I. INTRODUCTION

It is well known that multiple accidents take prominence inside the mines, causing personal and material damages, often irreparable. However, the costs that mining catastrophes generate far exceed what an opportune prevention could have cost in the first place. As aggravating, there are multiple legal repercussions due to damages in natural and social environments. Apart from that, the stigma continues increasing over one of the most controversial industries worldwide. For instance, the San Joaquin mine, located in Amagá (Path Paso Nivel), Antioquia, Colombia, suffered an explosion in 2010 that killed 73 workmen inside the mine 1. Only in pension insurances, COP $12.000 million (rough $US 6 million) were considered, excluding ruined machinery, environmental impacts, and labor resumption. With this outlook, it is appropriate to say that, given the complexity to establish coal concentrations and its fineness on the atmosphere, it is difficult to foresee when there will be a possible explosion inside the mine.

ATEX standards focus on controllable aspects, so risk factors can be decreased. Therefore, accidents like Amaga's are greatly preventable if these regulations are firmly considered. To demonstrate the importance of these regulations, it is appropriate to show the normative context that mining safety standardized in some countries, and the Colombian legislation position on this subject, and therefore, to reveal its deficits. In addition, this paper will show the definition of "Explosive Atmosphere" (hereafter: EA), its behavior, and formation elements. This is significant for giving a meaning to technic and management statutes that are essential for explosion risk control. Therefore, this article is important because it emphasizes the ethical and legal value of ATEX standards.

The approach of a complex technic normative like ATEX standards has represented a very ambitious labor for the European Union (EU), by studying, since its origins, the current normative worldwide seeking to synthetize and build a mandatory observance guide for member countries. This origin is given by the European Parliament and Council Directive 1994/9/ CE, relating to devices and protection systems for use on potentially explosive atmospheres (hereafter: PEA).

Finally, this paper seeks to provide a critical analysis supported on theoretical references and demonstrable evidences of the treatment or disregard of ATEX. In other words, it analyzes the consequences of avoiding the applicative process of such normative inside the mine, and the possible legal, material, and contextual repercussions.

II. EXPLOSIVE ATMOSPHERE CHARACTERISTICS

Two factors must coincide for an explosion to occur: an ignition source (IS), and an explosive atmosphere that supplies oxygen, and is defined as the "mixing with air, under normal atmospheric conditions of flammable substances in the form of gases, vapors, mists or dust, where, after ignition, combustion spreads to the entire unburnt mixture" 2. Combustion of a substance can give rise to a fire or explosion depending on the substance characteristics, and can be generated when mixing with air and in the presence of an IS. Therefore, the ignition point, the lower and upper flammable limits (LFL, UFL), and the oxygen limit concentration (OLC) are data to have in mind when analyzing the combustion behavior of the substance 3.

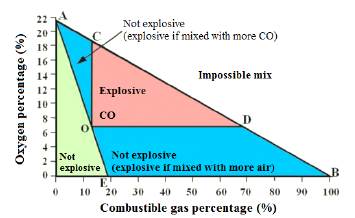

The Coward Explosive Triangle, published by Coward and Jones in 1952 4, is a practical method to rapidly determine the explosiveness degree of a gas mixture by assessing methane (CH4), carbon monoxide (CO), and hydrogen (H2). The LFL, UFL, and the Stoichiometric Value Limit represent the vertices of the triangle, referring to the percentage concentration of each gas (Table 1), dividing it into four zones (Fig. 1). The first zone on the AB line corresponds to an impossible mixture due to the absence of gas mixture. The second one is the absolute safety or non-explosiveness zone, located between points A, E, and the origin. The COD triangle represents the explosive zone and the nonexplosive areas AOC and DOEB that could exploit if they are mixed with more air or gas 4. An increase in temperature extends the explosiveness range, so the LFL is lower and the UFL is higher. In case of having several types of gases, vapors, mists, or combustible or flammable dust, the protective measures are adjusted to the greatest potential risk 5.

