Actualmente en Colombia se siembran aproximadamente 3.390 ha de tomate dentro de invernaderos caracterizados por un bajo nivel de control de clima. En zonas donde las bajas temperaturas nocturnas limitan la producción de tomate, el uso de pantallas térmicas puede ser una alternativa orientada a mejorar las condiciones de producción del cultivo. El trabajo se realizó en dos invernaderos ubicados en Chía y Susa (Cundinamarca). Cada invernadero fue dividido en dos secciones, una de las cuales se cubrió con una pantalla aluminizada. En ambas localidades las pantallas se extendieron sobre el área de cultivo durante las horas de la noche (5:00 pm - 6:00 am). En cada sección de invernadero y durante un ciclo de cultivo se registraron la temperatura (T, °C) y la humedad relativa (HR, %) de forma permanente al igual que las condiciones climáticas externas. El efecto de las pantallas térmicas en campo sobre la producción de tomate se comparó con los resultados de simulaciones realizadas por el modelo potencial de crecimiento del tomate "Tomgro". En ambas localidades la sección con pantalla registró las temperaturas más altas durante la noche. En Chía, el aumento de temperatura nocturna por efecto de la pantalla fue de 1,5±0,1°C mientras que en Susa el aumento fue de 1,1±0,1°C. Los registros de producción indicaron incrementos del 6,6% (Chía) y 3,3% (Susa) con el uso de la pantalla. Los resultados del Tomgro sugieren la posibilidad de alcanzar incrementos en la producción potencial de hasta 15,7 y 13,6% debida al uso de pantallas en las localidades Chía y Susa, respectivamente. El uso de pantallas térmicas en las horas de la noche logra retener el calor dentro del invernadero, lo cual se ve reflejado en un incremento de la producción.

Palabras clave: control climático, Tomgro, pérdida de calor, horticultura protegida, temperatura nocturna.

Introduction

In Colombia, the area cultivated with tomato (Solanum lycopersicum L.) under greenhouse conditions has increased for the last two decades. According to Cooman (2002), from 10 ha cultivated in 1996 the area under greenhouse conditions has expanded to around 200 ha in 2002. Currently this activity takes place in an area of approximately 3,390 ha (Miranda et al., 2009). Greenhouse tomato cropping has boosted production levels and helped reducing the risks related to phytosanitary problems while generating higher economic returns for growers (Cooman, 2002). In marginal areas for tomato production, the use of greenhouses has made possible the establishment of crops due to the improvements obtained in climatic conditions (Bojacá, 2009).

The features of the greenhouses used for growing tomatoes are similar to those of the structures used for the ornamental production. One important aspect is that these local greenhouses require a low investment compared to those used in other regions (Cooman, 2002). The main reason for this feature is that the local greenhouses generally, do not have active climate control systems. This restriction to control the environmental variables, contrasts with the objectives of protected agriculture, in which one of the principles is to increase the control of biological processes (Cooman, 2002). One major problem in some greenhouse tomato production areas in Colombia is the low temperatures during the night hours.

Tomato is cultivated in these areas with environmental constraints due to factors such as: proximity to market centers (e.g., Bogota) and the high pressure of pests and diseases that it is subjected to cultivation in lower regions (Rodríguez and Cardona, 2001). Firstly, these low temperatures are due to external weather conditions that occur during the night. Secondly, the limited ability of greenhouses to store the heat gained during the day resulting in its rapid loss to the atmosphere (Teitel et al., 2009). These low temperatures limit crop potential production by affecting the development rate of many biological processes (Trudgill et al., 2005).

