Introduction

Pineapple (Ananas comosus (L.) Merr) is one of the most-produced tropical fruits worldwide (Ancos et al., 2016). It is recognized as an important source of sugars, organic acids, fiber, minerals, and vitamins (Ancos et al., 2016; Montero-Calderón and Martín-Belloso, 2016). In addition, pineapple is rich in health-promoting bioactive compounds such as ascorbic acid, carotenoids, and flavonoids (Ancos et al., 2016; Montero-Calderón and Martín-Belloso, 2016).

Pineapple is commonly consumed fresh or used to make jam, jellies, desserts, and other products. Minimally processed pineapples are gaining popularity in developed countries due to their convenience and freshness (Montero-Calderón and Martín-Belloso, 2016). However, the typical minimal processing operations, such as peeling and cutting, increases the surface area of the fruit promoting browning, softening, decay, off-flavor and microbial growth that in turn shortens the shelf life of fresh-cut pineapple (Azarakhsh et al., 2012). Therefore, additional innovative strategies should be developed, such as using edible coatings, in order to extend the shelf life of fresh-cut fruits and vegetables.

Coatings are defined as mixtures of film-forming materials plus solvents and other additives (e.g., plasticizers) which, when applied to a surface and cured or dried, yield a solid protective, decorative and/or functional adherent in a thin layer (Bierwagen, 2016). Moreover, antioxidants, antimicrobial agents, oxygen scavengers, or moisture absorbers, among others can be added to coatings to obtain active coatings (Yousuf et al., 2018).

Over the past years, the application of coatings has become more and more important in the food field (Tharanathan, 2003; Versino et al., 2016). The application of coatings on food products allows an extension of shelf life of perishable and sensitive products, such as fruits and vegetables, since these materials act as an external protective layer. These coatings slow the respiration rate, reduce moisture and solute migration, gas exchange, oxidative reaction rates, and suppress physiological disorders of fresh-cut fruits (Robles-Sánchez et al., 2013; Yousuf et al., 2018).

Several polymers of natural origin have been used for the fabrication of food-edible coatings including starch (Praseptiangga et al., 2017), alginate (Mannozzi et al., 2017), chitosan (Mannozzi et al., 2018), pectin (Mannozzi et al., 2017), cellulose derivatives (Gunaydin et al., 2017), etc. Among these polymers, sodium alginate is well-known for its excellent film-forming properties and functionalities (López Córdoba et al., 2013; Mannozzi et al., 2017).

Alginates are a family of unbranched binary copolymers of (1-4)-linked β-D-mannuronic acid (M) and α-D-guluronic acid (G) residues of widely varying composition and sequential structure (Wüstenberg, 2015). The food industry uses alginates for specific gelling, thickening, and stabilizing applications. Sodium alginate films and coatings with food additives, such as antioxidants, antibrowning agents, antimicrobials, probiotic bacteria, etc., have also been prepared (Robles-Sánchez et al., 2013; Valero et al., 2013; Salvia-Trujillo et al., 2015). One of the most used additives in the fabrication of edible coating is ascorbic acid, because it has excellent antibrowning and antioxidant properties (Bierhals et al., 2011; Robles-Sánchez et al., 2013). Alginate-based edible coatings have been useful in maintaining postharvest quality of tomatoes, peaches, sweet cherries, plums, etc. (Valero et al., 2013; Cakmak et al., 2017). Recently, Mannozzi et al. (2017) studied the efficacy of edible coatings based on sodium alginate on the quality of blueberry fruits during 14 d of storage at 4°C.

They found that the application of sodium alginate coating improved the firmness of blueberry samples as compared to the uncoated ones. Moreover, changes in the surface reflection properties in coated blueberries induced a general lower lightness and a more intense blue hue color than the control sample. The microbiological results indicated that the alginate-coated blueberry samples significantly reduced the growth kinetics of yeasts and mesophilic aerobic bacteria (Mannozzi et al., 2017).

Several authors have reported that alginate-based edible coatings constitute a useful tool for maintaining the quality and shelf-life of fresh-cut pineapples. Montero-Calderón et al. (2008) studied the effects of edible coatings on the quality of fresh-cut pineapples, based on blends of sodium alginate and glycerol emulsified with sunflower oil. The sodium alginate-based coatings were crosslinked in a calcium chloride batch containing ascorbic acid and citric acid. The use of edible coatings significantly reduced juice leakage of fresh-cut pineapples increasing their shelf-life (Montero-Calderón et al., 2008). Azarakhsh et al. (2012) optimized alginate and gellan-based edible coating formulations for fresh-cut pineapples finding that weight loss and respiration rate were significantly lower, and firmness was maintained in both optimized coated samples as compared to a control. Mantilla (2012) used the layer-by-layer technique to obtain coated fresh-cut pineapples. Coating formulation consisted of sodium alginate, trans-cinnamaldehyde (antimicrobial agent), pectin, and calcium chloride. Mantilla (2012) observed that the coating improved the shelf-life of fresh-cut pineapple up to 12 d compared to uncoated samples.

