Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Revista MVZ Córdoba

Print version ISSN 0122-0268

Rev.MVZ Cordoba vol.20 no.3 Córdoba Sept./Dec. 2015

ORIGINAL

The effect of changing the pre-slaughter handling on bovine cattle DFD meat

Efecto del cambio en el manejo antemortem sobre la presencia de carne DFD en ganado bovino

Cristina Pérez-Linares,1 Ph.D, Alberto Barreras S,1 Ph.D, Eduardo Sánchez L,1 Ph.D, Bárbara Herrera S,1 M.Sc, Fernando Figueroa-Saavedra,1* Ph.D.

Universidad Autónoma de Baja California. Instituto de Investigaciones en Ciencias Veterinarias. Km 3.5 Carr. a San Felipe, Fracc. Campestre. C.P. 21386, Mexicali, Baja California, México.

*Correspondencia: fernando_figueroa@uabc.edu.mx

Received: September 2014; Accepted: February 2015.

ABSTRACT

Objective. To evaluate the effect that a series of changes in the handling techniques used throughout the pre and post slaughter periods and during the handling of cooled carcass have on the presence of DFD (Dark, firm and dry) meat. Materials and methods. Odds ratios (OR) and confidence intervals were estimated applying logistic regression models. Data from 18 visits to the slaughterhouse regarding: animal handling on arrival, slaughter period, and carcass storage was obtained through the use of a questionnaire. A total of 572 carcasses were analyzed to determine DFD meat using pH and color (L*, a*, b* and C*) measurements done on the Longissimus dorsi muscle. Results. Even after of the changes were made, the lairage period to slaughter continued to be a factor (p<0.05) associated to the presence of DFD meat (OR=1.13). Of the complementary variables, the amount of time that cattle spent on the resting pens was associated (p<0.05) to the presence of DFD meat (OR=1.003). Conclusions. Regardless of the changes made ââin the ante mortem handling, a high frequency of DFD was found (39%), suggesting a permanent audit program to detect other critical points in the supply chain.

Key words: Animal welfare, cattle, dark cutting meat (Source:CAB).

RESUMEN

Objetivo. Para evaluar el efecto de una serie de modificaciones en las técnicas de manejo usadas en el periodo pre y post-sacrificio y manejo de las canales en refrigeración en relación con la presencia de carne DFD (dura, firme y seca). Materiales y métodos. Se obtuvieron razones de desigualdad e intervalos de confianza empleando modelos de regresión logística. En 18 visitas a la planta de sacrificio, se aplicó un cuestionario obteniendo información sobre manejo de los animales desde su llegada a la planta, etapa de sacrificio y almacenamiento de las canales. Se estimó la frecuencia de carne DFD de analizar un total de 572 canales, registrando en el Longissimus dorsi pH y color (L*, a* b*, C*). Results. De las modificaciones realizadas, el tiempo de permanencia al sacrificio sigue siendo fue un factor asociado (p<0.05) a la presencia de carne DFD (OR=1.13). De las variables complementarias, el tiempo de espera en los corrales de descanso resultó correlacionado (p<0.05) a la presencia de carne DFD (OR=1.003). Conclusiones. Independientemente de los cambios realizados en el manejo ante mortem, se encontró una alta frecuencia de carne DFD (39%), sugiriendo un programa de auditoría permanente para detectar otros puntos críticos de la cadena logística.

Palabras clave: Bienestar animal, carne oscura para corte, ganado (Fuente: CAB).

INTRODUCTION

The global commercialization of beef and its products and a growing demand for animal protein has resulted in a worldwide increase in the numbers of animals that are being slaughter (1), as result of this, the animal welfare problem related to transportation and pre slaughter of cattle has worsen (2). An important objective for the beef industry is to supply products that are both safe and of high quality and consumers are aware of the importance of this characteristics but they are also interested in the production process and on the environmental impact of the beef industry (3) so that cattle welfare has become a social issue and has broaden the concept of food quality (4).

In this context, along the production chain, animals are exposed to a series of factors and procedures that may cause them stress. The most common factors are: changes in weather, transport conditions, the way that animals are handled, the preslaughter waiting period, the stunning procedure, and the slaughter method (5). The size of any negative effect depends on the type, duration and intensity of the stressing factors before the animal is slaughter and how susceptible it is to them. These preslaughter adverse effects not only have an impact on animal welfare, but also have negative effects on the quality of the meat and on the income of the production chain participants, specifically in bovines there is evidence that preslaughter stress is detrimental to meat quality (6).