Table 1 Vertices of the explosive triangles 4

| Gases | Flammable limits (%) | Stoichiometric Value (%) | |||

|---|---|---|---|---|---|

| Lower | Upper | Gas | Oxygen | ||

| Methane (CH4) | 5.0 | 14.0 | 5.9 | 12.2 | |

| Carbon monoxide (CO) | 12.5 | 74.2 | 13.8 | 6.1 | |

| Hydrogen (H2) | 4.0 | 74.2 | 4.3 | 5.1 | |

Hybrid EA consist of a heterogeneous mixture comprising gas with solid or liquid particles in suspension. Frequently, the total flammable gas concentration is > 10 % of the lower flammable limit (LFL), and the total suspended particles concentration is > 10 % of the minimum explosible concentration (MEC) 7. Examples of hybrid mixtures are methane mixtures, coal dust and air, and their flammability and explosiveness are markedly higher than those of the gas or dust separately 3,8,9.

An IS is an activation energy focus capable of producing a combustion that can be propagated to the unburnt mixture, such as hot surfaces, flames and hot gases, sparks of mechanical origin, electric currents, static electricity, and exothermic reactions, including the dust auto ignition. This energy in some cases does not need to be very high because a chain reaction is generated from the inflammation of the flammable substance. For EAs, ISs will always be present when the formation and duration probability cannot be assessed, according to the normative EN 1127-1 (3.5).

The National Institute of Safety and Hygiene at Work (INSHT), in its "Technical Guide for Evaluation and Prevention of Risks derived from Explosive

Atmospheres at the Workplace", according to the Royal Decree 681/2003, indicates the basic principles for explosion prevention and protection in these atmospheres (Fig. 2). For this, the formation of EA must be prevented by acting on the source to avoid the diffusion of explosive substances that may come into contact with some IS. Also, it considers the need to have equipment according to safety measures, and assess the risk that cannot be avoided, estimating the probability of EAs formation and their duration and extension, in addition to the probability of coming into contact with an IS and the final consequences. Finally, protection measures that attenuate the effects of an explosion, such as physical barriers or explosion orientation mechanisms, such as decks, screens, and windows are considered. 5.

III. NORMATIVE CONTEXT

Because EA rules vary according to the country where they are studied, showing the content and focus of some of them will indicate the importance and advantage (or disadvantage) of ATEX in mining. Therefore, the NFPA and ATEX will be the guidelines analyzed in this paper due to their accessibility and applicability. The comparison of these guidelines will give light into the choice of ATEX as the alternative to continue in Colombia.

A. North American normative

The NFPA (National Fire Protection Association) is an association founded in the United States to develop codes and standards for fire prevention and other hazards, and for minimizing their consequent effects. The accreditation given by the American National Standards Institute (ANSI) makes it a reliable entity committed to research 10. As for the mining scenario, the NFPA has more than 20 codes for mining equipment and methods for both coal and metals/nonmetals. It is worth emphasizing codes 68 or Standard on Explosion Protection by Deflagration Venting, and 654 or Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, which are perhaps the most representative in the area, encompassing other codes in their contents.

Code 654 was born in 1943 to prevent dust explosions in the plastic industry. Subsequently, it was expanded to chemical products, dyes, and pharmaceutical powders. It also has requirements against fire and explosions, and describes the requirements and methodology for dust cleaning 11. This code has general definitions and requirements ranging from the process and design of facilities to risk analysis, change management, and incident investigation that promote the creation of a safety culture in facilities. It also determines equations for calculating the depth of the dust layer and the mass of dust accumulated in a room depending on the danger of fire or explosion. In areas where combustible dust is produced and accumulated, it will be proceeding to separate and/or construct buildings such as firewalls, or to use the standard 68 to protect other facilities in order to minimize damages by fire or explosion 11.

