Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Vitae

Print version ISSN 0121-4004

Vitae vol.20 no.3 Medellín Sept./Dec. 2013

FOODS: SCIENCE, TECHNOLOGY AND ENGINEERING

REDUCTION OF MATRIX EFFECTS IN PESTICIDE RESIDUE ANALYSIS IN FOOD BY PROGRAMMABLE TEMPERATURE VAPORIZER

REDUCCIÓN DEL EFECTO MATRIZ EN EL ANÁLISIS DE RESIDUOS DE PLAGUICIDAS EN ALIMENTOS MEDIANTE EL USO DEL INYECTOR DE TEMPERATURA PROGRAMADA

AHUMADA D.A.1, GUERRERO J.A.1*

1 Grupo de Residualidad y Destino Ambiental de Plaguicidas en Sistemas Agrícolas. Departamento de Química. Facultad de Ciencias. Universidad Nacional de Colombia ‒Sede Bogotá. Edificio 451, Ciudad Universitaria, Carrera 30 No 45 – 03. A.A. 14490. Bogotá, Colombia.

* Autor a quien se debe dirigir la correspondencia jaguerrerod@unal.edu.co.

Received: 15 May 2012

Accepted: 28 November 2013

ABSTRACT

Background: The phenomenon known as the ''matrix-induced chromatographic response enhancement'' commonly affects the sensibility, precision, and accuracy in pesticide residue analysis. The presence of matrix effects can be given by adsorption and/or thermal decomposition of pesticides on the gas chromatograph injection port. Objective: To reduce the matrix-induced chromatographic response enhancement on pesticide residues analysis in food through the use of several operational modes of programmable temperature vaporizer inlet. Methods: The analyses were carried out in potato (Solanum tuberosum) extracts by gas chromatography with mass spectrometry detector. In this study, four programmable temperature vaporizer splitless modes were investigated: hot, pulsed, cold and solvent vent. Another topic developed in this study has to do with the influence of injection volume, assessed for the matrix effects. Results: The analysis of variance (ANOVA) (α = 0.05) indicates that when the hot splitless is used most compounds are subjected to matrix-induced chromatographic response enhancement. Furthermore, with the pulsed splitless, a decrease in the number of compounds with matrix-induced chromatographic response enhancement was found, approximately 20% compared to the classic hot splitless. Finally, a remarkable decrease in matrix-induced effects was found when cold splitless mode was used, since there was up to 55% reduction in the compounds, relative to traditional hot splitless, that showed statistical differences between responses in matrix-free standards and matrix-matched standards. Conclusions: It was found that the use of conventional hot splitless and pulsed splitless modes caused matrix-induced effects in more than 70% of the studied compounds. In addition, the results indicate that for most compounds there is an inverse relationship between matrix-induced chromatographic response enhancement and the volume of injection.

Keywords: Pesticides, gas chromatography, food, mass spectrometry, residues.

RESUMEN

Antecedentes: Diferentes investigaciones establecieron que el efecto matriz en el análisis de residuos de plaguicidas afecta la sensibilidad, precisión y exactitud de las metodologías; la presencia de este fenómeno se atribuye a la adsorción y/o descomposición térmica de los analitos en el puerto de inyección del cromatógrafo de gases. Objetivos: En el presente trabajo se evaluó la influencia de varios modos de operación del inyector de temperatura programada, con el objetivo de reducir el efecto matriz en la determinación de residuos de plaguicidas en alimentos. Métodos: El análisis se llevó a cabo en extractos de papa (Solanum tuberosum) mediante cromatografía de gases acoplada a espectrometría de masas. En este estudio se evaluó los modos de operación del inyector de temperatura programada sin división de la muestra, los cuales corresponden a: en caliente, con pulso de presión y en frío. Finalmente, también se evaluó el modo de venteo de solvente y el efecto del volumen de inyección sobre la variación de la respuesta cromatográfica (efecto matriz). Resultados: Los resultados mostraron que el modo sin división en caliente ocasiona que la mayoría de los compuestos presenten efecto matriz, mientras que al emplear un pulso de presión se encontró una reducción cercana al 20% de los compuestos que tienen efecto matriz. Por su parte, el sistema sin división en frío mostró el menor número de compuestos con efecto matriz. Conclusiones: Los resultados indicaron que los modos de inyección en caliente sin división y con pulso de presión ocasionaron la mayor presencia de efecto matriz en más del 70% de los compuestos estudiados. Por otro lado, el sistema sin división en frío mostró la mayor reducción de la presencia de efecto matriz, respecto a cualquiera de los sistemas sin división en caliente. Adicionalmente, los resultados mostraron que existe una relación inversa del efecto matriz con el volumen de inyección.

