Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería y Desarrollo

Print version ISSN 0122-3461On-line version ISSN 2145-9371

Ing. Desarro. no.22 Barranquilla July/Dec. 2007

Competitiveness in the supply chain management: An overview in an oils' and greases' manufacturer

Brayan Bravo1 , Krizztie Cortes2, Melyna Aguilar3, Sofía Granados4, Johanna Amaya-Leal5

1 Industrial Engineering Department, Universidad del Norte, Barranquilla, Colombia bbravo@uninorte.edu.co

2 cortesk@uninorte.edu.co

3 aguilarp@uninorte.edu.co

4 sgranados@uninorte.edu.co

5 amayaj@uninorte.edu.co Correspondencia: Universidad del Norte, Departamento de Ingeniería Industrial, Km 5 vía a Puerto Colombia, Barranquilla (Colombia).

Fecha de recepción: 16 de mayo de 2007

Fecha de aceptación: 29 de noviembre de 2007

Resumen

La logística es el conjunto de medios y métodos necesarios para llevar a cabo la organizacin de una empresa. Existen muchas herramientas electrónicas, mil y unas estrategias que se implementan, con un único fin: lograr una excelente logística en cualquier organización. En este artículo se muestran los resultados de un estudio exploratorio de la gestión de la cadena de abastecimiento propia de empresas manufactureras y en especial de aceites y grasas, como inducción a una investigación más rigurosa de lo que una empresa que extrae sus insumos del medio ambiente, lo haga sin afectarlo y manteniendo una posición competitiva. Se aplican diferentes conceptos logísticos y se muestra mediante un ejemplo la implementación de diversas herramientas que buscan incrementar la competitividad en empresas y lograr las metas propuestas al manejar y mantener una compañía de esta naturaleza.

Palabras claves: Competitividad, gestión de la cadena de abastecimiento, logística.

Abstract

Logistic is the means set and methods necessary to carry out the organization of a company. Many electronic tools and thousands of strategies are implemented with an only aim: to obtain excellent logistics in any organization. In this article, the results of an exploratory study of the management of the own chain of supplying of manufacturing companies are shown and specially the supply chain of oils and greases, as an induction of more rigorous investigation of a company that extracts its raw material from the natural resources, which does it without affecting it and holding always a competitive position. In the following paper, different logistic concepts are applied and the implementation of diverse tools oriented, for example, to increase the competitiveness in companies that entail to us to obtain the goals proposed when handling and to maintain a company of this nature.

Keywords: Competitiveness, supply chain management, logistics.

1. INTRODUCTION

Being competitive is what every company looks for and this implies the optimization of production activities, only through logistics, there are ways to maintain a strategic position in the market and to keep customers satisfied.

This paper will analyze an exploratory study of the management of the supply chain in manufacturing companies and, specially, that of oils and greases, as a start to a more rigorous investigation in which a company that extracts its raw material from the natural resources and still maintain its competitiveness. The challenge is to attend all suppliers, warehouse and distribution centers, located in different regions and even different countries, which will guide the authors to introduce a mathematical formulation of the problem including constraints and possible solutions to facilitate the interaction between all the members of the supply chain. Also, we take into account the possible activities that this type of companies could include in their daily processes to maintain a competitive position and be able to attend a variety of markets, keeping them satisfied.

The outline of the work is as follows: Section 2 gives a description of supply chain competitiveness; section 3 shows the implementation of the proposed mathematical formulation of the problem in the distribution centers administration on test; section 4 and 5 include proposed improvements in the supply chain management and in the logistic process; and finally, in section 6 this work is concluded and further studies are proposed.

2. FEATURES AND CONSTRAINTS OF SUPPLY CHAIN MANAGEMENT IN AN OILS AND GREASES MANUFACTURER

The supply chain management defines itself as the systematic and strategic coordination of the traditional functions of the business and the tactics through these enterprise functions within a company in individual, and through the companies that participate in the supply chain with the purpose of improving the long term performance of the individual companies and the supply chain as a whole [1]. In addition, this administration includes the integration of the activities related to the flow and transformation of goods, by means of the improvement of the relations of the supply chain to reach a sustainable competitive advantage [2].

According to logistics, the areas, in which the company has to work, are: Procurement, transportation, customer service, inventory and distribution. If we analyze these areas, global results in terms of competitiveness would be better.

