INTRODUCTION

Avocado fruit is considered the fourth most important in the world production of tropical fruits, with 5.0 million tons per year. Latin America and the Caribbean supplied 62% of this production with an annual increase of 2% in the sowing area 1. Avocado is a perishable product, very attractive in the world market due to its high content of unsaturated fatty acids (oleic 64.9%, 11.1% linoleic, linolenic 2.5%, 0.09% arachidonic); and vitamin A (146 IU / 100 g pulp), vitamin E (2.07 g / 100 g pulp), and minerals such as phosphorus (52 mg / 100 g pulp), magnesium (29 mg / 100g pulp) and potassium (485 g / 100g pulp) 2.

As a climacteric fruit, respiration rate increases during protein synthesis and physiological changes associated with oxidation reactions, either enzymatically or lipid, which limits its useful life 3. To minimize these effects, various conservation and processing techniques are used, which allow the use of the fruit, processing and generated added value 4. For example, guacamole was formed as the result of increased global marketing for preparing meals called "Tex-Mex". However, it remains highly perishable.

In order to provide new alternatives for preservation, various emerging technologies have been used, such as: high pressure, which reduces the enzyme activity of lipoxygenase leaving a remnant that alters the flavor of the paste 5 and microwaves, which decreases enzymatic action with the disadvantage of increasing lipid oxidation when destroying fat cells 6. Furthermore, the micro-encapsulation of avocado oil has been applied to reduce lipid oxidation using mixtures of whey protein and maltodextrin (MD) (90:10 ratios, 50:50 and 10:90), and input and output temperatures of air 180 and 80°C. Respectively, this allowed counteracted oxidation of the powder during storage for 8 weeks at room temperature, and additionally, improved wetting and density of the powder 7.

Some technologies for thermal treatments have generated significant physical changes and nutritional losses of fatty acids and vitamins 8. However, technologies such as spray drying is an important step in the agribusiness chain providing diversification of products such as powdered guacamole or avocado powder as an ingredient for the food, alternative pharmaceutical and cosmetic sectors, which helps improve their competitiveness. Spray drying is one of the most common methods in the industrial processing of a wide variety of food products in which a liquid feed is sprayed and transformed into a powder 9-11. This technology has been used in the dehydration of fruits and carbohydrate-rich compounds, which have obtained powders with favorable properties in terms of water activity, solubility, hygroscopicity, glass transition temperature, nutrient composition, among others 12-15.

Spray drying for avocados has had little exploration, due to its high oil composition and physiological characteristics of the fruit 7; however, there are some research such as Grajales-Lagunes et al., 1999 16, who evaluated a fixed operating condition, the effect of mixtures of some antioxidants (BHA, BHT, TBQH, citric acid, ascorbic acid and propyl gallate) on the stability and sensory quality of avocado powder. Research found that TBQH mixture of citric acid had less developed rancidity during storage. Furthermore, Schwartz et al., 2007 17 obtained avocado powder (variety Strong) with a higher fat content of 50% (w/w) and no color changes during storage, considering independent variables in the formulation of food (MD, preservatives and antioxidants) and in the process (feed flow and inlet and outlet air temperatures).

The physicochemical properties of powder obtained by spray drying depend on design variables such as: type of atomizer and air scattering 18-20; variables in the drier feed formulation; solids concentration including the wall material (which modify the viscosity, density, particle size, surface tension, etc.) 14,21; process variables (feed flow, pressure nozzle atomizer speed drive, chamber pressure, air flow, residence time, temperature and out of breath) 21,22, among others. Given the influence of these independent variables on the quality attributes of the product powder, it is very important the experimental process and product optimization, using statistical tools, allow to obtain powder products with better physicochemical, physical, nutritional characteristics, microstructural, sensory, among others 18-20,23.

The aim of this investigation was to experimentally optimize the spray drying process to obtain avocado powder (AP), in function of the independent variables: MD, disk atomizer speed and temperatures of the inlet and outlet air, and dependent variables: water activity (aw), moisture (Xw), pH, color, hygroscopicity (H), solubility (S), wettability (We), extractable oil, peroxide index (PI), yield (Y) and deposit formation (DF) within the drying chamber.