Palabras clave: Plaguicidas, cromatografía de gases, alimentos, espectrometría de masas, residuos.

INTRODUCTION

Fruits and vegetables are an important part of a healthy diet as they are a significant source of vitamins and minerals. Nevertheless, these foods can also be a source of toxic substances, such as pesticides, antibiotics and heavy metals (1). Initially, pesticides are applied at various stages of food cultivation and/or during their post-harvest storage, playing an important role in the agriculture intensification. The increasing demand of the consumers, along with the higher competition on the market emphasizes the importance of food analysis (2). Correct assessment of food quality, as well as the determination of food contaminants, is critical for the benefit of consumers. Therefore, the developing and use of analytical procedures, which helps to control the quality of the production process and final products, is important.

Nowadays, the analysis of pesticide residues is usually carried out by gas chromatography (GC) or high performance liquid chromatography (HPLC) (3, 4). The GC conventional detectors most commonly used for this purpose are the electron capture (ECD), nitrogen-phosphorus (NPD), and flame photometric (FPD) (5). However, gas chromatography with a mass spectrometric detector (GC–MS) is preferred lately due to its high selectivity and sensitivity (6). The sample introduction into the gas chromatograph (GC) is a very important step that influence or affect its sensitivity, accuracy, precision, and chromatographic response (7). The most important injection techniques for pesticide residues analyses are split/splitless, on-column and programmed temperature vaporization (PTV) (8). PTV is considered the most universal injection technique due to their multiple modes of operation since within it both cold splitless and solvent vent mode are included (9-11).

The matrix induced enhancement effects (matrix effect) are known to seriously affect the measurement accuracy in GC analysis, mostly leading to overestimated results when the convenient matrix free calibration standards are used (12, 13). This phenomenon has been studied according to diverse parameters, such as sample clean up, chemical structure of analytes, analytes concentration, injection temperature, matrix type, matrix concentration and injection techniques (14). Because of this, cold splitless and solvent vent are two PTV operation modes that have great potential to prevent degradation processes of analytes from the injector to the column (10). This is due to the fact that at the time of the sample introduction into the injection port the temperature is low, compared to the classic splitless mode. Furthermore, the used PTV inlet in splitless mode has an advantage of significantly smaller internal volume of 150 μl, instead of conventional splitless inlet with internal volume in the ranges of 250 μl - 980 μl (15). A smaller internal volume is advantageous for the analysis of thermolabile compounds due to the shorter residence time of sample vapors in a hot vaporizing chamber, so a decreased thermal decomposition is expected (14).

A previous work founded that potato (Solanum tuberosum) extracts causes the largest increase in chromatographic response compared to other fruits and vegetables (16). Based on these results, the aim of this study was to reduce the matrix effects produced by potato extracts through the use of different PTV injection modes. In our study, different operational modes of programmable temperature vaporizer inlet were used with the aim of reducing the matrix-induced chromatographic response enhancement on pesticide residues analysis in potato extracts.

MATERIALS AND METHODS

Reference materials, reagents and solutions

Pesticide reference standards, all > 95% purity, were obtained from Dr. Ehrenstorfer GmbH (Augsburg, Germany) and Chemservice (West Chester, PA, USA). Stocks were prepared in a concentration around 500 µg/mL, using ethyl acetate as solvent, and were stored in amber glassware under appropriate conditions, such as -20 °C, and exclusion of moisture and light. The mixture of pesticides was made in ethyl acetate by measuring different volumes of each stock in order to obtain a concentration range between 1.0 µg/mL to 96.1 µg/mL. The internal standard (I.S.) was prepared by dissolving tris (2-chloro-1-(chloromethyl) ethyl) phosphate in ethyl acetate to make a 500 µg/mL solution. All solvents used (ethyl acetate and cyclohexane) were residue grade (J.T. Baker, USA). Potatoes (Solanum tuberosum) were obtained from supermarkets and analysed to verify that they did not have pesticides or interfering signals; this matrix was selected according to previous studies (16).