The competitiveness of the supply chain is measured and evaluated under the competitiveness model of Donald J. Boverson. In the first place, we find that the interaction with the clients, one of the main factors which intervene in the supply chain, has a middle range scoring because of the logistics handled by the company, regarding the segmentation of them, such politics are directed to the relevance, capacity of response and flexibility.

With a system of transportation that is poorly developed, the market is limited to the areas that nearly surround the production facilities. As the production costs are extremely low, compared with those of a second point of production (that is to say, the difference of production costs compensates the transportation costs of taking care of the second market), it is probable that there is not too much competition. Nevertheless, the improvements in the transportation system, the costs reduced for products in distant markets can be competitive against other products that are sold such in markets [3].

If the demand of products of a company was known for sure and the products could be provided instantaneously to satisfy this demand, theoretically the storage wouldn't be necessary. Nevertheless, this is neither practical nor economic that a company operates in this way, since the demand cannot be foretold with exactitude. To even approximate it to a perfect coordination between the supply and the demand, the production would have to be able to respond immediately and the transportation would always have to be available with a time of delay in the deliveries equal to zero.

No company can reach this to a reasonable cost. For that reason, the companies use the inventories to improve the coordination between the supply and demand processes in order to lower the general costs. One derives to a point where the maintenance of inventory also produces the storage necessity and the necessity to handle the materials [4]. The storage area becomes an economic convenience more than a necessity.

It is important to highlight that in manufacturing companies and, specially, in companies dedicated to producing oils and greases, the purpose to keep it in a competitive position in the markets is a challenge, because there exist the necessity of planning how to extract their principal raw material from land without affecting it in the long term and combine that planning with the acquisition of another product required for the entire production process.

In this type of companies there are defined segments of the market according to the needs, expectations, desires, attitudes, conducts, values, psychographic variables and demographic variables starting from the relation of the consumer with the feeding.

Here, one of special ingredients is the client segmentation; they have catalogued certain clients as VIP-I and VIP-II, depending upon the purchase volume, positioning in the market and profits in the cash flow and associated costs.

Those clients have priorities in the dispatches, they have vehicles contracted dedicated to the operation, storage tanks are installed in the client's plants and tanks destined for the preparation of the products required by the clients. The delivery lead time is reduced to minimum with the supplier because they handle the stock with VMI, vehicles by offer and demand can stay the night in the client's plants up to 3 nights without charging stand by.

In massive consuming bakery and food services certified deliveries are done, CPFR, with cycles not above 8 days; cross docking, responsible of the transporters with only 30% of the vehicles sharing Geographical Positional System and the rest of them located by cellular phones.

Every business unit has selected which clients are catalogued as VIP and this is known by all the areas involved in the process (Logistics, Account Manager, Manufacture, R+D, Purchases), which are connected to achieving the objective of the total satisfaction of the client and in metrics established for each area attending this way the specific needs of each on of the primary clients.

However, the segmentation of clients require the integration of other areas not involved presently, like systems and finances, in addition, to designate a specific team that administers the relations with the client; also, it is required to design the PSAs to achieve the high levels of integration with the nodes of the web [5].

For all the units of special ingredients and bakery, the area of R+D in coordination with the commercial area, visiting clients to develop products exclusively for the client's processes is an important way of motivating. They make contests to stimulate the sales, they are allowed to audit the management system and help the personnel to give assessment, because it is one of the few companies in the coast that have an integrated management system [6]. The logistic of all the plants have a monthly schedule of visits to clients previously selected, or those reporting inconsistencies in the operation.

The web must guarantee the success of key clients because they accompany the client and, in addition, they measure weekly the result of the deliveries and in case of fallacies, they are integrated to the system for the respective case analysis and the implementation of corrective actions.

As a consequence of this, they handle a re-supply structure (CDD) which allows that the capacities of response to the business units can be shorter without affecting the variable costs structure. In all the countries, they have their own CDD in the main cities for a faster supply in the more distanced zones from the manufacturing plants.

Each one of the products has assigned some coverage days per dispatch center (DRP) and of production (MRP) according to the profile the products they handle. The flexibility is subject to the purchase order not being invoiced, if this is the case; it is managed so the merchandize is redirected to other client. A low score is presented in it because of the lack of agility in the moment these situations occur.

In a great sense, the integration with each client presents a middle character because of the concentration to VIP clients and low process flexibility. The value of the commercial partners is not only in the commercial transactions but in what they together contribute to the market through their cooperation from the design of the product to the delivery made to the client.