MATERIALS AND METHODS

Hass avocados were used from crops located in San Vicente, Antioquia, Colombia. Additives used were: gum Arabic (GA) (Tic pretested FT Gum Arabic Powder, Tic Gums, USA) and MD (Shandong Boalingbao Biotechnology Co Ltd) with dextrose equivalent between 18 and 20; plus, food grade salt and lemons (Citrus arauntiifolia) were used. The feed fluid to the spray dryer was an emulsion prepared with a homogenizer IKA Ultraturrax model TK50 (USA), at a constant rate of 10,000 rpm. The avocado pulp was mixed with water in a ratio 40/60 24 and then the lemon juice, salt and other additives were added.

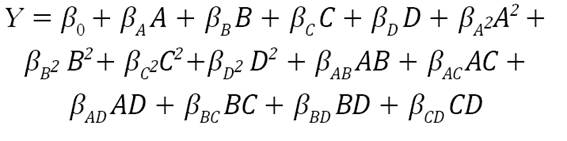

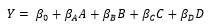

The drying process was conducted using a spray dryer in co-current flow (Vibrasec, model PSALAB 1.5), operating the system under a vacuum. The optimization process used the response surface methodology with an experimental design "Optimal", using the Design Expert Software version 8.0.5.2 (Stat-Ease, Inc. USA), according to the independent variables: (A) MD (2.81 - 11.25% w/w), (B) inlet air temperature (IAT) (140-160°C), (C) outlet air temperature (OAT) (80-90°C) and (D) atomizer disk speed (ADS) (20000 - 26000 rpm) and the dependent variables: Xw, aw, pH, color, H, S, We, extractable oil, PI, Y and DF in the interior of the drying chamber. Optimization experiments were performed with 25 experiments, and 3 samples/experiment at various times were taken under stable process. From the conditions obtained by optimization software, three additional experiments were performed to verify the accuracy of the model with respect to the actual response variables. A regression analysis was solved with a second-order polynomial model (Equation 1) or linear model 8 Equation 2), where β0 is an intercept, βA, βB, βC and βD are the coefficients of each factor; β A 2 , β B 2 , β C 2 and β D 2 are the coefficients of the quadratic interactions and βAB, βAC, βAD, βBC, βBD, βCD are coefficients defined by the interaction between the factors. The adjustment of the models was determined using the lack-of-fit test and the R2 regression coefficient. Likewise, an analysis of variance (ANOVA) with a significance level of 5% was conducted.

The methodologies of characterization of the products were the following: Xw was determined under the official AOAC 925.45 / 2002 25. aw was determined with a dew point hygrometer at 25°C (Aqualab Series 3TE, Decagon, Devices, Pullman, WA, USA) 26. H was evaluated by the gravimetric method, according to Martínez-Navarrete et al., 1998 27, simulating the environmental conditions of Medellin, Colombia (saturated solution of KI, 25°C and aw: 0.689). S was determined according to the method of Patil and Chauhan 2014 18 modified: 1g of AP was weighed, dispersed in 50 mL of water using vortex for 60s, the mixture obtained was centrifuged at 3000 rpm/5min at 25°C; subsequently, a 25 mL aliquot of the supernatant was taken and transferred to Petri dishes previously weighed and dried immediately at 105°C for 5 hours and the S (%) was calculated as the difference of weights between the initial weight. We was determined as the time required for 1g of AP disappears from the surface of a volume of 100 mL water at 20°C 15. Extractable oil content was determined according to the method described by Lee and Bae 7 modified: 1 g of AP was weighed into a 15 mL glass tube, 4 mL of water (40 °C) were added, and stirred with a vortex for 2 min, the starting mixture was mixed with 25 mL of hexane/isopropanol solution (3:1 v/v) while stirring for 5 min, then centrifuged at 3000 rpm/2min, separating the organic phase, which was then subjected to heating at 70°C/5h. The extractable oil content was quantified as a weight difference before and after heating. PI was determined according to the methodology described by Bae and Lee 7, taking a sample of 30-40 mg of oil extracted in the previous section. The zeta potential was measured using un Zetasizer Nano ZS90 (Malvern Instruments Ltd., Worcester, UK) and to avoid multiple dispersion effects and air bubbles presence, emulsions were diluted with deionized water in an emulsion: water ratio (1: 100) 28. Color was determined using a diffuse reflectance spectrophotometer (Datacolor 650, USA), illuminant D65 and 10° observer reference, with an opening MAV (illuminated area 20 mm and measured area 16mm) under the coordinates CIE-L*a*b*. Scanning electron microscopy (SEM): samples were deposited on a conductive copper tape and on a sample carrier, and then coated with gold in a vacuum evaporator (Dentom Vacumm, 30 mA, 5 kV, 100 millitorr). The micrographs were visualized to 15kV on a SEM (Jeol 5910LV) microscope and through integrated software to the equipment.