On the other hand, code 654 indicates that the equipment must operate in a way that allows the least possible dust escape, having an explosion protection design and incorporating one or more protection methods, such as the oxidizing agent concentration reduction (NFPA 69), explosion venting (NFPA 68), deflagration extinction systems (NFPA 69), and dilution of combustible dust. The standard covers equipment and some protection measures that are applied only to the surrounding environment of the devices, but not to themselves, contrary to ATEX 11. Another issue analyzed by the 654 and 80 standards is the control and cleaning of fugitive dust, which must be done with some recurrence; here, the standard refers to section 6.1, but specifies neither the frequency nor the mass amount nor the permissible dust layer. Also, cleaning methods are specified, preferably by vacuum extraction, with alternatives such as sweeping, water washing, and compressed air in places where the vacuum cleaner cannot access 11.

Fire protection includes fire and spark detection systems, fire extinguishers, hoses, hydrants, automatic sprinklers, detection systems, and alarm service. For training and procedures, employees should be instructed in the operation and maintenance procedures, taking into account the personal protective equipment (PPE), emergency response plan, incident preparedness and response, and training of contractors and subcontractors 11.

Code 68 emerged in 1945, undergoing through major transformations since then, in order to provide recommendations regarding venting of explosions, research gathering, and work done on the subject in other countries such as Great Britain and Germany. This standard presents the fundamentals and parameters that determine an explosion, as well as those that affect the venting of deflagrations. The choice of conduits, flow and pressure calculation methods, dust venting and hybrid mixtures, their effects, design, installation, and maintenance requirements are key points in minimizing the structural and mechanical consequences caused by explosions 7.

B. European regulation

In the EU, Directives are used as instruments for the legislation harmonization in the member countries, being the first ones on PEA in 1976 for the industry in general, and in 1982 for mining. The name ATEX was given by the French version of Directive 94/9/ EC: Appareils destinés à être utilisés in ATmosphères EXplosives, published in the Official Journal of the European Communities No L100, on April 19 of 1994 12.

The publication of the ATEX Directives formed the legal framework for safety of the environment, infrastructures, and workers in the installations. ECs develop in the midst of latent risks to which, despite their knowledge, do not apply the proper control, causing accidents and catastrophes. Therefore, the ATEX seek to regulate this type of situation by means of the following regulations 12:

RD 144/2016 (repeals RD 400/1996/ATEX-95): it transposes Directive 94/9/EC 13, establishes the safety requirements for equipment and systems, quality modules, "CE" certification systems, and distinction of teams in groups and categories (Group I for underground mining and Group II for the rest of the facilities) 14. It should be noted that Directive 94/9/EC was modified on February 26 of 2014 by Directive 2014/34/EU, which entered into force on April 20 of 2016 2.

RD 681/2003 (ATEX-137) 15: Specific decree within the framework of Directive 89/391/EEC, or Law on Prevention of Occupational Hazards published in the Official Journal of the European Communities No. L183, June 1989 16. It sets up the Explosion Protection document in a way that is consistent with the Occupational Hazard and Preventive Activity Planning documents. The field of application practically coincides with RD 144/2016.

Law 31/1995 on the Prevention of Occupational Risks determines the basic body of guarantees and responsibilities for the protection of the workers' health, leaving to the development of regulatory rules the minimum measures for an adequate protection (Article 43 Law 31/1995 LPRL) 5,12. On the safety side of products and equipment for use in EA, Directive 94/9/EC "Equipment and protective systems intended for use in potentially explosive atmospheres" (or ATEX 95) establishes the Essential Safety Requirements that must be complied, as well as procedures for the accreditation of conformity within the criteria known as "the New Approach".

Regarding occupational safety, the reference is to Directive 1999/92/EC on minimum safety requirements for the improvement of the workers' safety and health (hereafter OSH) exposed to risks arising from EA 17. The Directive 1999/92/EC details, for the explosion risks, the provisions of Directive 89/391/EEC on the "application of measures to promote the improvement of the safety and health of workers at work" (Directive MARCO). It also establishes the operation mode within the facility, and the suitability of the equipment for the work zones defined under this Ordinance. Also, referred as ATEX 137, it excludes extractive industries because of its specific regulation on workers' safety in EA, on Directives 92/104/EEC [18], transposed by the R.D. 1389/1997 19, and 92/91/EEC [20] transposed by the R.D. 150/1996 21.