While talking of internal integration we refer to all the internal and external interactions which may present with the clients, through the inter-functional unification handled throughout the chain, we can observe in it that it is low due to the poor communication between the different departments intervening in the web.

Regarding the standardization, they have established procedures and an instructive for all the operations in the plant. As an alliance, this year the management systems were standardized for the entire company less than one sole work group, obtaining this element a middle score. The results are published in the intranet through the dog manager. The standardizations include metric presentation, reports, etc.

In the alliance level, all the instructions to follow are imparted among all the alliance to guarantee that everyone executes the same operations, aside from the continuous synergy between them, within the best practices of logistics, which are CPFR, CROSSDOCKING, WMS, ABS, OTIF, VMI, cyclic inventories, EDI, PDA, Balance scorecard and management systems. According to the simplifications made, they have reduced the product portfolio according to the participation in the market, and the profits; however they are in that process, but still have more to go.

Regarding the logistics, the implementation of the best practices has reduced the variability of the stocks, the delivery procedures and merchandise dispatch. They have reduced the devolutions because of the minimum mistakes made in the purchase orders and have simplified the data capture and results of the measurement. This has been a medium factor within the clients.

These companies are in process of implementing the payment of in the incentives for results, the assessment was done and is expected to be implemented with the key positions and it is at present in the salary leveling. Not all the logistic's objectives are accomplished because they are in the leveling curve as the best practices executed.

In the structural adaptation they have reduced the lead times in deliveries, also they have also successfully used the continuous re-supply, quick response on time with the clients. They still need to improve the JUST IN TIME with the suppliers, because the lead times are too long compared to the dynamics of the demand [7].

The suppliers are chosen through a selection process, for each input and packing material, a maximum of two suppliers are handle, they generally supply for all the alliance. The synergy with some of them has been successful because they count with the technical support in a personalized manner, sending personnel to their plants and vice versa to get to know the process and proposed solutions to the quality problems which may arise.

Logistically, they have facilitated vehicles of the internal web to help them in their necessities in case they have difficulties in the transportation. Every 3 months the suppliers are evaluated in variables such as quality, speed and service, which are measured; this information is fed to the system and is then a feedback for the supplier [8].

For the development of new products, the supplier is invited so it interacts with the packing engineering and access the packing material while the RTD product goes to the client to develop the product with the characteristics required by the client. The suppliers are authorized through the purchases in order to utilize all the tools required to guarantee the success of the development.

One of the weaknesses is that a financial reserve toward the suppliers and clients doesn't exist. The costs of research and development done with the supplier are assumed by each one of the parts and that is why there is integration with the suppliers' media.

The financial investment for developing new material is in charge of the supplier. The collaboration is given in the service, time, personnel and physical facilities. All the ideas developed by the supplier are evaluated for the strategic business in which they participate actively.

During the integration of technology and planning it is foreseen that in the 3 years the WMS was implemented, the use of intranet was affirmed, managers and salesperson were given portable computers and PDA. Internally, the messenger used is Lotus Notes and new modules have been developed which allow the capture of accurate data in a shorter period of time.

The internal communications is effective and data from the entire alliance are obtained in real time. However, with the internationalization of the company a new wider operative system is being evaluated.

The use of EDI is being applied to clients of large chains, in which the clients and suppliers have direct communications with the company on-line.

They have invested in technology, purchasing licenses and new financial tools.

The CPFR have been implemented for key clients in each one of the units of business. All the personnel are involved because the godfather plan has been implemented for all the CPFR clients, they have to visit and established improvement opportunities, which reflect directly in the full cash cost. In addition, the demand planner was created to increase the accuracy of the forecast and to be a better channel of communications with the clients regarding the area of forecasting.

All this interaction between the technology and planning has permitted a decreasing in the history of the logistic web of an Oils and Greases Manufacturer with respect to the world, awarding it a middle score in this area, but nearly to be good. If at any moment the measures taken regarding the integration plan are to be known, all those performance metrics established for the entire web would be translated. For example: weekly/monthly report of VIP clients, CPFR, report of run-outs, storage capacity, excess reports, ABC, OTIF, FLAT, SICATIN, freight report, consumed report, balance of raw material, exactitude of the forecast.

