Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

CT&F - Ciencia, Tecnología y Futuro

versão impressa ISSN 0122-5383versão On-line ISSN 2382-4581

C.T.F Cienc. Tecnol. Futuro v.2 n.2 Bucaramanga jan./dez. 2001

*2Ecopetrol - Instituto Colombiano del Petróleo, A.A. 4185 Bucaramanga, Santander, Colombia

e-mail: ¡serna@ecopetrol.com.co e-mail: wafanado@ecopetrol.com.co

RESUMEN

En Ecopetrol-ICP se realizó una evaluación de las propiedades mecánicas y microestructurales de la aleación 9Cr-1 Mo modificada, ASTM A-335 Gr. P91, encontrando propiedades de resistencia mecánica, esfuerzos admisibles y resistencia a la termofluencia, muy superiores a las de una aleación 9Cr-1 Mo convencional, ASTM A-335 Gr. P9, recomendando la aleación P91 como material de reemplazo de la tubería de radiación del Horno de Viscorreducción de la Refinería de Cartagena (horno en proceso de cambio). Los resultados obtenidos permiten una reducción de espesor para los tubos de radiación de material P91 del 25% y un aumento del volumen interno del tubo cercano al 8%, lo cual es un parámetro a considerar en el Incremento de productividad y eficiencia del proceso. También se obtendría una reducción significativa en los costos de material entre un 5 y 10%. Además, las expectativas de vida útil de diseño y vida útil remanente se verían ampliamente favorecidas con el cambio de aleación.

Palabras clave: modificado 9Cr-1 Mosteel P91, temperatura alta, selección de materiales, productividad.

ABSTRACT

In Ecopetrol-ICP was carried out an evaluation of the mechanical and microstructural properties of modified 9G--1 Mo alloy, ASTM A-335 Gr. P91, finding higher strength mechanical properties, allowable stresses and creep rupture strenght, than the conventional 9Cr-1 Mo alloy, ASTM A-335 Gr. P9, recommending the alloy P91 as substitute tube material in the radiation zone of the Visbreaking heater of Cartagena's Refinery (furnace in revamping process). The results obtained permit a thickness reduction of radiation tubes of material P91 close to 25% and increase the internal volume tube over up 8%, which is a parameter to consider in improving productivity and efficiency process. Also would be obtained a significant savings cost in the material among 5 and 1 0%. Additionally, expectations of both design and remaining useful life would be seen extensively favored with this change of alloy.

Keywords: modified 9Cr-1 Mosteel P91, high temperature, materials selection, productivity.

INTRODUCTION

For materials selection and application in high temperature processes, the following properties and technical considerations must be taken into account (Bellanca et al., 1992):

- Thermal conductivity and expansion coefficient

- Mechanical strength and creep resistance at high temperature

- Weight considerations in accordance with dimensions

- Weldability and elimination of dissimilar welds

- Ease of fabrication, maintenance and repair

- Availability and handling experience

- Cost/benefit ratio.

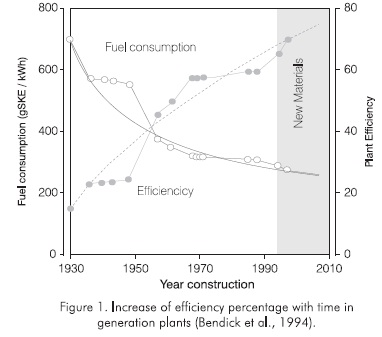

Currently, refining, petrochemical and power generation industries require both productivity and competitivety improvement. These purposes are achieved by increasing operating parameters, such as, temperature and pressure with the development of new alloy types, which reduce residence times and increase process efficiency, as currently takes place in equipment with pipes for heating fluids (furnaces, boilers) (Pelabon, 1988).

