Introduction

Panela is a traditional peasant product (Jaffé, 2015), whose production and consumption are widely distributed nationwide in 28 provinces, according to the Ministry of Agriculture and Rural Development (MADR, 2019). The province of Cundinamarca has 62,134 ha dedicated to panela production. This area corresponds to 22.64% of the total agricultural area of the province (Secretaria de Agricultura y Desarrollo Rural - Cundinamarca, 2015). Utica is one of the municipalities of Cundinamarca where panela production is an important economic activity, carried out by 272 farmers owning 165 "enramadas" or "trapiches" (Administración Municipal Útica - Cundinamarca, 2012).

An "enramada" or "trapiche" is the place where mills are located and sugarcane juice is extracted. As of August 2019, Utica had 3,017 ha cultivated with sugarcane. This produced an average of 16,401 t of panela and was the fifth most productive municipality in the province and the 47th in the country (MADR, 2019).

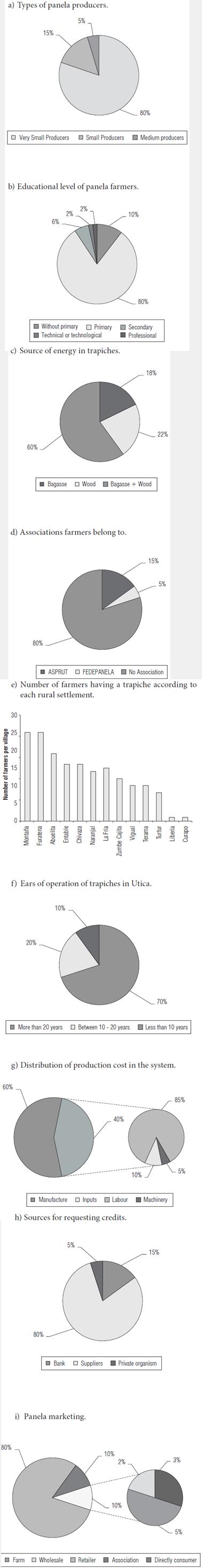

More than 80% of the panela farmers in these areas are small and medium producers. Sugarcane is one of the crops that support their economy. In addition, panela has high cultural importance in Colombia as an energy source that is mainly consumed by low-income people. However, nowadays its consumption by individuals with greater purchasing power is increasing because of its benefits. Panela has not had an important significance in the international market beyond the producing countries (Rao et al., 2007); nevertheless, it has gained recognition worldwide due to its nutritional properties, which have allowed the opening of new markets in different countries.

Due to the importance of panela in Colombia, this agroin-dustry has been prioritized by the national research agenda. According to Martínez (2013), the key points in such a program are technological, in order to overcome critical factors in the topics that affect competitiveness. These topics are first, sanitary and phytosanitary control; second, the innovation of inputs and products; third, integral crop management; and last, postharvest and transformation.

Agreeing on the research program, the panela farmers' guild and the local governments in producer areas have joined efforts to improve productivity, product quality, and supply and to promote the consumption of panela in national and international markets. Improvement of access to markets is a key factor that will undoubtedly support small farmers because it could be a way to improve their incomes, and hence, have better conditions for producing panela of higher quality (Gereffi and Lee, 2012).

Given this context, it is essential to understand and analyze the production and marketing perspectives that panela producers have and also to recognize the potential problems, benefits, and obstacles faced in the market to be competent and keep themselves stable economically. In this scenario, value chain, global value chain, supply chain, marketing chain, or distribution chain have been popular in market analysis. Webber and Labaste (2009) consider that all these terms are used depending on the product or the target market analyzed. However, all of them describe the steps, processes and interactions required to obtain diverse products, from cultivation or manufacture in the case of food, to the moment when they reach the final consumer.

Kaplinsky and Morris (2001) define value chain as a sequence of all the activities and their connections involved in the whole process of obtaining a product or service from the production, processing, marketing, and distribution to the final consumer. In other words, Hellin and Meijer (2006) describe the concept as a full range of activities that firms and workers perform to bring a product from its conception to its end use and beyond. Among these activities, the design, production, marketing, distribution and support to the final consumer are all considered.

