I. INTRODUCTION

Pozzolanic reactions are indispensable in the development of strength of lime stabilized soils, which predominantly depend on the progress of such reactions that result in the formation of cemented products responsible for developing strength. Pozzolanic reactions depend on the curing period and require extended periods for the reactions to proceed to gain significant strength. Pozzolanic reactions involve the reaction between soluble silica and soluble alumina in the soil with calcium from lime in a high pH environment that ensures the solubility of the silica and alumina. Pozzolanic reactions continue as long as enough calcium is available and the pH is high enough to maintain the solubility of the silica and alumina. A pozzolan can be defined as a fine material of siliceous and aluminous composition, which forms cemented products in the presence of water and calcium hydroxide [1]. Clay is a pozzolan as it supplies the silica and alumina for the pozzolanic reactions. However, certain soils lack sufficient silica and alumina, which decrease rapidly after the pozzolanic reaction starts, slowing down the reaction due to lack of raw materials. This results in the formation of very less cemented products, reflected in the low strength of the stabilized soil. Under such situations, adding external pozzolanic agents to the soil as auxiliary additives can augment the supply of silica and alumina, allowing the reaction to proceed longer, and, therefore, increase the development of strength. Industrial and agricultural solid wastes have long been the source for silica and alumina in such reactions, in both concrete and soil stabilization activities. Numerous researchers have worked on the utilization of different solid wastes as pozzolans in soil stabilization. Fly ash (FA) [2,3], rice husk ash [4,5], ground granulated blast furnace slag [6,7], phosphogypsum [8,9], bagasse ash [10,11], waste paper sludge ash [12], press mud [13,14], red mud [15,16] and egg shell ash [15,17] are some of the materials that have been used as pozzolans in lime stabilization of soils. It has been found that using industrial solid wastes as auxiliary additives to cement/ lime stabilization further improves the stabilization process [18]. Generally, a waste material is added in varying combinations as pozzolan to the primary binder. However, in this investigation, combinations of two industrial wastes viz. FA and Steel slag (SS) were used as pozzolans to lime in stabilization of soil. Both solid wastes are produced in high quantities around the world, and their reutilization in soil stabilization will result in pozzolanic strength benefits, as well as environmental benefit of waste management. The worldwide production of coal combustion products, including FA, stands at a whopping 780 million tons as of 2010 [19]; the SS generation around the world stands at 350 million tons [20]. In India, FA generation stands at 184.14 million tons as of 2015 [21], whereas the generation of steel slag stands at 12 million tons [22]. FA usage in stabilization of soil with lime has been reported extensively in the literature. SS is another industrial waste with applications in soil stabilization. SS has been used very effectively in civil engineering like in the manufacture of cement [23], mortars [24], road base material [25], immobilization of heavy metals [26] and soil improvement [27]. In earlier works, SS has been predominantly used as a standalone stabilizer in soil stabilization. This work aimed at studying the pozzolanic benefits achieved due to the amendment of lime stabilization by adding two industrial solid wastes viz. FA and SS.

II. MATERIALS AND METHODS

The various materials that were used in this investigation include the soil that needed to be stabilized, the lime adopted as the primary stabilizer, and the two solid wastes, FA and SS.

A. Virgin soil

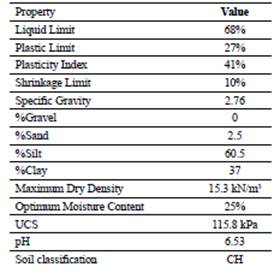

The virgin soil adopted in this study was collected from Thiruvallur district of Tamil Nadu, India. The soil was dark in color with a very high natural water content. The soil exhibited a shiny surface when cut, indicating very fine particle size. The soil was prepared in accordance with BIS (Bureau of Indian Standards) code and its geotechnical properties were characterized in the laboratory. Table 1 shows the properties of the soil determined in a previous investigation [9].

