Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Vitae

Print version ISSN 0121-4004

Vitae vol.19 no.1 Medellín Jan./Apr. 2012

FOODS: SCIENCE, TECHNOLOGY AND ENGINEERING

EFFECT OF ALGINATE/CALCIUM CONCENTRATION ON PHYSICAL AND SENSORY PROPERTIES OF FAT EXTENDERS

EFECTO DE LA CONCENTRACIÓN ALGINATO/CALCIO SOBRE LAS PROPIEDADES FÍSICAS Y SENSORIALES DE EXTENSORES GRASOS

Waldir A. PACHECO P.1; Diego A. RESTREPO M.2; Jairo H. LOPEZ V.3

1 Departamento de Innovación y Desarrollo. Tecnas S.A. Cra. 50G Nº 12 Sur 29. Itaguí, Colombia. wpacheco@tecnas.com.co.

2 Departamento de Ingeniería Agrícola y Alimentos. Facultad de Ciencias Agropecuarias. Universidad Nacional de Colombia, Sede Medellín. A.A. 1779. Medellín, Colombia.

3 Instituto de Ciencia y Tecnología de Alimentos–ICTA. Universidad Nacional de Colombia, Sede Bogotá. AV. Cra. 30 Nº 45-03. Bogotá D.C., Colombia.

Received: 23 November 2010

Accepted: 10 January 2012

RESUMEN

The fat extenders are fat replacer that can be used to provide some or all of the functions of fat in the meat products, yielding fewer calories than fat. The influence of several sodium alginate (0.69% - 2.81%) and calcium carbonate (0.21% - 0.84%) concentrations on the texture, melting point, and sensory properties of fat extenders made from pork back fat, and a mixture of the above two variables have been studied using a central composite rotable design and response surfaces. Sodium alginate and calcium carbonate concentration revealed a significant effect (p ≤ 0.05) on the texture parameters. In melting properties, there were not significant effects (p ≤ 0.05) on the established limit for variables, except for melting peak temperature. In sensory attributes, they had significant differences (p ≤ 0.05) between fat extenders and the standard, in regard to shine, color and hardness. Therefore, fat extenders made with the addition of 1.0% sodium alginate and 0.79% calcium carbonate displayed textural and melting point properties with higher values in comparison with other treatments, along with sensory characteristics closer to the standard.

Keywords: Fat replacer, fat extenders, alginates, cholesterol, fatty acids.

ABSTRACT

Los extensores grasos son reemplazantes de grasa que se pueden utilizar para proporcionar algunas o todas las funciones de la grasa en un producto cárnico, produciendo menos calorías que la grasa. El efecto de varias concentraciones de alginato de sodio (0,69% - 2,81%) y carbonato de calcio (0,21% - 0,84%) sobre las propiedades de textura, fusión y sensoriales de extensores grasos elaborados a parir de tocino de cerdo y la mezcla de estas dos variables, se estudió mediante el empleo de un diseño compuesto central rotable y superficies de respuesta. La concentración de alginato de sodio y carbonato de calcio mostró efectos significativos (p ≤ 0,05) sobre los parámetros de textura. Para el caso de las propiedades de fusión, no hubo efectos significativos (p ≤ 0,05) de estas variables sobre los parámetros establecidos, excepto en el caso de la temperatura pico de fusión. En cuanto a los atributos sensoriales se encontró diferencias significativas (p ≤ 0,05) entre los extensores grasos y el control en cuanto al brillo, color y dureza. Extensores grasos elaborados con niveles de alginato de sodio alrededor del 1,0% y de carbonato de calcio del 0,79% mostraron propiedades de textura y fusión con valores más altos en comparación con los demás tratamientos; así como características sensoriales más cercanas al control.

Palabras clave: Remplazantes de grasa, extensores grasos, alginato, colesterol, ácidos grasos.

