INTRODUCTION

The word “guacamole” is a term coined by the Mexican and refers to a sauce or dressing composed of avocado pulp and other ingredients such as tomato, onion, garlic, lemon, coriander, jalapeño and salt 1. Guacamole is highly appreciated in international gastronomy as a result of the increasing popularity of Mexican food 2. Guacamole powder is an important advancement in the generation of added value to the avocado production chain. It is also important for this agroindustry as it appears as an alternative, easy to use product with a longer lifespan that can be consumed by the public at any time.

Spray drying is a unit operation in which a liquid mixture is fed to the dryer and then dehydrated via contact with dry air in order to produce a final solid product 3. Spray drying has been widely used on vegetable matrices: for microencapsulating beet juice 4, tamarind pulp powder 5, melon juice 6, sunflower oil powder 7, mango 8, green coffee oil 9, orange juice 10, linseed oil 11, watermelon juice 12 and bloodberry juice 13 the effects of some processing parameters on moisture content, water activity, drying yield, bulk density, solubility, glass transition temperature (Tg). There is little literature on avocado, and even less on guacamole powder.

The experimental optimization of the spray drying process using surface response methodology (RSM) is an effective path that facilitates the industrial improvement of powder foods. As a result, the complexity of the process is reduced providing a better understanding of the influence of the independent variables on the properties of the powder matrix 14. The response surface methodology is a quick and economic experimental strategy that combines mathematical methods and statistical inference to enable effective exploration of a system. Its main advantage is the significant reduction of the number of experiments required for evaluation, analysis and optimization 15. This tool defines the conditions for operation as well as the formula for preparing the liquid to be fed to the dryer in order to obtain a product with the desired characteristics 16,17,18. This is highly consistent with the current demands in terms of design, improvement and formulation of new products 19. Experimental optimization of spray drying processes using the RSM has been widely used for a number of products: Lulo 20, tamarind pulp 21, kefir 19, cheese 22, microencapsulation of probiotics in raspberry juice 23, guava 14, microencapsulation of jabuticaba 24, azufaifa 25.

Process standardization is a competitive advantage for food industries because of the higher demands of modern consumers in the current global market 26. A standardized process is either an optimized technological method or the best alternative that enables reaching the highest efficiency in a process. It also removes unnecessary activities and includes a logical process sequence and generates a homogeneous product exhibiting the best quality traits 27.

The aim of this study was to standardize the spray drying process for obtaining guacamole powder using the response surface methodology. The optimized process should guarantee optimal operating conditions (atomizer disk speed, air inlet temperature, air outlet temperature and vacuum pressure) and a product with the desired quality attributes.

MATERIALS AND METHODS

Raw materials

The following materials were used: fresh avocados (Persea americana Mill) of the Hass variety grown in the Abejorral municipality, Antioquia, Colombia - these fruits were processed 11 to 15 days after ripening (dry material ≈ 32,8% y fat ≈ 18,7%) in accordance with the findings reported by Marulanda (28), gum Arabic (Master Gum FT), maltodextrin (dextrose equivalent between 18 and 20), TBHQ (tert-Butylhydroquinone), food grade salt, onion (Allium cepa), garlic (Allium sativum), bell pepper (Capsicum annuum), tomato (Solanum lycopersicum), coriander (Coriandrum sativum), lemon (Citrus aurantifolia) and water.