Performance of the process and material stuck to the drying chamber: the yield was calculated by the ratio of total solids between feeding the dryer and collected in the cyclone, expressed in percentage terms. The material adhered to the drying chamber was calculated with respect to adhering drier feed material expressed as a percentage 24.

RESULTS

The physicochemical and physical properties of fresh Hass variety avocado for processing (day 11 after harvest) were: Xw (67.17 ± 4.20%), aw (0.974 ± 0.03), pH (6.52 ± 0.12), L* (75.5 ± 2.7), a* (-5.9 ± 0.9), b* (42.0 ± 4.3), firmness (11.7 ± 0.8 N), oil content (18.7 ± 2.0%), Ash (6.3 ± 3.1%), Protein (5.9 ± 0.9%), zeta potential (-37.6 ± 1.40 mV), PI (0.920 ± 0.08 meq H2O2/kg). The fat content is considered a quality attribute for this fruit, which reported approximately 19% (w/w), its high aw and Xw, make this fruit perishable. Color parameters identify it as a clear product, with a green and yellow chromaticity.

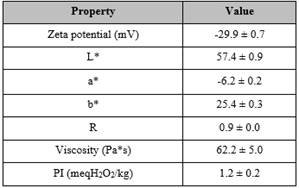

Table 1 shows the properties obtained from the base emulsion without wall material. These results were found in a previous study 24, wherein the emulsion was optimized as a function of the independent variables relative pulp: water, time of homogenization and GA, and dependent variables viscosity, zeta potential, stability index (absorbance ratio: A800/A400) and PI. The viscosity and zeta potential variables were significant (p<0.05), which alleviated the optimization process; the net charge of the latter at the interface was negative. The final emulsion was obtained at 10000 rpm, with a ratio pulp: water (40:60), GA = 0.42% and homogenization time of 6 min. The emulsion showed a pseudoplastic behavior to have a flow behavior index "n" <1 (n = 0.17 ± 0.01) and consistency coefficient "K" positive (K = 18.49 ± 1.61), determined by the power law (R2 = 0.94).