B. Lime

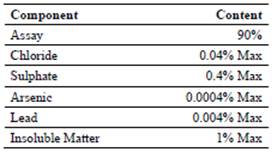

Hydrated laboratory grade lime was used in this investigation for stabilizing the soil, obtained from M/s. Loba Chemie Pvt. Ltd. Laboratory grade lime was adopted to reduce variations in the test results due to consistency in its composition. Table 2 summarizes the chemical composition of the lime as given by the manufacturer.

C. Flyash

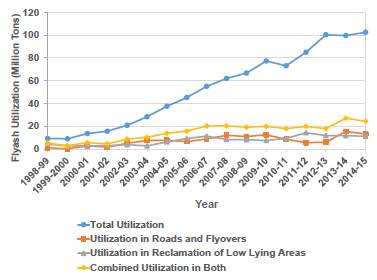

FA is a by-product of the combustion of coal during power generation in thermal power plants. It is one of the largest industrial by-product wastes in India, so much so that the Government of India leads the FA reutilization efforts for effective waste management. In India, the utilization of FA has steadily increased from 6.64 million tons in 1996-97 to 102.54 million tons in 2014-15 [21]. Its utilization in soil engineering has also increased over the years. Figure 1 shows the use of FA in soil engineering, including roads and embankments and reclamation of low lying areas. FA has been extensively adopted in various soil engineering applications like soil stabilization, stabilized soil blocks, as subgrade material and in fill applications. The cementitious property of FA is not comparable to that of lime, however, in the presence of an activator, it can produce cementitious products that can enhance the strength of the amended soil. The FA used in this work was class F type FA, obtained from Agni Steels Pvt. Ltd., Perundurai, Tamil Nadu, India. The FA was sieved through a 75-micron BIS sieve for removing lumps, and the fine fraction that passed through the sieve was adopted in the investigation.

D. Steel Slag

Steel slag is a by-product of the steel industry, produced during the separation of molten steel from the impurities in the furnace. The slag occurs as a molten liquid floating on top of the molten steel as scum, and is a complex mixture of silicates and oxides that hardens upon cooling. Steel slag is rich in silica, alumina, iron oxide and calcium oxide. It has applications in various areas of civil engineering, like manufacture of cement [23], mortar [24], road base material [25], immobilization of heavy metals [26] and soil improvement [27]. Crushed steel slag has a granular nature and can contribute to increase the friction component of a soil amended with steel slag. Chen et al. [24] adopted steel slag as a replacement for fine aggregates in cement mortar, whereas Liang et al. [27] noticed an increase in the friction angle of clayey soil when increasing the steel slag and water content. Thus, it is evident from the chemical composition and earlier literature that steel slag is capable of interacting both chemically and physically with the soil, modifying its properties, which prompted its consideration in this investigation. The steel slag used in this study was obtained from Messrs. Agni Steels Pvt. Ltd., Perundurai, Tamil Nadu, India.

E. Methodology

The methodology involved the preparation of soil [28], followed by its geotechnical characterization and classification [29], all in accordance with relevant BIS codes. Subsequently, the lime contents for soil stabilization were determined. According to Nasrizar et al. [30], there are three phases in the relationship between lime content and strength viz. below Initial Consumption of Lime (ICL), between ICL and Optimum Lime Content (OLC) and above OLC. Based on this work, the ICL of the soil was determined using the Eades and Grim pH test [31], according to the ASTM code D6276 [32], whereas the OLC was determined using the procedure suggested by Thompson [33]. After obtaining the ICL and OLC, two lime contents were adopted, one in the stage between ICL and OLC, and the other above OLC for stabilization of the soil. The lime stabilized soil was amended with an equal content of pozzolanic additive (FA and SS), and the effect of the pozzolanic amendment was studied. The combinations of FA and SS were varied within the total content of the pozzolan. The variations in FA and SS contents were selected at random. The UCS samples were prepared to a density of 14.72 kN/m3 at a water content of 25% in a split mold of 38 mm x 76 mm under static compaction. All samples were prepared to the same density and water content. Similar procedure was followed by earlier researchers [6,9,34]. After molding, the samples were ejected and immediately placed in sealable polythene covers for curing without losing moisture. The samples were cured for periods of 0 (2 hours), 7, 14 and 28 days for studying the immediate, early and delayed strength of the samples. ASTM recommends curing periods of 7, 28 and 90 days [35]. At the end of the specified curing periods, the samples were strained axially at a rate of 0.625 mm/min until failure.

