I. INTRODUCTION

Successful supply chains require successful logistics. Therefore, the role of 3PL providers has changed, from taking over a few simple tasks to total outsourcing, becoming a strategic provider, and working simultaneously with multiple partners in the supply chain 1

According to the 3PL Annual Report of 2016, 48 % of US companies that were analyzed use 3PL suppliers. In Colombia, the National Logistics Survey for the year 2015 showed that among the surveyed companies, 37.5 % of them had a logistics operator. This data supports the importance of working with these providers. Therefore, it is important to highlight the advantages identified with these types of providers: improvements in customer service, simplification of logistical processes, in the infrastructure investment reduction and concentration in activities for which the company is better qualified 2-5.

Some of the services provided by 3PL providers are transportation, distribution, warehouse management, inventory management, reverse logistics 4 and information systems. These services are fundamental to the supply chain. Each one of these activities implies a risk to the supply chain, which is why companies must have methods that support the selection of its logistics suppliers.

One of the relevant elements of a supplier management system is the evaluation of the supplier's performance, understood as the evaluation of the supplier's compliance in relation with the criteria defined by the organization as critical for their purchasing and acquisition processes 5. Having an existing scorecard with realistic objectives will make it easier to define the level of service expected 6.

Companies who hire 3PL providers must make good decisions when selecting which services require outsourcing. It is necessary to identify the possible benefits and risks associated with the hiring of a logistics operator before selecting one. Once the decision has been made and the 3PL provider is performing its work, it is very important to measure its performance. These measurements will not only display the quality of the service provided, but exactly which advantages and disadvantages were acquired while it executed its intended operations. Thus, action plans can be developed for the continuous improvement of the service, along with mitigation of risk and the development of strong and lasting relationships that will contribute to the strategic level of the company. Therefore, an objective and dynamic method for evaluation must be established to allow the company to make informed decisions regarding the continuity of a supplier or to be able to certify the suppliers with an outstanding result. In any of the above cases, the decision must be made on the basis of objective and quantitative elements which leave no doubt and provide transparency for all entities involved in the process 5.

The evaluation of suppliers is important for organizations because of the preponderant role they play in the dynamics of supply chains and the strategic importance of purchasing functions, due to outsourcing of the processes that are part of the know-how of the company 7.

It is of great benefit for an organization to evaluate its providers, because it provides information that reveals progress. It also helps to improve communication and diagnose problems. Evaluation includes financial and non-financial measures that relate to each of the company's organizational levels 8.

The evaluation/measurement of the performance is a problem that encompasses different types of qualitative and quantitative criteria. The definition of such criteria is a challenge that increases with the complexity and diversity of the tasks to be evaluated, which is why implementing an adequate performance measurement system is a multi-criteria decision.

On the review of literature related to the design and implementation of evaluation performance systems of 3PL providers, important revisions were found, such as 9 and proposals such as 7,10,11. In general, there are very few works available, so it is important to propose such a methodology for evaluation. Table 1 presents the main tools used for this purpose in the works found.

Table 1 Tools used in 3pl supplier evaluation

| Tools | Paper |

|---|---|

| AHP Fuzzy and TOPSIS | [12][13][14] |

| Fuzzy Sets | [15] [16] |

| AHP, ANP | [5][17] |

| Moora Method | [18] |

Regarding the criteria to be considered at the time of evaluation, some authors suggest important criteria such as logistics costs, quality of service, user compatibility, on-time delivery, information, total revenues, geographical coverage and the range of service offered 1. Table 2 presents the criteria used in the performance evaluation process.

Table 2 Criteria used in the performance evaluation of logistics providers

| Paper | Criteria |

|---|---|

| [15] | Service quality, On-time delivery, Reliability of delivery, Pre and post customer service, Target market responsiveness, Organization capability, Price, Geographical coverage |

| [11] | Reliability of delivery, Price, Innovation in services, Pre and post customer service, Legal contracts |

| [9] | Quality, Reliability of delivery, Flexibility, Price, Transportation Risk |

| [19] | Control management, Cost, Employee relationships, Control over providers |

| [17] | On-time delivery, Cost, Order accuracy, Consistency in invoices, Response to a purchase order, Orders received, Flawless deliveries, Frequency of damages in transportation, Inventory accuracy, Inventory rotation, Warehouse efficiency, Returns, Service level, Transportation risk, Warehouse risk |

| [18] | Price, Service innovation, Pre and post customer service, Responsiveness, Technology |

| [20] | Transportation risk, Warehouse risk |

It is important to emphasize that although there is a wide range of literature related to the selection of 3PL suppliers, it is not the same when it comes to the performance evaluation of these suppliers. To that effect, this article is a valuable contribution in that direction.

