I. INTRODUCTION

The unpleasant sound or noise is a factor that influences noise pollution (e.g., the noise produced by airplanes, cars, industrial process machinery, and sound systems), and therefore, devices like transformers can affect human beings 1,2. In electrical transformers, noise can be caused by different physical effects, such as the pile-up of magnetic sheets that form the core, the winding, and the air forced cooling systems 3,4, which combined may provoke really high levels of noise that would exceed the limits established by national and international standards. Some of the aggravating circumstances of the audible noise problem in transformers are the influence of noise outside the transformer that is added to the own transformer noise, the location of structures that amplify noise (e.g., the location of transformers in areas near noise reflecting surfaces), and the location in places where people are constantly around 5.

Since the 1930s the causes of noise in transformers have been studied using the sound pressure method 6. For instance, some authors have focused on the level of noise reduction in power transformers 7-9, others have investigated the reasons of audible noise in transformers and have developed techniques for their reduction 10, and others have proposed a diagnostic technique for power transformers based on core and coil vibrations 11. In Colombia, electric utilities as CODENSA, EPSA and EPM started demanding compliance of the audible noise levels in the transformers installed in their electric networks 12,13.

Noise is an inherent characteristic of transformers that cannot be totally eliminated due to the vibrations produced in their core by the magnetostriction effect 14,15, and in the winding by the effects of leakage flux 16,19. Consequently, it is necessary to verify the product in accordance to the audible noise limits. In Colombia, the maximum noise level emissions permitted, and the noise measurement procedures for these transformers are prescribed in the Colombian Technical Standards (NTC for its acronym in Spanish) 5978 and 5979, respectively 20,21. The test under a no-load condition is performed at rated voltage, however, transformers may function with different voltage levels from the rated one, which might imply changes in the noise level that can exceed the standards' threshold.

This paper presents the implementation and development of noise measurement tests applied to ten distribution transformers with diverse power (37.5 kVA-150 kVA), in accordance with NTC standards, with the purpose of determining their audible noise level at different supply voltages, and verifying whether the values are within the permitted limits.

II. METHODOLOGY

The NTC 5979-2013 defines two methods of noise level measurement in transformers: i) sound pressure method, and ii) sound intensity method. For the tests, we used the sound pressure level method because the sound level meter from the Audible Noise Laboratory only measures noise through changes in air pressure (sound pressure).

A. Noise level determination

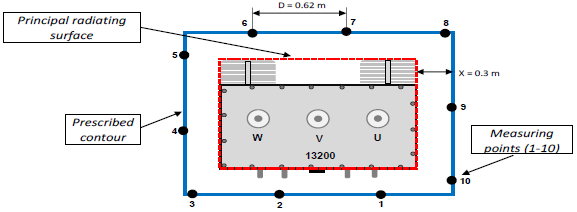

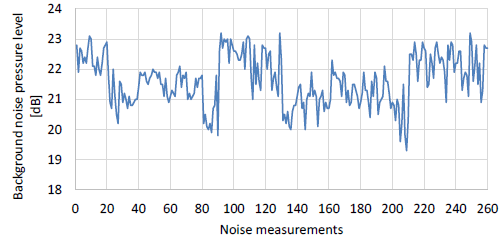

To determine the sound pressure level of a transformer, we considered the guidelines in 21. Figure 1 shows the top view of a 150 kVA transformer to which the test was performed.

1) Test parameters: Before performing the tests, we calculated the prescribed contour length (Lm), the height of the transformer (h), the measurement height (h/2), the number of measuring points (n), and the distance between each adjacent measurement points (D) (Table 1). These parameters are required to determine the exact position of every measuring point around the transformer, which are conditioned by its shape and principal radiating surface.

Table 1 Audible noise test parameters

| Id | Lm [m] | h [m] | h/2 [m] | n | D [m] | S [m2] | K [dB] |

| Transf. 1 Transf. 2 | 3.41 | 0.74 | 0.37 | 10 | 0.34 | 3.15 | 0.5 |

| Transf. 3 Transf. 4 | 5.26 | 0.53 | 0.27 | 10 | 0.53 | 3.48 | 0.6 |

| Transf. 5 Transf. 6 | 5.56 | 0.58 | 0.29 | 10 | 0.56 | 4.03 | 0.7 |

| Transf. 7 Transf. 8 | 5.62 | 0.62 | 0.31 | 10 | 0.56 | 4.36 | 0.7 |

| Transf. 9 Transf. 10 | 6.20 | 0.68 | 0.34 | 10 | 0.62 | 5.27 | 0.8 |

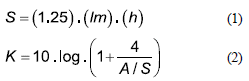

Other parameters such as the area of the measurement surface (S) and the environmental corrected factor (K), which account for the influence of sound reflections from room boundaries and/or reflecting objects near the test object, were calculated after every test using (1) and (2), respectively 21.

Where A is sound absorption area of the test room (m2)

Due to the influence of reflections from near objects, and the boundaries of the test room, the corrected average A - weighted sound pressure level (of the transformer) was calculated using (3) 21.