The basic chemical composition of conventional 9Cr-1Mo steel was developed initially forthe oil industry in 1936 to provide higher oxidation performance than 2¼Cr-1Mo steel. The 9Cr-1Mo material was known for its stable microstructure, high oxidation and sulfidation resistance, high thermal conductivity and low thermal expansion compared to austenitic stainless steel. Then in 1950 the 9Cr-2Mo-Nb-V steel with a higher mechanical strength, was developed. However, it was brittle and had low ductility at a temperature of 823K (550°C). Therefore a new alloy was developed and in 1972 the modified 9Cr-1Mo steel (T91/P91) with niobium (Nb) and vanadium (V) was obtained, with higher mechanical properties and creep strength compared to the conventional 9Cr-1Mo steel (Orr and Burton, 1993), being integrated in 1987 in the ASME Code-Case 1943, for boilers construction and design. At the same time in the 80's, laboratories such as Oak Ridge National Laboratory (ORNL) in United States and NOVATOME in France, characterized a modified 9Cr-1Mo steel for use in steam generators of nuclear reactors LMFBR (Liquid Metal Fast Breeder Reactor).

Due to its performance in service in the power generation industry, the use of modified 9Cr-1Mo steel P91 began in early 90's in plant applications around the world in the petrochemical and crude oil refining industries, with a favorable combination of mechanical, physical and corrosion resistance properties compared to other ferritic steels (2¼Cr-1Mo, 9Cr-1Mo) and some austenitic steels (AISI 3XX) up to 923K (650°C).

THEORETICAL FRAMEWORK

The small additions of Nb and V to the modified 9Cr-1MoP91 steel promote the formation of fine (Nb, V)C carbides and carbonitride particles evenly distributed throughout the matrix. According to Jones et al. (1991) and Dwivedi (1998) the higher resistance of modified 9Cr-1Mo steel must be caused by two main effects: First, fine M23C6 carbide particles nucleated in Nb(C, N) carbides or nitrides of niobium formed initially during the heat treatment. Second, vanadium diffuses toward M23C6 carbides retarding its growth during service in high temperatures, precipitating along interfaces of martensite as V4C3 and VC in the form of a fine lath throughout the matrix. These effects explain the higher microstructural stability and the increase in material strength over long periods of time at a high temperature service.

The main advantage of ASTM A-335 P91 (ASTM A-213 T91) steel derived directly from its high creep strength, is that it can be used in thinner section sizes, compared to other ferritic steel, which reduces costs, as well as the risk of thermal fatigue cracking. A thickness reduction between 25 and 50% produces a cost savings between 15 and 30% for diverse applications at high temperature and pressure in different components (pipes, headers, valves). Although this is the benefit claimed, it can be counterbalanced by other disadvantages. Thinner pipes improve more axial loads and cause tipe IV cracking in girth welds. In tubing, oxide scaling can have a more profund impact on thin pipes compared to thicker pipes.

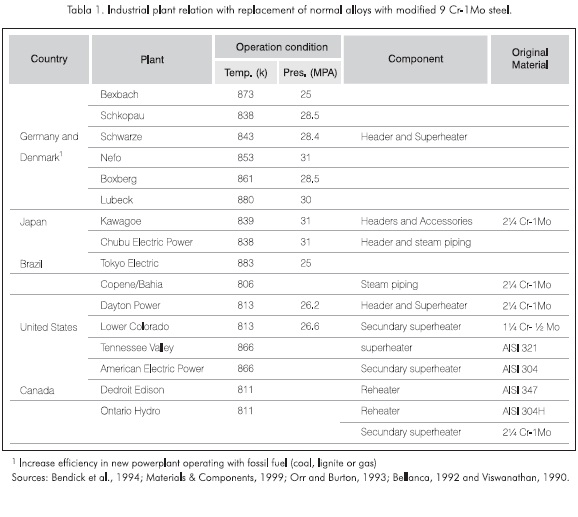

The increase in operating parameters promotes the reduction of pollutants (C02) by improving thermodynamic combustion efficiency in industrial processes (Orr and Burton, 1993; Bellanca, 1992; Bendick et al., 1994 and Viswanathan, 1990). In countries like United States, Germany, Denmark, Japan, Brazil, France, England and Canada, thermoelectrical generation capacity has increased between 400 and 900MW, as shown schematically in Figure 1 with the evolution in percentage of thermoelectrical plant efficiency up until the year 2010, according to Bendick et al. (1994). Table 1 summarizes some industrial plants, operating conditions, component type and original materials replaced.