II. METHODOLOGICAL PROPOSAL

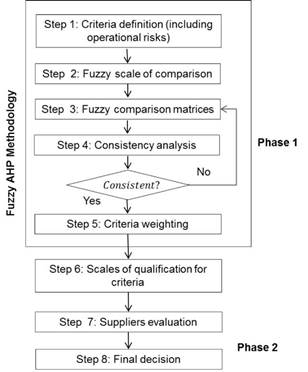

A methodological proposal can be presented to carry out the performance evaluation of 3PL suppliers through the use of the multi-criteria tool known as fuzzy AHP. Figure 1 presents this methodological scheme, which consists of two phases.

Fig. 1 Proposed methodological framework for the performance evaluation of 3PL suppliers considering the risk.

During Phase 1, those in charge of the organization will establish the weights of each criterion to be considered for evaluation through the use of fuzzy AHP. This phase only happens each time the organization decides to revise its criteria and the weights defined for them. That is to say that it is an activity with a strategic framework that is realized only whenever the business policies need to be changed. In order to establish these weights, a fuzzy scale presented in Table 3 can be used. Everybody in the organization related to the supplier evaluation process should be involved, considering both the administrative and technical aspects of this relationship.

Table 3 Proposed linguistic scale for fuzzy AHP. Adapted from 21

| Fuzzy Numerical Notation | Saaty Scale | Proposed Fuzzy Triangular Scale | Verbal interpretation of Scale |

|---|---|---|---|

| T1 | 1 | (1, 1, 2) | Equal importance of both elements |

| T3 | 3 | (2, 3, 4) | Moderate importance of one element over another |

| T5 | 5 | (4, 5, 6) | Strong importance of one element over another |

| T7 | 7 | (6, 7, 8) | Very strong importance of one element over another |

| T9 | 9 | (8, 9, 9) | Extreme importance of one element over another |

| T2, T4, T6, T8 | 2, 4, 6, 8 | (1, 2, 3); (3, 4, 5); (5, 6, 7); (7, 8, 9) | Intermediate trials |

Phase 2 is then developed each time the supplier evaluation is to be carried out. In this phase, each of the criteria defined by the rating scale that has been established is evaluated.

The final result of its application and the main objective of the evaluation will be to lead the organization to define an action plan regarding the evaluated provider to determine what the provider should be responsible for.

It is important to mention that the purpose is to include at least one criterion that is related to the operational risk associated with the activities that the 3PL provider is performing for the company. This must be done in Step 1 of Phase 1.

Both the weighing of the criteria and the scale of evaluation defined will be particular to each organization and may even be particular for each type of supplier to be evaluated. However, the fuzzy scale proposed and shown in Table 3 can be used in all cases. In addition, a proposal is presented in this paper with a rating scale from 1 to 5 and for the decision-making process with respect to the evaluated supplier. The following intervals have been established to guide the actions to be taken by the organization according to the final score:

High Performance: Ratings greater than 4.5 Ratings between 4 and 4.49

Normal Performance: Ratings between 3 and 3.9 (It is necessary to establish improvement actions to continue use of supplier.)

Performance with Risk: Deficient Performance: Ratings below 3 (continuing use of provider is not recommended).

It has been established as part of the proposal that, in the case of high performance and normal performance, use of the supplier can continue by mentioning improvement points that have prevented them from obtaining the maximum rating (5). If the performance is evaluated at risk, it is necessary to establish an improvement plan, which must be approved by the organization in order to continue commercial relations. If performance is evaluated as deficient, use of this provider should not be continued. In the event that the supplier is to be considered again by the organization, it must go through the selection process as if it were a new supplier.