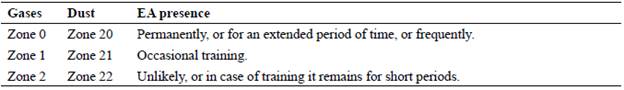

According to the ATEX directives, there are two types of EAs, which are classified according to the probability of their presence and the considered substance (Table 2) 12. ATEX do not consider explosions caused by unstable substances such as explosives, pyrotechnic material, and organic peroxides, or those occurring under non-normal atmospheric conditions.

IV. ATEX CLASSIFICATION OF EQUIPMENT

Team I consists of two categories of devices: M1 and M2. Category M1 deals with equipment designed with special protective means, for underground mining and surface parts of the mine that present explosion risks. Since they continuously operate in the presence of EA, they must have protection means so that in case of failures, they would at least have a second independent mean that ensures the required safety level. In M2, the equipment must be designed to operate according to the parameters set by the manufacturer and ensure a high level of protection. Since they are also used in underground mining, they must have energy-cutting systems in case of EA occurrence 2,14.

The second group covers three categories related to foreign, non-mining industry. Category 1 presents the same measures of group M1, although it is implemented in environments where EA formation is constant, lasting, or frequent. Category 2 is used in places with probable formation of EA, counting on protection measures that assure the required level, even in case of device failures. Category 3 demarcates the used equipment in areas with a low EA formation probability. Despite this, it is infrequent, and its presence is of short duration 2,14. The Decree has additional safety measures for the equipment, ranging from manufacture that inhibits dust penetration, to the guaranty that the surface temperatures of the apparatus pieces are below the ignition temperature of the dustair mixture 2,14.

A. Risk conditions and protection modes

Measures taken at classifying hazardous conditions cover the risk of firedamp and dust 22. In mining, "risk conditions" are defined for a particular site, unlike other industries that limit "zones" of specific dimensions.

Risk conditions 1 (EA): parts of the mine and its surface facilities with threat from firedamp or flammable dust. It includes labors in which the LFL is exceeded.

Risk conditions 2 (PEA): Parts of the mine and its surface facilities may be threatened by firedamp or flammable dust. It includes labors with content of firedamp out of its explosiveness range.

The standard UNE-EN 1710 23 specifies the requirements to be met by equipment and components that can be used in mines with a risk index of EA formation. It includes the electrical and mechanical protections applicable to fans, diesel engines, drilling equipment, etc., as well as protection against fire in machines and equipment such as conveyor belts. To achieve an adequate safety level, equipment must be designed according to safety principles, and constructed following certain constructive rules, or Protection Modes (Tables 3 and 4) 24.

Table 3 Protection methods for electrical and mechanical equipment suitable for explosive zones 24

| Method | Electrical modes | Mechanical modes |

|---|---|---|

| Confine the explosion | D | Dh |

| Separate the EA from the energetic source | p m q o t | ph kh ht |

| Reduce the energy or prevent sparks or arcs | e i | ch bh |

On the other hand, there are three different protection measures for mining, specially designed according to the characteristics of underground mining 25:

Primary protection: substitution of flammable substances or oxygen from air, or reduction of quantities up to the level where there is no danger of explosive mixture formation.

B. CE marking

The CE marking ("Conformité Européenne" or European Conformity) of equipment indicates that the product complies with the requirements established by the EU legislation subject to the principles in Regulation (CE) No 765/2008. This logo must be

visible, legible, and indelible; if that is not possible, the logo must be placed in the device packaging and documents. The minimum marking indications for an equipment are the following 2,14:

Name, registered trade name, or trademark and address of the manufacturer,

CE marking,

Designation of series or type,

Batch or serial number, if any,

Year of production,

The explosion protection specific marking©, followed by the symbol of the device group and its category,

For device group II, letter «G» (referring to EA due to gases, vapors, and mists), and/or la letter «D» (referring to dust).

