Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Vitae

versão impressa ISSN 0121-4004

Vitae v.19 n.1 Medellín jan./abr. 2012

FOODS: SCIENCE, TECHNOLOGY AND ENGINEERING

DEVELOPMENT OF A COOKIE WITH ADDED OMEGA 3 FATTY ACIDS SOURCE AS FUNCTIONAL FOOD

DESARROLLO DE UNA GALLETA DULCE ADICIONADA CON FUENTE DE OMEGA 3 COMO ALIMENTO FUNCIONAL

Iliana C. TORRES Q.1, Misael CORTÉS R.1, Kenneth R. CABRERA T.2

1 Facultad de Ciencias Agropecuarias, Departamento de Ingeniería Agrícola y Alimentos. Universidad Nacional de Colombia Sede Medellín. A.A. 568, Medellín, Colombia. ictorresq@unal.edu.co.

2 Facultad de Ciencias, Universidad Nacional de Colombia Sede Medellín. A.A. 3840, Medellín, Colombia.

Received: 25 January 2011

Accepted: 01 February 2012

ABSTRACT

The present work aims at develop of a cookie with added omega 3. Three different commercial forms of omega 3 were evaluated as docosahexaenoic acid and ecoisapentaenoic acid (emulsion, powder and oil) at different omega 3 (ω3): omega 6 (ω6) ratios (1:5, 1:8, 1:10). A multistage factorial system was used to evaluate, in general, the rheology of the dough, along with the texture, moisture, color, and aw of the cookies after baking. During the storage, the concentration of ω3 is evaluated as linolenic acid, ω6 as linoleic acid. Docosahexaenoic acid, ecoisapentaenoic acid and sensory attributes of the final product are also evaluated. Through the elaboration of the dough, it was encountered that the emulsion and oil commercial forms of ω3 best performed the rheological test, at the ratios of 1:8 and 1:10, while for the cookies elaboration the best combination is emulsion form at ratio of 1:10; which is stored under extreme conditions (40 ± 2°C y 75 ± 5% RH) for a 60 days period, presenting good acceptance from a semi-trained panel and a decrease in the concentration of ω3 fatty acids as docosahexaenoic acid plus ecoisapentaenoic acid of approximately 6%.

Keywords: Functional Food, omega 3, docosahexaenoic acid, ecoisapentaenoic acid, cookies.

RESUMEN

El objetivo de este trabajo es desarrollar una galleta dulce adicionada con omega 3. Tres formas comerciales de omega 3 se evaluaron como ácido docosahexaenoico y ácido eicosapentaenoico (emulsión, polvo y aceite) a diferentes relaciones de omega 3 (ω3): omega 6 (ω6) (1:5, 1:8, 1:10). En general, se utilizó un sistema factorial polietápico, para evaluar la reología de las masas, así como la humedad, textura, color y aw de las galletas después del horneado. Durante el almacenamiento se evaluó el contenido de ω3 como ácido linolenico, ω6 como ácido linoleico. Ácido docosahexaenoico, ácido docosahexaenoico y los atributos sensoriales del producto final también fueron evaluados. Durante la elaboración de las masas, las formas de ω3 que mejor desempeño presentaron en las pruebas reológicas son las formas de emulsión y aceite con las relaciones 1:08 y 1:10, mientras que en la elaboración de las galletas, la mejor combinación fue la emulsión a relación 1:10; la cual se almacena en condiciones extremas (40 ± 2°C y 75 ± 5% HR) por un período de 60 días y presenta buena aceptación por parte de un panel sensorial semi-entrenado y una disminución de la concentración de los ácidos grasos ω-3 como ácido docosahexaenoico más ácido docosahexaenoico, de aproximadamente 6%.

Palabras clave: Alimentos funcionales, omega 3, ácido docosahexaenoico, ácido eicosapentaenoico, galletas.

INTRODUCTION

The conception of healthy food over the world has been evolving throughout the time. People are aware about the health risks they are facing and the actions on how they can be prevented, thanks to the government's endeavours to inform the community, through different campaigns, the risk of suffering diseases. One of the most common illnesses in our time is from cardiovascular nature, understood as problems related with the heart that can be expressed in different ways as hypertension, arrhythmia, thrombosis and arteriosclerosis.