One of the main tools to retain the radiation captured in the day during the night hours and to reach more appropriate temperatures for the crop inside the greenhouse is the use of mobile thermal screens. The thermal screens are netting of filaments made from aluminum or acrylic sheets and plastic polymers. The thermal screens are used to reduce the loss of energy through long wave radiation conduction and convection during the night (Papadopoulos and Hao, 1997). This type of screens causes an increase in the minimum nighttime temperatures of the greenhouse, the crop and the soil. In developed countries, research related to the use of these screens indicated that when used during the night in order to reduce heat losses it was possible to obtain heating savings between 21 and 33% (Bailey, 1988). Recently, research related to such screens have become important mainly due to the increments in fuel costs in temperate zones, where it is necessary the use of heating systems at night (Teitel et al., 2009). The magnitude of energy savings varies considerably when comparing the results of different studies. Teitel et al. (2009) report an energy savings of around 40% with the use of aluminized screens, because of the lower heating demand during the night. On the other hand, Kittas et al. (2003), studying the influence of an aluminized thermal screen on the energy balance and microclimate in greenhouses, found that energy savings with an aluminized screen (65% shading) was only 15%.

Besides the discrepancies in the magnitude of energy savings, Okada (1985) indicates the existence of another problem in the evaluation of thermal screens; that the assessments have been done using heat balance models. These models are based on assumptions such as constant thermal state, absence of latent heat flux, no air infiltration and no presence of crops in the greenhouse. An alternative for assessing the effectiveness of the screens is the application of models to consider its effect on the development and production of the crop. Based on the foregoing, the present work used the second version of the tomato crop growth model "Tomgro" (Bertin, 1993; Gary et al., 1995, 1996), which was calibrated for the high Andes tropical conditions by Cooman (2002). Tomgro describes the phenological development and dry matter accumulation in different plant organs from the time of transplanting until the end of the growing season. Cooman and Schrevens (2007) analyzed the effect of variations in air temperature, carbon dioxide concentrations and the intensity of radiation on the sensitivity of this model. As a result of this work, the authors concluded that the temperature is the most significant variable that affects the total leaf area, the weight of vegetative organs and the dry weight of the fruit. These results were in agreement with other studies that have also shown that temperature is the main variable that determines the crop development rate (Zhao et al., 2001).

Based on the foregoing, the present study was undertaken to determine the effect using thermal screens on greenhouse tomato production in tropic highlands areas with low night temperatures. It also examines the feasibility of using crop growth models to determine the potential effect of thermal screens.

Material and methods

Study zone

The present work was carried out in two municipalities: Chia (04°53'03.29'' N and 74°00'48.96'' W) and Susa (5°27'12.88'' N and 73°48'10.98'' W), both located in the department of Cundinamarca. Chia is placed at an average altitude of 2,650 m a.s.l., with an average temperature of 13.4°C and an average global radiation of 12.3 MJ m-2 d-1 (Bojacá, 2009). In Chia, the study was conducted within a greenhouse of 3 spans, each one of 6.8 m wide and 55 m long (total area of 1,122 m2). This greenhouse had vents on all sides (170 m2) operated through moveable curtains and permanent ventilation through an open fixed ridge on each span (100 m2). The minimum height of the greenhouse under the gutter was 3 m and the maximum was 6 m.

Susa is located at an altitude of 2,549 m a.s.l., the mean temperature is 15°C and the average global radiation is 13.1 MJ m-2 d-1 (Bojacá, 2009). In Susa, the study was conducted in a two span greenhouse, each span measuring 7 m wide and 75 m long (1,050 m2). The greenhouse was ventilated by means of plastic windows in all sides with a maximum area of 125 m2 ventilation, while the permanent open fixed ridge ventilation was 30 m2. The minimum height of the greenhouse under the gutter was 3 m and the maximum was 4 m.

Both areas are considered marginal to tomato production because average temperatures are below the optimal for growing tomatoes (18-22°C). Additionally, low night temperatures (<10°C) can potentially cause pollination problems and fruit setting (Maisonneuve and Philouze, 1982). Installation and operation of thermal screens At each location, a thermal screen type Alumitex® (Tesicol S.A., Bogota) with 65% shading was evaluated. The screens were made of high-density polyethylene with additives to increase resistance to ultraviolet rays damage and an aluminum layer.

Each greenhouse was split transversely into two sections of equal area by a plastic wall. In one of the sections, the thermal screen was installed at a height of 3 m above ground covering the entire cropping area. At both locations, the section with the screen was opened and closed manually through a system of pulleys, without making structural changes to the greenhouse. The screens were closed at 5:00 pm and opened at 6:00 am; this procedure was performed during the whole production cycle.