Equipment

In this study, analyses were conducted on an Agilent Technologies GC model 7890A coupled to a 5975 mass-selective detector equipped with a PTV and an Agilent 7673 auto-injector. A HP-5MS (30 m x 0.25 mm ID x 0.25 µm) capillary column was used. The acquisition, control and data processing were performed using the MSD ChemStation version E02.00.493 software.

Chromatographic conditions

The carrier gas was ultrapure helium and was set at constant pressure mode (152 kPa) using the retention time locking (RTL) program with chlorpyrifos. The oven temperature program consisted of 70°C (0.4 min) to 120 °C at a rate of 15°C/min, then increased to 200°C at a rate of 3.5°C/min, followed by a final ramp of 7°C/min to 290 °C (6 min), the total run time was 45.4 min. PTV was operated in splitless, pulsed splitless, cold splitless and solvent vent modes (17).

The temperature program for PTV in solvent mode was: from 63.6 °C (0.53 min) to 267°C (3.00 min) at a rate of 625°C/min, then the temperature increased to 300°C (5.00 min) at 100°C/min. The flow through split-valve was 40 mL/min and splitvalve was closed after 0.6 min and opened after 2.45 min. The temperature program for PTV in cold splitless mode was: 61.7 °C (0.8 min) to 267°C (3.00 min) at a rate of 631°C/min, then the temperature increased to 300°C (5.00 min) at 100°C/min. The purge time was 1.9 min.

For the pulsed splitless the conditions were: a pulse pressure of 448 kPa, a pulse time of 0.6 min, the temperature of injection port of 256°C and the purge time was 0.8 min. The injection port temperature and purge time at classic hot splitless mode were 256°C and 0.8 min, respectively. For all splitless modes the purge flow was 40 mL/min.

Mass spectrometer conditions

The mass spectrometer was operated in the electron impact (EI) mode at electron energy of 70 eV in selective ion monitoring (SIM) mode. For each pesticide two or three specific ions were selected and sorted into groups; the used dwell time was 25 ms. The retention times, target ions, qualifier ions and start times of SIM groups for pesticides and for internal standards (I.S) are given in table 1.

Extraction procedure

For the extraction, a Stephan Blender homogenizer 2010, an Ultraturrax high speed homogenizer (IKA T25) and a Buchi R-114 rotary evaporator were used. The Clean-up process involved a gel permeation chromatography in a Bt Redement, model KL-SX-3, equipped with a glass column 20 cm x 10 mm id packed with gel Biobeads® S-X3 as stationary phase.

30 g of sample (homogenate) were blended for 2 min (at 10 000 rpm) with 30 mL of ethyl acetate, 30 g of anhydrous sodium sulphate and 4 g of sodium bicarbonate. The suspension was filtered through the layer of sodium sulphate (25 g) to collect 15 mL of the extract. Then the filtrate was concentrated by rotary evaporation (in water bath at 35°C) to approximately 250 μL, then was transferred quantitatively to a 2 mL volumetric flask with ethyl acetate.

A 500 µL aliquot of crude extract was loaded onto the GPC column. The flow-rate of the mobile phase (cyclohexane–ethyl acetate, 1:1, v/v) was 1 mL/min. The eluate fraction (7–22 mL) was concentrated to 0.5 mL using the rotary vacuum evaporator (in water bath at 35°C), and solvents were removed by a mild stream of dry nitrogen. Afterwards, this extract was quantitatively transferred into a 1 mL volumetric flask with ethyl acetate (Extract A).

Matrix-induced effects study

Due to the objective of this work, the reduction of the matrix effects using different PTV injection modes, two different types of GC system calibration solutions were prepared as follows:

- Solutions prepared in solvent (matrix-free solution): They were prepared taking 16 µL of pesticide mixture solution, then adding the internal standard and diluting to 1 mL with ethyl acetate.