In developed countries there's the conception that the consumption of lipids can contribute between 30–40% of the total energy of a human been, where the unique specific requirement of fat in the diet are the essential fatty acids as ω-3 and ω-6 (1).

The ω3 fatty acids are physiologically active compounds (PAC) that have an important role in the cholesterol reduction (2), promote the formation of compounds with a low inflammatory activity and powerful platelet aggregation inhibitors, which have an opposite effect to those responsible for common cardiovascular diseases (3).

Recent studies suggest that an ω3 above 8% is a reasonable value that can reduce the risk of suffering cardiovascular diseases (4), besides the fact that the American heart association has approved the use of omega 3 in a 1 g/day dose with a combination of docosahexaenoic acid (DHA) and ecoisapentaenoic acid (EPA), for patients with cardiovascular problems (5), while the Food and Drug Administration (FDA) establish that the consume of DHA and EPA should not exceed 3 g/day in the fish oil way, food and dietary supplements. However, the typical recommendations fall in a range between 0.3 to 0.5 g/day (6). The 288 resolution of 2008 from the Ministry of Social Protection in Colombia does not dispose a diary reference value for this component, and only sets general conditions about the declaration of properties related with the nutrients content, in the article 16, numeral 16.2, where should be declared ''Contains (quantity) g of omega 3 fatty acids per portion''.

The clearest association of these fatty acids with the prevention of suffering cardiovascular diseases lies on the fact that they are precursors of prostaglandins (I3), leukotrienes (B5) and thromboxanes (A3) of the series 3 and 5, cyclooxygenase and oxygenase way, that are involved in the regulation of inflammation, platelet aggregation and vasoconstriction/ dilatation, with far less intensity responses than other precursors like omega 6 (Araquidonic Acid) (7).

All this studies, made by the societies every day, search for new alimentation systems that prevent or reduce the risk of suffering these degenerative diseases that are against health, the well-being and even more capable of causing death.

In the baking sector, the application of functional food has not been well developed. Other sectors among this category, like confectionery and dairy, present the highest sell margin; without implying that the baking industry doesn't provide a good matrix for this kind of products, with good flavor and healthy benefits (8).

Nevertheless, studies developed by some authors show that the functionality of raw materials within the study matrix is of high relevance, because this can impact directly the quality of the final product. About this topic, there are a number of studies that evaluate the behavior of refined oils like girasol oil in cookies, the fat replacement with structured lipids, fiber, proteins and carbohydrates, among others, showing significant changes in the final product (9-12).Thus, it is necessary to observe the potential incidence of this PCA in the product.

The aim of this study is to develop a cookie with added ω3 fatty acids (DHA - EPA) under a proper preparation methodology and process as a technological model that allows obtaining a product with an excellent flavor and health benefits.

METHODS AND MATERIALS

Raw materials

For the elaboration of the cookies was used: soft wheat flour, red winter variety from United Stated with a 11.6% of moisture and prox. 8% of protein, vegetable shortening palm (VSP) (Grasco®) 99% solids, rolled oats (Pronalce®), water, raisins (Alba®), standard sugar (Manuelita®), salt (Refisal®), pasteurized whole egg (Avinal®) and chemical leavenings (Bellchem®), sodium acid pyrophosphate (98% purity), sodium bicarbonate (purity > 99%) and ammonium bicarbonate (purity > 99%).

The omega 3 types used in the experiments are: ROPUFA® 10 n-3 (ω-3P) powder from DSM, contains approximately 30% of omega 3; ecoisapentaenoic acid (C20:5 ω3, EPA) and docosahexaeonic acid (C22:6 ω3, DHA), modified starch, sodium ascorbate and silicon dioxide. OMEVITAL 1812 TG GOLD (ω-3A) oil from Cognis Nutrition and Health with approximately 26% of DHA + EPA, and DENOMEGA GAT 100 (ω-3E) emulsion from GAT Food Essentials with approximately 12% from DHA+ EPA, which has a combination of ω3, technological additives (emulsifier, antioxidant) and water.