V. ATEX MECHANISMS AND IMPORTANCE

Accidents caused by EA have become familiar in Colombia 26 because of their improper control and forecast, unlike other countries such as the United States, where their occurrence has required advances in the prevention of industrial explosions. For example, an explosion in February 8, 2008 at the Imperial Sugar Company in Georgia, USA originated from sugar powder that burned with an unknown IS.

Although an inspection had been carried out, and the employees had reported on the inadequate operation of the machinery, the time between the incident and the reports was insufficient to take corrective actions. In addition, measures to deal with an emergency were not sufficient for a catastrophe of such magnitude 27. Since this event, revisions, timely maintenance, and communication among the personnel were intensified since they are who identify in situ the aspects that can harm and impact the operation 27. From then on, these issues were reduced in the company, and surveillance for compliance of safety regulations was strictly increased, leading to a positive impact in the industry.

Therefore, the implementation of ATEX is much more than a mere formalism. When observing the regulation system of Directive 2014/34/EU, the certification of ATEX equipment has to be very meticulous and strict. First, a notified body conducts an EU type examination to assess the technical design of a product, and verify that it meets the stipulated requirements. The Directive also has modules that manage the evaluation procedures; the first of them is in accordance with the type based on the quality assurance of the production process, that is, it verifies that the manufacturer complies with the obligations established in the manufacture and marking of equipment, known as Essential Safety Requirements, stating that the products are as described in the EU examination under their responsibility. Another module is the one according to the type based on product quality assurance, by which the manufacturer declares that the products are subject to verification 2,14.

In order to promote the protection of OSH, Directive 89/391/EEC (Occupational Hazard Prevention Act) provides a legal framework of protection for those exposed to hazardous environmental factors. The Directive should apply to all public or private sectors, ensuring that employers carry out risk prevention activities and professional risk assessment. Likewise, a record of occupational accidents should be kept for the competent authorities, promoting participation in OSH decision-making, and training employees in order to eliminate risk factors that endanger the integrity of workers and equipment 16.

VI. COLOMBIAN PANORAMA

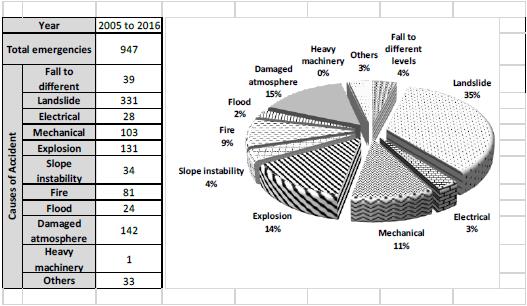

According to the National Mining Agency (ANM) in its report "Accident Statistics consolidated 2005-2016" of 2017, in Colombia there were 947 emergencies 26, of which 79 % belonged to coal mining occurring under multiple situations, being landslides the most common. However, accidents by explosion were 14 %, evidencing a lack of normative, knowledge, and rigorous application of the norm (Fig. 3).

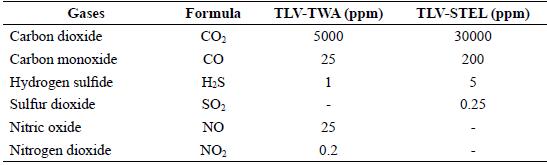

Decree 1886 of 2015 is the regulation concerning safety in underground mining operations in Colombia. In this case, responsibilities and obligations of the mining owner and workers, as well as the safety and industrial safety management in the mine and other provisions, such as the implementation of the Occupational Safety and Health Management System (MS-OSH), are arranged according to Decree 1443 of 2014. However, this is not the one referring to 1886, which refers to Resolution 1016 of 1989. Decree 1886 has a chapter of technical definitions (excepting for EA), but there are references to safety norms such as MSHA, ANSI and ATEX for equipment certification. In terms of ventilation, the Decree is strict in the air flow values that are considered in underground work, according to the personnel number, the mine elevation above sea level, the Threshold Limit Values (TLV) of contaminants (Table 5), and the used machinery. Consequently, the Decree states that no underground workplace is suitable for work if it has a volume of oxygen (measured with oxygenator) of less than 19.5 % or higher than 23.5 % 28.