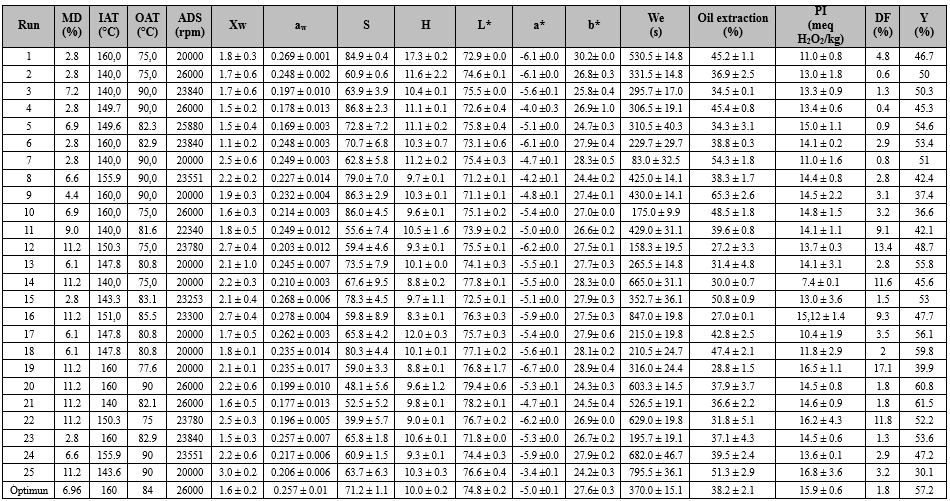

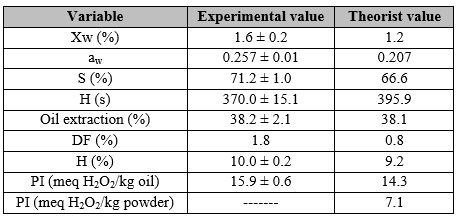

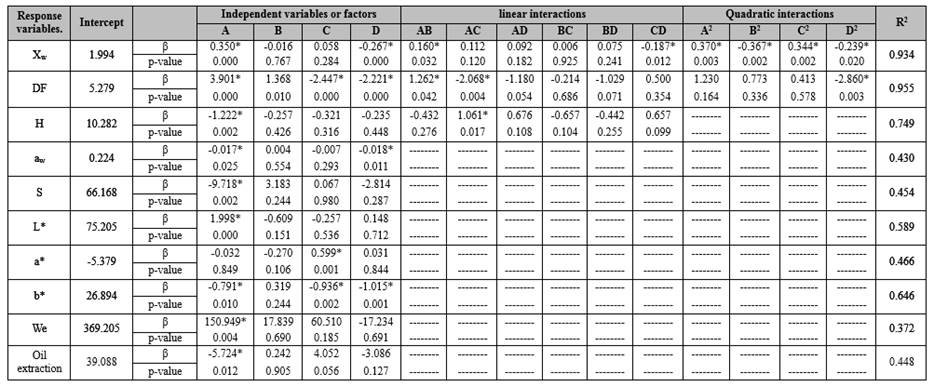

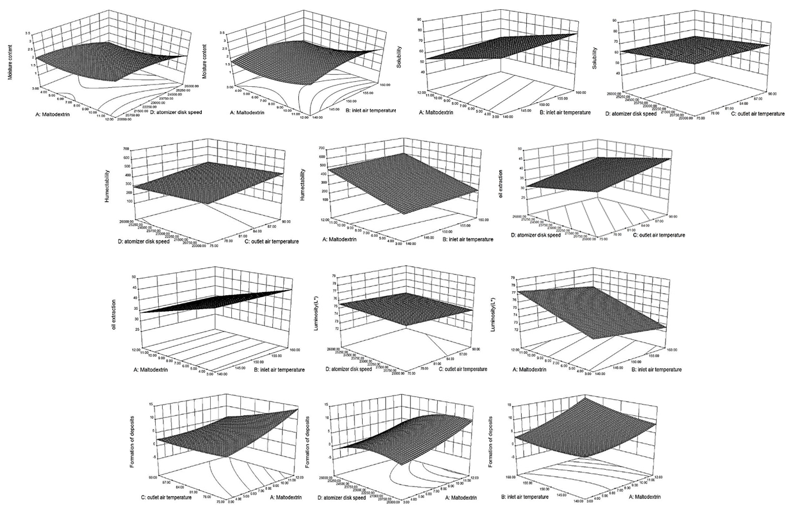

Table 2 presents the average values with standard deviation of the dependent variables of AP for each experiment in the experimental optimization applied. Table 3 and Figure 1 show the ANOVA models and response surface plots, respectively.

Table 3 ANOVA for response surface models of the avocado spray drying process.

β: Coefficiet, factor A: MD, factor B: IAT, factor C: OAT and factor D: ADS

Figure 1 Graphics response surface in relation to the process conditions: Xw, S, We, extractable oil, L* and DF.