Physicochemical Characterization

Several tests of moisture were performed under the norm AOAC 925.45 (13), water activity (aw) with a dew point hygrometer to 25°C (Aqualab Decagon TE series), refractive index under the AOAC 921.08 (13), iodine value (IV) through the AOAC 920.158 (13), and peroxide value (PV) under the AOAC 965.33 (13). The quantification of linolenic acid, linoleic acid, DHA and EPA were conducted under the AOCS Ce 1b-89 method (14) and by un accredited laboratory (TECNIMICRO, Medellin), with a gas chromatograph Shimadzu 2014 model, capillary column SHX70 Shimadzu, 0.25 mm inner diameter and 0.25 µm inner layer; the fat extraction was performed in cold conditions to avoid the damage of the fatty acids.

Physical Characterization

Color was determined using the spectrocolorimeter X-RITE SP64 model with a D65 illuminant and 10° observer as reference. From this reflection spectrums it was collected the coordinates data of color CIE-L*a*b*.

The texture was determined by fracturability test with the texture analyzer TA.XT2 Stable Micro Systems (SMS), using a load cell of 25 kg; the tests were set with a penetration speed of 2 mm/s and 30 mm distance. The fracture strength was defined at the point where it produces an appreciable drop of the strength caused by the partial or total rupture of the sample.

The alveograph measurements were done using the (AACC 54 - 30) method (15) and the Alveolink- NG software developed by Chopin S.A. (Villeneuve La Garenne, France). The results of the alveograms include the maximum over pressure tenacity (P) measured in ''mm'' necessary to blow the bubble dough (resistance to the extension index); the average of the abscise extensibility (L) measured in ''mm'' for the rupture of the bubble (dough extensibility index); the deformation energy (W) measured in ''J'' and the relation of the configuration curve (P/L) (gluten performance).

The alveograph measurements were performed with a 250 g of flour and 121 mL of a saline solution at a concentration of 2.5%, calculated from the initial moisture of the flour, and the omega 3. Finally, it was carefully mixed before the tests, so ensuring that the percentage of ω-3 remains the same in all doughs.

Sensory Evaluation

The sensory analysis was performed with a semi-trained panel of judges from the INTAL foundation (Medellin), through the quantitative response test under the NTC-5328 norm (16) at 0, 30 and 60 days of the stability study in accelerated conditions. The characteristics: odor, objectionable odor, hardness, crunch, oat flavor, sweet flavor and objectionable flavor were evaluated with an intensity scale of 7 points, where (0) = absent, 1 y 2 (low), 3 (medium low), 4 (medium), 5 (medium high), 6 and 7 (intense).

Storage

The accelerated storage of the cookies was performed using an environmental chamber Dies C480E 20512 series, where the final product was subjected to extreme conditions of temperature (40 ± 2°C) and relative moisture (75 ± 5°C). Moreover, it was evaluated the concentration of ω-3: ω-6, DHA and EPA at the time 0, 30 and 60 days of the storage. For the stability test was employed a metallic BOPP (biorented polypropylene) packing material, provided by Alico S.A.

Process

The cookies were prepared via the wire cutting technology, using agglutinant dough. The doughs were prepared with 1:8 and 1:10 ratios of ω-3:ω-6 compressing different forms of ω-3 (oil and emulsion), after performance behavior of the doughs in the alveograph tests. The mixing of the ingredients was carried in three steps: a first mix of vegetable shortening palm with ω-3, egg, water, sugar and leavenings (high speed), then the flour is added; the last addition is the oat with the raisins (low speed). The cookies were subjected to two baking processes; 150oC - 8 minutes and 160oC - 7 minutes, using an industrial convection oven heated with gas, Talsa brand. The selected cookie was taken under extreme storage conditions during 60 days to observe the stability of the PAC and the moisture absorption.

Experimental Design

The experiments were run following a diagram of multistage factorial design, which has the following phases:

Interaction of raw materials with ω-3

PV: In this phase the factors were the type of ω-3 with levels (emulsion, oil and powder) and ω-3:ω-6 ratios with levels (1:5, 1:8, 1:10). It was performed 4 replicas and 3 repetitions each one.

Dough Alveograms: The factors considered for this stage were the type of ω-3 with levels (emulsion, oil and powder) and ω-3: ω-6 ratios with levels (1:5, 1:8, 1:10). It was performed 4 replicas and 3 repetitions each one. The table 1 summarizes the experimental design of Dough Formulations for alveograph measurements.

Formulations of cookies with ω3. This stage considers as factors: type of ω-3 with levels (emulsion and oil) and ω-3:ω-6 ratios with levels (1:8 and 1:10). The response variables were: moisture, fracturability, aw and color. It was performed 3 replicas and 7 repetitions on each one.