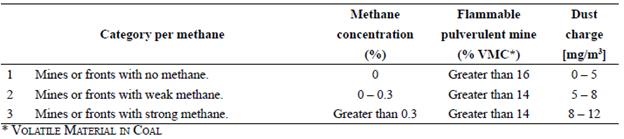

The TWA corresponds to the TLV -time-weighted average for an eight-hour day and 40-hour workweek, and the STEL, to the TLV- short-term exposure limit, for a short exposure time (less than 15 minutes) with a minimum of 60 minutes between two successive exposures at these levels, and less than four times in a day. In case the working day exceeds what is established, TLV-TWA must be corrected as provided in Paragraph 2, article 39. Accordingly, an atmosphere is unbreathable when the oxygen content is not adequate, and the gas content exceeds the PLV. The Decree also regulates the velocities of air currents according to the mining zone, and classifies the mines methane into three categories (Table 6), in which control, risk analysis and prevention associated with methane gas detachment, and registration and measurement of gas concentrations will be executed. For Category 1, controls will be executed at the start of each shift and demolition, for Category 2, the control is equal to Category 1, or it takes place at least every two hours during the working day, and for Category 3, control is mandatory at the start of the shift and is permanent in the places established in Article 46, Paragraph 2 28.

Categories for methane mines and their methane concentrations apply to any site of the mine according to the Decree 28. This means that the concentrations of the exploitation fronts and the abandoned areas, even if different, are considered as equal, having as measure for the latter the restricted passage through works and signs, which differ with the international standards in which zones are classified within the mine according to methane concentrations 28.

Table 7 shows the maximum permissible values of methane concentrations at various sites in the mine, having a critical value of 2 %, in which case the mine should be evacuated, and the percentage of Lower Flammable Limit Value (LFL) indicating the minimum concentration of flammable gases, in which the mixture is not explosive. With regard to flammable powdery mines, the Decree provides prevention and protection measures to the simultaneous presence of coal dust with a particle size of less than 0.5 mm, sufficient oxygen to maintain combustion, a potentially explosive dust cloud, and an IS. Dust cleaning activities must be carried out, along with starting fronts and loading points wetting, dust deposits neutralization, and location of barriers. However, the Decree does not refer to the type of mandatory safety equipment to avoid explosions, or the ideal tools and machinery; it only emphasizes that locomotives and electric lighting lamps must be explosion-proof, and conveyor belts flame-proof and antistatic 28.

Table 7 Maximum methane concentrations allowed 28

| Site | Maximum methane percentage (%) allowed | % LFL |

|---|---|---|

| In labors or exploitation fronts or advance | 1.0 | 20 |

| In the main air returns | 1.0 | 20 |

| In the cuts' air returns | 1.5 | 30 |

| In the air return of preparation and development fronts | 1.5 | 30 |

The Decree appoints the ANM as a regulatory agent that establishes and orders the rules regarding mining safety 28. It states the requirement of equipment to detect toxic, asphyxiating or explosive gases, as well as equipment to extract and analyze suspended dust particles, mining rescue equipment, or other equipment certified with Ex seal. Electrical installations in the mine are regulated by indicating its use, along with explosion-proof safety cables against firedamp in underground labors classified as so (Category 2 and 3) 28. For surface mining, Decree 2222/1993 does not offer any provisions against possible EAs.