Since the early 1990s, the term "global value chain analysis" has appeared as a tool for understanding the dynamics of international trade and economic globalization. This approach focuses on examining the structure, actors, and dynamics of the chain. The analysis includes the identification of the role of the participants involved in the value chain, as well as the relationships between them. Additionally, it includes knowing the structure of the rewards, the allocation of the added value, and the role of norms. It also allows identifying whether such a structure facilitates or obstructs the participation of all the stakeholders. In addition, different authors and research on the value chain have focused their attention on the impacts that it has on improving the conditions of livelihood of the population characterized by poverty, vulnerability (women and children), and environmental susceptibility. That is why most of the poor people around the world live in rural areas in developing countries, and most of them engage in agricultural production as a unique or primary source of income (Riisgaard et al., 2010).

Value chain analysis includes all vertical links described by Dunn (2014) as a commercial relationship in bringing the product up through the value chain. In other words, it includes all the relationships at different levels between buyers and suppliers involved in the passage of goods or services from production to consumption (Riisgaard et al., 2010; McKague and Siddiquee, 2014). Furthermore, it includes the horizontal links that are the relationships between enterprises at the same level. These relationships include other value chains that have a connection in the provision of some goods or services and that compete or help to reduce transaction costs and access to information, increase cost-effective access to inputs and services, and empower small firms (Dunn, 2014; McKague and Siddiquee, 2014). Webber and Labaste (2009) highlight the fact that value chain analysis must include an emphasis on value creation through the innovation of products, processes, and marketing strategies.

Value chain dimensions vary depending on the authors or their influences and study objectives. According to Schneemann and Vredeveld (2015), there are four dimensions: economic, social, environmental, and institutional. These are interconnected and allow an improvement in the quality and growth of the chain. The primary challenge in value chain analysis is to identify and propose alternatives for achieving sustainable growth for all the stakeholders in the previously mentioned dimensions (Faße et al., 2009).

The case of panela production in Utica, Colombia is an attractive example of analysis because it is the main cash crop for farmers and is the principal source of income for almost all the population. That is why panela production plays a significant role in the livelihoods of the majority of the inhabitants of the town. Given this context and knowing the conditions of panela production in the municipality, the objective of this research was to identify the alternatives for farmers in Utica to improve the agricultural practices of the sugarcane crop and the method of manufacturing panela to gain better access to markets while making the process sustainable.

Materials and methods

Location

This research was performed in the municipality of Utica, located in the northwest of the province of Cundinamarca, in the Gualiva region (5.1878° N, 74.4815° W). The area has a mean temperature of 26°C and an altitude that varies between 400 and 1,600 m a.s.l.). The location is strategic since it is situated just a few hours from Bogota, the capital of the country. However, the road that leads from Utica to the highway to Bogota is in poor condition, and more than 60% of the route is unpaved (Alcaldía de Útica - Cundinamarca, 2016).

Statistical analysis

The current study was organized in three phases. First, the characterization of panela farmers was undertaken. Second, the role and actions of the local political stakeholders were defined. Finally, in the third phase, the information gathered was analyzed using the software ATLAS.ti, a workbench for the qualitative analysis of large bodies of textual, graphical, audio and video data. The interactions of the previously mentioned dimensions were discussed in order to achieve sustainable growth for all stakeholders.

In order to characterize the farmers, semi-structured interviews (Supplementary Material 1) were carried out to identify the most important facts of the value chain. Since the total number of panela farmers was 272, the statistical sample size was calculated using the following formula (Becerra et al., 2011):

where:

n = Sample size

N = Population size

Z = Confidence level

e = Margin of error

p = Prior judgment of the correct P value

The calculated sample size had to include at least 55 farmers. However, the current research surveyed 72 producers.