During the pre-slaughter period, stress and physical activity contribute to exhaust muscular glycogen, and as a result of this pH increases and beef changes its appearance so it may be classified as DFD (dark, firm and dry) also known as a dark cut. DFD meat is highly susceptible to bacterial problems because of the increased pH (≥5.8) (7). It is difficult to commercialize DFD meat because the consumer relates its dark color to poor storage conditions or assume that the beef is old (8).

Studies conducted in northwestern Mexico reported a 15.43% and 47.63% incidence of DFD meat during the summer and concluded that both pre slaughter and postmortem factors contribute to the presence of DFD meat, the lairage period before slaughter, relative humidity and the elapsed time period between slaughters were the relevant factor during the premortem period, while cooling temperature and the time that the carcass spent in the cooler were found to be important post mortem factors (9-11). Regarding the economic impact of DFD meat in the same region it has been reported that as a result of this problem the carcass exhibits a 10% reduction of price so that its value decreases an average of 88.58 USD, if this amount is multiplied by the total number of carcasses produced between May and June of 2010 the estimated loss attributed to DFD meat is 5.272.946 USD (11).

In the state of Baja California slaughterhouses purchase the cattle on site and the seller is responsible for transporting the cattle to the plant, so if the animals are not handled properly during loading, transportation and unloading and as a result of this the carcass exhibits DFD meat, no economic sanction is received by either the transporter or the producer.

The objective of this study was to evaluate the effect that a series of changes in the handling techniques used throughout the pre and post slaughter periods and during the handling of cooled carcass have on the presence of DFD meat.

MATERIALS AND METHODS

Location. The study was done in the facilities of a (TIF) Federal Inspection Type Slaughter plant in the city of Mexicali, Mexico during the summer of 2009 (July-September). The region is geographically located at 32°40' N Latitude, 115°28' W Longitude, at an altitude of 10 meters above sea level, in Northwestern Mexico. Climate in this area can be described as dry desert with a 34.7°C average annual temperature of (-5°C in winter and 50°C in summer) 37 mm average annual rainfall and > 50 % relative humidity.

Pre-slaughter handling. The carcasses studied came from cattle fattened in three feedlots. The cattle are crossbreed Zebu x European (Zebu 30 and European 70%). The mean of final weight was 400 kg. Transportation from the feedlots to the plant was on trucks equipped with cattle cages with a capacity for 50 animals, within a distance of 16 kilometers. The trip time between the feedlots and the slaughter plant took between 15 and 30 minutes and once the cattle arrives to the plant the animals are unloaded and place in waiting pens until slaughter which takes place between 0700 to 1500 h according to the time of arrival.

The slaughter plant can process between 350 and 400 animal at a rate of 40 to 45 animals per hour. The stunning is done by one trained operator but in case of absence he is substituted by an operator with no training or lesser experience. The unloading ramp is made out of concrete with no non-sliding floor and has the same width of the pens which are connected by a series of corridors to a resting area with six 84 m2 roofed pens with non-sliding floors, water is available for the animal but they are not feed. An electric prod is use to lead the animals from the pens to the slaughter area through a curved corridor which connects the resting area to the stunning box that measures 1.80m high, 0.88 wide and 2.53m long and has mechanism to hold the cattle head, the animal enters the box through a guillotine type door and is taken out through a door with an horizontal opening. The slaughter process followed the guidelines established by the federal authorities in the NOM-033-ZOO-1994 norm for the humane slaughter of domestic and animals wild. After being stunned by a captive bolt pistol (model USSS-1 Jarvis) the animal is raised and hanged by the leg with a hook and after being bleed the cattle go to the production line for processing, the process after stunning takes around 40 minutes. The carcasses are stored in refrigerated rooms with temperatures between -2 and 2°C (12).

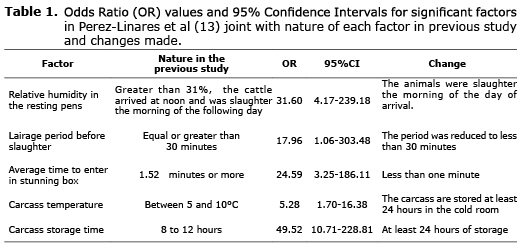

Data collection. The information was obtained from 18 randomly selected groups of animals, one third of this group came from each of the feedlots. Starting from the arrival of the animals to the plant and until the carcasses where stored all relevant information was recorded. The changes on the handling system were done based on the results obtained from a previous study (13). These results are shown on table 1. Due to their relation to the presence of DFD meat, information was obtained about the following handling procedures: use of the electric prod during unloading process, lairage period in the resting pens, temperature, relative humidity in the resting pens, number of persons that drive the cattle, use of the electric prod to drive the cattle, lairage time before slaughter, average time it takes to get into the stunning box, number of shots applied during stunning, average time between stunning and bleeding, room temperature during slaughter, the use of a cloth to cover the carcass, carcass storage time and if the carcass was sprayed with water during cold storage, so that it their association with of DFD meat was established.