In terms of certification, ISO standards are used in Colombia for accreditation of laboratories (ISO IEC 17025), products (ISO IEC 17065), and inspections (ISO IEC 17021). However, a standard in mining, which can certify mining equipment and tools for EA is still needed; moreover, the ONAC (Colombia's National Accreditation Organization) does not have accreditation programs for this activity.

The Technical Regulation of Electrical Installations -RETIE- is a guide of requirements that must be fulfilled to guarantee the protection against electric risks, defining the application field and the basic characteristics of electrical installations [30]. This regulation is mandatory according to Decree 1886/15, stating that in all methane mine, electrical equipment must have the Ex seal and be explosion-proof.

VII. ANALYSIS

Although this article aims to demonstrate the normative shortcomings in Colombia regarding EA, and its impacts on mining safety, the consequences of an explosion not only fall on the mine and its members, but on the surrounding environment and communities, which will adopt a position against mining because of such events. Additionally, the economic and legal repercussions that the mining owner must face because of the loss of human lives, machinery, and tools should encourage him to invest on measures that could reduce future costs.

The statistics of accidents and fatalities in the United States indicate a decrease in these events, with zero explosions taking place in underground coal mines between 2012 and 2017 (18 April), and with the largest fatalities caused by other events, such as powered haulage, fall of face and roof, and machinery 31. As Wei 32 indicated, fatalities in previous years (20002009) had shown a downward trend, with a rise in output, which can be seen as satisfactory, having an average of 0.0282 fatality rate per million tons.

In the European context, data were taken from Spain between 2003 and 2012, with the main causes of accidents indicated by analyzing a database composed of almost 70,000 occupational accidents and fatality reports in this economic sector. This database showed that less than 1800 accidents were due to electric problems, explosion, fire, overflow, overturn, leak, spill, vaporization, or emanation; whereas approximately 40,000 accidents were reported by control loss (total or partial) of the working machinery and body movement without physical effort 33. However, it should be clarified that this study considered all mining without differentiating between coal and other minerals. Therefore, the data can only indicate that, although the explosions are not the main source of accidents, they represent a factor to be further evaluated. Spanish coal mining presents a large decline from 2006 to 2014, going from 3.7 to 1.2 million tons/year for anthracite 34.

Despite decree 1886/15 is a recent update of decree 1335/87, a technical deepening of its content is required, since it is more of a management base, and has serious technical issues, making its application futile; in this case, it is necessary to consider complementary rules, given its non-mandatory applicability.

Furthermore, the TLVs for gases (Table 5) also consider nitrous gases. However, these are neither measured nor have available equipment to evaluate their presence. Although the TLVs have been reduced, the mining accident rate associated with them has not, foreseeing the need to reevaluate them.

Classifying mines or fronts as 'contaminated by firedamp' (Table 6) is improper since it is not assessed how methane and coal dust concentrations can vary according to study and time. The standard considers such concentrations as constant and long-lasting. It should be noted that typifying a mine depends also on the ventilation, which, although could dilute high gas concentrations, could also allow its accumulation. This same hypothesis applies for Table 7, which shows the maximum permissible methane concentrations. Therefore, within the sites presented in the table, areas abandoned or with low traffic, where gases and dust can be accumulated, representing a latent risk, are not considered.

ATEX standards ensure safety for infrastructure, communities, environment, equipment, and workers in mining facilities according to safety requirements and certifications. Colombian legislation mentions these aspects but in a shallow way, having a more administrative approach perceived as a regulatory lack, since it may be more of an industrial scheme that does not have the appropriate analysis for mining-associated risks and prevention mechanisms.

In addition, equipment accreditation procedures go hand in hand with manufacturer responsibility, and the adequacy of these is duty of the mining owner, who must watch over OSH. The Decree suggests that work tools must have safety conditions, but without indicating what those conditions are. In ATEX, the equipment design takes into account possible anomalies in its operation and misuse as a preventive measure, whereas 1886/15 only indicates that personnel should be trained for proper use. Electrical and mechanical equipment located in potential EA formation areas must have design parameters (Protection Modes) that allow an adequate level of safety; however, in Colombia, the normative considers neither EAs nor a definition nor training mechanisms, except for the requirement that equipment must be provided with safety parameters against firedamp explosions.