If the ABC costing is used by all the businesses that are revised monthly to determine which are profitable, in other cases, the involved parts are gathered and action plans are executed. The cost of revision is done monthly through the reports or the execution of the budget, master balance of the month's beginning.

3. DISTRIBUTION CENTERS ADMINISTRATION (CDD)

Analyzing how logistics activities are handled, it a mathematical formulation is proposed to the problem including: 6 objective markets, 3 production plants, and 6 locations for storage area (Warehousing).

Regarding the administration of these distribution centers, they consider the quantity of the products sent from the production plants to the warehouses, and from warehouses to the markets, in a way such that the transportation and production costs are minimized [9]. With this information, it is evaluated which distribution centers are worth operating and which have to close.

They have information regarding the forecasted demand for the 4 markets, also the production capacities of the plants and storage capacity of the warehouses, and the production and freight costs for each destination.

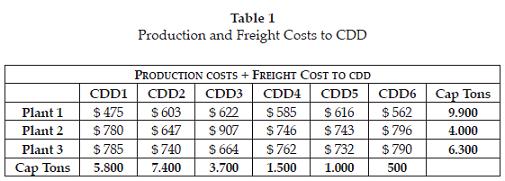

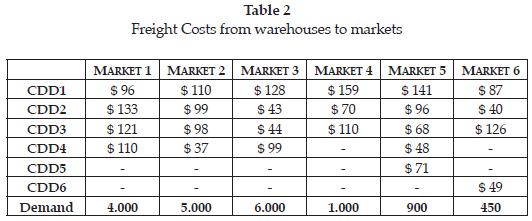

With this data we would formulate a linear programming model following models, as proposed in [10] which shows the determinants to take further decisions. Charts 1 and 2 show the production costs and freight between points:

In this way, we propose a linear programming model for this problem: Variables:

- Xij: Number of tons delivers from production plant i to the warehouse

- Yij: Number of tons delivers from warehouse i to the market.

j. i = 1 to 3; j = 1 to 6

j. i = 1 to 6; j = 1 to 6

Objective Function:

MinZ = 475X11 + 603X12 + 622X13 + 585X14 + 616X15 + 562X16 + 780X21 + 647X22 + 907 X23 + 746X24 + 743X25 + 796X26 +

785X31 + 740X32 + 664X33 + 762X34 + 732X35 + 790X36 + 96Y11 + 110Y12 + 128Y13 + 159Y14 + 141Y15 + 87Y16 + 133Y21 + 99Y22 + 43Y23 +

70Y24 + 96Y25 + 40Y26 + 121Y31 + 98Y32 + 44Y33 + 110Y34 + 68Y35 + 126Y36 + 110Y41 + 37Y42 + 99Y43 + 48Y45 + 71Y55 + 49Y66

-

Production Plants Capacity

X11 + X12 + X13 + X14 + X15 + X16 ≤ 9900

X21 + X22 + X23 + X24 + X25 + X26 ≤ 4000

X31 + X32 + X33 + X34 + X35 + X36 ≤ 6300 - Warehouse Capacity

X11 + X21 + X31 ≤ 5800

X12 + X22 + X32 ≤ 7400

X13 + X23 + X33 ≤ 3700

X14 + X24 + X34 ≤ 1500

X15 + X25 + X35 &le 1000

X16 + X26 + X36 ≤500 - Products Demand

Y11 + Y21 + Y31 + Y41 ≥ 4000

Y12 + Y22 + Y32 + Y42 ≥ 5000

Y13 + Y23 + Y33 + Y43 ≥ 6000

Y14 + Y24 + Y34 ≥ 1000

Y15 + Y25 + Y35 + Y45 + Y55 ≥ 900

Y16 + Y26 + Y36 + Y66 ≥ 450 - Flow Conservation (Warehouse)