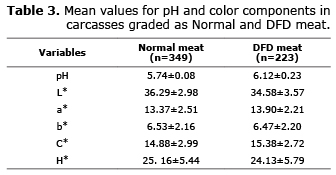

Meat quality evaluation. The relative frequency of DFD meat was estimated by analyzing 572 carcasses taken at random during the study period. At 24 h after slaughtering the animals, the pH values and color variables measurements (L* a*, b* and C*) were taken from the Longissimus dorsi muscle between the 11th and 12th ribs allowing 30 minutes to pass before the measurements were taken, all the measurements were repeated three times. The pH was measure in center of the muscle using a Delta TRAK ISFET pH 101 (Delta TRAK, Inc., Pleasanton, CA., U.S.A. ). Color was determined in the muscle surface through a Minolta CM-2002 spectrophotometer (Minolta Camera Co., Ltd. ) provided with SCI (Specular Component Included), a D65 standard illuminant and 10° standard observer function, where L* represents the lightness index (0≤ L* ≤100). Chroma measures the saturation of color and was estimated as C*= (a*2 + b*2)0.5 (14). Beef meat was graded for according to the following categories: normal pH24 5.4-5.8, L* 40-60 and C* >30; and DFD beef pH24 >5.8 (24 hours after slaughter), L* <40 and C* <30.

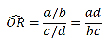

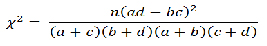

Statistical analysis. The present study was of the observational, prospective and transversal type. All the variables are of dichotomous nature. The sample size (n=506) was determine using a simple randomized procedure with attributes, considering an infinite population, 95% confidence interval, 5% precision and maximum variance (p=0.5), the sample included an additional 100 carcasses to improve the estimators. The occurrence of DFD meat was estimated as a relative frequency. A Chi squared test was used to perform the independent DFD frequency distribution test in the ith class of the jth handling variable. Odds Ratio (OR) was used as a measure of effect of the handling practice on the occurrence of DFD meat using the following formula:

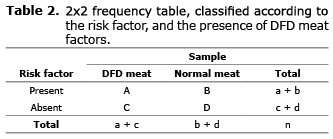

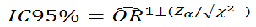

where a, b, c and d represent frequencies for each class defined in a 2x2 contingency table. Confidence intervals at 95% were estimated for each OR considering:

and Zα=1.96, χ2 was estimated using the following formula

OR value indicates magnitude of association between the predisposing component of a factor and positive DFD meat cases. The estimating of OR parameter from data samples organized in 2x2 frequency tables (Table 2).

Components on the right side of the equation represent frequencies observed in each class defined in the 2x2 contingency table. Statistical assessment of associations was performed using OR and its confidence intervals, so that if OR>1 and a lower interval value >1 it indicates that the variables are associated. The SAS software 9.3 was used for all the statistical analyses.

RESULTS

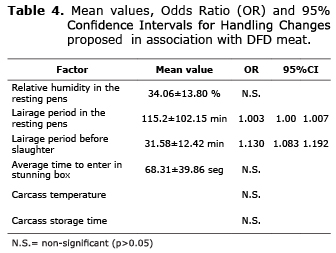

The study found a 38.99% frequency of DFD meat n=(223/572). The average values for pH and color for normal and DFD meat are showed on table 3 and the results of the association between the handling changes and DFD meat are presented in table 4, it can be seen that during the pre-slaughter period only two factors showed a significant association (p<0.05) to DFD meat this are: the time spent by the cattle on the waiting pens with an OR of 1.003 and a mean of 115.2±102.15 minutes and the waiting period to slaughter which showed a O.R. =1.130 and a mean of 31.58±12.42 minutes, the relative humidity in the waiting pens showed no statistical significance. In the slaughter stage none of the variables were found to be associated to DFD meat this was also the case for all the cold storage variables.