Stability design and sensory analysis: This stage contemplates just one combination of a cookie (emulsion, 1:10 ratio), which was performed in 3 repetitions for each response variable (quantity of ω-3, moisture and sensory analysis).

In this study, the collected data were analyzed using the statistical software R.

RESULTS AND DISCUSION

Raw Material Characterization

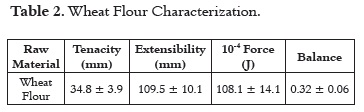

Tables 2 and 3 present the average values and the standard deviation of the physicochemical and mechanic characteristic of the principal raw materials.

The characterization results of the flour, in terms of dough rheology, are consistent with those reported by Wang et al., 2002 (11), i.e., tenacity values of 48mm, extensibility 107mm, force 119 x 104 J and balance 0.5.

The table 4 presents the average values of the PV and standard deviation of the mix between VSP and PCA.

The PV of the different types of ω-3, according to the ratios chosen for the study, presented a significant difference (p < 0.05) in the ANOVA by the effect type of ω-3. The emulsion type presented the highest values (≈ 0.5 meq O2/Kg), followed by the oil type (≈ 0.4 meq O2/Kg) and the powder kind (≈ 0.3 meq O2/Kg).

PV measures the degree of oxidation subjected to fat or oil (12). The values of PV and IV of the VSP used, present typical average values for this kind of multipurpose fats, PV (0.2 - 0.6 meq O2/ g), IV (65 - 80 g Iodine/100 g) (12). Verardo et.al., 2008 (17), in the study of lipid oxidation of spaghetti with ω-3 fatty acids described how the propagation period in lipid oxidation proceeds considerably faster for this product through the storage time. Nevertheless, at the end of the study it did not present significant differences compared with the control. This information allows suggesting that even the ω-3 degrade faster than other fatty acids, at the end of the storage the peroxide value will be the same for products without this PAC.

However, it is important to note that as the lipid is oxidized, its concentrations falls and the amount of hydroperoxide increases to a maximum, but it falls subsequently. Therefore, the measure of oxidation, based purely on peroxide value, can be confusing. The volatile products, which are derived lipids, then rise slowly (18).

Dough with ω3 Characterization

The Figure 1 presents the average values and the standard deviations of alveograms parameters as a function of ω-3 and ω-3:ω-6 ratio. The ANOVA presented significant difference (p < 0.05) in all the variables by the effect of ω-3 type and ω-3:ω-6 ratio.

In all cases, the type ω-3P gives more tenacity (P) to the dough, compared with the ω-3A y ω-3E and reaches a maximum point at the1:8 ratio.

In type ω-3A the tenacity increases whit the decrease of ω-3:ω-6 ratios, while type ω-3E, have a tendency to remain constant; however, the values don't differ from the tenacity average presented by the flour that do not contains this kind of polyunsaturated fatty acids (See Table 2).

The lipid/protein relation proposed by Pomeranz et al., 1978 (19), suggests that the doughs are strengthened by the capacity of polar lipids to associate with the protein and the starch (20); This phenomenon can be observed with the ω-3 powder, because of its composition with starch (polymers), that is interacting in the protein-lipid-starch complex, making it stronger than the other two types of ω-3, with higher tenacity values.

Researches done by Addo et al., 1995 (21), with sucrose esters fatty acids in hard red winter wheat flour have shown a decrease of the tenacity with the increase of these fatty acids.

In all the cases, the ω-3A gives more extensibility (L) to the doughs, followed by the types ω-3E and ω-3P, where the last decrease the values; which can indicate that the type of fluid used, impact directly in a more elastic dough. Song and Zheng., 2007 (22), cite to Watanabe et al., 2003 (23), and explain that this could happen due to the limit of tension reached by the extended fat in solid condition, where the gluten network structure starts to brake, and particularly the addition of non polar lipids facilitates the aggregation of gluten and gives a more elastic behavior to the doughs, which can be confirmed with the higher values of extensibility presented by the ω-3A (See Figure 1). The decrease of the ω-3:ω-6 ratios (< addition of ω-3 to the mix), increase the elasticity of the doughs.