Crop management

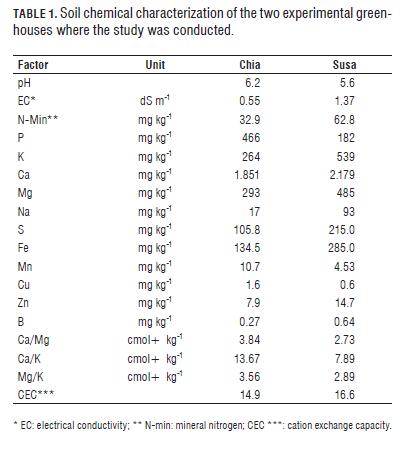

In Chia, the length of the cultivation cycle was 232 d (30/12/2008 to 19/08/2009) using the cultivar Sheila® (Sakata, Japan). In Susa the cultivar Rocio® (Rogers/Syngenta, USA) was planted and the cultivation cycle had a duration of 190 d (29/12/2008 to 07/07/2009). Fertilization in both locations was done based on the results of the soil chemical analysis. The results of these analyses are shown in Tab.1. At both locations it was used a typical planting density for the study area: 2,7 plants/m. Transplant was carried out when the plants showed an average of 10 nodes. At both locations the plants were managed with a single stem by removing all lateral shoots. The fruit pruning scheme was as follows: the first four clusters were pruned to six fruits, the next four were pruned to five fruits and after the eight cluster only three fruits were left per cluster. The crop management was carried out following the recommendations made by Escobar and Lee (2010).

Data acquisition

During the cultivation cycle, at each section of the two greenhouses, temperature and relative humidity were recorded. For this purpose two thermocouples (Type-T, measuring range -40 to 70°C, resolution 0.1°C and an accuracy of 0.3°C) were installed around the central area of each greenhouse section. A thermocouple recorded the air temperature (dry bulb) while the other one was covered with a wet wick (wet bulb) for subsequent calculation of the relative humidity (Alliston and Wolfe, 1973). Thermocouples were placed inside reflective white capsules, which were artificially ventilated by a fan (air speed between 1 and 3 m s-1). Although the spatial variation of the temperature inside a greenhouse and its effect on plant development is an unavoidable fact (Bojacá, 2009), only one sensor was installed per section, and was considered sufficient to reach the objectives of this work. The sensors were carefully placed at an intermediate location between the edge and the center of each section. As the central areas tend to have highest temperatures rather than the edges (Bojacá, 2009), this would lead to a model over-or underestimation.

Thermocouples have a measurement range between -40 and 70°C and, those were calibrated before installation. The calibration was performed according to the procedure suggested by the manufacturer (DLS Escort, Auckland, New Zealand), in which the temperature readings recorded by the sensors were compared with the ice melting point, to obtain a measurement accuracy of ±0.01°C. According to the manufacturer's quality certificate, the thermocouples have a resolution of 0.1°C and an accuracy of 0.3°C. At each section, the thermocouples were connected to data loggers (EJ-2E, DLS Escort, Auckland, New Zealand) that stored temperature measurements every 10 min.

Climatic conditions outside the greenhouses were recorded by weather stations with sensors located 2 m in height. At both locations, weather stations (iMetos® Compact, Pessl Instruments GmbH, Weiz, Austria) that recorded data every 10 min were used. The stations were equipped with temperature (range: -30 to 99°C and 0.1°C accuracy), relative humidity (range: 10 to 95% ± 1%) and solar radiation sensors (range: 0 to 2,000 W m-2 and an accuracy of ± 0.1%). At each section, for both locations, 40 plants were randomly selected in order to record the fruit production. Since the beginning of harvest until the end of the cycle, fruit production was recorded on a weekly basis for each plant (kg/plant). A digital scale LBK-6a (Adam Equipment Co, Danbury, USA) with a measuring range from 0 to 6 kg and accuracy of 0.05 kg was used to make those measurements. The fruit production obtained on each pass was accumulated to obtain the total plant productivity for the entire production cycle. Based on the planting density, yields were calculated in terms of kg per square meter for each greenhouse sections.