DISCUSSION

The frequency of DFD meat were two times higher than reported in a previous study (15.43%) (9), and are also much higher that what other researchers have reported (13.89% con pH>5.8 y 4.02% con pH >6.0) (15). Some studies have found a relation between both cold temperatures and hot temperatures and pre slaughter stress (13), cattle are considered more sensitive to hot than to cool temperatures. Therefore, during the hot seasonal temperatures (over 25oC) the ability of cattle to dissipate body heat to the environment is impaired imposing physiological stress on animals. Stressful conditions that lead to depletion of muscle glycogen reserves before slaughter may lead to higher meat ultimate pH values, and result in low residual levels of glucose (16).

The results of this study suggest that it is better to transport and unload the animals during the morning and not to extend the lairage period before slaughter for more than 4 hours, this is recommended because both the temperature and the relative humidity have not reach the highest values that may be seen on summer in the region (50°C with a relative humidity of 50% de H.R. at midday). Although the resting period allows the animal to recuperate from the stress that results from transportation, during this time the high temperatures had an important effect on the presence of DFD meat an important factor for this was that in the lairage pens the only spaces where animal take shelter from the sun have metal sheet roofs and concrete floors which provide a microclimate that contributes to an increase in temperature. Hot enviroments disrupt animal bevahiour and impose physicological stress, which activate glycogenolysis in skeletal muscle (16).

Other factors that influence the welfare of the animals and have a direct efect on the percentage of DFD meat are: the rotation of personnel in charge of stunning, the reason for this is that is common to substitute a skilled operator for one with lesser experience and without adequate training in this specific activity and also because of problems with the maintenance of the stunning equipment (17). In this study it was observed that design deficiencies of the shutte that impede the trap door to shut all the way down, also lack of maintenance of the stunning equipment and things that distract the cattle when it being driven are important factor of stress (18), when the plant has a good stunning equipment and the personnel in charge of stunning and bleeding the animals is well trained the efficiency of the insensibilization process increases and as a result of this (19), the frequency of DFD meat is reduced.

Slaughter plants are designed taking in to account conventional arquitectural criteria and because of this the plants have a design that facilitate the work that is done by humans but do not consider the behavioral needs of the animals (20), for this reason the animals are exposed to a great quantity of stressing stimuli like crowding, fastening, noise and unknown smells (21) all of which are factor for DFD meat (22). In one of the feedlots that provided animals for this study it was found that after unloading the animals are mixed with others in new groups and as a result of this fights for dominance take place causing stress (23), this situation should be avoided because it is an additional stress factor. Although the average waiting time before slaughter was reduced from 18 to 4 hours, the results of the study suggest that this is due to an excessive use of the electric prod to drive the cattle from the lairage pens to the shutte entrance, causing the animals to react in different ways, one of them is to try to escape increasing the possibility of injury when the animal fall, collide with the installations or with each other (21), because of this situation it is necessary to apply a audit system, so that welfare problems may be detected more efficiently (17) and it also recommended to increase the training programs of the personnel (19).

Another finding was that the carcass temperature in the refrigerated room was notabily lower when the storage time increase and that by increasing the storage time to the recommended 48 hours (22) the carcass temperature was optimal, before the recommended changes were made the carcasses were sold after only between 8 and 10 hours of cold storage.

In conclusion, after the changes were implemented in the plants a drop in the percentage of DFD meat was expected, however what was seen was a unexpected increase of DFD meat, which led to think that it is possible that during the loading of the animals in the feedlot and during transport other stressing factors are present. Because of the increase cases of DFD meat found by this study after the changes done in the handling system, it is recommended to extend the research and include the period between loading and arrival of the cattle to the slaughter plant, so that it is possible to determine which are the relevant handling factors that contribute to the problem of DFD meat and to also increase the welfare of animals that are going to be slaughter trough adaptations made in the facilities and better training of the personnel.

Acknowledgments

The authors which to thank the personnel of the TIF slaughter plant for all the aid given to carry out this study.

REFERENCES

1. Blokhuis HJ, Keeling LJ, Gavinelli A, Serratosa J. Animal welfare's impact on the food chain. Trends Food Sci Tech 2008; 19(Supl 1):S79-S87. [ Links ]

2. Miranda de la Lama GC, Villaroel M, María GA. Livestock transport from the perspective of the pre-slaughter logistic chain: a review. Meat Sci 2014; 98(1):9-20. [ Links ]

3. Sepúlveda W, Maza MT, Mantecón AR. Factors that affect and motivate the purchase of quality-labelled beef in Spain. J Meat Sci 2008; 80(4): 282-289. [ Links ]