Where:

: Corrected average A - weighted sound pressure level (dB).

: Corrected average A - weighted sound pressure level (dB).

: Average A - weighted sound pressure level (dB).

: Average A - weighted sound pressure level (dB).

: Average A - weighted background noise pressure level (dB).

: Average A - weighted background noise pressure level (dB).

K: Environmental corrected factor (dB).

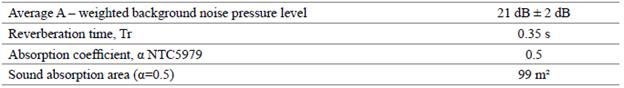

2) Test environmental conditions: During each test, we measured the environmental conditions, and found the following average values:

B. Test infrastructure

Tests were performed in an enclosure with a 45 m2 effective area (Fig. 2). Walls, ceiling, and doors were covered with acoustic components that soundproof and reduced the reverberation effects.

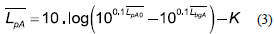

The Audible Noise Laboratory at Universidad del Valle is the only one in the country certified by the Colombian National Certification Organization (ONAC for its acronym in Spanish) to perform audible noise measurement tests in distribution transformers. We performed 260 measurements to verify the sound pressure level at the laboratory with a de-energized transformer (Fig. 3).

Under normal conditions, the background noise pressure level at the laboratory (without the influence of great power sources) was between 19 dB and 23 dB. The enclosure acoustic specifications, obtained by measurements in the audible noise laboratory and considering the NTC 5979 standards, are shown in Table 2.

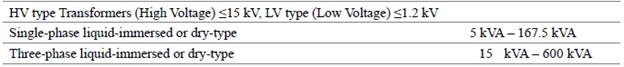

The characteristics for the audible noise test in distribution transformers are shown in Table 3.

1) Measuring instruments: Noise measurements were made using the following instruments:

Sound Level meter/Measuring Instrument Bruel & Kjaer, type 2250

Microphone Bruel & Kjaer, type 4189

Calibrator Bruel & Kjaer, type 423

The sound level meter frequency weighting was adjusted to level A to make coincide the measurements with the human hearing sensibility threshold as in 21.

C. Objects under test

The sound measurement test was performed on 10 transformers provided by a manufacturer. Power and rated voltages of the monophasic transformers (Transf. 1 and Transf. 2) and the three-phasic transformers (Transf. 3 to Transf. 10) are shown in Table 4. We choose transformers of same power, constructive, and electric characteristics with the purpose of observing the differences in the emitted sound level.

Table 4 Power and rated voltage values on tested transformers

| Id | Power [kVA] | Voltage Ratio [V] |

| Transf. 1, Transf. 2 | 37.5 | 13200/240 |

| Transf. 3 | 45 | 13200/214 |

| Transf. 4 | 45 | 13200/220 |

| Transf. 5, Transf. 6 | 75 | 13200/220 |

| Transf. 7, Transf. 8 | 112.5 | 13200/220 |

| Transf. 9, Transf. 10 | 150 | 13200/214 |

Tests were performed at the rated voltage of the secondary voltage for each one of the transformer. For transformers 7 and 10, which had the highest power (112.5 kVA and 150 kVA, respectively), we varied their voltage supply between 90 % and 110 % of rated voltage. It is important to note that during the test, a constant voltage power supply must be guaranteed.

D. Operation conditions

To determine the sound pressure level (background noise and energized transformer noise), we used two operation conditions: i) no-load transformer, and ii) transformer on load. The choice on the operation condition depends on different aspects, such as the transformer power, the load current, and the attached equipment (auxiliary cooling systems), among others. For each transformer, the described operation condition was held for the noise tests.

III. RESULTS

This study revealed that the highest noise level is produced when the transformer operates with no-load, and that a transformer on load presents a negligible noise level. Taking this into account, we only show the results corresponding to no-load transformers.