- Solutions prepared in potato matrix (matrixmatched solution): these solutions were prepared as described above (i), but adding 0.5 mL of potato extract (Extract A) and internal standard before filling up to the final volume of 1 mL with ethyl acetate. These extracts were obtained by applying the extracting method explained above to potato, which had not been treated with any pesticide, and the final matrix content was 1g/mL.

Comparison of PTV injection modes

Two experiments were necessary to evaluate the PTV injection modes over the matrix-induced effects, the first was related to the use of the PTV splitless modes, and the second experiment concerning to the effects of sample injection volume.

A factorial design was used to evaluate and to compare the effect of PTV splitless modes on the matrix effect. The first factor comprised the injection in matrix-free standard (solvent injection) and matrix-matched standard. The second factor was the PTV splitless modes: hot splitless (2 µL), pulsed splitless (2 µL), cold splitless (2 µL) and cold splitless with injection volume of 4 µL. Four replicates were performed for each experiment and all samples were injected randomly.

Studies with Solvent vent mode and injection volume

The evaluation of the solvent vent mode was performed using a factorial design with three levels of injection volume (10 µL, 15 µL and 20 µL), injections in matrix-free and matrix-matched solution. There were four replicates of each experiment and all samples were injected randomly.

Statistical analysis

In order to determine the extent in which the co-extractives effectively affect the response, the results of this completely randomized design were analysed using an analysis of variance (ANOVA). The performance of this analysis was only done after a careful and systematic checking of the assumptions hereafter: first of all, the experimental error is an independent random variable due to a random sequence analysis; secondly, that it follows a normal distribution proved by the Shapiro-wilk test; thirdly, that its mean is equal to zero, reckoned by least squares method; and finally, that the design has homogenous variances tested by Levene's test.

The analysis of variance (ANOVA) of the obtained data was performed using the version 9.0 of the Software SAS®. The significance level was stated at 95%, with p-value 0.05.

RESULTS

Matrix Effect: splitless injection modes

The ratio between matrix and solvent areas for each compound (matrix standard/matrix-free standard x100%) is known as percentage of matrix effect, and is the first indication of the presence of this phenomenon (18). Table 2 lists the percentages of matrix effect calculated for some compounds under study.

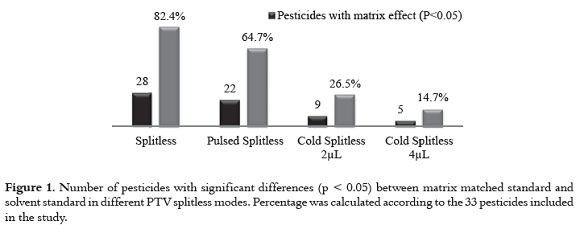

The ANOVA demonstrates significant differences (p < 0.05) between matrix standard and matrix-free standard for some pesticides. Figure 1 shows a summary of the results obtained from the corresponding analysis of variance (ANOVA) with a significance level of 0.05. This figure shows the number of compounds having statistical differences (p < 0.05) between chromatographic responses of matrix-matched standard and matrix-free standard, that is, for those compounds to which matrix effect was found.

Matrix Effects: Solvent vent mode and injection volume

Figure 2 shows the percentage of matrix effect at different injection volumes (10 μL, 15 μL and 20 μL) for organochlorines (OC), pyrethroids, miscellaneous compounds and the figure 3 shows the percentages for organophosphorus.

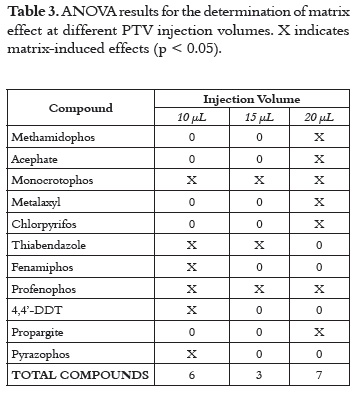

Table 3 lists the results of the statistical evaluation performed using ANOVA, for all injection volumes, for those compounds to which matrix effect was found in some volumes (p < 0.05).