4. María GA. Public perception of farm animal welfare in Spain. Livest Sci 2006; 103(3):250-256. [ Links ]

5. Apple JK, Kegley EB, Galloway DL, Wistuba TJ, Rakes KL. Duration of restraint and isolation stress as a model to study the dark-cutting condition in cattle. J Anim Sci 2005; 83(5):1202-1214. [ Links ]

6. Fergunson DM, Warner RD. Have we underestimated the impact of the pre-slaughter stress on meat quality in rumiants? Meat Sci 2008; 80(1):12-19. [ Links ]

7. Van de Water G, Verjans F, Geers R. The effect of short distance transport under commercial conditions on the physiology of slaughter calves; pH and colour profiles of veal. Livest Prod Sci 2003; 82(2-3):171-179. [ Links ]

8. Mounier L, Dubroeucq H, Andanson S, Veissier I. Variations in meat pH of beef bulls in relation to conditions of transfer to slaughter and previous history of the animals. J Anim Sci 2006;84(6):1567-1576. [ Links ]

9. Pérez-Linares C, Figueroa-Saavedra F, Barreras-Serrano A. Management factors associated to DFD meat in bovine on desertic climate. Arch Zootec 2008; 57(220):545-547. [ Links ]

10. Sotelo-Flores AP. Evaluación de cambios en las prácticas de manejo y su asociación con la presencia de carne DFD en bovinos. [Tesis de maestría]. Mexicali (BC): Universidad Autónoma de Baja California; 2008. [ Links ]

11. Leyva-García IA, Figueroa-Saavedra F, Sánchez-López E, Pérez-Linares C, Barreras-Serrano A. Impacto económico de la presencia de carne DFD en una planta de sacrificio Tipo Inspección Federal. Arch Med Vet 2012;44:39-42. [ Links ]

12. Miranda de la Lama GC, Leyva IG, Barreras-Serrano A, Pérez- Linares C, Sánchez-López E, María GA, Figueroa-Saavedra F. Assessment of cattle welfare at a comercial slaughter plant in the northwest of México. Trop Anim Health Prod 2012; 44(3):497-504. [ Links ]

13. Pérez-Linares C., Figueroa-Saavedra F, Barreras-Serrano A. Relationship between management factors and the occurrence of DFD meat in cattle. J Anim Vet Adv 2006; 5(7):578-581. [ Links ]

14. Young SK, Seok HY, Young HS, Sung HL. Effect of season on color of Hanwoo (Korean native cattle) beef. J Meat Sci 2003; 63(4):509-513. [ Links ]

15. Mach N, Bach A, Velarde A, Devant M. Association between animal, transportation, slaughterhouse practices, and meat pH in beef. Meat Sci 2008; 78(3):232-238. [ Links ]

16. Kadim IT, Mahgoub O, Al-Ajmi DS, Al-Maqbaly RS, Al-Mughiry SM, Bartolome DY. The influence of season on quality characteristics of hot-boned beef m. Longissimus thoracis. J Meat Sci 2004; 66(4):831-836. [ Links ]

17. Grandin T. Auditing animal welfare at slaughter plants. J Meat Sci 2010; 86(4):56-65. [ Links ]

18. Miranda de la Lama GC. Transporte y logística pre-sacrificio: principios y tendencias en bienestar animal y su relación con la cálida de la carne. Vet Méx 2013; 44(1):31-56. [ Links ]

19. Gregory NG, Lee CJ, Widdicombe PJ. Depth of concussion in cattle shot by penetrating captive bolt. J Meat Sci 2007; 77(4):499-503. [ Links ]

20. Miranda de la Lama GC, Liste G, Villaroel M, Escós J, María GM. Critical points in the pre-slaughter logistic chain of lambs in Spain that may compromise the animal's welfare. Small Ruminant Res 2010; 90(1-3):174-178. [ Links ]

21. Nanni-Costa L, Lo Fiego PD, Tassone F, Russo V. The relationship between carcass bruising in bulls and behaviour observed during pre-slaughter phases. Vet Res Commun 2006; 30(9):379-381. [ Links ]

22. Chanona, J, Alamilla L, Mendoza E, Gutiérrez GF. Refrigeración y congelamiento. En: Hui, YH, Guerrero I, Rosmini M. Ciencia y Tecnología de Carnes. México: LIMUSA; 2006. [ Links ]

23. Mounier L, Veissier I, Andanson S, Delval E, Boissy A. Mixing at the beginning of fattening moderates social buffering in beef bulls. Appl Anim Behav Sci 2006; 96(3-4):185-200. [ Links ]