INTRODUCTION

Traditional pork back fat had has been used as a source of fat in the formulation and manufacture of by-meat products thanks to its excellent physical and sensory properties compared with other fat sources (1). However, a series of factors about its use, like availability, supply, quality variations and health have been of concern. Therefore, the pork industry has advanced up to developing pig races with a low content of subcutaneous fat as an answer to customer demand of lean pork meat. Besides, they have been related to the reduction and production of pork fat during seasons of the year and specific differences in quality characteristics. Those changes were mainly associated with flavor, texture, and oxidative phenomenon that is negative for meat processing products (2-4). Alike, animal fat has the highest levels of cholesterol and saturated fatty acids, especially pork meat, that has been related to the development of cardiovascular and coronary arteries diseases, among other illnesses associated to the ingestion of meat products with higher levels of pork fat (5-7).

In this way, as an alternative to minimize the technical facts aforementioned, fat extenders with functional properties are used nowadays, keeping the ones contributed by pork back fat, thus allowing manufacturers to standardize the quality of fat material, and improving control over inventory during seasons of shortage and the formula of meat stuff with lower or reduced contents of fat, which results in a less caloric intake. Within this kind of replacements, the fat extenders are systems capable of optimizing the fat functionality, allowing the reduction of the accustomed quantity used in products (8). After all, these systems comprise a standard proportion of fat or oil mixed with other functional ingredients, such as polysaccharides like carrageenan, starches, gum, cellulose, pectin, and alginate. Several research outcomes reported the use of polysaccharides as a fat replacement in the production of food products with low content of fat (9-14), showing significant advantageous influence over its final characteristics.

Among polysaccharides, hydrocolloids are frequently used as thickeners, stabilizers, and gelling agents in food processing. In fact, the alginate has become an interesting option thanks to its ability to form ionotropic plus thermal irreversible gels, under specific conditions of low temperature and in the presence of bivalent ions, mostly calcium (15). All these features have contributed to the development of demi-soft or demi-moist products through different textures like: by-products of fruits, vegetables, as well as fish and structured meat, desserts and bakery cream, among others (16). Some pharmaceutical and food researches have been conducted with the aim to study how the adding of certain compounds in alginate/ calcium gels (polysaccharides, proteins, enzymes) would contribute to the advance of new systems (along with encapsulation, coverage edible films), as well as to higher functionality products, resembling restructured foods (17-25).

Now, the study of different mechanisms of gelling process and the behavior of the formed food gels properties will lead to the creation of new texture materials, where fat will take part as a gel ingredient. Thus, an appropriate selection of the relation alginate/ calcium and the adjustment of conditions to form a gel, has demonstrated to be essential in the attaining of desirable characteristics in this kind of products (26).

The present study aims at establishing the most suitable relation of sodium alginate: calcium carbonate that allows extending the pork back fat into an estimated proportion of 50%, in order to keep the important industrial characteristics of fat used in meat emulsified products.

MATERIALS AND METHODS

Materials

In order to manufacture fat extenders, pork back fat was used and acquired from a local supplier. Sodium alginate (NaC6H7O6, TIC Gums, Inc.), calcium carbonate (CaCO3, Microminerales S.A.), glucono delta lactone-GDL (C6H10O6, Rhodia S.A.), and sodium erythorbate (C6H7NaO6, Jebsen & Jessen G.m.b.H. & Co.) were used. All compounds matched USP (United States Pharmacopeia) specifications, and were got by company Tecnas S.A. (Itagüí, Colombia). A cutter (Mainca®, model CM-14, Barcelona, España) was used to chop and mix pork back fat, along with different components through the production of fat extenders. Plastic boxes of 18 x 32 x16 cm were used to shape the paste.