For the second phase of the study, the results obtained in the characterization were contrasted with other relevant actors using face-to-face interviews (Supplementary Material 1). One of these actors was the local government, in charge of coordinating the rules in the territory as well as providing an environment for producing sugarcane and commercializing panela. At the local level, the Mayor and the Planning Secretary of Utica, and at the national level, the advisor of the panela productive chain of the Colombian Ministry of Agriculture and Rural Development were interviewed. Also, we interviewed the legal representative of the Association of Agricultural Producers of Utica and Neighboring Municipalities (Asociación de Productores Agropecuarios de Útica y Municipios Vecinos ASPRUT) and 16 employees from different areas of the National Federation of Panela Producers (Federación Nacional de Productores de Panela FEDEPANELA), including the general manager as head of the political sphere, the director of the technical division, and the director of the marketing area (a division called COMERPANELA). We also included a member of the Colombian Institute for Technical Training (Servicio Nacional de Aprendizaje SENA) Villeta campus.

Results and discussion

General characterization of panela farmers in Utica

Some of the results of the general description of panela farmers in Utica (Supplementary Material 2) showed that they are divided into three groups: medium, small, and very small producers (this last one as the largest group). Panela production is a common tradition characterized by a significant number of family members, and the traditional knowledge of panela processing has been passed from generation to generation. Nevertheless, the level of formal education of the farmers is low with 80% reaching a level of primary school and only 4% with secondary education, and 10% with no formal education, although they were literate.

Most of the farmers owned from 1-5 ha. Additionally, 90% of sugarcane crops had been producing for more than 20 years while the remaining 10% had been producing for 10 - 20 years. The crop yields were far from an optimal level, mainly due to a lack of a consistent renovation process.

Farmers in the area engage in minimal crop management. Only 5% of the farmers had conducted soil analysis, preventing the organization of a plan to cover the needs of the harvest. No prior soil preparation was performed when crops were established.

The primary source of energy for operating the "trapiches" was the bagasse resulting from the first part of the process after extracting the sugarcane juice. However, many of the mills required other sources of energy since they are not self-sufficient and use only the bagasse produced. The old burners with low technology need more time to reach dehydration of the juice so that farmers must look for an alternative source of energy. In many cases, this is firewood obtained from their farms. The consequences of requiring additional use of firewood as a source of combustion have generated deforestation in many parts of the municipality. The farmers cut down native vegetation to plant species that serve as firewood for later use in the trapiches and to sow sugarcane to increase production. The consequences of panela production with regards to this issue have been described in other studies in Colombia (Ordoñez-Díaz and Rueda-Quiñónez, 2017).

Price fluctuation was described as a big problem for farmers. In the case of Utica, an ordinary family of four people (parents with two children) with an average of 3 ha of sugarcane obtains 2.16 USD per day per person. According to the World Bank (2015), a person that earns less than 2 USD per day is considered as poor. It means that the incomes derived from panela manufacturing in Utica are barely enough to stay above the poverty line.

Given this fact, it is not clear why panela farmers continue performing this non-profitable activity. The possible reason is that it is a traditional activity in the area, and hence, it is important for the farmers to continue doing the same activities that their parents did before. As sugar cane is a traditional crop, it is an activity they learned from their ancestors, and for most of them, it is the only thing that they know how to do (Bernal et al., 2016). When asking farmers about this issue, the answer was straightforward in most of the cases. They said that manufacturing panela was like having a money box in the house. When they had no money, they harvested the cane, regardless of its price and quality. With panela produced on Friday, they could get paid the next Sunday. With that money, they were able to cover all their needs.

Regarding the role and actions of the local political stakeholders, according to the Mayor and the Planning Secretary, the administrative staff focused their efforts on improving panela production. They clearly understand that panela production was the basis of the local economy. Nevertheless, they agreed that such efforts are sometimes lost for various reasons. First, because the smallholders most of the time prefer to work alone and show little commitment to working together with the government. Second, even though the government has the best will to solve problems, the bureaucracy and small budgets do not allow effective decision-making. And finally, the conjunction of the two previous concerns creates skepticism and an atmosphere of discontent between the government and the farmers. This diagnosis is similar to the analysis performed by Orjuela and Colmenares (2011).

An interview carried out with the President of the ASPRUT organization concluded that ASPRUT members look forward to accomplishing two main goals: first, that the member might obtain support from the government; and second, that the members have the best access to markets. Regarding governmental support, the members requested adequate training that would allow them to improve panela manufacturing and meet the current legislative standards. Concerning access to markets, the members wish to produce the best quality panela and to reach different markets. Managing this might allow the members to avoid retailers as much as possible and to obtain consumers directly, so as to receive a fair price for their product.