On the other hand, for the force (W) case, while the relation ω-3:ω-6 decrease, the values increase. The values with the type ω-3A are closer to the characterization and the type ω-3E slightly decreases the parameter. However the change in force is the result of its dependency to P and L, hence the change is not going to be a true response by the factors, as the other two parameters are in fact (21).

The balance of the doughs, is the product of the relation between tenacity and extensibility (P/L); the ω-3P type gives higher values, due to the high tenacities and low extensibilities. Previous studies have found that there is a positive correlation between (P/L) and the diameter of the cookie (10, 24). This could predict that with the ω-3P it would be obtained a smaller diameter from the regular.

All these analysis suggest that types of ω-3 are able to proceed to the next step of elaboration and baking of the cookies. Those are the ω-3A and ω-3E types at the 1:8 and 1:10 ratios, because these combinations present closer values to the averages found in the flour characterization and help to the functionality of the doughs.

Cookies

Moisture

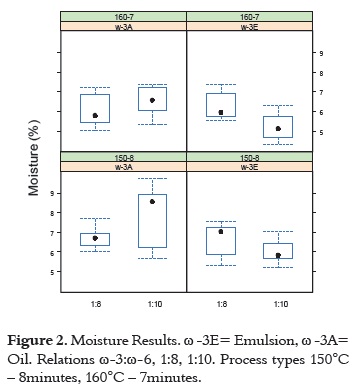

The Figure 2 presents the average values and the standard deviation of the moisture of cookies elaborated with ω-3, function of ω-3 type, ω-3:ω-6 ratios and baking processes. The ANOVA presented significant difference (p < 0.05) in this variable by the effect of ω-3 type and process, besides noticing an interaction between relation and type.

In all cases, the ω-3A type gives higher moisture to the cookies compared with the ω-3E type. Parallel, the baking process at 150°C - 8 minutes dehydrated less the product in comparison with the process at 160°C - 7 minutes, where the moisture decrease.

On the other hand, when ω-3:ω-6 ratios decrease, there's a direct impact by increasing the moisture with the ω-3A and decreasing with ω-3E.

This behavior could be explained by the importance of the type of fatty acids added to the wheat flour, because this can affect the formation of the lipid-amylose complex which influences the dough viscosity (25).

The effect of increasing the lipids content produces a decrease in the dough viscosity value, which can be translated in higher moistures (26, 27), similar to the behavior shown by the ω-3E type. Furthermore, some studies suggest that when fat is dispersed into a food material, it blocks the migration of water in a solid matrix, decreasing the effective diffusivity of moisture (28), so this could explain why the moisture increases as well when there is more quantity of lipids in ω-3E; the opposite effect happen with the ω-3A, because it doesn't have this properties.

In bakery, Emulsifiers are compounds that specifically facilitate the formation or stabilization of one liquid phase into another liquid phase, acting as surfactants that mainly interact with gluten and crumb softeners or anti-firming agents capable of forming complex of gelatinized starch (29). This is the reason why the cookies are softer whit the ω-3E.

This suggests that the behavior of the ω-3A, is not only different from the expected, but also from what is found in the literature. It has an unstable performance at the 150°C - 8 minutes process in the 1:10 relation due to the higher deviation, compared to the 160°C - 7 minutes process.

aw

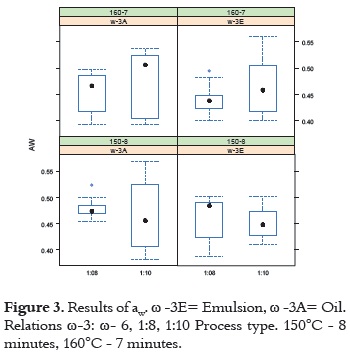

The figure 3 presents the average values and the standard deviation of aw of the cookies with ω-3, as function of the ω-3 type, ω-3:ω-6 ratios and baking process. The ANOVA presented significant difference (p < 0.05) by the effect of ω-3 type, plus an interaction between process and relation.

The ω-3A increases the response variable while the ω-3E decreases it. For the low relations, the process at 160°C - 7 minutes increases the values of aw while the process at 150°C - 8 minutes decreases it. This behavior suggests that the time makes more difference on the free water extraction than the temperature of baking does.