Optimization process and validation of model

The optimization process assessed by surface response allowed to obtain the most suitable operational conditions for the AP with low Xw and aw, less H, greater S and We, lower DF, greater Y and retaining the characteristic color of the avocado pulp. The optimum conditions of the independent variables were: MD: 6.96%, IAT: 160°C, OAT: 84°C, ADS: 26000 rpm. To validate the model, three experiments under optimum conditions found were performed by using the software in order to check how suitable the response surface model to predict the optimal values is. Table 4 compares both the experimental values as predicted by the software, and good agreement between the two values was observed.

DISCUSSION

The fat content was approximately 19% (w/w), similar to those found by Forero et al., 2011 29, which reported a value of 25.5%. Fresh avocado can be considered a natural stable oil-in water due to its high viscosity, its protein content 30 that act as emulsifiers, and the presence of ionized salts that contribute to the interface electronic charge around fat molecules, generating high values of zeta potential (-37.6 ± 1.40 mV) 24.

The emulsion showed a pseudoplastic behavior, adjusted to the power law model when n value was 0.7 ± 0.01 and consistency coefficient K value was 8.49 ± 1.61 31. Similar data have been reported by Freitas et al., 1996 (32) for avocado pulp (n = 0.17 and ln K: 10.05). The color of the emulsion retains its green chromaticity, which is consistent with low lipid oxidation found (PI <<<), being favored at low pH values (3.62 ± 0.05); on the other hand, presents a decrease in L* and b*, attributed primarily by enzymatic browning matrix undergoing the enzymatic activity of polyphenol oxidase 33.

ANOVA showed significant differences in moisture (p<0.05) with respect to factors A and D, and with regard to interactions AB, CD and each quadratic factor. An increase in the Xw by interaction AB high temperature air inlet is observed, which is attributed to rapid formation of the coating on particle surface, according to content MD increase, making it difficult for water migration from the inside to the drying medium, generating a wetter powder 34. At low IAT, a minor effect on Xw is observed. This result is similar to that found by Thirugnanasambandham et al., 2017 20 in pomegranate powder, whose correlation moisture and MD was positive, due to the formation of the barrier offered by large polysaccharide molecules, preventing diffusion of water to the surface particle.

Interaction CD exhibited a positive synergy, where a lower OAT (C) generates a greater temperature differential within the chamber by increasing the evaporative rate and water reduction in the particle. Additionally, an increase in moisture D decreases, because the particle experiences a smaller diameter, giving an increase in surface area enhancing the transfer of heat and mass. The Xw is directly related to the IAT; under low temperatures induce convective heat transfer coefficients and lower evaporative rate (>> Xw), which can cause the formation of sticky or poor flow ability microcapsules (interparticle agglomeration) and greater DF within the drying chamber. Operation at higher temperatures causes rapid evaporation, generating the collapse of the membranes and inducing release of the encapsulated material 35.

The aw behavior was similar to the Xw regarding the factors A, B, C and D, both variables being coherent, but the observed changes were in a low range (from 0.169 to 0.278), which was consistent with the low Xw found (0.9 to 3%). This can ensure good microbiological and physicochemical stability of the food matrix which presented an acid pH ranging from 4.8 to 5.2 generated by the addition of citric acid from lemon juice 36. Some research for spray drying oils of various fruits of the same position have been reported in the present study found 37.

The H presented statistically significant differences (p<0.05) with respect to factor A and AC interaction, however there is a consistent behavior with aw and Xw, showing little decrease (8-17%) with increasing MD. That decrease with high temperatures of air inlet is due to the higher vapor pressure experienced by the matrix on the surface in the environment of constant relative humidity in the experiment (± 68%) performed. The literature reports no comparison values, being a food matrix of little study, whereas in fruits, high H values attributed to the high content of carbohydrates (9, 38, 19, 20) are reported. H values of 54% (HR 81.0%) and 25% (HR:75.3%) have been reported in lulo fruit powders and khaki, respectively. Identifying a similar behavior than avocado powder, where the drying additives increase in food formulation, the H of the powder product was decreased 23,37. The interaction of the introduced AC factors adversely affects the H, with low MD and OAT, the powder is H and more consistent with the stated above. The low IAT produces a particle with lower chemical potential, which most water is adsorbed in the environment of constant relative humidity (68%).