Mechanical properties of modified 9Cr-1Mo material at the laboratory level and in plant performance have been extensively characterized (Bendick et al., 1994; Blondeau et al., 1990; Khare and Sikka, 1986; Orr, 1993 and Sasaki et al., 1991), including the following:

- Microstructural stability up to 923K (650°C) under tensile loads and creep conditions

- High (UTS) ultimate and (Ys) yield strength values from room temperature to 973K (700°C)

- High allowable stress and creep strength to temperatures over 823K (550°C)

- Better impact properties with low transition temperatures and high energy absorption

- Good weldability in heavy and thin sections

- Relative high thermal conductivity and low thermal expansion coefficients.

- Good corrosion and cracking resistance in aqueous and gaseous environments.

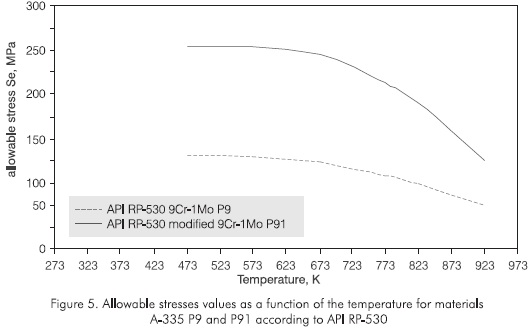

Figure 2 compares the allowable stresses data specified by the standard API RP-530, showing higher values between one and three times for modified P91 steel compared to conventional P9 steel.

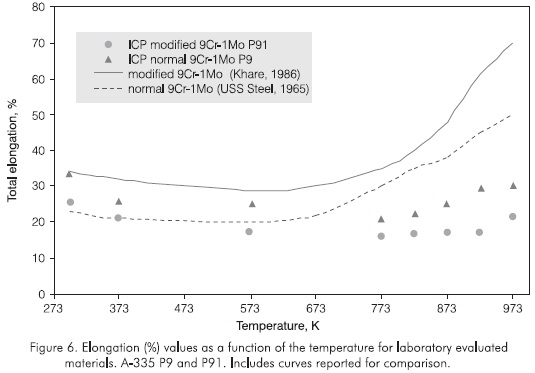

The excellent mechanical strength properties at high temperature are accompanied by a slight decrease in ductility, and the need for better control of the welding process in comparison with the conventional 9Cr-1Mo steel (Swindeman et al., 1998).

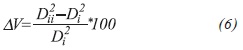

Equations taken into consideration for thickness comparison

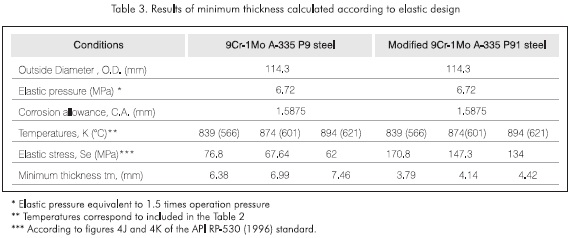

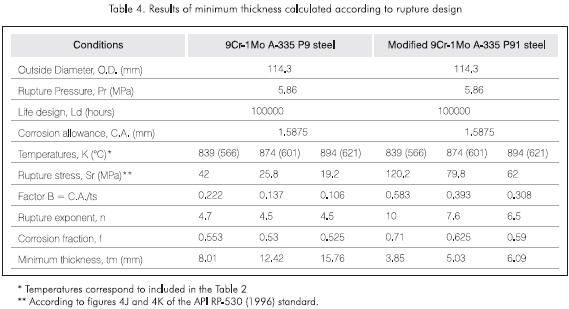

Theoretical calculations of minimum thickness, as well as the calculation of remaining useful life for process furnace tubes, are based on the API-RP530 standard (1996) and the UOP's recommendation manual for inspectors (1996). At low temperature, the design is considered in the elastic range (stress based on elastic stress, Se), while at high temperature, it is considered the creep-rupture design (stress based on rupture stress, Sr).

