Introduction

Several studies have been recently conducted on yerba mate (Ilex paraguariensis) because of its effects on human health (Kahmann et al., 2017; Zielinski et al., 2020; Croge et al., 2021). The alkaloids, terpenes, polyphenols, and essential oils, among other compounds present in its chemical composition are responsible for pharmacological activities that have anti-inflammatory, anti-obesity, and antioxidant effects (Croge et al., 2021). The most common use of yerba mate consists of an infusion of its leaves, such as chimarrão (a hot infusion of yerba mate leaves), tereré (a cold infusion of leaves) and mate tea (Zielinski et al., 2020). However, in the last years, yerba mate has been used as raw material in non-traditional uses that include the production of beers, soft drinks, sweets, and functional cheeses (Croge et al., 2021).

Yerba mate production is particularly favored in eastern Paraguay, north-eastern Argentina and southern Brazil, where its cultivation and processing are an important economic activity, not only for South America but also for international trade (Heck & De Mejia, 2007; Frizon et al., 2017). The geographical origins associated with environmental conditions, soil composition, harvest time, and processing and cultivation can affect the levels of the bioactive compounds (Kahmann et al., 2017; Zielinski et al., 2020). Additionally, other anthropogenic activities can influence the chemical composition of yerba mate by introducing compounds harmful to health (Toppel et al., 2018; Valduga et al., 2019).

The drying is a vital stage in the processing of the yerba mate leaves. This process involves simultaneous mass and heat transfer through the leaves, which may cause significant changes in yerba mate characteristics. The drying stage influences the product quality as well as its cost (Timm et al., 2019; Siqueira et al., 2020). These concerns could be addressed by using m athematical simulations of the drying process (Siqueira et al., 2020). Hence, knowing the drying characteristics of bio logic al materia Is is es se nt i al to design, optimize, and control the drying process (Pilatti et al., 2016).

In this context, this study evaluated the drying characteristics of yerba mate leave s cultivated in sоuthern Вrazil and proposed a mathematical model of the drying process. This research also determined the concentrations of diverse toxic metals, such as As, Cd, Pb, Ni , С г and Hg since studies about the presence of toxic metals in yerba mate leaves are scarce.

Materials and methods

Plant material

Yerba mate leaves were evaluated from three different geographical locations fro m Brazil. The samples from Cruz Machado (26°1'0" S, 51°21'0" W) located in Paraná state, Brazil were identified as PR. Samples from Santiago (29°11'30" S, 54°52'2" W), located in Rio G ra nd e do Sul state, Brazil were identified as RS. Finally, leaves from Antônio Prado (28°50'13" S, 5Г17 '45" W) also located in Rio Grande do Sul state, Brazil were identified as NT.

Drying equipment and experimental setup

Leaves of each sample were cut with dimensions of 2 x 2 cm to be used in the drying experiments. The initial moisture content of each sample was determined using a convection oven at 70 ± 2°C. The drying was carried out in a Gibertini Eurotherm thermobalance (Novate Milanese, Italy) with 350W power, using approximately 1g of sample. The temperature used was 70°C. The sample mass was determined at 5 min intervals, directly by the thermobalance front display, until a constant mass was reached.

Modelling of the drying process

To evaluate the drying characteristics of yerba mate, the moisture ratio (MR) values were determined from the moisture content data (kg water/kg dry matter) at time t from Equation 1:

where Mt, Mo and Me are the moisture content at any time of drying (kg water/kg dry matter), the initial moisture content (kg water/kg dry matter), and the equilibrium moisture content (kg water/kg dry matter), respectively. Me was neglected since its values were relatively small compared to Mt and Mo (Mewa et al., 2019; Yilmaz et al., 2019).

The drying rate of yerba mate leaves was obtained according to Equation 2:

where DR is the drying rate (kg water/kg dry matter per min), M t + dt is the moisture content at t + dt time (kg water/ kg dry matter) and t is the drying time (min).

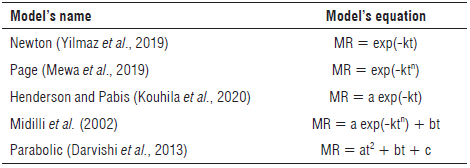

The drying data obtained were fitted to five different drying models detailed in Table 1.

TABLE 1 Mathematical models applied to the drying curves.

MR - Moisture ratio; t - time; a, b, c, k, n: constants.

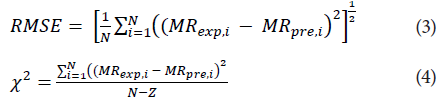

The nonlinear least-squares regression analysis was used to estimate model parameters using the software Origin® 2018 (OriginLab Corporation, Northampton, MA, USA). The coefficient of determination (R2) was the primary parameter used for selecting the best model to define the drying curves (Darvishi et al., 2013). However, to better determine the quality of the fit, reduced chi-square (χ2) and root mean square error (RMSE) were also calculated. These two statistical features were calculated according to Equations 3 and 4, respectively:

where MR exp,i is the experimental moisture ratio, MR pre,i is the predicted moisture ratio, N is the number of observations, and Z is the number of constants. The model that best described the drying characteristics was chosen as the one with the highest R2, followed by the lowest x2 and RMSE values (Sarimeseli,2011;Yilmaz et al., 2019).