III. APPLICATION AND RESULTS OF THE PROPOSED METHODOLOGY

Phase 1 started with the definition of the objective of the method. Subsequently, a team formed by the organization was gathered, the criteria to be considered for the performance evaluation of that supplier were defined, and through the application of the fuzzy AHP, the weights presented in Table 4 were obtained. For the definition of the weights, a pair comparison was used considering the fuzzy scale shown in Table 3.

Table 4 Established criteria and their corresponding weighting according to the fuzzy AHP

| Criteria | Weighing (%) |

| Delivery compliance | 22.5 |

| Transportation conditions (Risk for raw materials) | 27.3 |

| Fleet conditions (Technical risk) | 16.8 |

| Documentation Management (Inventory and payment process risk) | 20.8 |

| Service Quality | 12.6 |

A fundamental part of this methodology is the definition of criteria associated with operational risk. In this case, five criteria were defined for the evaluation. Three were related to operational risk: transportation conditions (risk for raw materials), fleet conditions (technical risk) and documentation management (process risk).

The proposed methodology was applied to a Colombian manufacturing company for one of its land freight transport providers.

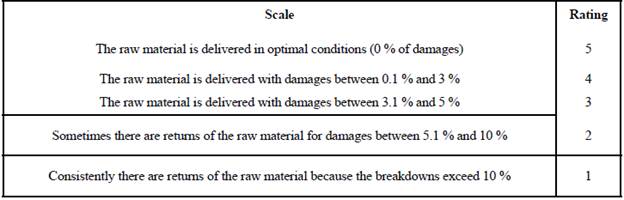

To proceed with the established weights and proceed with Phase 2, providers must be rated within each criterion. Because of this, it is necessary to define a uniform rating scale that is easily applicable by the staff of the organization. In this particular case, a numerical scale of 1 to 5 was established where the value 1 corresponds to the lowest possible results and the value 5 to the best possible values. The rating scales for the criteria "delivery compliance" and "transport conditions" are presented in Tables 5 and 6, respectively, and the remaining three criteria are similarly classified.

Table 5 Rating scale for the criterion delivery compliance

| Scale | Rating |

|---|---|

| On-time delivery and exact quantities | 5 |

| On-time delivery with variation in quantities up to 5 % | 4 |

| Delayed delivery between 1 and 3 days with exact quantities | 3 |

| Delayed delivery between 1 and 3 days with variation in quantities up to 5 % | 2 |

| Delayed delivery with variation in quantities | 1 |

Table 7 displays the overall result of the 3PL provider evaluation. As shown, the provider's performance was normal, so the organization can continue working with them until the next evaluation period. Finally, this process must be repeated every period having a duration established by the organization.

Table 7 Final evaluation of a 3pl provider that transports raw materials

| Criteria | Rating (%) | Score* | Weighted rating |

|---|---|---|---|

| Delivery compliance | 22.5 | 4.2 | 0.95 |

| Transportation conditions (Risk for raw materials) | 27.3 | 4.8 | 1.31 |

| Fleet conditions (Technical risk) | 16.8 | 3.7 | 0.62 |

| Documentation Management (Inventory and payment process risk) | 20.8 | 4.6 | 0.96 |

| Service Quality | 12.6 | 4.2 | 0.53 |

| Final Evaluation of the provider during the established period | 4.37 |

*The score corresponds to the mathematical average of the values obtained in each of the evaluations carried out during the established period.

IV. CONCLUSIONS

This methodology has been proposed to strengthen the decision-making processes of organizations.

Presented here is a multi-criteria methodology that allows organizations to track their suppliers -particularly, third-party logistics providers- so that these relationships can be optimized by seeking a mutual benefit between the evaluating company and the supplier being evaluated.

The methodology has been designed so that the organization applies it whenever it needs to evaluate its suppliers. However, the definition of the criteria and their weights are associated with the strategic objectives.

One of the most valuable contributions of the methodology presented is the incorporation of operational risk as part of the criteria to be considered in the performance evaluation, taking into account the trend towards risk management that is being appreciated in the management of supply chains.

With the company's application of the proposed methodology, it is evident that it can be incorporated as a process for different organizations, since it is structured from cited theoretical foundations and is of easy adaptability.

Decision-making processes involving different parts of an organization contain a high level of uncertainty. The use of a tool such as fuzzy AHP in these processes diminishes the subjectivity commonly found in expert judgments, since these judgments are commonly found in the use of linguistic scales that involve triangular fuzzy numbers.