Experimental design and data analysis

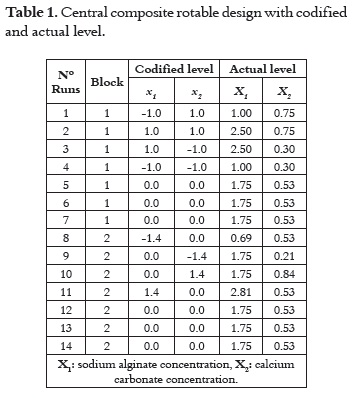

A Central Composite Rotable Design was used (27) that match-up the central composite arranges of 22 + 2 x 2 + 3 (2 factors, 2 axial points, 3 replicates of the central point, 2 complete and random blocks) to estimate the simultaneous influence of two variables on fat extenders composition (factors): concentration of sodium alginate (X1) and the concentration of calcium carbonate (X2). The first variable falls into the exploration range from 1.00% to 2.50% and the second from 0.30% to 0.75%. The effect of these factors was assessed on the properties of texture and melting of the material. The application of the model generates 14 runs, ranging from 0.69% – 2.81% of sodium alginate and 0.21% – 0.84% of calcium carbonate. Table 1 shows all experimental trials (treatments/combinations) as the codified character of the selected factor levels, and the respective experimental figure (-α, -1, 0, 1, α; where α = 1.4).

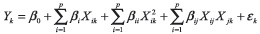

Experimental data analysis was performed following the response surface method (MSR), where a matrix operation was the main character to find the regression equation coefficients. Then, registers for Y-axis were determined by applying the second degree polynomial model expressed in the equation 1 to generate the surface (28):

Equation 1.

Equation 1.

where Yk was the observed response when ρ factors were applied in the levels Xij. Here, β0 was the constant, βi, βii and βij were the coefficients of linear, quadratic and crossed terms, respectively. Also, εk was the experimental error with k = 1,2,…, n. Response surface graphics were obtained from regression equations, keeping the response variable over Z axis and the independent variables over X and Y axis.

An analysis of variance (ANOVA) with a significance level of 0.05 was performed to find out the influence of independent variables. Likewise, the determinant coefficient (R2) was calculated to define the regression equation correction to Y observed records. All analysis was executed using Statgraphics® Centurion XV (Version 15.2.06, Chicago, Illinois, USA) statistic software (29).

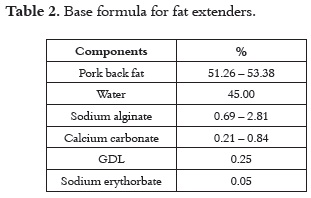

Fat extenders formulation and processing

All fat extenders were manufactured following the base formula shown in table 2, where percentage of water, glucono delta lactone (GDL) and the sodium erythorbate were kept constant. Then, pork back fat percentage was adjusted between 52.26% and 53.38%, according to each percentage of sodium alginate and calcium carbonate established by the experimental design in every trial, up to 100% of complete formula. The fat extenders were manufactured in 4.0 kg/run batches according to the experimental design. For this purpose, pork back fat was previously chopped and processed in the cutter until getting homogeneity (approx. 1 min). At that time, water was added and mixed for approx. 1 min. Then, sodium alginate, calcium carbonate and the other additives were poured until an emulsion of creamy mass was obtained. The order of addition of dry ingredients was as follow: sodium alginate, calcium carbonate, GDL, and at last, the sodium erythorbate. Finally, the emulsion was set in plastic shapes and stored under refrigeration conditions (0 - 1°C) for 24 hours, before its preparation for respective analysis.

Instrumental Texture Analysis

The measure of texture properties of fat extenders was performed using a texture analyzer (model TA-XT Plus, Stable Micro Systems Ltd, London, England). Firstly, puncture test was performed to estimate the firmness of the extenders. For the conduction of this test, it was disposed square samples of extenders (2.0 x 2.0 cm), using needle P/0.25S with a cell load of 5.0 kg and warp percentage of 60%, pre-test speed of 1.00 mm/s, test speed of 1.70 mm/s, followed by a further test speed of 10 mm/s and a compression force to assess the firmness (N) of the samples. Afterward, shear test was conducted to calculate the extensors resistance to shear, useful to establish mechanical capacity for operations of cutting, grinding, and chopping process. These tests were performed over rectangular samples of 6.5 x 1.0 x 1.0 cm, using a knife edge drill with a load cell of 50 kg, pre-test and test speed of 2.0 mm/s, then increased to 10.0 mm/s. Under those conditions, a blade measured the cutting stress (N) necessary to split the sample, and the work of shear (N/s) to scroll a drill throughout the sample. According to the design established, each parameter was determined 5 times per sample.