X11 + X21 + X31 = Y11 + Y12 + Y13 + Y14 + Y15 + Y16

X12 + X22 + X32 = Y21 + Y22 + Y23 + Y24 + Y25 + Y26

X13 + X23 + X33 = Y31 + Y32 + Y33 + Y34 + Y35 + Y36

X14 + X24 + X34 = Y41 + Y42 + Y43 + Y45 X15 + X25 + X35 = Y55

X16 + X26 + X36 = Y66 - No Negativity

Xij , Yij ≥ 0 ∀i, j

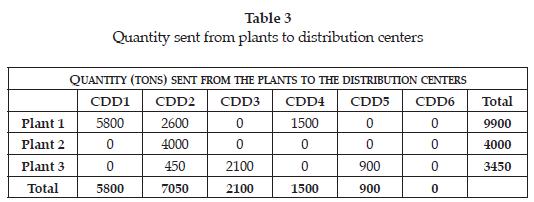

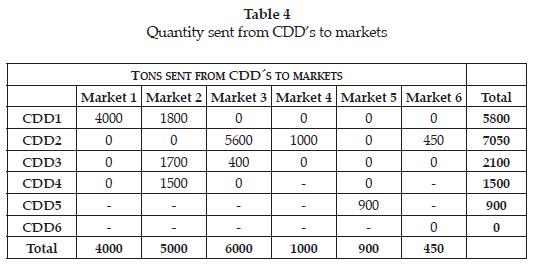

After solving the problem with an optimizer, we obtained the following results (charts 3 and 4):

Given the results, it can be analyzed that the distribution centers located in Market 5 and 6 only aim at one market, which represents a considerable cost to the company. For the particular case, these centers must continue being monitored for the following months to verify the probability of letting them to continue operating or be substituted by existing CDD's. The results obtained in this paper show that the CDD's of the Markets 5 and 6 must be closed and replaced by CDD's operating in cities nearby.

4. PROPOSED IMPROVEMENTS IN THE SUPPLY CHAIN MANAGEMENT

Given the analysis of the competitiveness of the supply chain we propose the following improvements for it:

- Creating intimacy with the consumer leads to a competitive advantage while you identify the logistic requirements specifically to every client segment.

- Create external bonds with partners in the supply chain so that compact flows are created and at rhythm with the activities of manufacture. They must accomplish an adequate mix of processes internally and open to the suppliers so that can satisfy the every time more ample demands of the consumer.

- Building specialized work teams for development of high levels of integration among the members of the supply chain.

- Design, develop and implement the PSA for VIP clients.

- Conform a team of scientists who coordinate the investigation and development department, also be uncharged of direction to their studies and products toward new benefits of the oil as a product of added value in the areas of general health, cardiovascular, obesity and nutrition.

- Install the satellite tracking devices to 100% of the vehicles transporting merchandize.

If the company handles the concept that the cooperation it is an import factor that generates value to the commercial relations, for the company, the partners are not only valued by the commercial transactions but also in what they can together give to the market through the collaboration starting from the design of the products and ending in the delivery to the final consumer, all this is a strategic tool which establishes differences with competing companies.

The improvement aspects identified with the client where such as optimization of purchase orders and deliveries, having good product stocks in the sales point, reduces the run-out levels and improving the sales of the briefcase. To improve it is required that the projects count with the support and commitment of all the functional areas of the company.

The involvement and team work of the logistic area and commercial area not only internally to the company, but to our clients, is a key factor for implementing difference activities in the collaboration relations. This link with the self services chains allows the increment of the "Cross docking", the dispatch advice, sales, reduction of run-outs and optimization in the use of the EDI.

Focusing in the key competences of the business and the mutual collaboration with the clients has allowed for them to handle correct coverage in the recovery of the inventories, executing action plans to improve the operational efficiency and allowing the absolute integration of the processes [11].

Analyzing a business model and determining if it is adequate, as to determine which business processes are key, and which can be third party, helps convert the stationary costs in variable costs structures. It is also fundamental that the company checks the security if its processes and its infrastructure so they are ready to function always and in any place. For this reason it is important that the company starts this transformation now because the business under demand, which is the factor that determines the competitiveness, will be the capability of reaction towards charges.

There must be and an inter-functional operation in the management of the logistical process, from the supply chain reception to the delivery of the products, in addition to the internal coordination of the process related to the materials supply, manufacture and physical distribution.

The started efforts between the actors of the chain lead to a better satisfaction of the final consumer, also eliminating double operations and resources waste.

The focus on activities that create strong bonds with partners in the supply chain in a way that establishes continuous flows with the activities of labor/manufacture of the company. The company must perform and adequate mix of processes towards the suppliers which allows the satisfaction of the every time more demanding consumers. This recommendation makes the company focalize in the consumer and reach an inter-organizational coordination with the goods and services' suppliers.