Based on the interview with the staff of FEDEPANELA and SENA, both institutions seek to support panela farmers, focusing their efforts on technical processes and marketing concerns. According to the interviewed, the likelihood of offering their services in Utica was low. The most relevant explanation was that because panela farmers in the town are not interested in such support. This was evident from the low rate of affiliation with FEDEPANELA, scarcely reaching 5% of the farmers. This was probably due to the fact that most of the farmers expressed apathy for the training programs. According to the interviewed SENA members, panela farmers argued that they were too old to learn new techniques, and they preferred continuing to do things as usual.

In the marketing field, FEDEPANELA has opened new markets at the national and international levels. However, one of the most critical obstacles for panela farmers reaching such markets is fulfilling the standards requested. Overcoming this challenge required the involvement of the different stakeholders.

The most significant findings of the interviews are presented as follows. The information is organized into four different dimensions of the value chain: the institutional, environmental, social, and economic dimensions.

Institutional dimension

The institutional dimension could be understood as the axis that establishes the rules of the game in the value chain. It creates the environment regarding the laws and the coordination between the public and private sectors. However, regulation can sometimes be difficult to achieve for small farmers, so this becomes an obstacle for reaching the objectives of productive systems (Schneemann and Vredeveld, 2015). These results are shown in Figure 1.

As the leading actor in the institutional dimension, the government proposes laws and regulations. According to the Ministry of Health and Social Protection, the most important point to consider is that of sanitation. Regarding this, the Resolution 4121 of 2011 (Ministerio de Protección Social, 2011) was established to define the requirements for the production and commercialization of panela for human consumption. According to the standard the most significant changes that must be applied in the conventional mills are (1) the use of drinking water throughout the process, (2) the distribution of the mill with a sequential flow, clearly delimiting the areas for the different activities, and (3) the construction of the trapiche with easy-to-clean materials. These improvements involve significant investments that farmers are not willing to make, which is why the farmers continue manufacturing panela in conventional trapiches (Martínez, 2013).

Since the farmers do not comply with the regulations, they do not have the support of the institutions. Panela farmers have to comply with the requirements of the standards if they want to commercialize a reliable product for human consumption supported by FEDEPANELA. Given this scenario, panela farmers that cannot fulfill the requirements have to commercialize their panela through conventional channels.

The participating stakeholders agreed that technical assistance was one of the reliable tools for improving and following up the panela productive system. First of all, technical assistance controls illegal practices carried out by some farmers. Some of these practices are the addition of dyes, saturated animal fats, bleach, white sugars or any other substance that changes panela quality while putting the health of consumers at risk. Second, technical assistance helps to identify particular problems in each area and seeks to solve them through training. Finally, it allows sharing the new technological findings in the panela productive sector and keeping the growers informed and updated (Franco et al., 2016).

Farmers recognize the importance of technical assistance, and some of them remark on its absence in their particular cases. Nevertheless, it is important to note that many of the farmers ignored recommendations and assistance because they are reluctant to change their traditional ways of manufacturing panela (Ordoñez et al., 2013). Despite the criticism of some stakeholders about the pertinence and quality of the technical support, all of them agree that it is a crucial element for arriving at an improved value chain and finding alternatives for better access to the markets.

Environmental dimension

Environmental education is central to this dimension. The absence of an environmental conscience has triggered most of the problems that currently occur in panela production in Utica. Besides a lack of commitment from farmers on this issue, a lack of knowledge of the environmental impacts caused by production and the ways to solve or mitigate them are the principal challenges concerning environmental interests in Utica (Bernal et al., 2016). The main connections regarding environmental matters are emphasized in Figure 2.

The impact of modern agriculture on climate change is evident, especially because of some common practices of current livestock production and monoculture (Barker, 2007). However, traditional practices also have impacts on the environment. The degradation of natural resources is tangible in Utica, and deforestation in some "veredas" (scattered rural settlements) is evidence of it. This condition is one of the consequences of logging trees to establish new crops or to use as firewood as a source of energy for the mills and boilers in panela manufacturing (Rojas, 2011). The main impact of these practices is the elimination of biodiversity that alters the balance of the natural system in the region. Similarly, soil deterioration represented by the loss of fertility, erosion, and other consequences is the result of poor management of sugarcane crops.