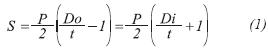

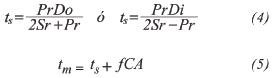

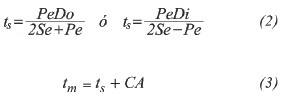

In the temperature range near the limit between elastic range and rupture range, thickness must be evaluated for both conditions, considering the highest thickness value calculated for design applications. Equation (1) gives a good estimate of the pressure that may produce yielding in the pipe wall and a correlation between creep rupture of a pressurized pipe and a uniaxial tensioned specimen. This equation is given by (API RP-530):

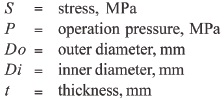

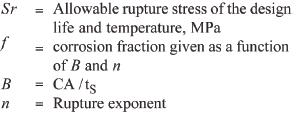

Where:

The elastic design is based on preventing failure by bursting or failure of pipes when stress is higher than yield strength during the design life of the component. For elastic conditions, the equation of design thickness is calculated by:

Where:

The rupture design is based on failure prevention by creep during the component's useful life. For rupture conditions, the equation of design thickness is calculated as follows:

Where:

EXPERIMENTAL PROCEDURE

Materials Characterization

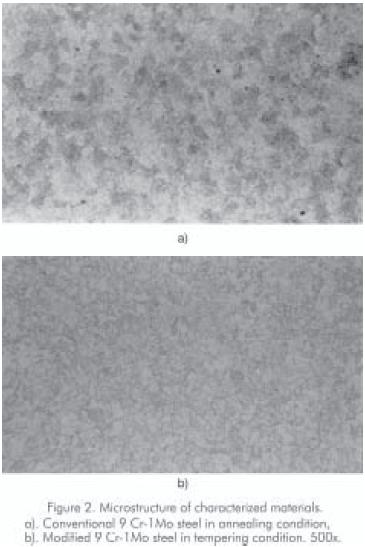

Both materials selected for comparison correspond to a conventional 9Cr-1Mo alloy (UNS K50400), currently in service, and a modified 9Cr-1Mo alloy with Nb and V (UNS K91560), grade P9 and P91 respectively, generally used in process furnace pipes. The materials in supply state show a structure in agreement with that specified by ASTM A-335 (1995) standard, with amicrostructure entirely ferritic in annealed condition for the P9 material and a tempered martensitic microstructure (normalized plus tempering) for the P91 steel (Figure 2).

Method

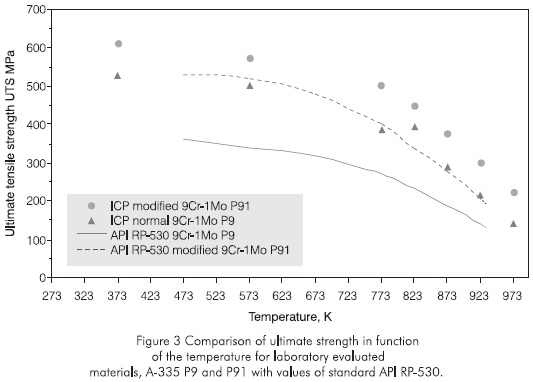

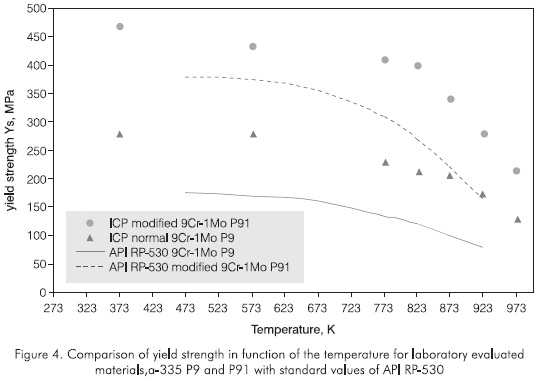

The mechanical properties (UTS and Ys) were evaluated in the Material Resistance Laboratory of Empresa Colombiana de Petróleos - Instituto Colombiano del Petróleo (Ecopetrol - ICP), in a servohydraulic machine INSTRON, equipped with a furnace with temperature control from 298K (25°C) to 973K (700°C), in agreement with the standard tension test at high temperature ASTM E-21. The variation in mechanical properties was determined in function of temperature for both P9 and P91 steels evaluated, in regard to those specified by standard API RP-530 (1996), showing data comparatively in a graphic way (Figure 3).

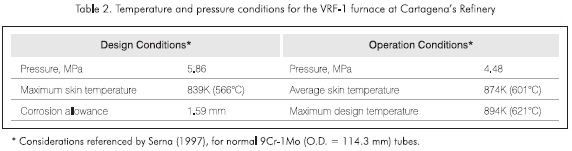

Theorical calculations were made for thickness and useful life for standard 9Cr-1Mo steel grade T9 (equivalent to P9) of current use, and for a modified 9Cr-1Mo steel grade P91 recommended as a replacement, considering design and operating conditions (temperature and pressure) for the radiation pipes in a visbreaking furnace, VRF-1, of the Cartagena Refinery, as shown in Table 2.