Calorimetric analysis

Melting properties analysis of fat extenders was performed by a differential scanning calorimetry (DSC) using a calorimeter (DSC1 Stare System, Mettler-Toledo AG Analytical, Schwerzenbach, Switzerland) and an infra-red Perkin Elmer® Spectrum 100 FT-IR Spectrometer (Waltham, Massachusetts, USA). The analysis employed 10 mg (approx.) of sample, at a range of temperature from 30 to 500°C and at a heating rate of 10°C/min. From data outcome, temperatures were assumed as response variables for the melting properties of extenders, such as Tonest (initial temperature of thermal transition), Tpeak (peak temperature of thermal transition) and ΔH (melting enthalpy).

Sensory Evaluation

In order to compare the sensory properties of a control sample (pork back fat) against the manufactured fat extenders, a sensory evaluation was performed. Hence, a Quantitative Descriptive Analysis (QDA) was used to evaluate shine, color, flavor, hardness, greasy, and the general quality of the final product. For sensory analysis, 7 judges were previously selected, and subjected to assess the samples in a intensity scale of 7 points, where 0 was absent, 1 and 2: fair, 3: medium-low, 4: medium, 5: medium-high, 6 and 7: intense. The sensory panel results were analyzed using one-way analysis of variance (p ≤ 0.05), along with the HSD Tukey test. These analyses were accomplished using the Statgraphics® Centurion XV (Version 15.2.06, Chicago, Ill., USA) software (29).

RESULTS AND DISCUSSION

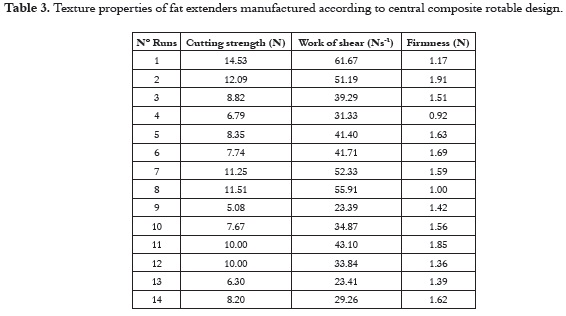

Properties of texture

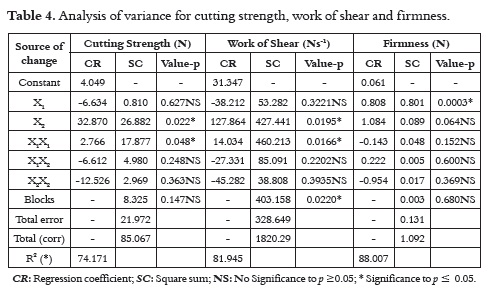

In table 3, the data of texture parameters from fat extenders is displayed, highlighting cutting strength data from 5.08 to 14.53 N. The work of shear was between 23.41 to 61.67 N/s, and firmness between 0.92 to 1.91 N. Currently, all changes in fat extenders parameters were assigned to the use of different levels of sodium alginate and calcium carbonate, so working on the final texture characteristics of the product after the gelling process is completed (26, 30). This influence was upheld with the aid of data yielded by ANOVA analysis presented in table 4, demonstrating that calcium carbonate concentration had a significant effect (p ≤ 0.05) on cutting strength and work of shear; while, sodium alginate had a significant effect in the firmness (p ≤ 0.05) of extenders.

Therefore, texture parameters of cutting strength, work of shear, and firmness were associated with the hardness of material, due to the force of gel. As a result, the high values of parameters showed that cutting strength and compression needed to cut and strain the material were higher because of the hardness, representing an important characteristic of the process. Nonetheless, the significant influence of sodium alginate and calcium carbonate in these parameters should be mainly related to their composite levels of a specific compound to form a gel, in consequence giving specific characteristics of texture. Alan, 2010 (31), established that alginate capacity to form a gel and the resultant gel force was closely related to the availability of calcium ions, because they hinge on the number and zone size to link to the gel structure. Moreover, Roopa et al., 2010 (16), stated that gel formation is a critical factor that affects the gel texture attributes.