5. PROPOSED ACTIVITIES TO IMPROVE THE LOGISTICAL PROCESS

To implement a strategy in all the organizational processes which assures success in the business and establishes efficient tools which align executives, business units, human resources, information technology, and financial resources it is found that the following activities that must be taken into account:

- Integrate the most possible amount of strategic clients to the CPFR program in all the business units.

- Achieve that 100% of the transport vehicles have satellite tracking devices.

- To take roads with the values, beliefs, ideas or affairs which form the corporative culture to the entire cooperation web

- Create better economical conditions so that the capital moves where it generates more value.

- Share with all the common web of business in order to reduce costs starting from several income sources.

- Generate and develop new improvement plans in each of the process to determine efficiency increases in the distribution system.

- Create strategic consciousness at all levels of the organization and for that to happen it is required that the leadership teams communicate the strategy and find ways to reinforce them consistently.

- Establish objective measuring, based on results.

- Transmit the urgent feeling to justify the change required.

- Create a climate where changes are accepted, understanding whatever worked in the past; it may not work in the future.

6. CONCLUSIONS

In an agitated and dizzying world like the one lived today it is necessary to be at the vanguard in order to maintain a status. When it is spoken about status, special emphasis is made in obtaining recognition through the differentiation and innovation, having, as a base point, the utilization of modern mechanisms and technology. They allow and make possible the conservation and protection of a solid entrepreneurial stability and of course, the social aspect.

Competitiveness is a common term for the every day life, but to cope with if and fulfill the requirements that score us as competitive, it is necessary to use tools that allow us to find a way tangible for the visualization of it. Dispositive, formulas, theories, programs, schemes and software's are available to obtain this purpose.

It is significantly important to count with the will of utilizing all and every one of the methods available. It is of no use having them and not use them correctly, that is why logistics counts with thousands of tools which make it "easy" to handle the distribution of any business though a supply chain, highly systematized, characterized and documented.

In the specific case exposed, the company used many tools which enabled to achieve with success the proposed goals, taking into consideration that modernization and automation of their supply chain is new for them. For this reason, they will not obtain big goals because of many factors such as the cultural factor; despite that their process is admirable and qualified. As time passes and they gain experience, they will be able to achieve all the goals established given that they manage cycles of correction and feedback.

Finally, we propose for future research a study of competitiveness between supply chain management of manufacturer companies without raw material from land and supply chain management of manufacturer companies with this type of resources in their raw material under the frame of global warming.

REFERENCES

[1] HANDFIELD, R. and NICHOLS, E. Introduction to Supply Chain Management. Upper Saddle River : Prentice Hall, 1999, p.2 [ Links ]

[2] MENSERT, John, DE WITT, William, KEEBLER, James, SMITH, Carlos. Defining Supply Chain Management, Journal of Business Logistic, Vol. 22, N° 2, 2001, p.12.[7] [ Links ]

[3] BALLOU, Ronald. Logística, 5th. Ed., Ed. Pearson - Prentice Hall, 2004. [ Links ]

[4] DEL CAMPO, Pedro. Planeamiento, Gestión de stock y JIT. Gestión de Operaciones. Argentina, 2006. [ Links ]

[5] JIMÉNEZ SÁNCHEZ, José Elías. Publicación técnica No 215 "Marco conceptual de la cadena de suministros". Instituto Mexicano de Transporte, México, 2002. [ Links ]

[6] GUANSEKARAN, A., PATEL, C. "Performance Measures and Metrics in a Supply Chain Environment" International Journal Operations & Production Management, Vol. 21 No. 1/2, 2001, pp. 71-87. # MCB University Press, 0144-3577, 2001. [ Links ]

[7] CHOPRA, S y MEINDL, P. Supply Chain Management. Ed. Prentice-Hall, New Jersey, 2004. [ Links ]

[8] DE BUEN RICHKARDAY, Oscar. Publicación técnica N° 10 "Incremento de competitividad en el transporte de carga: Acciones emprendidas por transportistas a nivel mundial". Instituto Mexicano de Transporte, México, 1992 [ Links ]

[9] FRANCIS, Richard. On some problems of rectangular warehouse design and layout. Journal of Industrial Engineering, Vol 18. Octubre, 1987. [ Links ]

[10] HILLIER, F.S., Lieberman. Investigación de Operaciones, 7th ed. Bogotá: McGrawHill, 2001. [ Links ]

[11] Instituto Aragonés de fomento. Programa de Innovación Logística (Programa PILOT). "Las claves de Supply Chain", 2002. [ Links ]