Physicochemical properties

Water activity (a w ): The values for water activity in the powders were determined with a dew point hygrometer at 25ºC (Aqualab series 3TE, Decagon, Devices, Pullman, WA, USA) 29. Moisture (Xw): Moisture content was determined with the oven drying method at 105°C for 5h 15. Titratable acidity: The acidity of the lemon juice was measured using NaOH 0.1N and expressed as the percentage of citric acid. Solubility (S): It was determined by the method used by Cano-Chauca 8, with some modifications. 1 g of powder was dispersed in 50 mL of distilled water using a vortex for 60 s. The dispersion was centrifuged at 3000rpm/5min and 25°C. Then, a 25 mL aliquot was taken from the supernatant and transferred to a previously weighed Petri dish that was immediately dried in an oven at 105°C for 5 h. Solubility was calculated as the difference of weights and expressed as a percentage. Hygroscopicity (H): It was determined using the static method for the construction of sorption isotherms including only one atmosphere of constant relative humidity (68.86%) obtained with an supersaturated potassium iodide solution at 25°C in a hermetic flask 30. Extractable oil content (EO): this value was determined as per the method described by Bae and Lee 31 with some modifications. First, 1g (±0.0001) of powder was dispersed in 4mL of water (40°C) and then shaken in a vortex for 2 min be-fore adding 25mL of a hexane/isopropanol solution (3:1 v/v). The mix was then shaken for 5 min and centrifuged at 3000rpm/2min, thus separating the organic phase, which was later heated at 70°C until it evaporated. The content of extractable oil was quantified as a difference of weights before and after heating. Peroxide index (PI): this index was evaluated using a spectrophotometric method based on the peroxides’ ability to oxidize ferrous ions and trans-form them into ferric ions that react in the presence of a number of reactive agents that produce complex colorings 32. The PI of the powder’s EO content was quantified using a standard curve. In addition, the PI was expressed as meq H2O2/powder kg. Particle size: Powder particle size was determined via laser diffraction using a Mastersizer 3000 (Malvern Instrument Ltd., Worcestershire, UK). The sample was suspended in 500 mL of distilled water until reaching a darkening of 10±1%. Size distribution was calculated with Mie’s theory, using a refraction index of 1.52. Particle size was represented as percentiles D10, D50 and D9033. Color: This was determined using an X-RITE spectrophotometer model SP64 with illuminant D65 and a 10 degree observer as reference. The reflection spectra were used to obtain the CIE-La*b* color coordinates.

Preparation of the emulsion to be fed to the spray dryer

The composition of the emulsion was standardized at a content of 18, 8% of dry solids and a total acidity of 0.1% adjusted with lemon juice. A premixture labeled A composed of avocado, water and lemon juice was homogenized (Ultraturrax IKA model UTL50, USA) at 10000 rpm for 5 min and mixed with premixture B, composed of maltodextrine, water, gum Arabic, TBHQ, salt, onion, garlic, bell pepper, tomato and coriander.

The evaluated properties of the emulsions were: viscosity, zeta potential, stability index (SI), color, D10, D50 and D90. The emulsion viscosity was measured with a rheometer (Brookfield DV-III Ultra, Brookfield Engineering Laboratories, Inc., USA) fit with a Brookfield bath model TC-502 equipped with a thermostat and controlled temperature of 25ºC. The spindle RV4 was used at a speed of 0.01 to 100 rpm and the viscosity was reported at 100 rpm. The procedure for measuring viscosity has been described in previous studies 34. The zeta potential was measured using un Zetasizer Nano ZS90 (Malvern Instruments Ltd., Worcester, UK) 35 and to avoid multiple dispersion effects and air bubbles presence, emulsions were diluted with deionized water in an emulsion: water ratio (1: 100). The stability index (SI) is based on the light scattering properties, which is related to the average droplet size and wavelength. R was determined by absorbances ratio at 800 and 400 nm (A800/A400) 36 w/w, x1, using a UV-Visible Spectrophotometer (Thermo Scientific Evolution 60). Emulsion samples were diluted in water (1: 100) and triplicates were performed by emulsion.