The analysis of the surface for texture bounds, according to the regression model shown in table 4, dropped out both like force and shear stress, and has a significant rising amount when calcium carbonate concentration had been increased as presented in figure 1a and 1b. The same was found for high texture parameters between 0.73 and 0.79% for calcium carbonate and 1.0 to 1.1% for sodium alginate. Regarding firmness, surface analysis showed a noteworthy increment when sodium alginate and calcium carbonate has been increased, plus high records for alginate concentration between 2.3 and 2.5% and for calcium carbonate amid 0.67 - 0.79%, as shown in figure 1c.

Roopa et al., 2009 (32), studied the alginate gel split with different concentrations of alginate and calcium, both yielding as a conclusion that a puff up in alginate concentration produces easy riven of gels without high figures of stress/ energy, despite a raise of calcium concentration swells the force and split energy. These results were similar to the outcomes in the present paper, and are implicit about the calcium concentration over force and cutting strength in extenders. About firmness, they also came on the conclusion that alginate gel firmness was mainly influenced by the calcium concentration, more than the alginate. On the other hand, Cubero et al., 2002 (30), stated that when calcium was abundant in the compound, the gel would be tough but granulate, albeit more proportion of alginate in products causes further firmness in gel, but may presented weird textures.

The determination coefficient (R2), resulting from regression analysis, for each one of the response variables, showed that fitted models explain 74.171, 81.945 and 87.711% of variability in cutting strength, work of shear, and firmness, with at least 95% confidence level. All those showed that the relation in alginate/calcium concentration had enough influence over assessed texture parameters in fat extenders; therefore, regression is acceptable for cutting strength, work of shear and firmness.

Properties of melting

In figure 2 are shown melting curves of fat extenders, plotted from DSC analysis according to planned design. All results showed the formation of two great endothermic peaks in some extenders and only one in the others, between temperature intervals of 49 to 134°C approx.

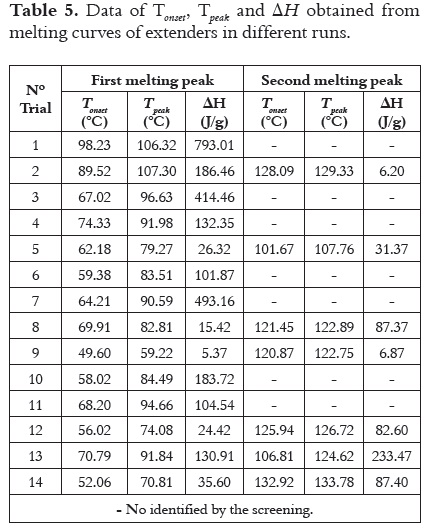

Furthermore, the first endothermic peak was associated with possible dehydration processes (missing water) while the second peak was related to melting processes for any component of the product or free water that could not evaporate in the first endothermic event. The figures and peaks of Tonset, Tpeak and ΔH are displayed in table 5.

As can be seen, there was a noticeable evidence of change between Tonset and Tzpeak in the two endothermic peaks, while melting enthalpy showed the highest records in the first peak. Then, the development of two transitional endothermic peaks and the variation found, between Tonset and Tpeak in those peaks, would follows that the composition and structural form of the product is influenced by the molecular interactions between different extender constituents, mainly for alginate and calcium to link water and pork fat that was dispersed into crystal zones. In this respect, Takahashi et al., 2000 (33), advert that physical-chemical properties of gel are controlled by an excess of connected water along with three dimensional matrix of a polymer. Therefore, lost water was associated with the first endothermic peak and can be marked to water evaporation, linked in the system during the temperature screening record.

Bellini et al., 2009 (34), reported differences in melting peaks and melting enthalpy in spheres or alginate capsules, pointing those differences and observable variations toward water quantity and melting profiles due to the network, or chains in gel shape. In other hand, Soares et al., 2004 (35), reported dehydration processes in alginate gel at Tpeak from 80.7 to 113.6ºC. In the same manner, Pongjanyakul et al., 2007 (36), recorded endothermic peaks at 70°C in alginate/calcium bubbles associated with lost water by evaporation, these records are similar to data found in the present research. Martínez et al., 1998 (37), states that transition phase of material was a consequence of molecular mobility when system components went from a network arrangement to a disorder, similar to the change from solid crystal state to liquid, as a result of melting temperature.