III. RESULTS AND DISCUSSION

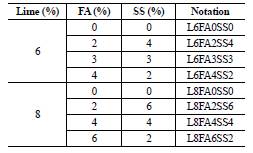

The minimum lime content required to raise the pH of the stabilized soil to 12.4 is called the ICL for a given soil [32]. The ICL determined from the Eades and Grim pH test was 5.5%. The lime content that produces the maximum strength of the stabilized soil is called the OLC. The OLC was determined as 7%. Based on these two boundaries, two lime contents, one between ICL and OLC (6%) and one above OLC (8%) were chosen for soil stabilization. Based on these two contents, an equal amount of pozzolanic additives of FA and SS were added along with lime for amending the stabilization of the soil. Table 3 shows the combinations of lime, FA and SS adopted in this investigation.

A. Uniaxial strength of amended lime stabilized soil

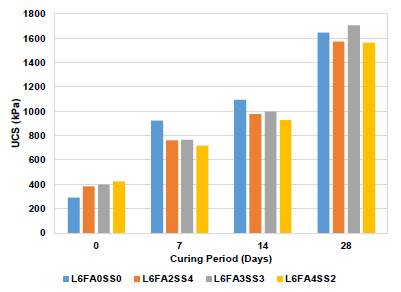

Adding FA and SS to lime stabilization of an expansive soil, modified the development of strength of the 6% lime stabilized soil (Fig. 2).

The immediate strength of the stabilized soil increased in all the three combinations of FA and SS investigated (Fig. 2). The maximum increase in strength was achieved by the L6FA4SS2 combination at 2 hours of curing. The immediate strength of lime stabilized soil increased from 289.09 kPa to 425.25 kPa. However, the immediate gain in strength was not sustained at early curing period of 7 days. It is clear that none of the combinations were capable of producing strength higher than pure lime stabilized soil. The trends of strength gain among the three combinations also changed with L6FA3SS3, producing the highest strength of the three combinations at 7 days of curing. The strength of the combination was 754.22 kPa against 990.58 kPa for pure lime stabilized soil. Thus, none of the combinations were capable of augmenting the early strength of the stabilized soil. At 14 days of curing, the trends of the strength development were similar but with clearer differences in strength among the three combinations. But, the strengths remained lower than pure lime stabilized soil, though the difference between the strength of pure lime stabilized soil and the pozzolan amended lime stabilized soil decreased at 14 days of curing. The strength of L6FA3SS3 was 996.59 kPa against 1092.57 kPa produced by 6% lime stabilized soil. At 28 days of curing, L6FA3SS3 was the only combination that produced a strength (1705.025 kPa) higher than that of pure lime stabilized soil (1646.157 kPa). Thus, the pozzolanic benefit of adding FA and SS to lime content slightly higher than ICL was only visible after a delayed curing time of 28 days, though still marginal in comparison with pure lime stabilized soil. The delayed gain in strength may be attributed to the coarser steel slag particles, which may have taken a longer time to dissolve and contribute to the reaction, thus slowing down the rate of progress of the reaction.