Spray drying

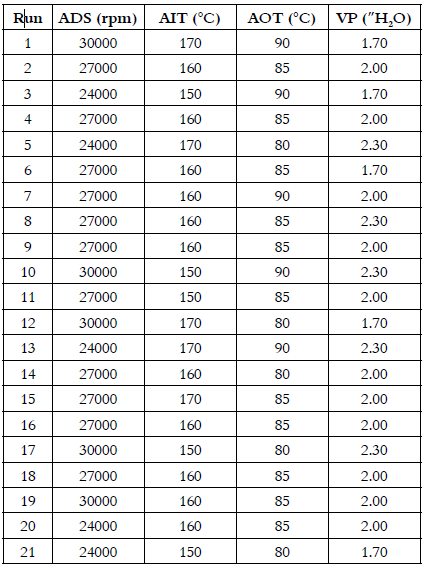

An automated pilot spray dryer (Vibrasec S.A. model PSALAB automatic) was used with its air flow in co-current mode. In addition, it had systems for regulating atomizer disk speed, air inlet temperature, air inlet flow and feeding flow and temperature. The spray drying process was optimized experimentally using the response surface methodology based on a compound design with 5 repetitions in its central point, which accounted for a total of 21 experiments (Table 1) and made it possible to assess the main and combined effects of the independent variables on the dependent variables. The spray drying process was optimized based on three independent variables: atomizer disk speed (ADS) (24000-30000 rpm), air inlet temperature (AIT) (150-170°C), air outlet temperature (AOT) (80-90°C) and vacuum pressure (VP) (1.7-2.3 “H20). As for dependent variables, the following were considered: water activity (aw), moisture (Xw), solubility (S), hygroscopicity (H), color (L*, a* and b*), extractable oil content (EO), peroxide index (PI) and particle size (D10, D50 and D90). In addition, two dependent variables associated with the process were determined, namely yield (Y), which is the ratio of the total DS in the resulting powder to the total DS in the mixture being fed to the dryer 21),(37, and deposit formation (DF) inside the drying chamber, which is the ratio between the material attached to the interior of said chamber to the total amount of the finished product or mixture fed to the dryer.

Statistical analysis

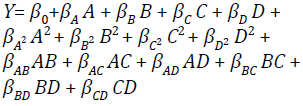

The experimental design matrix, the analysis of the results and the optimization process were all made possible by the Statgraphics Centurion XVI.I software. The relationship between the dependent (Y axis) and independent variables was solved using a complete quadratic model (Equation 1), where is the constant of the model and β A , β B , β C and β D are the linear coefficients of each factor, β A 2 , β B 2 , β C 2 and β C 2 are the quadratic coefficients of each factor, and β AB , β AC , β AD , β BC , β BD , β CD are the coefficients of the interactions between the independent variables. The adjustment of the models was determined using the lack-of-fit test and the R2 regression coefficient. Likewise, an analysis of variance (ANOVA) with a significance level of 5% was conducted.

RESULTS

Characterization of the emulsion to be fed to the spray dryer

The emulsion fed to the spray dryer had the following properties: zeta potential:-27.67±0.29 mV, the color parameters L*: 51.3±1.0; a*: -5.8±0.8; b*: 30.0±1.9, viscosity: 1034.6±95.9 cP, SI: 0.78±0.03, PI: 0.7±0.3 meqH2O2/emulsion kg, D10: 8.1 ± 0.7 µm; D50: 56.2±11.5 µm; D90: 346.6±94.6 µm. The emulsion had good stability in terms of repulsive interactions between colloidal particles, since the values for zeta potential were greater than 25 mV and its viscosity was high. The color of the emulsion kept its green chromaticity, which is consistent with the low lipid oxidation, found (low PI values) thanks to the addition of TBHQ and its synergistic effect with citric acid. Particle size was also very process-dependent, and had high variability, which in this case is desirable given the amount of ingredients used in the formulation.