Exploratory data analysis

The first step in data analysis was to conduct an exploratory analysis, which aimed to extract preliminary information about the effect of the thermal screens. Some graphs were constructed to compare radiation levels and to establish the temperature variations for each greenhouse section (with and without screen). Average and standard deviation for temperature (°C) and relative humidity (%) were calculated for each hour of the day considering the entire production cycle and for each greenhouse section. Finally, we calculated the correlation between minimum night temperature (Tmin) and temperature differential (ΔTem, maximum nighttime temperature minus nighttime minimum temperature) in order to establish the effectiveness of thermal screens.

Crop growth model

In order to determine the potential effect that the use of thermal screens would have on tomato production, the second version of the model "Tomgro" was used. Tomgro is a deterministic model (not consider the variability present in real systems) used to simulate the development and growth of a tomato plant. The model describes, from planting until the end of the cycle, the phenological development and dry matter accumulation for all plant organs in response to variations in climatic variables such as: radiation, air temperature, CO2 concentration and so vapor pressure deficit. Tomgro is a photosynthesis driven model and, both organogenesis and senescence are temperature dependents. However, the model also includes interactions with other factors such as plant age and source/sink relationship. In Tomgro, the accumulation and distribution of dry matter is considered potential because the model assumes optimum production conditions meaning that limitations imposed by e.g. nutrient deficiencies, pest incidence, drought stress are absent. A detailed explanation of the model calibration and validation for tropical high Andean conditions and a complete description of its parameters can be found at Cooman (2002).

Tomgro requires hourly weather data including the intensity of global solar radiation (R, W m-2), temperature (T, °C), the vapor pressure deficit (VPD, kPa) and carbon dioxide concentration in the environment (Ca, mg kg-1). For each one of the four simulated environments (both sections at two study zones) one input climate file was built based on the measurements registered inside and outside each greenhouse. The global solar radiation was obtained from the stations located outside of greenhouses in each study zone. As the model requires solar radiation inside the greenhouse, it was assumed a 75% transmission rate of the plastic cover for both sections. The air temperature was obtained from the dry bulb temperature and, using the formula suggested by Irigoyen et al. (2005), the VPD calculated was calculated.

The level of Ca in all environments was assumed constant and set to a value of 350 mg kg-1 for the entire production cycle. The plant development as function of the temperature was measured using the response variable dry weight of mature fruits on each greenhouse section. In order to calculate the fruit fresh weight, an assumption of 95% fruit water content was made, and afterwards yield was estimated in terms of area (kg m-2) and multiplied per plant density. Based on the above, comparisons were made between climatic conditions for both locations and within greenhouse sections (i.e. with and without thermal screen). The effect of these variations on tomato production was assessed by a comparative analysis of yields (kg m-2) measured in the field versus the potential yield simulated with the Tomgro model.

Results and discussion

Next we present and discuss the results showing that the use of thermal screens inside greenhouses can retain heat during night hours, allowing increased yields, especially in areas where night temperatures are a constraint for tomato crop. Additionally, we illustrate the utility of using models as an alternative to the classical methods applied in agricultural research.