In this research, we studied the effect of edible coatings during storage, based on sodium alginate and its blends with ascorbic acid on the behavior of the physicochemical properties of fresh-cut pineapple. Uncoated and coated pineapple samples were prepared and stored at 4°C for 10 d. The physicochemical properties of the fruits were periodically monitored, and the changes that occurred due to the effects of the treatment were statistically analyzed. As far as the authors are aware, there are no studies on the effect of similar coating formulations on cut pineapples.

Materials and methods

Pineapples (Ananas comosus (L.) Merr) were obtained from a local supermarket from the same batch. Visual inspection was conducted to ensure consistent ripeness and absence of significant defects or physical damages that could interfere with the experiments. The fruits were washed in a 50 mg L-1 NaClO solution and then peeled manually and cut in pieces.

Sodium alginate (Saporiti, Argentina) and glycerol (JT Baker, Mexico) were used as coating material and plasticizer, respectively. Ascorbic acid was used as an antioxidant and antibrowning agent.

Preparation and application of coating materials

Coating solutions without ascorbic acid (AlgNa) were prepared by dissolving sodium alginate powder (1% w/v) in distilled water, heating the solution under constant stirring until the mixture became clear. Then, 0.5% (w/v) glycerol was added to the sodium alginate solution and stirred for 5 min. Coating solutions with 0.1% w/v ascorbic acid (AlgNa+AA) and sodium alginate/glycerol blends were mixed.

Fresh-cut pineapple samples were randomly divided into three groups: the control group (uncoated fruit), fruit coated with sodium alginate, and fruit coated with the sodium alginate/ascorbic acid blend. Fruits were dip-coated by immersion in the coating solutions for 90 s, drained of excess coating, and air-dried at room temperature during 24 h. Uncoated and coated samples were packed in separate polyethylene plastic bags and stored at 4°C. Changes in the fruit quality parameters (visual appearance, soluble solid content (°Brix), pH and titratable acidity (%)) were monitored after 3, 7 and 10 d of storage at 4°C according to AOAC standards (AOAC, 1998).

Fruit samples were crushed using a blender and filtered through filter paper to obtain fruit juice. The soluble solid content was measured in the fruit juice using a refractometer (Zhifong®, Changhua, Taiwan) and expressed as °Brix (AOAC 932.12). Titratable acidity (%) was determined by titration with 0.1 N NaOH up to pH 8.1 using 1 g of sample in 10 ml of distilled water (AOAC 942.15). The results were expressed in citric acid percentage. The pH of fruit samples was assessed using a digital pH meter (Oakton Instruments, Vernon Hills, IL, USA) (AOAC 981.12).

Statistical analysis

The statistical analysis was performed using the Systat Inc. software (Evanston, USA). Analysis of variance (ANOVA) and Tukey pairwise comparisons were carried out using a 95% confidence level. The experiments were performed at least in duplicate, and data were reported as mean ± standard deviation.

Results and discussion

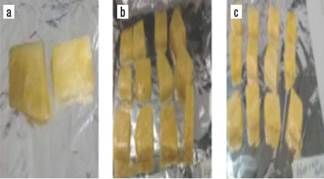

Coating-forming solutions based on sodium alginate (Al-gNa) and its blends with ascorbic acid (AlgNa+AA) were obtained. They were easy to prepare and handle and yielded a transparent and homogenous coating on the fresh-cut pineapple samples. Moreover, the coatings adhered well to the fruit and gave its surface a bright appearance (Fig. 1).

General appearance of uncoated and coated fresh-cut pineapple samples

The general appearance of uncoated and coated fresh-cut pineapple samples was visually evaluated before and after storage. On day 0, the surface of the coated fruits was bright and shiny (Fig. 1).

FIGURE 1 Digital images of uncoated and coated samples on day 0 of the assay. a) uncoated sample, b) coated sample with sodium alginate and c) coated sample with sodium alginate and ascorbic acid.