Spray drying process for obtaining guacamole powder

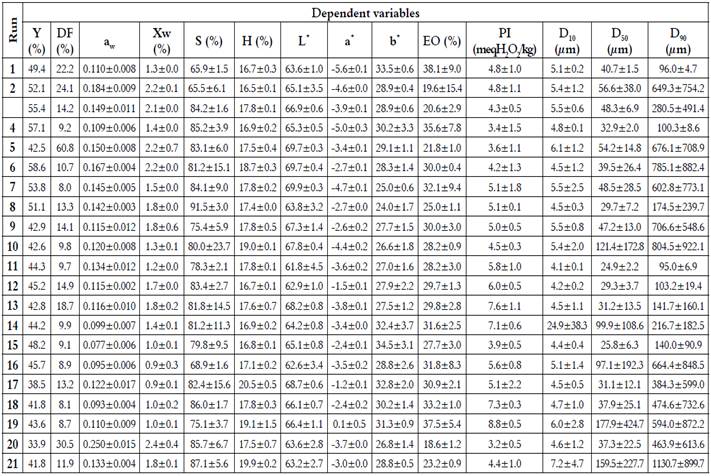

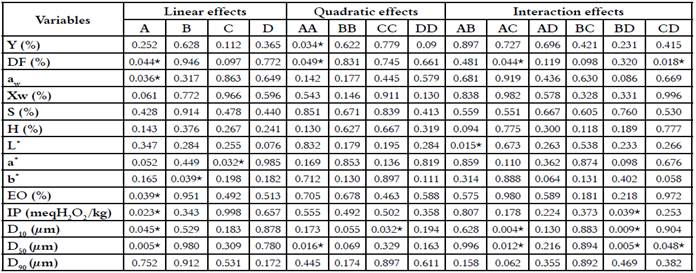

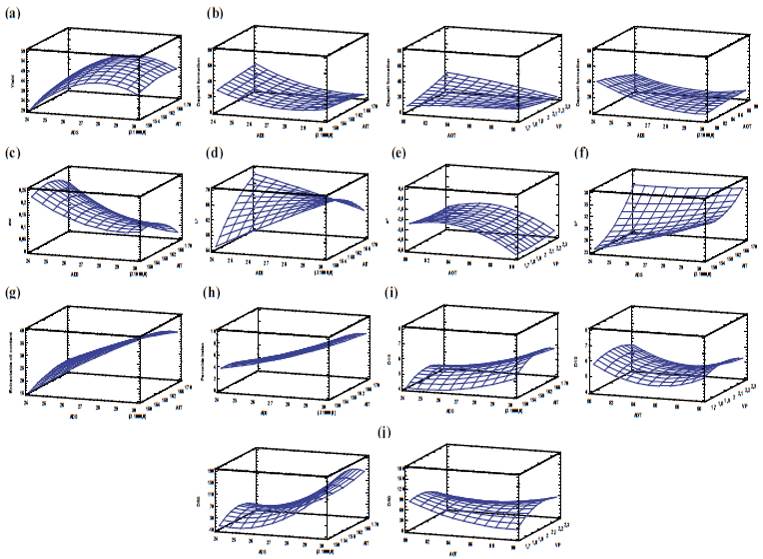

Table 2 shows the mean values and standard deviation of the dependent variables for each experiment run; Table 3, in turn, shows the ANOVA results. Moreover, Figure 1 shows the response surface charts for the statistically significant dependent variables.

Table 2 Results of the experimental design for the spray drying process for obtaining guacamole powder.

Table 3 ANOVA for the response surface models of the guacamole spray drying process.

* Significant at (p<0.05).

Figure 1 Response surface charts: yield (a), deposit formation inside the drying chamber (b), water activity (c), L*(d), a* (e), b* (f), extractable oil content (g), peroxide index (h), D10 (i), D50 (j) as a function of the studied independent variables.

Table 2 shows that the values for Y were low in general, ranging from 33.9 to 58.6%, which is coherent for the prepared batch sizes (3 kg), where the losses caused by the material stuck on the walls of the emulsion preparation tank, the spray dryer’s feeding tank and the pipelines themselves become significant in terms of percentage. Y had significant differences (p<0.05) as a result of the quadratic effect of the ADS.