Exploratory data analysis

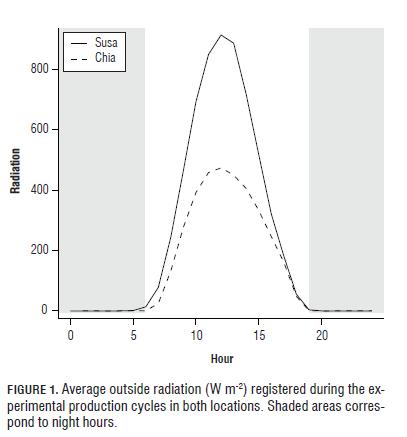

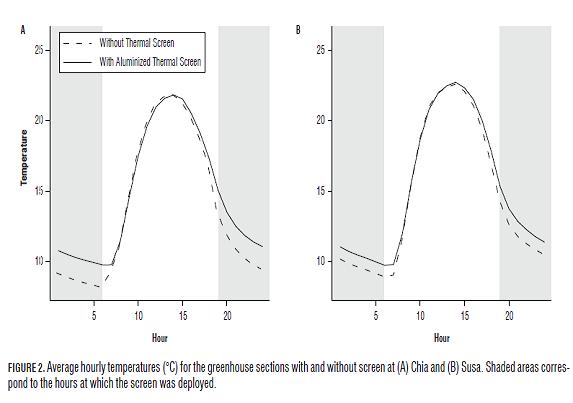

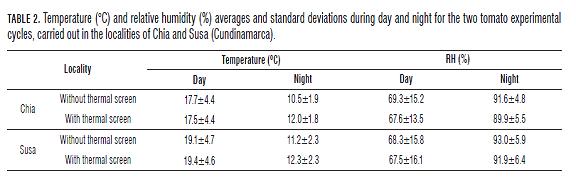

Both locations exhibited similar climatic conditions, but daily global radiation averages showed a significant difference (Fig.1). At Susa an average of 424.3 W m-2 for I was observed, while Chia registered an average of 284.7 W m-2. Air temperature differences between sections with and without screen were dependent on the hour of day. Fig.2 shows the temperature differences for each section throughout the day, indicating the highest differences during the night when the screens were deployed. In Chia, average temperature difference between sections with and without the aluminized screen was 1.5±0.1°C, while in Susa the average difference was 1.1±0.1°C. These increments in night temperature caused by the use of aluminized screens are similar to those reported in other studies. Kittas et al. (2003) reported average increases of 2.5°C while Abak et al. (1994) reported increases between 2.5 and 3.4°C. For the Bogota plateau, Cooman et al. (1999) determined that the installation of plastic screens inside greenhouses increased the average temperature about 2°C compared to greenhouse without screens. Fig.2 shows that during the day, temperatures in both type of sections did not differ because the thermal screen was extended only during nighttime.

Besides, increased nighttime temperatures, the use of thermal screen resulted in lower RH (Tab.2) also. Based on the climatic conditions registered in the sections with thermal screens, it is possible to infer a faster plant development, with a lower pathogens incidence due to lower moisture levels (Kim et al., 2008). For the correlation between Tmin and ?Tem, we found a linear negative association for all cases (Fig.3). In both locations, the highest correlation was found in the section with aluminized screen, which indicates that its use increases ?Tem in comparison with the section without the screen. In consequence, thermal screens will exhibit a higher capacity to retain heat inside the greenhouse in colder nights.

The use of thermal screens during nighttime reduced the heat loss from the crop, soil and in general of the greenhouse structure in both localities. Heat loss is due to transfers from inside to outside of the greenhouse by processes such as radiation, conduction and convection (Teitel et al., 2009). The temperature differences because of the thermal screens between two locations are explained by the specific climatic conditions of each locality

Cooman (2002), indicates that during the night the temperatures inside the greenhouses located in Chia are below the optimum for tomato production. Due to the altitude at which both locations are placed, these are considered marginal for growing tomatoes because of the aforementioned reason. In temperate regions, the technological solution used to solve this issue has been the installation of heating systems that use fossil fuels (Teitel et al., 2009). However, the results of this study showed that the thermal screens are a relatively cheap alternative for increasing nighttime temperatures in areas with similar conditions to those considered in the present study. An additional benefit achieved with the use of thermal screens is the frost risk reduction (Teitel et al., 1996; Sethi and Sharma, 2008).

The highest temperature sums inside the sections with thermal screen should be reflected in higher productivity levels. To determine this effect, next are presented the yield results obtained in the experimental greenhouses and contrasted it with those simulated with the Tomgro model.