ATEX standards have a device differentiation for EA and technical committees responsible of standards development regarding mining and prevention measures. It also has a marking protocol (CE) for equipment, setting a quality control that guarantees safety. In Colombia, there are no regulations on this, but the marking is used because the machinery is imported and the national standards are barely strict with mining equipment manufacturers and traders in the country. Failure to perform controls and inspections promotes the use of unsafe equipment in potentially explosive areas.

Risk conditions in ATEX evaluate EA, duration time, and origin location, taking into account TLVs, possible firedamp and flammable dust generator activities, contrary to the Colombian case and its standards. While accidents such as the one at Imperial Sugar Company led to the responsible standard implementation for avoiding future accidents, the opposite happens in Colombia, where despite the persistent mining disasters, safety protocols for extraction continue to be ignored.

Work accident records, formulation of reports for mining authorities, participation in OSH decision-making, employees training, introduction of new technology, reports to the competent official about either malfunctioning machinery or misuse by personnel, and other provisions of the standard are measures to eliminate known risk factors. Nevertheless, in the Colombian context these are mere administrative or formality acts that lack of technical knowledge in matter of OSH, remaining into simple requirements for procedures.

In the light of such study, it is important to question why these rules are not taken into account in Colombia. Who is responsible for the non-application of safety standards (workers, mine owners, companies, the State)? Why, despite the recurrent mining disasters, there are no mandatory EA standards for safety in the mine and surrounding communities, such as RETIE and ISO? Answers, while not clear, allow us to reaffirm the urgent need for a regulation that improves mining practices in terms of EA. Knowing the existence of regulations like ATEX that have proven to be so complete and effective, represents an opportunity to advance in the construction of a national instruction for mining activity.

The consideration of international standards prompts a study and analysis to determine which standards would be the most optimal according to the needs and conditions of the country, taking into account their particular characteristics and applicability. In the national context, observing the constant reports of mining accidents due to explosions, evasion of safety decrees, and breach of commitment by the authorities to enforce regulations lead to the question of whether or not the country should take the global normative models in mining safety to appropriate them confidently, since these laws are crucial to achieve a more secure mining activity.

Despite the decree updates to strengthen its mission of caring for workers with occupational safety and health programs, prevalent theoretical and technical gaps that impede the achievement of a national mining safety goal still remain. Will the solution be to modify and restructure again the mining entity and its control and regulation functions?

VIII. CONCLUSIONS AND RECOMMENDATIONS

ATEX could be a clear and detailed guideline with the criteria to avoid mining catastrophes. That being so, there is a need for additional training and sensitization to all personnel in the mining industry, and awareness of the implications of whether or not to follow the norms required for mining execution. Such training would result in greater legal and social responsibility on the mining workers part. Nevertheless, it should be noted that, as international standards are not a must in the country, such plan would depend on the intrinsic motivations of the mining company. The evasion of legal norms in mining can be causing more losses and social conflicts than expected. This is not due to the mining itself, but mostly to the evasion of rules, which leads to the tragedies that ATEX seek to avoid.

To some extent, there is a correspondence between the absence of mining safety standards applicability, illegal mining, and disasters in such context. If the rule exists, but there is no one who applies it, it loses usefulness. This suggests that a guarantee entity is required to constantly watch over the rules application, given the evident lack of interest in following them when there is not a fixed external regulation. It is possible that, if there is a concrete entity that acts as a lookout for mines and their operation, laws may be complied, reducing human error accidents.

This is the case of the United States and the EU, which are territories where mining is characterized by its good functioning and quality in procedures, machinery, and human resources. Although this was not always the case, since the implementation of standards such as ATEX and NFPA, the situation improved markedly, demonstrating that a strong and well-executed normative leads to an effective reduction of mining disasters.