RESULTS AND ANALYSIS

Figures 4 and 5 show the experimental values of mechanical properties (UTS and Ys) as a function of the temperature for materials P9 and P91 evaluated in laboratory, and curves for comparison with the API RP-530 standard. It is observed that stress values decrease when temperature increases, with higher mechanical properties for the modified P91 steel than the conventional P9 steel over the entire temperature range. This behavior is explained by the effect of small additions of Nb and V, which improves the formation of (Nb,V)C carbides and carbonitrides finely distributed throughout the alloy (Jones, 1991 and Sasaki et al., 1991).

Figure 6 compares the percentage of elongation values obtained experimentally with data reported by Khare (1986); Swindeman et al., (1998) and USS Steel (1965). In all temperature ranges, the P91 steel shows ductility (elongation%) values smaller, between 5% and 10%, regarding the P9 steel, as a consequence of greater hardness in the modified steel (higher UTS and Ys).

The result of thickness calculations for both elastic and rupture design for materials P9 and P91 according to equations taken into consideration for comparison, are shown in Tables 3 and 4. According to the thickness values obtained, radiation pipes of the furnace VRF-1 should be evaluated under rupture design conditions (equations 4 and 5).

Regarding the thickness values considering the current pipes diameter (O.D.= 114.3 mm), the API RP-530 standard recommends a minimum wall thickness of 5.3 mm for new pipes of ferritic alloys. For the VRF-1 furnace under current process conditions (standard 9Cr-1Mo steel; T = 874K; P = 5.86 MPa; initial thickness 8.01mm), and considering the use of modified P91 steel with a thickness of 6.35 mm, a decrease of 25% in thickness would be obtained and a reduction in weight of about 10%. This reduction in thickness represents for the same pipe of O.D. = 114.3 mm, an increase in the internal diameter of the pipe, raising the available volume approximately by 8.3%, calculated according to equation 6:

Where:

This reduction in wall thickness and increase in internal volume in the radiation pipes, would directly generate an increase in load capacity of the visbreaking process for the VRF-1 Furnace. Considering that equipment productivity is directly proportional to the available volume multiplied by a realistic factor of furnace efficiency, estimated at 80%, a greater increase in productivity up to 5% will be reached. Upon considering different options for increasing the operating parameters, temperature and pressure safely, it is possible to recalculate residence times, combustion efficiency, thermal efficiency of the furnace and conversion factors.

The drastic thickness reduction for radiation pipes under considered conditions is explained for the higher tensile strength and allowable stress properties shown in Figures 2, 4 and 5, and by the increased creep strength of modified steel due to the effect of Nb and V alloying elements. The wall thickness reduction results in a similar reduction of thermal stress, due to rapid changes of temperature during runnings and stops of the furnace and possible operation regime changes during the process.

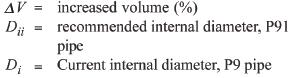

Theoretical calculation of useful life

To determine the effect of higher mechanical properties obtained in the modified 9Cr-1Mo steel in regard to conventional 9Cr-1Mo steel, theoretical useful life was calculated for the radiation pipes of the VRF-1 visbreaking furnace. According to limits specified by the UOP manual and the API RP-530 standard, useful design life of process furnaces are estimated at 11 years or 100000 hours of continuous operation. The VRF-1 furnace has been in service from 1982 to the present time, with approximately 18 years of operation (equivalent to 140,000 hours of continuous exposure) with conventional 9Cr-1Mo steel pipes. Although the actual furnace has exceeded useful design life, experience indicates that the useful life of this equipment is greater than that specified by design if is operated below permitted design condition parameters for different materials, especially by maintaining them below maximum operating temperature.

For calculating the remaining useful life (FVUR), the theoretical rate of thickness reduction was considered with time due to oxidation and wear or accumulated erosion damages, estimated according to the tendency shown in Figure 7.

The evaluation of theoretical FVUR was based on the methodology recommended in the API RP-530 standard (Appendix E "Calculation of remaining pipe life"), with average pressure and temperature data, and considering the individual effect of operating periods (runs) in the decrease in useful life in the radiation pipes (Serna et al., 1997).