Texture

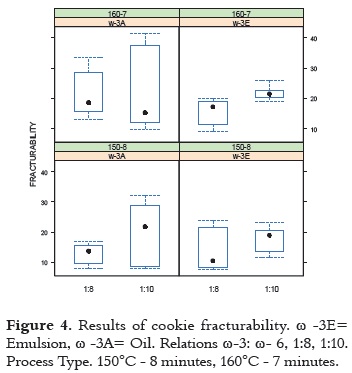

The Figure 4 presents the average values and the standard deviation of the cookie with ω-3 fracturability, as function of the ω-3 type, relations of ω-3: ω-6 and process. The ANOVA presents significant difference (p < 0.05) by the effect of relation and process.

In all the cases when ω-3:ω-6 ratios decrease, the fracturability of the cookies increase. In the process at 150°C - 8 minutes the fracturability is lower, while in process at 160°C - 7 minutes is higher.

Greethead, 1969 (30) cited by Jacob et al., 2007 (9) suggests that the more plastic and softer the fat, the better its performance. A softer fat, g ives less fracturability to the cookie; in general, the plasticity of fats is necessary in the cremated stage in order to trap air, resulting on important leaving effects and softer cookies. On the other hand, the oils are dispersed in globules form through the dough and they are less effective on their softening and aerating properties (9). This explains why the cookies with ω-3A are harder (higher fracturability) than the cookies elaborated with ω-3E, which contain emulsifier in their composition and have the capacity to trap air and improve the cremated system properties.

The higher the level of this component, the higher the softness of the cookie. So in this vein, when they have a low level, the products get harder (31).

The high dispersion of the data with the ω-3A at 1:10 ratio (See Figure 2), may indicates that low dosages didn't disperse well through the whole matrix, reflecting the variability of the fracturability in cookies.

Color

The Figure 5 presents the averages values and the standard deviation of the color in cookies with ω-3 as a function of the ω-3 type, ω-3: ω-6 ratios and baking process.

The ANOVA presented significant difference (p < 0.05) by the effect of the ω-3 noticing an interaction between process and ratio. However, the variations are small, and barely perceptible to the human eye. The dispersion of the data is due to the rugosity of the cookie which influences directly in the measurement.

According to the results in this stage, is determined the ω-3E at 1:10 ratio and the process at 160°C - 7 minutes, presenting a better behavior and stability results.

Stability

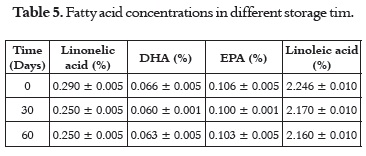

The Table 5 presents the average values and the standard deviation of the ω-3 fatty acids concentration during 60 days of storage in extreme conditions of temperature (40 ± 2°C) and relative moisture (75 ± 5%).

The ANOVA presented significant difference (p < 0.05) by the effect of time over the response variables ω-3 and ω-6, decreasing the values when the storage time increase. There is not a significant change in the DHA + EPA content.

It could be determine that the DHA and EPA losses are approximately 6% from the initial theoretical dose, similar to a study performed by Sadiq et al., 2007 (32), where the loss of vitamin A before and after baking of a fortified cookie was about 8.69 - 11.1%.

The cookie contributes with approximately the 4.80% of ω-3 and 2.72% of DHA + EPA per 26 g portion of cookie (product presentation) from the recommendation by the FDA (1.6 g/day). Another organism, like the OTAN, suggests that the requirements may falls in a range between 0.3 - 0.5 g/day of ω-3 (6); so the portion contributes with approximately 19.5% ω-3 and the 11.05% of DHA + EPA.

The Table 6 presents the average values and the standard deviation of the cookies moisture during the storage time. The ANOVA presents significant difference (p < 0.05) by the effect of time.

The values increase with the storage time, which is an expected behavior; the values are consistent with those obtained in the process, and they do not negatively influence the sensory evaluation of the products, as can be seen in later results (See Table 7).

The ANOVA presents significant difference (p < 0.05) by the effect of time in all the response variables. The changes in sweet flavor, crunch and odor characteristics were more drastic compared to the other attributes, which decrease the values when the storage time increases. However the rating between 30 and 60 days are similar, indicating that the sensory loss is more appreciable between 0 and 30 days.

In any of this three study times the odor was not objectionable, and this can be explained by the reasons given by Caceres et al., 2008 (33), in a study done with sausages and ω-3, where this attribute is appreciable when the levels of fat are low. It determines that the fat plays an important role when this component is used because it masks the odor and flavor of ω-3.