DISCUSSION

Table 2 shows the percentage of matrix effect, which is the ratio between the response of the pesticide in extract and the response of pesticide in pure solvent. According to some authors, ratios over 120% suggests occurrence of matrix-induced effects; thereby, observing table 2, it should be noted that some compounds, such as chlorpyrifos, thiabendazole, fenamiphos, profenofos, permethrin, among others, have values above this criterion in almost all splitless injection modes, which suggests presence of matrix effects (18). On the contrary, table 2 shows that pesticides, such α –Endosulfan and HCB in cold splitless mode, have values close to 100%, indicating that probably these pesticides are not sensitive to matrix effect.

Regarding the use of different PTV splitless modes, table 2 shows that hot splitless mode causes the greatest percentages of matrix effect, these results are in agreement with previous studies. Even for this splitless mode, it was found that some compounds such as HCB have high values (matrix standard/matrix-free standard), which is not very common (19, 20). The odd behaviour of HCB is unexpected and there are no experimental evidences that could explain this event; however, these results can also be attributed to some analytical error, instrumental variations, and/or decomposition of analytes in blank extract, among others (21).

When the results of conventional hot splitless with pulsed splitless (with a pressure pulse at the injector) were compared, a decrease in the pesticides with ratios up to 120% was found. For example, table 2 shows a considerable percentage decrease of matrix effect for compounds such as thiabendazole, 4,4'-DDT, captan and permethrin. Moreover, a significant decrease in these ratios was not noted in pesticides such as chlorpyrifos, tebuconazole, profenophos and propargite. This indicates that pressure pulse does not decrease the adsorption and/or decomposition of these molecules at the injection port, which can be explained because these molecules possibly have high adsorption and degradation kinetics.

Furthermore, the cold splitless (2 µL) results shows that some pesticides had a significant improvement in the percentages (regarding as hot splitless and pulsed splitless); this improvement is reflected in values closer to 100%, which indicates a reduction in matrix-induced effects. As can be noted, for cold splitless injection, when comparing the results between the two injection volumes, it was found that chlorpyrifos, thiabendazole, tebuconazole and deltamethrin have percentages of matrix effect closer to 100% when a volume of 4 µL is injected, which indicates that the increase in the injection volume decreases matrix effects.

Several authors have reported different variables that influence the chromatographic response enhancement or matrix effects; one of the most important is the pesticide concentration (14, 22), which has an inverse relationship with matrix-induced effects. This relationship is due to low concentrations, since it has a lower number of molecules in the injection port; consequently, the loss of these molecules is more significant that when is working with high concentrations of pesticide (13). Thus, the chromatographic response enhancement decreases with the increase of the injection volume, which can be attributed to a greater number of molecules in the injection port when cold splitless (4 µL) mode is used.

In the statistical evaluation we sought to determine the influence of different PTV splitless modes. For this purpose, we considered the factorial design that was shown in the experimental section. Results of analysis of variance (ANOVA) of this design showed that there was no interaction between the variables included. In this context, the results presented below correspond exclusively to the statistical evaluation for the comparison of chromatographic responses of matrix-matched standard and matrix-free standard.

Figure 1 shows that the hot splitless injection presents the greatest number of compounds with matrix-induced effects. It also shows that by applying a pressure pulse the number of compounds with matrix effects decrease. This behaviour indicates, as expected, that the pressure pulse decrease the possibility of compounds adsorption and/or decomposition in the inlet, thus matrix-induced effects are reduced by nearly 20%.

Figure 1 illustrates that the use of cold splitless injection has reduced significantly the matrix effect, because with an injection volume of 2 μL only nine pesticides presented matrix-induced effects (triflumurone, monocrotophos, dichlofluanid, malathion, captan, fenamiphos, profenophos, λ-Cyhalothrin and pyrazophos). With 4 μL in cold splitless mode, the number of compounds with matrix effect also decreased.

Finally, when comparing the results shown in figure 1 with the matrix effect percentages listed for some compounds in table 2, a good correlation between them was found. Similarly, both results show that the increase of injection volume decreases the number of compounds having matrix effect.

Experiments with solvent vent mode were not carried out in splitless modes because the injections of 10 μL, 15 μL, and 20 μL produced high chromatographic responses. Thus, for these experiments it was used five times lower concentrations than those reported in table 2. On the other hand, the injection volume was included in the second experimental design to observe its influence on the matrix effect, which was not included in the previous experiment (studies with splitless injection modes) because it would require a more complex design.