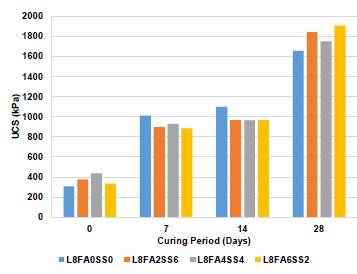

Figure 3 pozzolanic shows the pozzolanic effect of adding FA and SS to the 8% lime stabilized soil. Similar to the 6% lime stabilization, there was an increase in the immediate strength of the stabilized soil due to FA and SS amendment of the soil. The maximum increase in strength was produced by the L8FA4SS4 combination with 437.35 kPa against 357.07 kPa for pure 8% lime stabilized soil. The trends in early strength, at 7 and 14 days of curing, were similar to that of the 6% lime stabilized soil, wherein none of the combinations produced strength higher than pure lime stabilized soil. However, the strength development of the pozzolan amended combination showed a transition during this period. The strength development of combinations L8FA2SS4 and L8FA6SS2 caught up with that of L8FA4SS4 by 14 days of curing; therefore, the variations among them were marginal. However, in the following 14 days of curing, the two former combinations overtook the strength development of the latter. The combination L8FA6SS2 produced a maximum strength of 1904.33 kPa against 1653.877 kPa of pure 8% lime stabilized soil. The next highest strength was gained by the L8FA2SS4 combination with a strength of 1839.23 kPa.

However, this was a surprising result so that a clear understanding of the contribution of FA or SS could not be achieved. A steady increase in strength resulting from combinations with either FA/SS content or equal ratio blend would have been easy to interpret regarding the contributory effects of the pozzolan. However, although the maximum strength obtained with L8FA6SS2 indicates that FA is the major contributor, the next highest strength gained by L8FA2SS6 contradicts it by indicating that SS is the major contributor. The equal ratio blend produced the lowest strengths of all three combinations. Thus, complex interactions among the three components and the soil are responsible for the results obtained. This needs a more detailed investigation at the micro level, studying the mineralogy and microstructure of the stabilized soil specimens.

B. Percentage strength gain

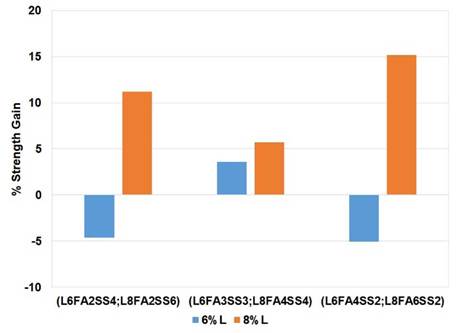

To better understand the pozzolanic benefit of adding FA and SS to lime stabilized soil, a percentage strength gain analysis was performed. Similar analyses have been performed by earlier researchers [36,37]. The calculations were done by measuring the gain in strength of the pure lime stabilized soil (control) after amending it with solid wastes. Figure 4 shows the percentage strength gained with the three FA and SS combinations. The gained strength for both lime contents (6% and 8%) showed contrasting results, with the equal blend ratio producing the maximum gained strength at 6% and the lowest gained strength at 8%. At 6% lime stabilization, only the L6FA3SS3 combination produced a strength gain of 3.57%, whereas the other two combinations resulted in a strength loss of around 5%. In contrast, at 8% lime stabilization, the same combination produced the lowest gained strength (5.72%), whereas the other two combinations, L8FA2SS6 and L8FA6SS2, produced strength gains of 11.2% and 15.1%, respectively. It is clear that the relationship between development of strength and lime content is different in the zone between ICL and OLC (6% lime) and above OLC (8% lime) lime as found by Nasrizar et al. [30]. However, the difference is that the trends are seen here in a lime-pozzolan stabilization of expansive soil. A previous investigation, did not find contrasting trends in lime stabilization amended with Phosphogypsum (PG) as additive, but stabilized at ICL and OLC; in addition, both lime contents showed an increase in strength with increase in PG content [9].