CONCLUSIONS

Through this study was found that the emulsifiers properties of ω-3 (DENOMEGA GAT 100) help the incorporation of air into the system, as well as to the softness of the cookies. The liquid state provides undesirable conditions of hardness for the texture of the product, and the dispersion of the data always was high compared with the emulsion, indicating that the product tends to be unstable. The ω-3 powder influences the rheology of the dough, taking tenacity to higher values and poor extensibility. Furthermore, it was encountered that the ω-3:ω-6 ratios have an incidence in the final product; it is observed that when the values increase, they have a negative effect in each variable response evaluated. The process at 160°C - 7 minutes decreases the moisture, which is directly related with the shelf life of the product, but cookies fracturability increases, which makes the product crunchier than the one obtained by the process at 150°C - 8 minutes. After all the study is determined that the best combination is the emulsion type and 1:10 ratio, because its better results in dough and cookie performance, while also keeping good stability during the storage time. The losses of DHA + EPA were approximately 6%.

BIBLIOGRAPHICAL REFERENCES

1. Ferguson LR. Nutrigenomics approaches to functional foods. J Am Diet Assoc. 2009 Mar; 109 (3): 452 - 458. [ Links ]

2. Harrison RA, Sagara M, et al. Can foods with added soya protein or fish oil reduce risk factors for coronary desease? A factorial randomised controlled trial. Nutr Metab Cardiovas Dis. 2004 Dec; 14 (6): 344 - 350. [ Links ]

3. Mataix J, Gil A. Libro blanco de los omega-3. Granada, España: Puleva Food; 2002. 162p. [ Links ]

4. Harris W, Miller M, Tighe AP, Davison MH, Schaefer EJ. Omega 3 fatty acids and coronary heart disease risk: Clinical and mechanistic perspective. Atherosclerosis 2008 Mar; 197 (1):12 - 24. [ Links ]

5. Lavie CJ, Milani RV, Mehra MR, Ventura HO. Omega 3 polyunsaturated fatty acids and cardiovascular diseases. J Am Coll Cardiol. 2009 Aug 11; 54 (7): 585 - 594. [ Links ]

6. Kris-Etherton P, Williams H, Appel L. Fish Consumption, Fish Oil, Omega-3 Fatty Acids, and cardiovascular Disease. J Am Heart Assoc. 2002 Nov 19; 106 (21): 2747-2757. [ Links ]

7. Riediger ND, Othman RA, Suh M, Moghadasian MH. A Systematic review of the roles of n-3 fatty acids in health and disease. J Am Diet Assoc. 2009 April; 109 (4): 668 - 679. [ Links ]

8. Siró I, Kápolna E, Kápolna B, Lugasi A. Functional food. Product development, marketing and consumer acceptance: A review. Appetite 2008 Nov; 51 (3): 456 - 467. [ Links ]

9. Jacob J, Leelavathi K. Efect of fat type on cookie dough and cookie quality. J Food Eng. 2007 March; 79 (1): 299 - 305. [ Links ]

10. Agyare KK, Addo K, Xiong YL, Akoh CC. Efect of structured lipid of alveograph characteristics, baking and textural qualities of soft wheat flour. J Cereal Sci. 2005 Nov; 42 (3): 309 - 316. [ Links ]

11. Wang J, Rosell CM, Benedito de Barber C. Effect of the addition on different fibres on wheat dough performance and bread quality. Food Chem. 2002 Nov; 79 (2): 221 - 226. [ Links ]

12. Ghotra BS, Dyal SD, Narine SS. Lipids Shortenings: A review. Food Res Int. 2002; 35 (10): 1015 - 1048. [ Links ]

13. AOAC. Official methods of analysis of the Association of Official Analytical Chemist International. Moisture in feeds. Method 925.45; Refractive Index. Method 921.08; Iodine Value. Method 920.158; Peroxide Value. Method 965.33 [CD-ROM]. USA: AOAC; 1997. [ Links ]

14. AOCS. Official method American Oil Chemists' Society. Marine Oil–Fatty Acid Composition by GLC. Method Ce 1b-89 [CDROM]. USA: AOCS; 1989. [ Links ]