The ANOVA analysis of data outcome for first endothermic peak is presented in table 6, and it displays only one significant effect (p ≤ 0.05) for calcium carbonate concentration on the Tpeak, compared to the others, whereas nor this variable or alginate concentration reported significant influence over the same Tpeak, Tonset, and ΔH. In addition, the surface analysis done to these parameters, according to the regression model in table 6, explains the increase in calcium carbonate concentration, as well as to the one occurred to the figures in the first endothermic peak.

In figure 3, the highest data for these parameters was found in the zone between 0.73 and 0.75% for calcium carbonate, 1.0 and 1.1% for sodium alginate, except for Tpeak where the data of the last one was between 2.3 and 2.5%. Cubero et al., 2002 (30), reported when alginate gel got shape, according to the calcium ions quantity and crystal zone length, the gel would be thermo reversible or not, and based on these reasons there was the highest temperatures recorded for large calcium concentrations. Finally, the determination coefficient (R2) recorded showed that fitted models explained 71.673, 76.579 and 72.549% of variability in Tonset, Tpeak and ΔH, with at least 95% confidence level. Therefore, the regression was accepted for the 3 parameters tested.

Sensory evaluation

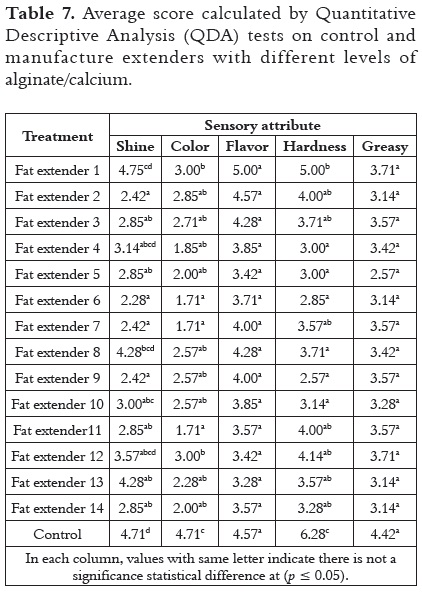

In table 7 are listed the outcome yielded by Quantitative Descriptive Analysis (QDA) for fat extenders as a function of sensory attributes as shine, color, flavor, hardness, and greasy attributes. Significant difference was found (p ≤ 0.05) between the control and the fat extenders regarding color, hardness, and shine. However, there were not significant differences in flavor and grassy attributes. Nevertheless, fat extenders manufactured with 1.0% of sodium alginate and 0.75% of calcium carbonate (Fat extender 1) reached the closest score values toward control.

CONCLUSIONS

In retrospect, the extension of pork back fat in almost 50% is possible using sodium alginate and calcium carbonate, because this will produce a compound with appropriate texture (cutting strength, work of shear, firmness), melting (temperature and melting enthalpy), and sensory properties (shine, color, flavor, hardness and greasy) for process operations throughout the manufacture of meat by-products. Thus, the outcomes show that adequate sodium alginate and calcium carbonate concentrations of 1.0 and 0.75 - 0.79%, respectively, are suitable in order to make extenders with high performance grades in texture and melting parameters.

Moreover, it is possible to get extenders with similar sensory characteristics to a piece of pork back fat when alginate and calcium carbonate concentrations are used in this order, mostly in flavor, greasy and hardness. Finally, to get optimum concentrations as a function of maximum and minimum responses, it is necessary to conduct a research in recognized concentration regions for these ingredients, according to surface response analysis completed.

ACKNOWLEDGEMENT

Authors are grateful to the company Tecnas S.A. (Itagüí, Colombia) for its technical and financial support given to the development of this research.