C. Effect of curing on the development of strength

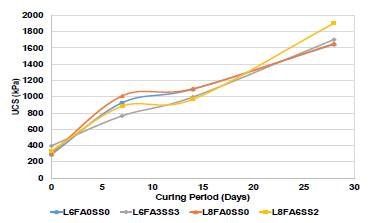

To study the development of strength of lime stabilized soil with curing, the optimal combinations L6FA3SS3 and L8FA6SS2 were analyzed. In general, the strength of the lime stabilized soil sample increased with curing, regardless of the amendment with FA and SS (Fig. 5). This agrees with the results reported by earlier researchers [9,38,40], wherein increasing curing increased the strength of lime stabilization. Approximately 50% of the strength of the lime stabilized soil was developed within the first 7 days of curing (Fig. 5), which agrees with Bell [38]. However, here, the same result was found for the amended lime stabilized specimens modified with FA and SS. In contrast, Bhuvaneshwari et al. [36] reported that 50% of the strength of lime stabilized soil was achieved within the first 3 days of curing. The second observation is the lack of major differences betweenthe strength of L6FA0SS0 and that of L8FA0SS0 (Fig. 5), despite they belong to two different phases of lime stabilization [30 A possible explanation is that increasing lime content beyond ICL increases strength until OLC, beyond this, the strength of the stabilized soil decreases. Perhaps, the choice of lime contents adopted in this investigation was such that they were on the opposite sides of OLC but produced similar strength: one in the zone of strength increase, and the other in the zone of strength decrease. This can be compared to similar densities being achieved, one on the dry side of optimum and the other on the wet side of optimum in the moisture density relationship curves. Finally, the development of strength between days 7 and 14 slowed down slightly, which is rare and, therefore, needs further probing in future investigations; beyond 14 days of curing, there was a rapid gain in strength.

The third significant observation is that the amendment of lime stabilization using solid wastes produced the difference in the lime stabilization stages below OLC and above OLC. The strength development of the two lime stabilized soils were similar as stated earlier when only lime was used for stabilization. However, amending the stabilization process with a combination of FA and SS resulted in strength differences, as well as in optimal combinations that produced the maximum strength. For below OLC lime content of 6%, the amendment of the stabilization process resulted in a marginal increase in strength. But, for lime content above OLC, the amendment produced a significant increase in strength at the end of 28 days of curing, as seen from the significant gap between the curves. Then again, the optimal dosages of additives also changed for both cases: for 6% lime content, the maximum strength was produced when equal doses of FA and SS at 3% each were added, whereas, for 8% lime content, 6% FA and 2% SS produced the highest strength. Therefore, these results only further reinforce the theory of Nasrizar et al. [30] who suggest the existence of different stages of lime stabilization related to the development of strength.

The fourth significant observation is that the addition of solid wastes influences the development of strength. Adding FA and SS combination results in a slower development of strength (Fig. 5). The strength gain curve of the amended stabilized samples was lower than those of pure lime stabilized soil samples at early curing periods of less than 14 days. Only when a curing period of 28 days is attained, the strengths of the FA/SS amended samples are stronger than the pure lime stabilized soil. Thus, it can be stated that the pozzolanic combination of FA and SS can provide pozzolanic strength benefits, but at a relatively lower pace in terms of strength gain. As mentioned earlier, this may be due to the fact that the coarser steel slag particles take longer to dissolve than the soil particles.

D. A comparative discussion

To better understand the results obtained here, we attempted to compare them with previous studies (Figs. 6-8). Earlier researches adopted a combination of FA and SS, whereas we used FA and SS as additives to lime stabilization of soil. In order to bring out the stabilization effects on a comparable level, the modification or improvement in soil strength was expressed as 'Strength Gain Ratio' (SGR), which is expressed as the ratio of modified strength of the soil after stabilization to the strength of the virgin soil. Since we used a combination of lime, FA and SS, we assessed the strength of lime stabilized soil before and after amending it with FA and SS to determine the SGR and thus, gauge the effect of FA and SS. To determine the effect of the two solid wastes, we expressed the total additive dosage used as FA/SS ratio.