There are several problems related to panela production affecting the environment: first, water pollution due to the lack of treatment of wastes generated during the production of panela; second, the air pollution produced by the practice of rubber burning. Though this practice is severely sanctioned, some farmers in Utica still use car tires as a common source of energy. Also, the management of solid and liquid waste, especially by small farmers and the use of firewood for the burners implies that extensive deforestation is an important environmental concern. One of the biggest problems is the fact that wood was still used for combustion for evaporating sugarcane juice, and some farmers do not respect the legislation regarding this issue. Concerns about contamination caused by the traditional practice of burning the soil's vegetation cover to establish new crops, especially maize, is also a serious problem. The process starts as a step carried out before sowing sugarcane. This practice pollutes air significantly and affects the quality of the land since it leaves it without cover. Regarding these issues, training focused on good agricultural practices of growing sugarcane and manufacturing panela should be made available to the farmers as a partial solution for some environmental problems.

Compliance with laws and regulations is a way to control the degradation of natural resources (Riisgaard et al., 2010). The implementation of adequate technologies, especially better farming and manufacturing practices, will improve the quality and efficiency of the entire productive system. In this regard, panela farmers would be able to reduce production costs through the implementation of training projects to adopt new technologies. In this way, panela growers would make their processes more efficient and would become more environmentally friendly.

Regarding the benefits of being environmentally friendly, the implementation of Good Farming Practices (GFP) during sugarcane growing as well as Good Manufacturing Practices (GMP) in the trapiches would be useful to get the certifications for facilitating access to markets. Indeed, these kinds of good farming and manufacturing practices add value to the final product, because nowadays the consumers are willing to pay more if they realize that the product protects the environment and the wildlife.

Paradoxically, while panela manufacturing practices impact the environment, sugarcane crops are incredibly susceptible to the effects of climate change. In addition to the problems associated with the market, sugarcane crops have been severely impacted by the problems of climate variability in the last few years. Utica had a strong rainy season during 2011 and 2012 followed by extreme dry seasons during 2014 and 2015. Sugarcane crops have also been recently impacted by a strong El Niño (Southern Oscillation Cycle ENSO). Growers are becoming more sensitive to this problem. However, in their daily work, it is evident that the farmers continue doing their activities as usual.

Social dimension

The social dimension involves significant topics that go beyond agricultural production. Nevertheless, such topics are narrowly related to the economic activities carried out in the countryside. Equity, equality, the likelihood of participating, inclusiveness, access to productive and environmental resources or decent working conditions are clear examples of the topics related to this dimension. However, one of the most relevant aspects is the participation of women (Farah-Quijano, 2009). The connections among social aspects are highlighted in Figure 3.

For Alviar (2012), rural women are the pillar of the agribusiness since, without them, there would be no development in rural areas. Although the production of panela is considered a tough job, women have gained valuable spaces in the different stages of the process. Women can be more perceptive and have a greater degree of natural development so that the process can become more innovative. Three important aspects can be highlighted from these qualities: first, the importance of women in the countryside; second, their strength to do particular tasks; and finally, the topic of the innovative mind (Fletschner, 2000).

Regarding these topics, women have played a prominent rural role, so their potential to share the necessities of work is immense. Linking women to the panela process would be a great success, as they tend to be more receptive, innovative, and propositional, among other qualities. The work of women is and always has been indispensable in different areas. For instance, cooking for the people manufacturing panela is a very important and labor-intensive task because these panela workers must work for long hours. Women can perform all the tasks in panela manufacturing besides cooking. As an example of the tasks that women can perform is commercializing the panela produced. However, FEDEPANELA does not currently have special programs to support or train women in order to include them in the panela manufacture or commercialization processes.