15. AACC. Official Method American Association of Cereal Chemistry. Alveograms. Method 54-30 [CD-ROM]. St. Paul, USA: AACC; 1993. [ Links ]

16. Instituto Colombiano de Normas Técnicas y Certificación. Norma Técnica Colombiana. NTC 5328. Análisis Sensorial. Directrices para el uso de escalas de respuestas cuantitativas. Bogotá: ICONTEC; 2004. pp 9. [ Links ]

17. Verardo V, Ferioli F, Riciputi Y, Iafelice G, et al. Evaluation of lipid oxidation in spaghetti pasta enriched with long chain n-3 polyunsaturated fatty acids under diferent storage conditions. Food Chem. 2009 May 15; 114 (2): 472 - 477. [ Links ]

18. Hamilton R, Kalu C, Prisk E, Padley F, Pierce H. Chemistry of free radicals in lipids. Food Chem. 1997 Oct; 60 (2): 193 - 199. [ Links ]

19. Pomeranz Y, Chung OK. Interaction of lipids with proteins and carbohydrate in bread making. J Am Oil Chem Soc. 1978 Feb; 55 (2): 285 - 289. [ Links ]

20. McCann TH, Small DM, Batey IL, Wrigley CW, Day L. Protein-lipid interactions in gluten elucidated using acetic-acid fractionation. Food Chem. 2009 Jul; 115 (1): 105-112. [ Links ]

21. Addo K, Slepak M, Akoh CC. Efects of sucrose fatty acid ester and blends on alveograph characteristics of wheat flour dough. J Cereal Sci. 1995; 22 (2): 123 - 127. [ Links ]

22. Song Y, Zheng Q. Dynamic rheological properties of wheat flour dough and proteins. Trends Food Sci Tech. 2007 March; 18 (3): 132 - 138. [ Links ]

23. Watanabe A, Yokomizo K, Eliasson AC. Effect of physical state of nonpolar lipids on rheology, ultracentrifugation and microstructure of wheat flour dough. Cereal Chem. 2003 May/Jun; 80 (3): 281-284. [ Links ]

24. Indrani D, Sai MR, Jyostna R, Ventkateswara RG. Alveograph as a tool to assess the quality characteristic of wheat flour for parotta making. J Food Eng. 2007 Feb; 78 (4): 1202 - 1206. [ Links ]

25. Zohu Z, Robards K, Helliwell S, Blanchard C. Composition and functional properties of rice. Food Sci Technol Int. 2002 Dec 11; 37 (8): 849 - 868. [ Links ]

26. Singh N, Smith A. Rheological behaviour of different cereals using capillary rheometry. J Food Eng. 1999 Feb; 39 (2): 203-209. [ Links ]

27. Dautant FJ, Simancas K, Sandoval AJ, Müler AJ. Effect of temperature, moisture and lipid content on the rheological properties of rice flour. J Food Eng. 2007 Feb; 78 (4): 1159 - 1166. [ Links ]

28. Roca E, Guillard V, Guilbert S, Gontard N. Moisture migration in a cereal composite food at high water activity: effects of initial porosity and fat content. J Cereal Sci. 2006 Mar; 43 (2):144 -151. [ Links ]

29. Pareyt B, Finnie S, Putseys J, Delcour J. Lipids in bread making: Sources, interactions, and the impact on bread quality. J Cereal Sci. 2011 Nov; 54 (3): 266 - 279. [ Links ]

30. Greethead GF. The role of fat in bakery products. Food Aust. 1969; 21: 228 - 230. [ Links ]

31. Pareyt B, Talhaoui F, Kerckhofs G, Brijs K, Goesaert H, Delcour MJA. The rol of sugar and fat in sugar-snap cookies: structural and textural properties. J. Food Eng. 2009 Feb; 90 (3): 400 - 408. [ Links ]

32. Sadiq BM, Umair AM, Shahzad AM, Tahir NM. Bioavailability and store stability of vitamin A fortificant (retinyl acetate) in fortified cookies. Food Res Int. 2007 Dec; 40 (10): 1212 - 1219. [ Links ]

33. Cáceres E, García ML, Selgas MD. Effect of pre-emulsified fish oil as source of PUFA n-3 on microstructure and sensory properties of mortadella, a Spanish bologna type sausage. Meat Sci. 2008 Oct; 80 (2): 183 - 193. [ Links ]