REFERENCES

1. Ospina J, Cruz A, Pérez-Álvarez J, Fernández-López J. Development of combinations of chemically modified vegetable oils as pork backfat substitutes in sausages formulation. Meat Sci. 2010 Mar; 84 (3): 491-497. [ Links ]

2. Rocha A. Controlando la calidad y composición de la grasa para mejorar la estabilidad de la emulsión [Internet]. Carnetec. Jul 2009 [Actualizado 2009 Jul 22; citado 2010 Ago 2]. Disponible en: http://www.carnetec.com/MembersOnly/technology/details.aspx?item=1059#1. [ Links ]

3. Piasentier E, Di Bernardo N, Morgante M, Sepulcri A, Vitale M. Fatty acid composition of heavy pig back fat in relationship to some animal factors. Ital J Anim Sci. 2009; 8 (2): 531-533. [ Links ]

4. Hugo A, Roodt E. Significance of porcine fat quality in meat technology: A review. Food Rev Int. 2007; 23 (2): 175-198. [ Links ]

5. Omojola A, Fagbuaro S, Ayeni A. Cholesterol content, physical and sensory properties of pork from pigs fed varying levels of dietary garlic (Allium sativum). World Appl Sci Journ. 2009; 6 (7): 971-975. [ Links ]

6. Lo Fiego D, Macchioni P, Minelli G, Santoro P. Lipid composition of covering and intramuscular fat in pigs at different slaughter age. Ital J of Animal Sci. 2010; 9 (2): doi:10.4081/ ijas.2010.e39. [ Links ]

7. Jiménez-Colmenero F, Herrero A, Pintado T, Solas M, Ruiz- Capillas C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res Int. 2010; doi:10.1016/j.foodres.2010.06.010. [ Links ]

8. American Dietetic Association. Position of the american dietetic association: fat replacers. J Am Diet Assoc. 2005; 105 (2): 266-275. [ Links ]

9. Bayarri S, Chulia S, Costell E. Comparing λ-carrageenan and an inulin blend as fat replacers in carboxymethyl cellulose dairy desserts. Rheological and sensory aspects. Food Hydrocolloid. 2010 Ago; 24 (6): 578-587.

10. Min B, Bae I, Lee H, Yoo S, Lee S. Utilization of pectin-enriched materials from apple pomace as a fat replacer in a model food system. Bioresource Technol. 2010 Jul; 101 (14): 5414-5418. [ Links ]

11. Mun S, Kim Y, Kang C, Park K, Shim J, Kim Y. Development of reduced-fat mayonnaise using 4αGTase-modified rice starch and xanthan gum. Int J Biol Macromol. 2009 Jun; 44 (5): 400-407.

12. Pietrasik J, Janz A. Utilization of pea flour, starch-rich and fiberrich fractions in low fat bologna. Food Res Int. 2010 Mar; 43 (2): 602-608. [ Links ]

13. Jiménez-Colmenero F, Cofrades S, López-López I, Ruiz-Capillas C, Pintado T, Solas M. Technological and sensory characteristics of reduced/low-fat, low-salt frankfurters as affected by the addition of konjac and seaweed. Meat Sci. 2010 Mar; 84 (3): 356-363. [ Links ]

14. Cierach M, Modzelewska-Kapituta M, Szacito K. The influence of carrageenan on the properties of low-fat frankfurters. Meat Sci. 2009 Jul; 82 (3): 295-299. [ Links ]

15. Walewijk A, Cooper-White J, Dunstan D. Adhesion measurements between alginate gel surfaces via texture analysis. Food Hydrocolloid. 2008 Ene; 22 (1): 91-96. [ Links ]

16. Roopa B, Bhattacharya S. Texturized alginate gels: Screening experiments to identify the important variables on gel formation and their properties. LWT-Food Sci Technol. 2010 Nov; 43 (9): 1403-1408. [ Links ]

17. Kim W, Chung H, Shin I, Yam K, Chung D. Characterization of calcium alginate and chitosan treated calcium alginate gel beads entrapping allyl isothiocyanate. Carbohyd Polym. 2008 Mar; 71 (4): 566-573. [ Links ]

18. Tavakol M, Vasheghani-Farahani E, Dolatabadi-Farahani T, Hashemi-Najafabadi S. Sulfasalazine release from alginate-N,Ocarboxymethyl chitosan gel beads coated by chitosan. Carbohyd Polym. 2009 Jun; 77 (2): 326-330. [ Links ]