Migration is a fact in rural areas for different reasons. First of all, young people leave seeking new possibilities for access to services such as education, health, or culture. Second, they leave because governmental institutions do not offer alternatives for good jobs with decent wages or projects for improving agricultural activities. Finally, in the case of Colombia, young people leave because of rural violence forces the people to abandon their lands (Brittain, 2005). The situation of panela farmers in Utica is similar to the one in other rural localities of the country. Aside from the young population, adults are also looking for new opportunities for work, education and other activities in nearby municipalities or Bogota. According to the findings in our interviews, rural young people are looking for a new life far away from the countryside. This fact has impacted the panela producing sector because labor is becoming scarcer and, therefore, more expensive. This has increased production costs. Regarding this issue, one of the most important activities that FEDEPANELA should implement is encouraging the peasant youth to remain in the countryside, otherwise, the labor force would be scarcer every day.

Economic dimension

According to Schneemann and Vredeveld (2015), most of the stakeholders involved in value chain analysis consider the economic dimension as its baseline. They state that the economic dimension is the potential for market growth, job creation, and added value. In conjunction with the other analyzed dimensions, the highlighted topics will be useful for beginning better productive projects. The main connections are defined in Figure 4.

Financial resources are at the heart of any economic activity. In the current case, it is essential to take into account the scarce resources of the farmers and institutions working in Utica. As described previously, the government and the other institutions involved in the panela value chain have limited economic resources available. It means that given such scarcity, all the stakeholders must spend their funding better.

Although not always well-accepted and efficient for addressing real problems, the institutional presence offers a series of benefits that can be connected to an improvement in the conditions of all the farmers of the particular sector. Technical assistance is crucial in the panela manufacturing process because it can improve the yield without affecting or deteriorating the necessary resources (soil and water) for production. Equally, technical assistance has to prepare farmers to face or mitigate the problems caused by climate change (Feola, 2017). Similarly, the government and other institutions are essential in the process of acquiring new technologies, equipment, and infrastructures for carrying out manufacturing more efficiently, and, hence, for complying with the regulations. Nevertheless, the most critical concern that all involved stakeholders must solve is consolidating the farmers' organization and affiliation to FEDEPANELA to acquire more governmental support.

Conclusions

Panela producers suffer severe disadvantages and are threatened by many modern trends. Nevertheless, they must take advantage of their strengths as small farmers using their traditional knowledge to overcome their deficiencies. The success of different value chains of small farmers has been due to the adoption of solutions based on local advantages and experience, which offer alternatives to development. The traditional knowledge of panela production is the most reliable tool and must be reinforced and renewed based on current legislation and market demands. Otherwise, an important activity that has been carried out for generations could end.

The condition of farmers in Utica is cyclical. The panela manufactured by the farmer reaches the retailers who pay him according to his need to sell at that moment, which is generally at a low price. Retailers get better prices in other markets outside the town, where farmers usually never sell. The farmers receive money for their production, but it is barely enough to meet their basic needs. They do not receive additional income allowing them to make improvements and transform their production and manufacturing methods.

To address the value chain problems of panela in Utica, the following recommendations will be useful: first, the crops may require new management practices, such as Good Agricultural Practices that involve taking care of the environment. Another recommended transformation is to move towards an organic system, which would generate a significant added value considering the current market trends for consuming clean and healthy food. In order to do this, small farmers are required to renovate crops and to undertake practices of soil recovery. Second, the improvement of panela manufacturing facilities is a complicated situation due to the high expenses of these upgrades. However, by taking advantage of the programs proposed by the government and institutions and by working together, farmers would have to make fewer adjustments to solve this bottleneck.

The government, institutions and farmer organizations should work to find solutions to the problems. Nevertheless, without a proper organization of farmers into associations or other forms of teamwork, it is difficult to solve the individual problems of each farmer. Associated farmers can access training and new technologies more easily, and they can also obtain updated information and learn about the new challenges that the panela sector has in the country and around the world. Although the allocation of resources for new projects, new technology and financing for the poorest may be difficult because of the historical context of the country, panela production could greatly benefit from it. Then, if the aid is available, it should be assigned to those who need it most to avoid a situation in which farmers expect everything to be a gift and make use of the benefits without planning and projecting the efficient use of the resources for the future.