S, We and extractable oil presented significant differences (p<0.05) relative to factor A, where the increase in the concentration of the MD decreases S and oil extraction, in addition it increases We (longer wetting indicating a delay in the interfacial solvation of the powder being less instantaneous reconstitution). Reconstituting a powder product takes place in several stages: wetting, sinking, dispersing and completely dissolved 39; in this regard, a high wetting time reduces the solubility, which was proven by the results obtained. The increase of A gives better protection to the oil matrix; being generally these three key variables during reconstitution of the powder. The minimum and maximum values for these were: S (39.9 to 86.8%), We (83-847 s), and extractable oil (27.03 to 65.29%).

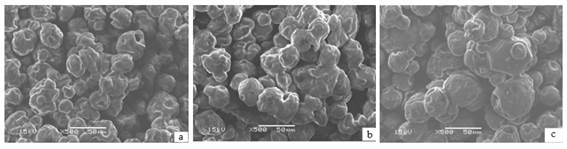

S decreased throughout the range of IAT and ADS, while the effect of temperature is observable output. This decrease can be attributed to structural interactions between fat and MD, which generates a lower affinity for water or a less polar surface structure. Roccia et al., 2014 35 state that the reconstitution properties are affected by the final composition of the powder, especially in the presence of an oil phase, which promotes the formation of bridges between particles and cause slight deformations (caused by phase changes of fat); thus, producing more cohesive and restricting the entry of water into them. With increasing MD content in the formulation an increase in the size of the powder particles and an increase in the cohesive strength of the aggregation state, visualized by SEM (Figure 2) is presented. This infers a difficulty diffusion of water into the particles, since it has a smaller area of contact with the water and channels between the particles. Pang et al., 2014 40 found an increase in the particle size of the extract of Orthosiphon with increasing MD concentration, which is attributed to the increased viscosity of the drier feed. Karaca et al., 2015 41 attributed the formation of a rigid surface layer of the powder particles with the increase of the MD, which would prevent the diffusion of water molecules through the particles, thereby decreasing the We of the particle and dissolution of the powder.

Figure 2 SEM micrographs of avocado powder with different levels of MD: a (2.8%), b (6.9%) and c (11.2%).

Some studies report conflicting results regarding the incidence of MD in the hydration process and subsequent solubility of powder obtained by spray drying, where the hydrophilic character of the additives wall, and rich carbohydrate composition enhances its solubility, as in the case of sugarcane 42; while the avocado interaction exhibits are completely different because they are high in fat component 2,3.

The micrographs of AP at different MD percentages, show an amorphous, rough surface depression and structure; the latter was inversely proportional to the percentage of MD. The results are in agreement with other authors 7, who found that the micro-encapsulated avocado oil occurs with a high degree of agglomeration of small spherical particles, and the state of agglomeration or aggregation increases with the content of MD.

MD was negatively correlated with respect to We, reducing the latter by increasing MD. These results are similar to those reported by Caliskan and Dirim (2013) 36 in the dust of sumac (Rhus coriaria L.), where We is potentiality decreased with increasing temperatures and out of air, forming a rigid wall microstructural changes caused by suffering protein and fat present in the composition. The complexity of food systems, provides antagonistic or synergistic interactions, We being variable, depending on other properties such as density, particle size, porosity, presence of amphiphilic substances, and surface characteristics of the powder (area, loading and activity) 11.

The extractable oil content reached levels of 34-45% (w/w) in AP, conferring a hydrophobic character which promotes particle-particle interaction and reduces its interaction with water. An opposite effect was evident with increasing MD, generating a protective film covering the oil, and removal was difficult. This result is similar to that reported by De Barros et al., 2014 43, who worked in the microencapsulation of rosemary essential oil using modified maltodextrin and starch as wall materials. He found that the retention of bioactive compounds and volatile particles is dependent on the concentration of the wall material. On the other hand, Bae et al., 2008 7 concluded that decreased MD increased surface oil in the micro-capsules of avocado oil.