According to the given values of design and operation for radiation pipes in the furnace VRF-1, a theoretical comparison was carried out at the same conditions for the current alloy in service, conventional 9Cr-1Mo, and forthe recommended modified 9Cr-1Mo alloy. The conditions were:

| Outside diameter, O.D. | :114.3 mm |

| Initial thickness, e0 | :8.01mm |

| Final thickness, eƒ | :5.3 mm |

| Constant C (ferritic steel) | :20(P9), 30(P91) |

| Operation period | : 20 runnings |

| Total operating time | : 140,000 hours (17.8years) |

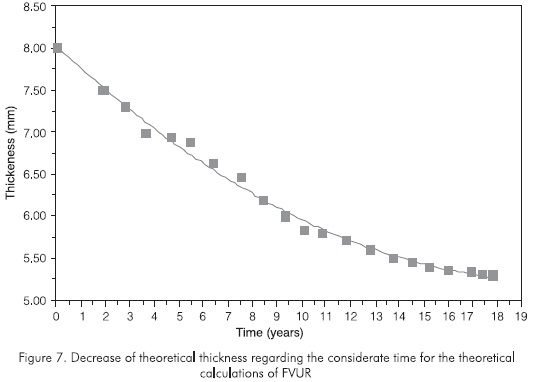

Figure 8 shows the results of theoretical FVUR for P9 and P91 pipes considering an average skin temperature (T=874K) and a pressure of 4.82MPa. A great increase in the FUVR is observed for the modified 9Cr-1Mo material in comparison with the material of current use.

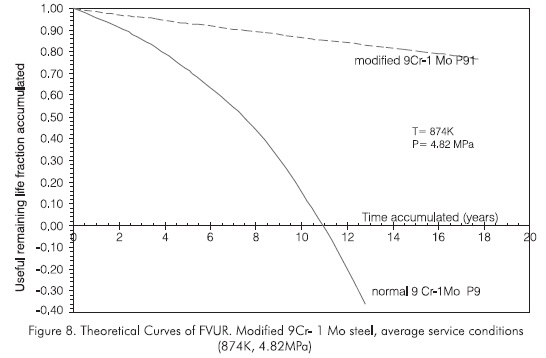

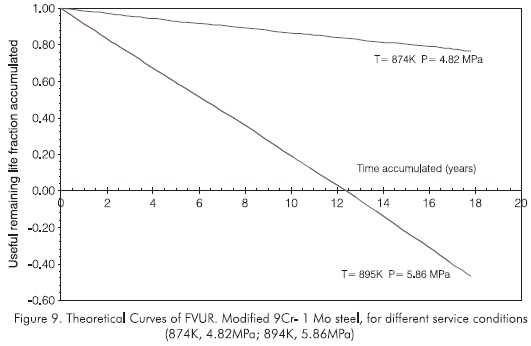

Figure 9 shows the theoretical FVUR of the P91 steel for two different service conditions (T, P), reaching an accumulated operating time greater than design time 100,000 hr (11 years) at higher temperature and pressure conditions (895K; 5.86MPa), which confirms its better behavior in service compared to conventional 9Cr-1 Mo steel.

CONCLUSIONS

-

According to results obtained in the evaluation of mechanical properties at different temperatures, the modified 9Cr-1Mo steel presents higher values of ultimate strength, yield strength and allowable stress than the conventional 9Cr-1Mo steel (approximately 50%). This behavior is explained by the hardening effect of alloying elements (Nb and V) in the modified material with a slight reduction of ductility (Jones, 1991 and Swindeman, 1998).

-

Theoretical evaluation of useful life fraction with actual operation data of the Furnace VRF-1, shows that for the same operating conditions (874K, 4,82 MPa), the conventional 9Cr-1Mo material consumes its theorical life (at 11 years of continuous exposition), whereas the modified P91 steel only presents a consumed FVU approximate of 15% at the same time of service.

-

The appreciable reduction in wall thickness in the radiation pipes (25%) considering the use of alloy P91, besides increased transfer and thermal efficiency in the furnace, it would reduce total weight and cost in support structure and welding process.