Effective moisture diffusivity

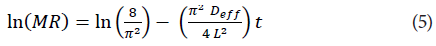

The effective moisture diffusivity can be determined from the slope of the normalized plot of MR, ln(MR) versus time, when the drying time is abundant (Darvishi et al., 2013; Incedayi, 2020; Kouhila et al., 2020), using Equation 5

where (Deff) is the effective moisture diffusivity (m2/s) and L is the half thickness of the sample (m).

Metal content determination

The arsenic, cadmium, lead, nickel, chromium, and mercury contents in yerba mate leaves were analyzed using ICP-OES equipment (ICAP 7000, Thermo Scientific, Cambridge, UK). The samples were previously dried in a convection oven at 70°C until constant weight. The samples were prepared according to the EPA method 3050B (EPA, 1996) and the APHA method 3120B (Gottler, 2017), and analyzed in triplicate.

Results and discussion

Drying characteristics

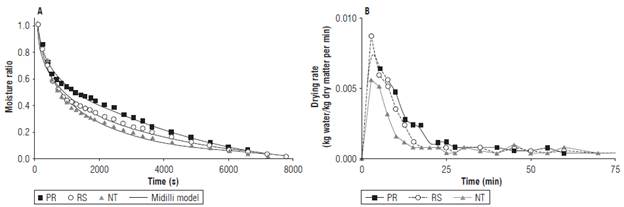

The evolution of moisture content as a function of time can be represented by the drying curve. Figure 1A shows the variations in the moisture ratio (MR) with the drying time for all leaves studied. According to Kouhila et al. (2020), the drying curve can be separated in three main phases. In the first phase, a transition between transient to permanent regime of drying takes place. The sample temperature reaches the wet bulb temperature. The main part of energy is used to increase the sample's surface temperature through a sensible heat input which will result in water evaporation. As seen in Figure 1A, before the initial 1000 s, all samples show very similar behavior, which is consistent with the first stage of drying.

The second drying phase corresponds to a more prominent drying since the steady state phase begins. At this stage, the free water present in the sample's surface is evaporated. The saturation vapor pressure inside the oven is equal to the vapor pressure at the sample's surface (Kouhila et al., 2020). The drying rate is constant during this stage and only depends on the external conditions, such as temperature, air humidity and flow characteristics (Darvishi et al., 2013; Kouhila et al., 2020). It was not possible to identify the steady state phase in Figure 1A. After the first period, all samples only showed a falling rate period. A similar behavior was observed by Pilatti et al. (2016) for yerba mate leaves.

Phase 3 corresponds to the falling drying rate period. As shown in Figure 1A, this period can be identified approximately from 1000-6000 s. At this period, the energy is used to evaporate the water from the inside of the sample. In organic materials, such as yerba mate, the water evaporates from the inner layers of the sample generally by a diffusion-controlled process. Consequently, the drying rate decreases increasing the drying time, as can be seen in Figure IB. Thus, the constitution of each yerba mate leaf may influence the mass and heat transfer that may cause the decrease in the drying rate. Pilatti et al. (2016) reported that, at this stage, the drying is governed by the water diffusion in the solid that agrees with the results of this study. After 6000 s, the moisture ratio was reduced, indicating that the drying process was near reaching the equilibrium moisture content.

Modelling of the drying curves

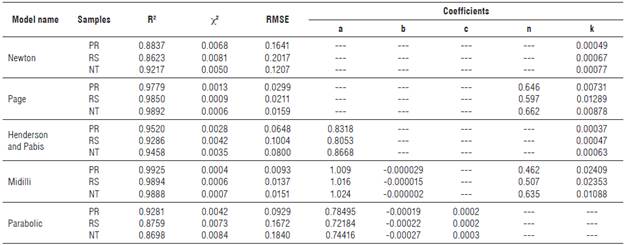

The best model for describing the drying characteristics of the leaves studied was selected according to the highest R2 and the lowest x2 and RMSE values. The statistical results for the models tested are summarized in Table 2.

TABLE 2 Results of the statistical analysis on the modelling of moisture content versus drying time for the samples of yerba mate leaves studied.

PR: samples from Paraná; RS: samples from Rio Grande do Sul; NT: samples from Antônio Prado. R2: coefficient of determination, x2: reduced chi-square; RMSE - root mean square error.