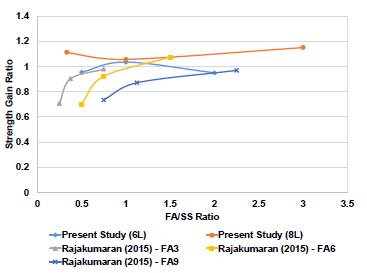

Two earlier works by Rajakumaran [41] and Yildirim et al. [42] were used for comparison. These works are compared individually with the present study to avoid confusions and reduce the distortion of the curves due to scaling effects; subsequently, an overall comparison is presented. Comparing this study with Rajakumaran [41] shows that the addition of FA and SS in the present study produced contrasting results: at 6% lime, the SGR increased at only one particular FA/SS ratio, whereas at 8% lime, there was an initial decrease in SGR at a FA/SS ratio close to 1, followed by an increase (Fig. 6). For three distinct FA contents, Rajakumaran [41] found a steady increase in the SGR when increasing the FA/SS ratio, with the maximum SGR achieved when FA content was 6%. If the peak values of SGR of the three FA contents were considered a trend, then it shows a similar pattern as that shown by the 6% lime stabilized soil amended with FA/SS. This may be due to the fact that the three curves of Rajakumaran [41] were based on a fixed FA content with varying SS content. However, in the present study, both FA and SS contents were varied.

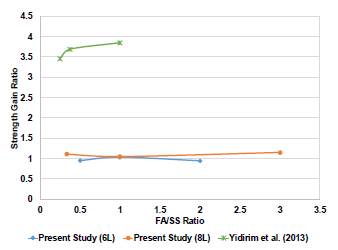

Yildirim et al. [42] achieved a huge SGR compared to the present study (Fig. 7). In addition, they reported, like Rajakumaran [41], an increase in the SGR when increasing the FA/SS ratio. The high SGR achieved by Yildirim et al. [42] may be due to the fact that they adopted class C type FA in their investigation, whereas both Rajakumaran [41] and we adopted class F type FA. Because class C type FA is cementitious, it could have a better stabilization effect and, hence, a higher SGR. Moreover, in the previous studies, the SGR was derived in relation to the strength of the virgin soil, whereas in the present study, the strength of lime stabilized soil was taken as reference. The strength gained by lime is already high when compared to virgin soil and, hence, the SGR values are lower.

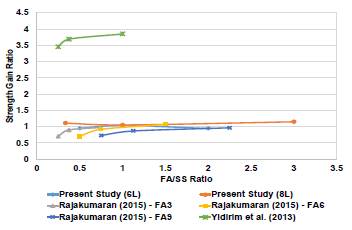

Comparing the three works (Fig. 8), it is seen that irrespective of FA class, the increase in FA/SS ratio led to an increase in SGR. Beyond a FA/SS ratio of 1, the slopes of the curves decline, indicating a reduced rate of increase in SGR.

IV. CONCLUSIONS

Based on the investigation conducted in stabilizing an expansive soil with lime and a combination of FA and SS, the following points can be concluded.

i. Amendment of lime stabilization of soil with FA and SS can result in pozzolanic strength benefits leading to a gain in strength. A gained strength between 3.5% and 15% can be achieved when sufficient lime is available for stabilizing the soil.

ii. Increasing the length of the curing period results in a strength gain of the soil when FA and SS are added during stabilization. Within the first 7 days, 50% of the strength of the stabilized soil is achieved; however, adding FA and SS retards the rate of strength gain during early curing.

iii. The strength gained due to the addition of FA and SS depends upon the lime content adopted for stabilization. The optimal FA/SS ratio changed from 1:1 to 3:1 when the lime content changed from 6% to 8%. Thus, the effects of FA and SS on the development of strength are different for lime contents below and above OLC.

iv. The influence of FA and SS on the strength gain was different compared to previous studies, wherein an increase in the FA/SS ratio resulted in a greater strength gain. A comparison with earlier studies revealed that FA class did not influence the strength gain trend in the present study. Moreover, a FA/SS ratio greater than 1 did not produce much of a benefit in terms of strength gain. However, the above conclusions may be due to the presence of lime in the present study.

The combination of FA and SS yielded some interesting results in soil stabilization with and without lime; therefore, this is an area that needs more research for achieving better clarity and identifying optimal blends that allow attaining maximum pozzolanic benefits.