Matrix Effects: Solvent vent mode and injection volume

The figure 2 shows that the organochlorine pesticides (first five in figure 2) presented the lowest percentage of matrix effect. These compounds (OC) have lower polarity, hence less susceptible to adsorption in the injection liner; in addition, this type of molecules are relatively thermo-stables. Interestingly, other authors have reported chromatographic responses enhancement similar to those found in our study (14). In general, it was found that for these compounds there are percentages around 100%, indicating that matrix effect is not present. Only in the case of 4,4'-DDT a relatively high percentage was found, which agrees with the sensitivity of this compound to decompose at 4,4- DDD in the injection port.

Synthetic pyrethroids (next five pesticides in figure 2) compounds, with high molecular masses (over 400 g/mol), generally were compounds that have some degree of matrix effect (23). In this study, they presented similar results to OC pesticides since all the percentages presented values around 100%.

In general, organophosphorus compounds have greater probability to have matrix-induced effects, due to their relatively high polarity, therefore for these pesticides values up to 500% have been reported (22). Figure 3 shows that some organophosphorus (P = O) pesticides (acephate, monocrotophos, Fenamiphos, profenophos and iprodione) have values considerably greater than 100%. However, some organophosphorus containing P = S groups, chlorpyrifos and malathion, the incidence of matrix effect was less pronounced in some injection volumes. On the contrary, compounds as diazinon, parathion-methyl and isofenphos presented percentages close to 100% for all injection volumes.

It is also noted in figure 3 that some compounds, such as metamidophos, acephate and dimethoate, have the highest ratios of matrix standard to matrix- free standard with 20 μL injection. However, for compounds such monocrotophos, malathion, phenamiphos, profenophos, tetradifon, iprodione and pyrazophos, it was found that the percentage of matrix effect decreases as the injection volume increases.

Table 3 shows the results only for pesticides that presented statistical differences (p < 0.05) between the injection volumes and for the remaining compounds, and no matrix-induced effect was found (statistically; p > 0.05). Regarding table 3, the results agree satisfactorily with those presented previously because compounds such as HCB, that presented low percentages of matrix effect, does not present statistically differences (p > 0.05) at different injection volumes evaluated, and other compounds such as monocrotophos or fenamiphos (with high percentages of matrix effect) presents statistical differences (p < 0.05).

Table 3 shows that, for an injection volume of 10 µL, pesticides such as thiabendazole, fenamiphos, 4,4'-DDT and pyrazophos have matrix-induced effects; however, if the volume increases no statistical difference (P > 0.05) appears between matrixmatched and matrix-free solutions, which implies that the matrix effects disappears. This behaviour is given by the previously mentioned concentration process in the liner.

In contrast, metamidophos, acephate, chlorpyrifos, metalaxyl and propargite have a different behaviour. As can be seen when larger volumes were used the matrix-induced effects increased. This may be attributed to the concentration of matrix components along with the pesticides, at the time of solvent elimination; consequently, there are more matrix compounds. This facilitates the transfer of pesticides to the analytical column and therefore chromatographic responses are higher in matrixmatched solution (14).

From table 3 it can also be seen that for some compounds it was not possible to reduce matrixinduced effects, indicating that these molecules are extremely sensitive to decomposition and / or adsorption, which agrees or confirms literature reports (13, 14). Moreover, it is possible that these processes of loss of molecules were carried out in the chromatographic column and not in the liner injection (24).

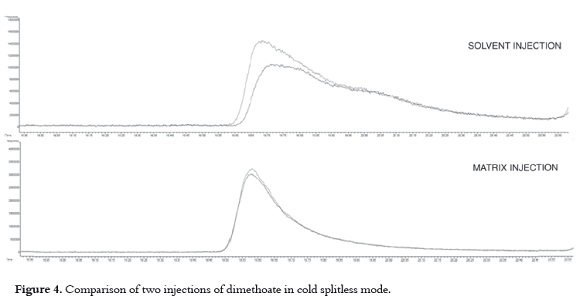

In addition, in our study, although a significant reduction of matrix effects was found in potato extracts by using cold splitless and solvent vent modes, we noticed that the stability of the chromatographic signals by using matrix-matched standards is greater than the matrix-free standards. Thus, although the area of some compounds in solvent was statistically equal to the matrix-matched areas, the characteristics of the chromatographic signals were completely different. The figure 4 shows some chromatograms obtained in matrix-free standards and matrix standards. For example, for most compounds, injections with matrix-matched solutions had more symmetric signals and a better peak height to peak width ratio (H/A) compared with the matrix-free solutions, while the solvent signals showed low symmetries, peak widths and variation in retention times.