Model optimization and validation

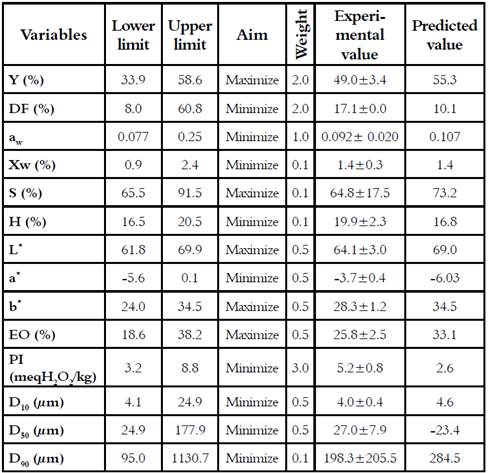

The experimental optimization of the spray drying process for obtaining guacamole powder was carried out to obtain the desired criteria for each response variable. To achieve this, the following criteria were established: Y, S, L*, b* and EO were maximized, while DF, Xw, aw, H, a*, PI, D10, D50 and D90 were minimized. The software Statgraphics Centurion XV I.I generated the following optimal process conditions for guacamole powder: ADS = 27451 rpm, AIT = 168ºC, AOT = 90ºC (feed flow = 38 mL/min), VP = 1.77 ″H2O (residence time =10.5 s). Table 4 summarizes the conditions under which the optimization was carried out. It also shows the weights considered for each quality attribute or dependent variable and shows the values for the dependent variables predicted by the polynomial model and the experimental values obtained by replicating the experiment conditions three times.

DISCUSSION

Spray drying process for obtaining guacamole powder

Figure 1a shows that, as the ADS increases, so does Y, until it eventually reaches its highest value in the curve (≈ 50%), which corresponds to approximately 28000 rpm and an AIT of 170ºC. After this point, the quadratic effect showed a negative or inverse result for Y with values ranging from 44 to 39%. Moreover, Y is typically inversely proportional to DF, the latter being very dependent on the conditions imposed in the process, the size and geometry of the drying chamber, the adhesiveness of the particles in relation to the material of the drying chamber’s walls, the stickiness or cohesiveness of the product and the usage of drying additives (or lack thereof) 38. The most favorable conditions for maximizing Y were: ADS: 26800 rpm, AIT: 150°C, AOT: 89°C, VP: 1.7″H2O.

For the guacamole powder process, DF showed statistically significant differences resulting from the linear and quadratic effects of the ADS. It also showed differences for the AOT-VP and ADS-AOT (p<0.05), the effects of these interactions being negative and positive respectively. Figure 1b shows that DF increases as the ADS decreases (contrary to expectations). Likewise it also increases with the AOT-VP interaction when AOT decreases (80ºC) and the vacuum is high (2.3 “H2O), and with the ADS-AOT when both ADS and AOT are low (24000 rpm and 80ºC respectively). This could be attributed to the fact that the system with high ADS produces higher speed in the radial and tangential components, thus reducing droplet size in the area and, when the system operates under high vacuum in the chamber, it induces higher drag and causes fewer droplets to crash into the internal walls of the drying chamber. Moreover, a decrease in the AOT is regulated with greater flow in the feed, which might reduce the rate of evaporation and increase the moisture content of the particles in the zone. Additionally, if particles crash into the wall or into each other, the product becomes more adhesive and cohesive, thus increasing DF and reducing Y. The Y and DF variables are closely related to efficiency and production costs 21, where glass transition temperature (Tg) plays a very important role since quick evaporation produces amorphous particles that could be in a rubbery state and have greater molecular mobility, which in turn increases DF and reduces Y 39 heat and momentum balances for a single droplet drying as well as temperature and humidity profile of the drying medium. A log-normal volume distribution of the droplets was generated at the exit of the rotary atomizer. This generation created a certain number of bins to form a system of non-linear first-order differential equations as a function of the axial distance of the drying chamber. The model was used to calculate the changes of droplet diameter, density, temperature, moisture content and velocity in association with the change of air properties along the axial distance. The difference between the outlet air temperature and the glass transition temperature of the final products (ΔT. The most favorable conditions that minimize DF were: ADS: 30000 rpm, AIT: 170°C, AOT: 87°C, and VP = 2.3”H2O.