-

All these reasons make the selection of the modified 9Cr-1Mo P91 alloy, one of the best technical and economical options for replacement of current P9 steel, which estimates a considerable increase in furnace productivity of both crude oil heater and visbreaking furnaces similar to the VRF-1 Furnace at Cartagena's Refinery. Because of the increase in the current conditions of operational severity with a reduction in residence times, and benefits in productivity and impact on combustion efficiency, is enough incentive for designing and construction of other components and equipments for high temperature operation, with the same modified ferritic steel.

REFERENCES

APIRP-530, 1996. "Calculation of Heater. Tube Thickness in Petroleum Refineries". 4th ed., Washington: API, Oct., 121. [ Links ]

ASTMA-335/A-335M-95a. 1995. "Standard specification for seamless ferritic alloy-steel pipe for high-temperature service". West Conshohocken: ASTM, 7. [ Links ]

Bellanca, C, Infield, J., Zschau, M. and Haarmann, K., 1992. "Experience with installation of new P91 secondary superheater outlet headers". In: Pressure Vessels & Piping Conference, New Orleans, ASME, June, 230: 53-59. [ Links ]

Bendick, W., Haarmann, K., Ullman, K. and Zschau, M., 1994. "Use of P91 in Europe and Overseas". In: Joint International Generation Conference, Phoenix, ASME, Oct., JPGC-PWR(35):6. [ Links ]

Blondeau, R., Bocquet, P. and Cheviet, A., 1990. "Development of a modified 9Cr-1Mo steel for use in hydrotreating reactors", New York, ASME, 201:49-53. [ Links ]

DOE and EPRI Newsletter., 1999. "Materials & Components". Judkins, R. ed., ORNL., Oct, 142:6-13. [ Links ]

Dwivedi, VS. and Jha, B.K., 1998. "Microstmctural evolution of modified 9Cr-1Mo steel". J. of Mater. Scien. Letters, 17:325 -330. [ Links ]

Jones, W.B, Hills, C.R. and Polonis, D.H., 1991. "Microestructural evolution of modified 9Cr-1Mo Steel". Metallurgical Transactions A., May., 22A: 1049-1058. [ Links ]

Khare, A. K. and Sikka, V. K., 1986. "Evaluation of modified 9Cr-1Mo steel forgings". Steel Forgings, ASTM STP-903, Philadelphia, E. G. Nisbett and A. S. Melilli eds., 303-327. [ Links ]

Metals Handbook. 1990. "Properties and Selection: Irons, Steels, and high performance Alloys". 10th ed., Ohio, ASM, 1:617-651. [ Links ]

Orr, J. and Burton, D., 1993. "Development, current and future use of Steel 91". In: Ironmaking and Steelmaking, 20 (5): 333-337. [ Links ]

Pelabon, J. and Pellicani, K, 1988. "Développement industriel d'une nuance 9Cr-1Mo modifiée pou surchauffeurs et générateur de vapeur de centrales nucléaires". Revue de Metallurgie, Mai, 273-286. [ Links ]

Sasaki, T, Kobayashi, K., Yamaura, T., Kasuya, T., and Masuda, T., 1991. "Production and Properties of Seamless Modified 9Cr-1Mo Steel Boiler Tubes". Kawasaki Steel Technical Report, Sept., 25:78-87. [ Links ]

Sema, A., 1997. "Evaluación de la vida residual del horno VRF-1. viscorreductora refinería Cartagena". Informe técnico Ecopetrol-ICP, Jun.,31. [ Links ]

Swindeman, R. W., 1988. "Cyclic stress-strain-time response of a 9Cr-1Mo-V-Nb pressure vessel steel at high temperature". Low Cycle Fatigue, ASTM STP-942, Philadelphia, 107-122. [ Links ]

Swindeman, R.W., Sikka, V.K. and Maziasz, P.J., 1998. "Evaluation of T91 after 130,000 hours in Service". Fatigue, Environmental Factors, and New Materials, ASME, 374:305-312. [ Links ]

UOP - Train Your Refinery Inspector. 1996. "Inspection Training Manual". Tiry School, I y II. [ Links ]

Viswanathan, R., Berasi, M., Tanzosh, J. and Thaxton, T., 1990. "Ligament Cracking and the use of Modified 9Cr-lMo Steel (P91) for Boiler Headers", New York, ASME, 201:97-104. [ Links ]