Effect of thermal screens on yield

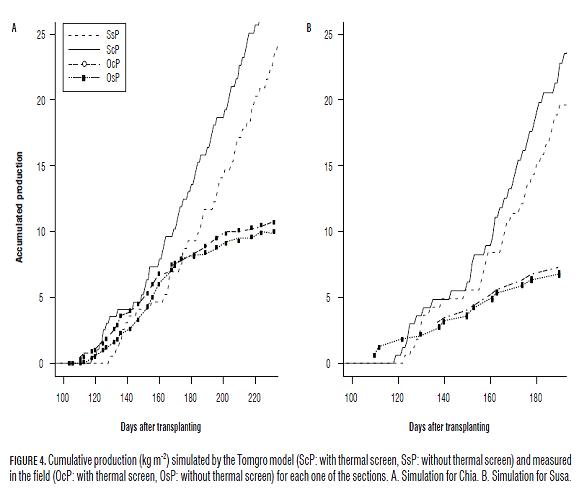

The harvest in Chia began 104 days after transplanting (dat) and ended at 232 dat, with the maximum production level between 153 and 168 dat. In this locality, average yields of 9.9±0.8 kg m-2 in the section without the screen and of 10.6±0.2 kg m-2 in the thermal screen section were registered during a harvest period of 19 weeks (Fig.4). In Susa, the harvest was carried out between the 95 and 190 dat. In Susa the section without screen showed an average yield of 6.6±0.8 kg m-2 while the section with the screen yielded an average of 6.9±0.3 kg m-2, during a harvest period of 14 weeks. The maximum production period in both sections was between 109 and 130 dat. Although Susa has more favorable climatic conditions for tomato production, Chia yields and harvest periods were upper. This is mainly associated with socio-economic characteristics of the growers. In Susa, the low investment capacity diminishes the efficiency with which they can perform activities such as hanging and fruit, stems or leaves pruning. This low investment capacity also affects the pest management, because the growers do not have enough products to spray at the appropriate times and do not have adequate equipment to perform this task in an effective way. On the other hand, in Chia although environmental conditions are less favorable, all necessary practices were carried out on time while supplies and equipment were in place in order to make an efficient management of the crop.

When making a yields comparison with Tomgro, the model simulated a higher yield for the section where the thermal screen was deployed during nighttime versus the section without the screen (Fig.4). The simulation results suggest a yield increase in Chia from 21.5 kg m-2 in the non-screen section to 25.5 kg m-2 in the section with the thermal screen. On the other hand, in Susa the simulations indicated a yield increase from 19.6 kg m-2 in the non-screen section to 22.7 kg m-2 in the section with the thermal screen.

In terms of percentage, Chia and Susa reported yield increments of 6.6 and 3.3%, respectively, for the sections with the screens versus those without the screens. The Tomgro model simulated yield increments of 15.7 and 13.6% with the use of thermal screens in the localities of Chia and Susa, respectively. These results does not account for radiation losses that may be about 5% of photosynthetic active radiation, which would reduce potential output in both areas (Cooman, 2002). The differences between simulated and observed data are explained by the fact that Tomgro is a potential model that does not include any biophysical limitation on plant health and/or nutrition. This is a proof that we need to develop appropriate research to decrease the gap between potential yields and those currently achieved. Although most of the research studies are focused on pest management and nutrient supply issues, this work shows that climatic improvements made through structural changes can help to reduce the gap between potential and actual yields.

On the other hand, it is evident that the use of thermal screens in localities with lower nighttime temperatures increases the production. In other studies, thermal screens has increased up to 30% the production of tomatoes and other crops such as paprika, eggplant and cucumber (Pérez-Rojas and Paul-Cortés, 2007). Grange and Hurd (1983) found slighter increments in tomato production carried out in greenhouses using thermal screens compared with greenhouses that do not use it, however the data was not shown. Callejón-Ferre et al. (2009) highlight the importance of greenhouse shading but they do not discuss the differences between the effects of aluminized screen compared with the shading obtained by techniques such as bleaching. This technique consists of painting white bands along the roof of the greenhouse.

The results of the present study showed a positive effect due to the use of thermal screens as a strategy to improve the heat retention during nighttime, and subsequently reflected in higher yields. However, the production potential increments were different for each study areas. The greatest potential for increasing production was found in Chia that has less favorable climatic conditions for the development of tomatoes, such as lower average radiation (Fig.1) and lower night temperatures. Therefore we can say that, the better effects on yield due to the use of thermal screens can be achieved in areas where climatic conditions are less favorable.