Physicochemical characterization of guacamole powder

Moisture content is a very important property for powdered products that is related to drying efficiency and plays an important role in deter-mining its fluidity, stickiness and stability during storage 29. No statistically significant differences (p>0.05) were observed between the values for guacamole powder moisture and the studied factors and interactions. Furthermore, its low values (0.88 - 2.41%) were similar to those reported by Marulanda 28 with avocado powder, which might favor its preservation during storage since it has aw values between 0.077 and 0.250 (40) which are in turn considered appropriate and favor its stability against microbiological, hydrolytic, and enzymatic reactions as well as and lipid oxidation 19. aw showed significant differences (p<0.05) caused by the linear effect of the ADS, i.e. it decreased when the latter increased (see Figure 1c). However, in general terms these aw values may correspond to the moisture content of the monolayer, where the adsorption forces experienced by the dry matrix are high 41, since it has a good ability to adsorb water. This was evidenced during the storage phase in environments with a relative humidity of 68%, where the hygroscopicity in equilibrium reached moisture contents of 16.5 and 20.5%, which conditions the product to having a packaging with low water vapor permeability. The most favorable conditions that minimize aw were: ADS: 29000 rpm, AIT: 168°C, AOT: 80°C, and VP = 2.3 ″H2O.

The solubility of the guacamole powder showed no significant differences with any of the studied independent variables. Its values ranged from 65.53 to 91.52%. Similar results were reported by Marulanda 28 with avocado powder. Reconstitution properties are affected by the final composition of the powder; in this case, the presence of an oil phase restricts water diffusion inside the particles given the lack of thermodynamic affinity among them resulting from the presence of high free energy in their interface 42. A number of authors report the influence of maltodextrin on the hydration process and resulting solubility of powdered products obtained through spray drying. This is mainly associated with the influence of maltodextrin as a very water-soluble encapsulant 8,43. In general, powdered products are considered to be good when their hygroscopicity, moisture and aw are low and their solubility is high 44.

The color of guacamole powder is one of the most visible and attractive attributes found in this study; however, the browning potential of the product (< L*) with the increase in AIT was not observed, which suggests that this is due to the low residence times of the particles inside the drying chamber (9.3 - 11.6 s). The powder matrix was identified with a clear green tone resulting from the mixing of the green (a*) (-5.6 and 0.1) and yellow (b*) (24.0 and 34.5) chromaticities respectively. This places the tone in the 2º quadrant of the a*b* chromatic plane. L* showed variability values between 61.8 and 69.9, which was statistically significant (p<0.05) with respect to interaction ADS-AIT. Chromaticities a* and b* were significantly (p<0.05) influenced by the linear effects of the AOT and AIT, respectively. Figure 1d shows that guacamole powder has a lighter tone when the system operates at low ADS and high AIT (negative interaction), this could be attributed to the fact that, when particle sizes are smaller (a situation that occurs at lower ADS), the increase of the AIT accelerates drying kinetics and reduces the particles’ moisture content, which renders the samples clearer, as there is less light absorption on the surface of the particles 45. Other authors have obtained similar results 40,42. Additionally, figures 1e and 1f show that decreasing AOT and AIT helps decrease green (> a*) and yellow (< b*) chromaticities regardless of ADS and VP. This could be due to a higher strengthening of the thermal degradation phenomena of carotenoid pigments, and to the high ratio of the surface area to the volume of the mix fed to the machine, which causes quick pigment oxidation 46. The individual conditions that maximize L* and b*, and minimize a* were: ADS: 25900, 24000, 24000 rpm, AIT: 165, 169, 150°C, AOT: 90, 90, 89°C, and VP = 1.7, 1.7, 2.0 ″H2O, respectively.