A. Rated voltage no-load transformers

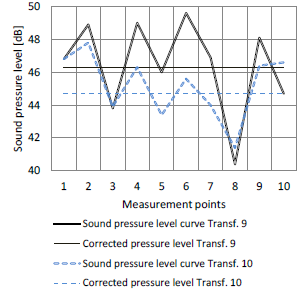

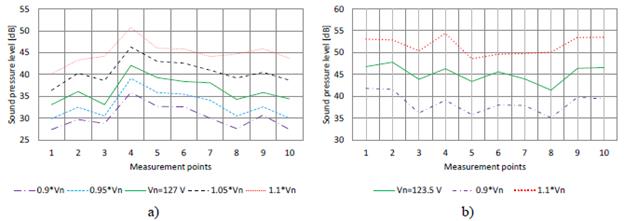

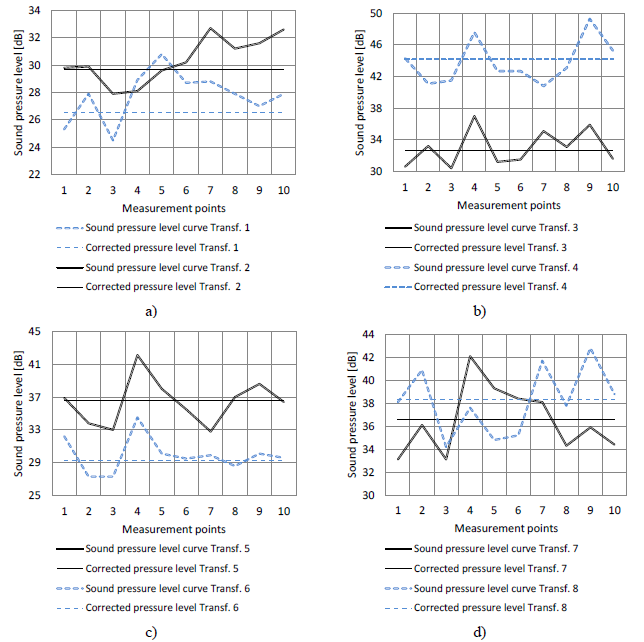

Figures 4 and 5 present the results of the noise measurements, and detail the sound pressure level curves. The horizontal axis shows the 10 measurement positions around the transformer.

Fig. 4 Sound pressure level curves: a) Transformers 1 and 2, b) Transformers 3 and 4, c) Transformers 5 and 6, d) Transformers 7 and 8.

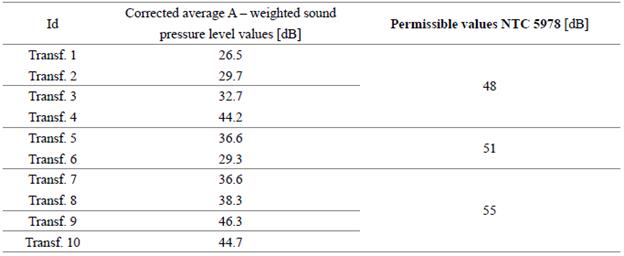

The sound pressure level for transformers with the same power showed different behaviors, with points where the sound pressure level was much higher than the average value (Fig. 4 and 5). For transformer 4, in the measuring point 9, the noise pressure level is higher than the one established in the standard: 48 dB (Fig. 4). In the other cases, none of the transformers exceeded the permissible level (Fig. 4 and 5). In virtue of the above, this paper suggests to evaluate the transformer audible noise considering the maximum permissible value at each measuring point.

The corrected average A - weighted sound pressure level values were within the permissible limits according to the standard 20 (Table 5).

B. Transformers with variations on voltage levels

Figure 6 shows the results obtained from varying the voltage supply between 90 % and 110 % in the 112.5 kVA and 150 kVA transformers' secondary rated voltage (Vn) (Transf. 7 and Transf. 10, respectively).

Variation in the voltage supply resulted in noticeably changes in the sound pressure level at each point around the transformer; but the combined sound pressure level curves for the different voltage levels described a similar behavior. The sound pressure level increased as the transformer supply voltage went up 22.

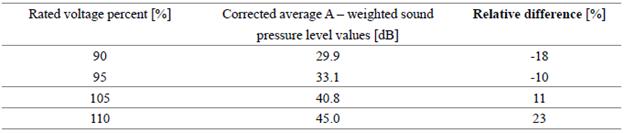

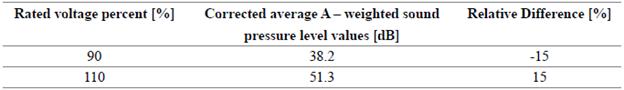

Relative percent differences for transformers 7 and 10 (36.6 dB and 44.7 dB, respectively) at a rated voltage were obtained using their corrected average A - weighted sound pressure level values as a reference (Tables 6 and 7).

Table 6 Corrected average a - weighted sound pressure level and relative differences for transformer 7

Table 7 Corrected average a - weighted sound pressure level and relative differences for transformer 10

Results showed that for transformer 7, a ±5 % voltage level variation can cause a ±10 % relative increase in the noise emitted by the transformer, which can reach 23 % (Table 6). In transformer 10, a ±10 % voltage level variation caused a ±15 % increase in the relative emitted noise. These results reveal that in conditions where the voltage level is 10 % higher than the rated voltage, permissible noise levels could be exceeded (transformer 10, measuring point 4 where a 54.4 dB sound level is reached).

IV. CONCLUSIONS

The audible noise test implementation allows to verify the compliance of the standard regarding environmental pollution by the emission of audible noise that can be generated by distribution transformers in Colombia.

The tests performed here showed different sound pressure levels at each one of the measuring points around each transformer. In some of those points, as it is for the measuring point 9 in transformer 4, a sound pressure level higher than the standard was observed. This result highlights the importance of how the maximum permissible noise condition presented in the standard NTC 5978-2013 is evaluated. The way to validate the results should correspond to the maximum permissible for each measuring point of the transformer, and not to the average of combined sound measurements.

The noise level emitted by the evaluated transformers is significantly sensitive to supply voltage variations. A ±5 % voltage variation generates differences in the noise level in the order of ±10 %. Hence, a transformer operating in overvoltage conditions can lead to exceeding the permissible noise level. Furthermore, it is necessary to guarantee the voltage stability during the test.