From all modes tested, the Midilli model seems to be the best model describing the drying characteristics of the three samples, as can be seen in the adjustment done in the experimental data shown in Figure 1A, and also verified by the highest R2 and lowest x2 and RMSE values shown in Table 2. However, the Page model also showed similarity with the experimental data and could not be discarded. Pilatti et al. (2016) evaluated the drying of yerba mate leaves in a bench dryer and found that the Page model was suitable to predict the experimental data. Holowaty et al. (2018) also observed that the Page model better described the drying of yerba mate leaves.

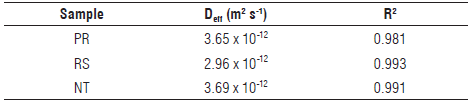

Effective moisture diffusivity results

The values of effective moisture diffusivity are shown in Table 3. The Deff values ranged from 2.96 x 10-12 to 3.69 x 10-12 m2 s-1. The values obtained in this research are in the general range of other values found in the literature for yerba mate leaves ranging from 10-14 to 10-10 m2 s-1 (Ramallo, 2001). Ramallo et al. (2001) found moisture diffusivity between 2.3 x 10-11 and 2.5 x 10-10 m2 s-1 for yerba mate leaves cultivated in Argentina, drying the leaves at 100-130°C, while Pilatti et al. (2016) obtained moisture diffusivity ranging from 2.3 x 10-11 to 2.5 x 10-10 m2 s-1 for yerba mate leaves from Brazil, when drying the samples at 55°C, 65°C and 75°C.

TABLE 3 Values of effective moisture diffusivity (Deff) for the yerba mate leaves.

PR: Samples from Paraná; RS: samples from Rio Grande do Sul; NT: samples from Antônio Prado; R2: coefficient of determination.

The NT showed the highest Deff value followed by PR and RS. This result corroborated the moisture ratio showed in Figure 1A. When samples were dried, the activity of water molecules increased (Xiao et al., 2010) since the energy was used to heat the sample; consequently, the movement and collisions between water molecules increased, which resulted in higher moisture diffusivity.

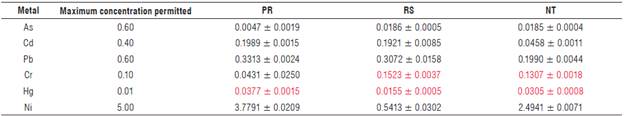

Metal content

The concentration of arsenic, cadmium, lead, chromium, mercury, and nickel found in the leaf samples is shown in Table 4. The maximum metal content permitted in yerba mate according to Brazilian legislation (Presidência da República - Brasil, 1965; Ministério da Saúde - Brasil, 2013) is shown in Table 4.

TABLE 4 Metal concentration (mg kg-1 DW) found in the yerba mate leaves.

Values in red are higher than the maximum permitted by Brazilian legislation (Presidência da República - Brasil, 1965; Ministério da Saúde - Brasil, 2013). PR: Samples from Paraná; RS: samples from Rio Grande do Sul; NT: samples from Antônio Prado.

Based on the results shown in Table 4, the contents of As, Cd, Pb and Ni were below those permitted by Brazilian legislation, while the Hg content obtained in the three samples of yerba mate leaves was above that allowed by Brazilian legislation. The highest levels were obtained for the PR and NT samples, with contamination 3 times higher than the maximum content established by Brazilian legislation. The Hg contamination in the RS sample was 50% higher than that allowed by Brazilian legislation.

Mercury is present in the entire biosphere, although it is far from natural or anthropogenic sources. Mercury compounds such as chlorides, nitrates and sulphates are stable and are even more abundant in the environment (Xiao et al., 2010). Thus, contamination of soils and waters with Hg can generate leaf contamination during plant growth.

The Cr content was 50% above that established by Brazilian legislation for the RS leaf samples and 30% above for NT. Saidelles et al. (2010) evaluated yerba mate samples and verified higher levels of Cr. The authors obtained Cr content that ranged from 1.3 and 1.6 mg kg-1 for samples commercialized in the southern region of Brazil. According to Valduga et al. (2019), the elemental composition of the yerba mate leaves can be altered by the chemical properties of the soil, fertilization, and limestone use. Water used for soil irrigation may also contain toxic metals (Kosanic et al., 2017; Santos et al., 2018) and contribute to the higher levels of metals in the yerba mate leaves analyzed. Therefore, other studies need to be carried out to confirm these hypotheses.

Conclusions

Drying characteristics and concentrations of As, Cd, Pb, Ni, Cr, and Hg in the yerba mate leaves were investigated. The drying curve revealed only the presence of a falling drying rate period. The Midilli model seemed to be the best mathematical model to describe the drying process. The moisture diffusivity ranged from 2.96 x 10-12 to 3.69 x 10-12 m2 s-1. All samples studied showed Hg levels higher than those permitted by Brazilian legislation, while the RS and NT samples showed higher levels of Cr. The higher levels of Hg and Cr may be associated with soil composition, use of fertilizers, limestone addition to soil, or contamination of the water used for soil irrigation. However, new studies are required to confirm these hypotheses.