Callejón-Ferre et al. (2009) evaluated the use of aluminized screens on greenhouse tomato production in Almeria, Spain. Their results found that during the months of October to March (fall and spring) when temperatures are low, the use of screens during the night resulted in higher production (from 17.2 kg m-2 to 18.5 kg m-2 with the screen). In the months from April to September when nighttime temperatures are appropriate for the crop, the screens slightly increased production (from 20.8 kg m-2 to 21.4 kg m-2 with the screen). However, during this period the production increase was due to the deployment of the screens during midday hours to reduce the adverse effect of high temperatures (>26°C).

Jaramillo (2009) says that in Colombia multiple research actions have been undertaken to improve tomato production. Generally topics such as phytosanitary constraints or genetic material selection in terms of geographical areas, fertilizer strategies, have been prioritized. Nevertheless, the results of the present study demonstrate how the improvement of greenhouse climatic conditions can result in significant yield increments.

Conclusions

The use of thermal screens was able to increase nighttime temperatures in a range from 1.1 to 1.5°C with respect to the sections that did not use it. These increments in temperature were accompanied by reductions in the relative humidity during the night.

The use of thermal screen allows heat retention during nighttime that were reflected in the yield increments observed for both locations (Chia: 6.6% and Susa: 3.3%). Simulations carried out with the Tomgro model made possible to detect and confirm the positive effect in the use of thermal screens on tomato yields.

Acknowledgements

This work was carried out under the framework of the project "Desarrollo de alternativas de manejo integrado del cultivo del tomate en sistemas de producción bajo invernadero en los municipios de Chía y Susa en Cundinamarca y Piedecuesta en Santander" co-funded by the "Ministerio de Agricultura y Desarrollo Rural" and "Fondo Nacional de Fomento Hortofrutícola", and executed by researchers of the "Facultad de Ciencias Naturales e Ingeniería" of the "Universidad Jorge Tadeo Lozano".

Literature cited

Abak, K., A. Basçetinçelik, N. Baytorun, Ö. Altuntas, and H.H. Öztürk. 1994. Influence of double plastic cover and thermal screens on greenhouse temperature, yield and quality of tomato. Acta Hort. 366, 149-154. [ Links ]

Alliston, C.W. and S.A. Wolfe. 1973. Computation and summary of psychrometric data from dry bulb and dew point temperatures. Agr. Meteorol. 11, 169-176. [ Links ]

Bailey, B.J. 1988. Control strategies to enhance the performance of greenhouse thermal screens. J. Agr. Eng. Res. 40(3), 187-198. [ Links ]

Bertin, N. 1993. Environnementclimatique, competition pour les assimilats et modélisation de la nouaison de la tomate en culture sousserre. Ph. D. thesis. Institut National Agronimique Paris-Grignon, France. [ Links ]

Bojacá, C.R. 2009.Generic modeling approaches to technical sustainability on field level for farming systems in the high Andean tropics. Ph. D. thesis. Katholieke Universiteit Leuven, Leuven, Belgium. [ Links ]

Callejón-Ferre, A.J., F. Manzano-Agugliaro, M. Díaz-Pérez, A. Carreño-Ortega, and J. Pérez-Alonso. 2009. Effect of shading with aluminized screens on fruit production and quality in tomato (Solanum lycopersicum L.) under greenhouse conditions. Span. J. Agric. Res. 7(1), 41-49. [ Links ]

Cooman, A. 2002. Feasibility of protected tomato cropping in the high altitude tropics using statistical and system dynamic models for plant growth and development. Ph. D. thesis. Katholieke Universiteit Leuven, Leuven, Belgium. [ Links ]

Cooman, A. and E. Schrevens. 2007. Sensitivity of the Tomgro model to solar radiation intensity, air temperature and carbon dioxide concentration. Biosyst. Eng. 96, 249-255. [ Links ]

Cooman, A., M. Salamanca, E. Schrevens, and G. De Rijck. 1999. Influence of different greenhouse adaptation strategies on the greenhouse climate in the Bogota plateau. Acta Hort. 482, 377-386. [ Links ]

Escobar, H and R. Lee. 2010. Manual de producción de tomate bajo invernadero. Universidad de Bogotá Jorge Tadeo Lozano, Bogota. [ Links ]