19. Bellich B. Thermal behavior of water in micro-particles based on alginate gel. J Therm Anal Calorim. 2009 Sep; 97 (3): 871-878. [ Links ]

20. Panouille M, Larreta-Garde V. Gelation behaviour of gelatin and alginate mixtures. Food Hidrocolloid. 2009 Jun; 23 (4): 1074- 1080. [ Links ]

21. Bajdik J, Makai Z, Berkesi O, Süvegh K, Marek T, et al. Study of the effect of lactose on the structure of sodium alginate films. Carbohyd Polym. 2009 Jul; 77 (3): 530-535. [ Links ]

22. Wang Q, Hu X, Du Y, Kennedy J. Alginate/starch blend fibers and their properties for drug controlled release. Carbohyd Polym. 2010 Oct; 82 (3): 842-847. [ Links ]

23. Ozyilmaz G, Gezer E. Production of aroma esters by immobilized Candida rugosa and porcine pancreatic lipase into calcium alginate gel. J Mol Catal B Enzym. 2010 Jul; 64 (3): 140-145. [ Links ]

24. Hong G, Chin K. Evaluation of sodium alginate and gluconod- lactone levels on the cold-set gelation of porcine myofibrillar proteins at different salt concentrations. Meat Sci. 2010 Jun; 85 (2): 201-209. [ Links ]

25. Lennon A, McDonald K, Moon S, Ward P, Kenny T. Performance of cold-set binding agents in re-formed beef steaks. Meat Sci. 2010 Ago; 85 (4): 620-624. [ Links ]

26. Roopa B, Bhattacharya S. Alginate gels: I. Characterization of textural attributes. J Food Eng. 2008 Mar; 85 (1): 123-131. [ Links ]

27. Rodrigues M, Lemma F. Planejamento de experimentos e otimizacao de processos. Barao Geraldo, Brasil: Casa do Pao; 2005. p. 153-228. [ Links ]

28. Gutiérrez H, Vara, R. Análisis y diseño de experimentos. México, D.F.: McGraw-Hill; 2004. 493p. [ Links ]

29. Statpoint Inc. Statgraphics Centurion XV. Manual del usuario. Estados Unidos: Statpoint, 2006. p. 257-282. [ Links ]

30. Cubero N, Monferrer A, Villalta J. Aditivos alimentarios. Madrid, España: Mundi-Prensa; 2002. p. 123-128. [ Links ]

31. Alan I. Food Stabilisers, Thickeners and Gelling Agents. United Kingdom: Blackwell Publishing; 2010. Capitulo 4, Alginate; p. 50-69. [ Links ]

32. Roopa B, Bahattacharya S. Alginate gels: rupture characteristics as a function of the conditions of gel formation. J Food Eng. 2009 Abr; 91 (3): 448-454. [ Links ]

33. Takahashi M, Hatakeyama T, Hatakeyama H. Phenomenological theory describing the behaviour of non-freezing water in structure formation process of polysaccharide aqueous solutions. Carbohyd Polym. 2000 Ene; 41 (1): 91-95. [ Links ]

34. Bellich B, Borgogna M, Carnio D, Cesàro A. Thermal behavior of water in micro-particles based on alginate gel. J Therm Anal Calorim. 2009 Sep; 97 (3): 871-878. [ Links ]

35. Soares J, Santos J, Chierice G, Cavalheiro E. Thermal behavior of alginic acid and its sodium salt. Eclet Quím. 2004; 29 (2): 53-56. [ Links ]

36. Pongjanyakul T, Puttipipatkhachorn S. Xanthan–alginate composite gel beads: Molecular interaction and in vitro characterization. Int J Pharm. 2007 feb; 331 (1): 61-71. [ Links ]

37. Martínez N, Ándres A, Chirlat A, Fito P. Termodinámica y cinética de sistemas alimento entorno. Valencia, España: Universidad Politecnica de Valencia; 1998. p 219-244. [ Links ]