Limitations

Finally, it is important to note that although this study was limited to the use of extracts of potato, the choice of this extract was based on a previous study which found that potato extracts causes the largest increase in chromatographic response compared to other fruits, vegetables and cereals (16). However, it is believed that the results found in this study cannot be directly extrapolated to other types of food and other pesticides, because the effects that can cause the different matrices on the chromatographic responses depend on many factors, such as chemical composition (e.g. lipids, carotenoids, water content, chlorophylls, among others), the extraction solvent, the amount of extractable matrix, the clean-up procedure, the extraction procedure and, last but not least, the physicochemical properties of pesticides. Despite all of this, it is important to note that the objective of this study was not to perform the above, but to reduce the matrix effect through the use of the PTV injector, and the results showed that this is possible.

CONCLUSIONS

In this study it was found that the use of classic hot splitless and pulsed splitless modes cause matrix-induced effects in more than 70% of the studied compounds in potato extracts. On one hand, it was warned that the use of pulse pressure decreases the decomposition and / or degradation of the compounds by about 20%. On the other hand, a remarkable decrease in matrix-induced effects was achieved using cold splitless mode, since there was up to 55% reduction in the compounds that showed statistical differences between responses in matrixfree standards and matrix-matched standards, compared with the traditional hot splitless mode.

For most compounds in cold splitless and solvent vent modes an inverse relationship between the injection volume and the presence of matrix-induced effects was found, but it was not possible to clearly determine the effect of the injection volume on the matrix-induced effects, since in some compounds these effects increased with the injection volume.

ACKNOWLEDGMENTS

The Authors are grateful to the Chemistry Department of National University and the International Atomic Energy Agency (IAEA) through the project COL5/022.

REFERENCES

1. D'Mello JPF. Food Safety: Contaminants and Toxins. 1st Ed. Oxon, UK: CABI Publishing; 2003. 91p. [ Links ]

2. Harris J. Chemical Pesticide Markets, Health Risks and Residues. 1st Ed. Cambridge, USA: CABI Publishing; 2000. 64p. [ Links ]

3. Gómez-Ramos MM, Ferrer C, Malato O, Agüera A, Fernández- Alba AR. Liquid Chromatography-High-Resolution Mass Spectrometry for pesticide residue analysis in fruit and vegetables. Screening and quantitative studies. J Chromatogr A. 2013 April; 1287 (26): 24-37. [ Links ]

4. Walorczyk S, Drozdzynski D, Kowalska J, Remlein-Starosta D, Ziólkowski A, Przewozniak M, Gnusowski B. Pesticide residues determination in Polish organic crops in 2007-2010 applying gas chromatography-tandem quadrupole mass spectrometry. Food Chem. 2013 Aug; 139 (1-4): 482-487. [ Links ]

5. Grob R, Barry E. Modern Practice of Gas Chromatography. 4th Ed. New York, USA: Wiley Interscience; 2004. 275p. [ Links ]

6. Cherta L, Beltran J, Pitarch E, Hernández F. Comparison of Simple and Rapid Extraction Procedures for the Determination of Pesticide Residues in Fruit Juices by Fast Gas Chromatography– Mass Spectrometry. Food Anal Method. 2013 Dec; 6 (6): 1671-1684. [ Links ]

7. Snow NH. Inlet Systems for Gas Chromatography. 4th Ed. New York, USA: Wiley Interscience; 2004. 461p. [ Links ]

8. Zrostlíková J, Hajslová J, Godula M, Mastovská K. Performance of programmed temperature vaporizer, pulsed splitless and oncolumn injection techniques in analysis of pesticide residues in plant matrices. J Chromatogr A. 2001 Dec; 937 (1-2): 73-86. [ Links ]