Gary, C., J.F. Barczi, N. Bertin, and M. Tchamitchian. 1995. Simulation of individual organ growth and development on a tomato plant: a model and user-friendly interface. Acta Hort. 399, 199-205. [ Links ]

Gary, C., N. Bertin, and M. Tchamitchian. 1996. TOMGRO, un modèle explicatif de fonctionnement de cultures sous serre : un outil pour la recherche et pour l'aide à la décision. pp. 90-99. In: Baille, A. (ed.). Actes du séminaire de l'AIP intersectorielle "Serres", INRA, Avignon, France. [ Links ]

Grange, R.I. and R.G. Hurd. 1983. Thermal screensenvironmental and plant studies. Sci. Hort. 19(3-4), 201-211. [ Links ]

Irigoyen, A.I., A.D. Maggiora, and J.M. Gardiol. 2005. Métodos de cálculo del déficit de presión de vapor medio diario y su efecto sobre la de referencia en la localidad de Balcarce, Argentina (online). In: XIV Congreso Brasileiro de Agro-Meteorología. Campinas, SP, Brasil. [ Links ]

Jaramillo, J. 2009. El estado de la investigación en tomate en Colombia. Acta Hort. 821, 47-52. [ Links ]

Kim, K., J. Yoon, H. Kwon, J. Han, J. Son, S. Nam, G.A. Giacomelli, and I. Lee. 2008. 3-D CFD analysis of relative humidity distribution in greenhouse with a fog cooling system and refrigerative dehumidifiers. Biosyst. Eng. 100, 245-255. [ Links ]

Kittas, C., N. Katsoulas, and A. Baille. 2003. Influence of an aluminized thermal screen on greenhouse microclimate and canopy energy balance. Transactions of the ASAE 46(6), 1653-1663. [ Links ]

Maisonneuve, B. and J. Philouze. 1982. Effect of low night temperature on a collection of varieties of tomato (L. esculentum). I. Study of pollen quantity and quality. Agronomie 2, 453-458. [ Links ]

Miranda, D., G. Fischer, J.C. Barrientos, C. Carranza, M. Rodríguez, and O. Lancheros. 2009. Characterization of productive systems of tomato (Solanum lycopersicum L.) in production zones of Colombia. Acta Hort. 821, 35-46. [ Links ]

Okada, M. 1985. An analysis of thermal screen effects on greenhouse environment by means of a Multi-Layer screen model. Acta Hort. 174, 139-144. [ Links ]

Papadopoulos, A.P. and X. Hao. 1997. Effect of three greenhouse cover materials on tomato growth, productivity, and energy use. Sci. Hort. 70, 165-178. [ Links ]

Pérez-Rojas, H. and M. de Paul-Cortés. 2007. Simulación y control de la temperatura dentro de un invernadero. Undergraduate thesis. Faculty of Engineering Design and Automation Electronics, Universidad de La Salle, Bogota. [ Links ]

Rodríguez, I. and C. Cardona. 2001. Problemática de Trialeurodes vaporariorum y Bemisia tabaci (Homoptera: Aleyrodidae) como plagas de cultivos semestrales en el valle del cauca. Rev. Colomb. Entomol. 27(1-2), 21-26. [ Links ]

Sethi, V.P. and S.K. Sharma. 2008. Survey and evaluation of heating technologies for worldwide agricultural greenhouse applications. Solar Energy 82, 832-859. [ Links ]

Teitel, M., U.M. Peiper, and Y. Zvieli. 1996. Shading screens for frost protection. Agr. For. Meteorol. 81, 273-286. [ Links ]

Teitel, M., M. Barak, and A. Antler. 2009. Effect of cyclic heating and a thermal screen on the nocturnal heat loss and microclimate of a greenhouse. Biosyst. Eng. 102, 162-170. [ Links ]

Trudgill, D.L., A. Honek, D. Li, and N.M. Van Straalen. 2005. Thermal time: Concepts and utility. Ann. Appl. Biol. 146(1), 1-14. [ Links ]

Zhao, Y., M. Teitel, and M. Barak. 2001. Vertical temperature and humidity gradients in a naturally ventilated greenhouse. J. Agr. Eng. Res. 78, 431-436. [ Links ]