The values for EO were fluctuating (18.587 - 38.154%), this could be attributed to the stability of the colloidal system and the resistance of the encapsulated matrix due to the diffusion and extraction of the organic solvent used 7. In addition, the PI was very coherent with the variability of EO (3.2 - 8.8 meq H2O2/powder kg) and, as indicator of the degree of oxidation of lipids, fat and oils, it identifies an important effect of the process on this variable 47. PI and EO showed statistically significant differences (p<0.05) with respect to the linear effect of the ADS, since they decreased together with it (see Figures 1g and 1h). Besides, PI was also significantly (p<0.05) influenced by the effect of the AIT-VP interaction, as it decreases when the system is operated at high AIT and low VP. This situation can be attributed to the fact that decreasing the ADS also decreased droplet size, thus creating more thermal stress and structural collapse on the surface and inside the particles, which in turn favors solvent diffusion and increases EO content and PI. Similar results have been reported by Drusch and Berg 48 with microencapsulated fish oil, and by Homayoonfal et al,49, with nut oil emulsions. The type of lipids more susceptible to lipid oxidation in avocados are the polyunsaturated fatty acids present in them, which react with the free radicals produced during lipid peroxidation inside oil droplets 50. Thus, the higher the EO content, the higher the concentration of polyunsaturated fatty acids and the susceptibility to oxidation 49.

The D10 and D50 particle sizes had a strong dependence on the process: they ranged from D10 (4.0 - 24.9 µm) to D50 (24.9 - 177.9 µm) and both variables had significant differences (p<0.05) with respect to the linear effect of the ADS and the effect of the ADS-AOT and AIT-VP interactions. Additionally, D10 had statistically significant differences (p<0.05) with respect to the quadratic effect of AOT, while D50 had the same differences with respect to the quadratic effect of ADS and the AOT-VP interaction. In contrast, the D90 size showed no significant differences (p>0.05) and its variability ranged from 95.0 to 1130.7 µm. In general, particle sizes were large and very fluctuating. However, this situation was not considered critical, since traditional guacamole also contains pieces of vegetables of varying sizes. Moreover, the particles of the guacamole powder obtained in this study were agglomerated; this explains their large sizes and could be associated with a rubbery amorphous state reached by the particles during the quick water evaporation phase inside the chamber. Marulanda 28 reported a similar situation with avocado powder obtained through spray drying with the same proportion of maltodextrin (dextrose equivalent 18-20). Said study identified a second order transition corresponding to a vitreous transition temperature of -49.92ºC. The individual conditions that minimized D10, D50 and D90 were: ADS: 24000, 26422, 24000 rpm, AIT: 150, 150, 150°C, AOT: 86, 85, 88°C, and VP = 2.2, 2.3, 2.2 ″H2O, respectively.

Model optimization and validation

An acceptable approximation of the values obtained during the experiments to those predicted by the model can be observed in the results; this indicates the model’s suitability for optimizing the spray drying process for guacamole powder production. Other research projects on different food products have applied optimization methods with good results: avocado powder 28, sugarcane pow-der biofortified with kefir grains 18, sugarcane powder 17, cape gooseberry powder with added active components 16.

CONCLUSIONS

This study presents a novel development as there is no study concerning the same topic in the literature. This in turn represents an important advancement in the value chain of avocado and contributes to the strengthening of its productivity. The support provided by the statistical tools that made the experimental optimization possible was very effective when obtaining the best conditions for the spray drying process. ADS = 27451 rpm, AIT = 168ºC, AOT = 90ºC and VP = 1.77 ″H2O. The quality attributes of the guacamole powder obtained by spray drying and composed by 59.3% of DS from the mixture of avocado, onion, garlic, bell pepper, tomato, coriander, lemon and salt were affected by the process conditions that were mainly imposed by the ADS since, as this speed increased, DF and aw decreased, while EO content and PI increased. Guacamole powder is not found as a thermodynamic solid, but in an amorphous rubbery state, which gives it an agglomerated product appearance, as particle cohesiveness is enhanced.