9. Hernández F, Cervera MI, Portolés T, Beltran J, Pitarch E. The role of GC-MS/MS with triple quadrupole in pesticide residue analysis in food and the environment. Anal Methods. 2013 Aug; 5 (21): 5875-5894. [ Links ]

10. Hoh E, Mastovska K. Large volume injection techniques in capillary gas chromatography. J Chromatogr A. 2008 Apr; 1186 (1-2): 2-15. [ Links ]

11. Walorczyk S. Gas chromatographic–tandem mass spectrometric analysis of pesticides residues in produce using concurrent solvent recondensation-large volume injection. J Chromatogr A. 2012 Jan; 1222 (27): 98-108. [ Links ]

12. Yu S, Xu X. Study of matrix-induced effects in multi-residue determination of pesticides by online gel permeation chromatography- gas chromatography/mass spectrometry. Rapid Commun Mass Sp. 2012 Mar; 26 (9): 963-977. [ Links ]

13. Poole CF. Matrix-induced response enhancement in pesticide residue analysis by gas chromatography. J Chromatogr A. 2007 Jul; 1158 (1-2): 241-250. [ Links ]

14. Hajslová J, Zrostlíková J. Matrix effects in (ultra)trace analysis of pesticide residues in food and biotic matrices. J Chromatogr A. 2003 Jun; 1000 (1-2): 181-197. [ Links ]

15. Kende A, Vrabecz A, Angyal V, Rikker T, Eke Z, Torkos K. Liner as the Key of Injection Optimization in Pesticide Analysis. Chromatographia. 2006 Feb; 63 (3-4): 181-187. [ Links ]

16. Ahumada DA, Guerrero JA. Estudio del Efecto Matriz en el Análisis de Plaguicidas por Cromatografía de Gases. Vitae. 2010 Jan-Apr; 17 (1): 51-58. [ Links ]

17. Ahumada DA, Guerrero JA. Optimización del inyector de temperatura programada en el análisis de residuos de plaguicidas mediante el método simplex. Rev Colomb Quím. 2010 May-Ago; 39 (2): 221-236. [ Links ]

18. Aparecida F, Guido AI, Lopes ME Queiroz, Teófilo RF, Neves AA, Pinho G. Evaluation of matrix effect on the GC response of eleven pesticides by PCA. Food Chem. 2012 Nov; 135 (1): 179-185. [ Links ]

19. Garrido A, Martínez JL, Fernández JL, Romero-González R. Compensation for matrix effects in gas chromatography–tandem mass spectrometry using a single point standard addition. J Chromatogr A. 2009 Jun; 1216 (23): 4798-4808. [ Links ]

20. Lozano A, Rajski L, Uclés S, Belmonte-Valles N, Mezcua M, Fernández-Alba AR. Evaluation of zirconium dioxide-based sorbents to decrease the matrix effect in avocado and almond multiresidue pesticide analysis followed by gas chromatography tandem mass spectrometry. Talanta 2014 Jan; 118 (15): 68-83. [ Links ]

21. Kocourek V, Hajlová J, Holadová K, Poustka J. Stability of pesticides in plant extracts used as calibrants in the gas chromatographic analysis of residues. J Chromatogr A. 1998 Mar; 800 (2): 297-304. [ Links ]

22. Amvrazia EG, Papadi-Psylloua AT, Nikolaos G. Pesticide enrichment factors and matrix effects on the determination of multiclass pesticides in tomato samples by single-drop microextraction (SDME) coupled with gas chromatography and comparison study between SDME and acetone-partition extraction procedure. Int J Environ Anal Ch. 2010 Mar; 90 (3-6): 245-259. [ Links ]

23. Schenck FJ, Lehotay S. Does further clean-up reduce the matrix enhancement effect in gas chromatographic analysis of pesticide residues in food? J Chromatogr A. 2000 Jan; 868 (1): 51-61. [ Links ]

24. Anastassiades M, Mastovská K, Lehotay SJ. Evaluation of analyte protectants to improve gas chromatographic analysis of pesticides. J Chromatogr A. 2003 Oct; 1015 (1-2): 163-184. [ Links ]