During storage, uncoated samples showed visible symptoms of decay, whereas fruit samples coated with sodium alginate and its blends with ascorbic acid had a better appearance during the assay, looking fresher and more attractive, mainly in AlgNa samples (Fig. 2). Robles-Sánchez et al. (2013) studied the influence of alginate edible coatings carrying ascorbic and citric acid as antibrowning agents on quality parameters of fresh-cut Kent mangoes stored at 4°C. They found that the combination of alginate and antibrowning agent preserved the color of fresh-cut mangoes. This was attributed to antibrowning agents such as ascorbic and citric acids, which inhibit the polyphenol oxidase activity functioning as reducing agents (o-quinones to diphenols) and pH reducers (Robles-Sánchez et al., 2013).

Behavior of physicochemical properties of uncoated and coated cut pineapple samples during storage

Behavior of the pH and titratable acidity (%)

The behavior of the pH and titratable acidity (%) of uncoa-ted and coated cut pineapple samples is shown in Figures 3 and 4, respectively. At the initial time, statistically significant differences were not found between uncoated and coated samples (P<0.05); similar values of pH (~3.74) and titratable acidity (~0.64%) were obtained. These results suggest that the application of edible coatings based on sodium alginate and its blends with ascorbic acid allow the preservation of coated fresh-cut pineapple with similar characteristics to the uncoated fruit. Values of pH and titratable acidity (%) of 3.5 and 0.18, respectively, were reported by Dussan-Sarria et al. (2014) when working with the pineapple (Ananas comosus) variety Manzana.

FIGURE 3 Behavior of pH during storage of uncoated (control) and coated (AlgNa and AlgNa+AA) cut pineapple samples.

FIGURE 4 Behavior of the titratable acidity percentage during storage of uncoated (control) and coated (AlgNa and AlgNa+AA) cut pineapple samples.

Figure 3 shows the behavior of pH of cut pineapple samples during storage. All samples showed a gradual increase in the pH with the passing of time until reaching pH values of around 4.11 at the end of storage (P<0.05). A decrease of around 38% in the initial values of titratable acidity was observed for all samples, obtaining titratable acidity values of 0.4% for control and AlgNa samples and 0.3% for the AlgNa+AA samples (P<0.05) (Fig. 4).

The decrease of the titratable acidity (%) in both uncoated and coated pineapple samples agreed with the increase in pH of the samples (Figs. 3 and 4). In a recent study, Pizato et al. (2019) evaluated the effect of a different gum-based edible coating on the shelf life of fresh-cut pineapple (variety Smooth Cayenne). They also found a decrease in the acidity of the minimally processed pineapple and an increase in the pH with the passing of storage days. According to Valero et al. (2013) , the decrease in total acidity is typical during postharvest storage and has been attributed to the use of organic acids as substrates for the respiratory metabolism in detached fruit.

Behavior of the soluble solid content

The behavior of the soluble solid content of uncoated and coated cut pineapple samples is shown in Figure 5. At the initial time, statically significant differences were not found between uncoated and coated samples (P<0.05) with values around 11 °Brix observed. With the passing of storage days, the uncoated and the coated samples showed soluble solid contents fluctuating between 10 and 12 °Brix during storage. At the end of storage, control and AlgNa samples exhibited a slight decrease in the values of soluble solid content, while in the AlgNa+AA coated samples, this parameter was similar to the initial one. It is well known that sugars are the most important components in soluble solids of fruits and that their concentration varies with the species, cultivar, maturation stage, and climate. Soluble solid contents from 7 to 14% have been reported for several pineapple cultivars (Dussan-Sarria et al., 2014; Pizato et al., 2019), and different behaviors have been observed in the soluble solid content of cut pineapple samples during refrigerated storage. For instance, Pizato et al. (2013, 2019), who worked with minimally processed peaches and pineapples, observed an increase in the soluble solid content of fruits with the passing of storage days. This result was attributed to the significant water loss suffered by the fruit, resulting in a concentration of total soluble solids.

Conclusions

The application of edible coatings based on sodium alginate and its blends with ascorbic acid have proven to be a useful strategy for the preservation of the visual appearance of minimally processed pineapple under refrigerated storage. These coatings formed a good film on the surface of fresh-cut pineapple samples giving the fruit a bright, translucent, fresh-like appearance. Coated samples showed better appearance during storage when compared to the uncoated ones. Overall, these results suggest that the use of sodium alginate coatings for the preservation of fresh-cut pineapple is a promising strategy that could find useful applications in postharvest technology.