FD showed significant differences (p<0.05) with respect to factors A, C and D, the interactions AB, BC and D. Quadratic interaction DF values ranged between 0.4 and 13.4%, throughout the temperature range evaluated air inlet, DF increased with increasing MD (positive interaction AB), being greater when DF inlet temperatures are higher. The effect of OAT and speed of the atomizer disc are more evident at higher contents of MD, from about 5 to 13% and from 10 to 2% respectively. The AC interaction had a negative effect associated with the increase in temperature led to lower output FD.

The effect of the independent variables on the color coordinates (L*, a*, b*) was important. The lightness (L*) was significantly different (p<0.05) with respect to the factor A; red-green chromaticity (a*) only showed significant differences with respect to the factor C; while the yellow-blue (b*) chromaticity was significantly different (p<0.05) with respect to the factors A, C and D. In general, dust avocado is clear, showing more clearly (> L*) with increased content of MD (71.1 - 79.4), which is a white polymer. Additionally, the low water content of the product in turn decreases the homogeneity in the refractive index of tissue, decreasing the adsorption of light at the surface area, making these lighter 44. The variation found in the chromaticity a* (-6.69 to -3.38) and chromaticity b* (24.23 - 30.16), located in AP in the second quadrant of the color plane to *b*, are within the limits of the gray and yellow area. A higher outlet air temperature, reduced green chromaticity seen in avocado powder (<a*), which implies a higher chlorophyll degradation and Maillard reactions (presence of D-manno-2-hetulose, D-glycero-D-mannose-octulose, D-erythro-L-gluco-2-nonulose) by effect of the heat treatment 45. These results agree with those found by Caliskan et al., 2014 36, who determined that the powder color sumac is affected by the concentration of MD and temperatures in/out. The concentration of MD presented a direct bearing on L* and reverse on a* b*. MD to a concentration of 10% (w/w) reported that a lower differential temperature decreases the value of L*, and increases the value of b*, whereas the value of a* is kept constant.

The PI showed significant differences (p>0.05) with respect to the factors A, B and C and CD interaction. The increased concentration of MD presented a greater effect when the inlet air temperature was higher, providing an increase in the oxidation of the matrix. PI decreased from 15 to 11 meq H2O2/kg oil when OAT increased from 90-75°C respectively. This variable is considered very critical, due to the evolution which has since been fresh fruit (0.920 ± 0.08 meq H2O2 / kg oil), moving to the emulsion supply to the dryer (1.25 ± 0.23 meq O2 / kg oil) and finally converted into powder, where the values varied between 7.4 and 16.8 meq O2/kg oil. This increase in PI reflects a very significant influence by the drying process, due to lipid oxidation of the food matrix, which is enhanced by the temperatures imposed on the spray drying process. The PI accepted by the Alimentarius Codex for virgin oils and cold pressed fats is 15 meq O2 / g o 7.5meq H2O2 / kg 46. In reviewing the literature on avocado oil, the peroxide value is dependent on the extraction method, and is as follows: when a value extracted by soxhlet 31.66 meq H2O2 / kg oil, it decreased to 16.87 meq H2O2 / g oil, if using supercritical fluids 47 were obtained. On the other hand, the commercial oil has a value of 38.1 meq H2O2 / g oil for commercial oil 48. When compared with values obtained, peroxide dust is observed that complies with the standards of the Codex Alimentarius.

The yield was not significantly different (p>0.05) with respect to independent variables evaluated, however, best performance values are highlighted with high MD composition and high ADS. Higher yield under the following conditions was obtained: MD: 12%, IAT: 140°C, OAT: 82°C ADS and 26000 rpm

CONCLUSION

The experimental process optimization is presented as an effective tool for agribusiness, which improves product quality in terms of the factors that affect it, and in the case of avocado, allows the development of new value-added products, with potential uses in the food industry, pharmaceutical, cosmeceutical, among others. The multiple optimization performed provided the following results: MD (6.96%), ADS (26000 rpm), IAT (160°C) and OAT (84°C). MD was the significant factor on the response variables contributing to greater retention of the oily matrix and lower H. Avocado powder obtained has a fat content, which makes it very sensitive to oxidative processes during processing, which involves the possibility of using preferably natural antioxidants, which are not derived flavors or odors.