Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

CT&F - Ciencia, Tecnología y Futuro

Print version ISSN 0122-5383On-line version ISSN 2382-4581

C.T.F Cienc. Tecnol. Futuro vol.2 no.3 Bucaramanga Jan./Dec. 2002

1Ecopetrol - Instituto Colombiano del Petróleo, A.A. 4185, Bucaramanga, Santander, Colombia (SA)

e-mail: vechever@ecopetrol.com.co e-mail: hvidales@ecopetrol.com.co

2Ecopetrol - Gerencia Complejo Industrial Barrancabermeja, A.A. 77605, Bucaramanga, Santander, Colombia (SA)

e-mail: Gladys.Monsalve@ecopetrol.com.co

ABSTRACT

The Colombian Petroleum Institute -ICP-, the research and development branch of Ecopetrol has developed a unique technological package used to treat oily sludge in a continuous way. The sludge comes from a refinery with a 220 000 barrels of crude per day load, located in the Middle Madgalena River Valley in Colombia.

The Technological Package allows for :a) the recovery of the hydrocarbon contained in oily wastes (up to 50%); b) the elimination of the oil contained in solid using a biodegradation process; and, c) the availability of an economically and technically feasible solution to handle oily sludge generated in the refinery. The oily wastes treated in this process come from maintenance of refinery's equipment and also from the physical-chemical separation process at the industrial waste water treatment plant.

Oily sludge is a complex system where light and heavy oils, contaminated water and contaminated solids coexist in the form of direct, inverse and multiple emulsions. The comprehensive technological package allows the treatment of oily sludge in a cost-effective way.

ICP's Technological package developed includes technologies combining mechanical, thermal, chemical and electrostatic dehydration techniques, and stimulated and intensive bioremediation to decontamination of solids saturated with residual oil.

This technological package brings a solution to the old environmental problem caused by the inappropriate final disposal of oily wastes such as storage in ponds, marshes and open pits. Nowadays oily wastes generated are treated in a continuous process that is environmentally friendly and economically profitable.

Keywords: Oily sludge, dehydration, centrifugation, biodegradation, remediation.

RESUMEN

El Instituto Colombiano del Petróleo -ICP-, centro de investigación y desarrollo de Ecopetrol, ha desarrollado un paquete tecnológico único, para tratar lodos aceitosos de una manera continua. El lodo proviene de una refinería que procesa 220 000 barriles de crudo por día, y se encuentra localizada en el Valle del Magdalena Medio, en Colombia.

El paquete tecnológico permite: a) la recuperación de hidrocarburo contenido en los residuos aceitosos (hasta un 50%); b) la eliminación del aceite contenido en los sólidos, mediante el uso de un proceso de biodegradación; y, c) la disponibilidad una solución económica y técnicamente factible para manejar lodos aceitosos generados en la refinería. Los residuos aceitosos tratados en este proceso provienen del mantenimiento de equipos de la refinería y del proceso de separación físico-química en la planta de tratamiento de aguas residuales industriales.

El lodo aceitoso es un sistema complejo donde aceites livianos y pesados, agua contaminada y sólidos contaminados coexisten en forma de emulsiones directas, inversas y múltiples. El paquete tecnológico completo permite el tratamiento de este tipo de lodos de una manera rentable.

Este paquete tecnológico ha permitido solucionar antiguos problemas ambientales, resultantes de la inapro-piada disposición final de residuos aceitosos tales como almacenamientos en ciénagas, diques y piscinas a cielo abierto. Hoy día, los desechos aceitosos generados son tratados en un proceso continuo, ambiental-mente amigable y económicamente rentable.

Palabras clave: Lodo aceitoso, deshidratación, centrifugación, biodegradación, remediación.

INTRODUCTION

The petroleum industry in its production, refining, transport and storage processes, generate oily residues, which have been stored in pits, marshes or open earth pools for many years, causing a high degree of contamination, not only in the storage areas but also in nearby areas.

In the refinery of Barrancabermeja - Colombia, through the years, the former marshes in the nearby areas ended up containing near 2 million cubic meters of polluted sludges associated with more than 5 million barrels of contaminated oily waters.

The appropriate treatment and correct disposal of this type of wastes prevents the contamination of superficial and ground water, the contamination of the surrounding air; and reduces the risk of fires, explosions, poisoning of the food chain and destruction of green areas.

Among the several technologies for the treatment of these oily wastes, are the extraction with solvents, filtration, thermal desorption, incineration, and biodeg-radation (Arnold, K. and Stewart, M., 1986). Ecopetrol through the Colombian Petroleum Institute (ICP) has developed and adapted technologies, such as, gravitational, thermal, chemistry and electrostatic dehydration, emulsified washing and biodegradation (Grosso, 1995b). With the application of these technologies, Ecopetrol - ICP has eliminated numerous contaminated sites (previous sources of contamination) and nowadays, ICP has implemented process technologies for the continuous treatment of the oily wastes from the refinement and petrochemical industry of the Colombian refineries, mainly at Barrancabermeja, where more than 300 000 barrels of oily residues with initial oil content ranging from 20% to 30%, are properly treated annually. One important advantage of the adopted process is that approximately 60 000 barrels of the treated wastes is recovered as slop oil that is sent back to petrochemical processes with significant economical benefits.

Due to the continuous treatment and the processes implemented no significant areas for temporary storage are needed. The risk for potential contamination of air and water resources is significantly decreased.

It is important to remark that the development of the methodology has been the result of experimental work at laboratory and pilot plant, and ratified at the industrial level with several applications as a result of a strong collaboration between the research and the operative areas of The Colombian Petroleum Company -Ecopetrol-.

ANTECEDENTS

From the beginning of operations of the Refinery of Barrancabermeja - Colombia, back in 1917, the oily wastes coming from the cleaning of process equipment, storage tanks and API separators, among others, were deposited in former marshes or in open pits inside the refinery areas where they remained for many years, generating important contamination sources to the soil, air, water and groundwater. These places were known as oily marshes for years, and ended up occupying more than 150 000 m2, storing nearly 1 000 000 m3 of oily wastes within the refinery.

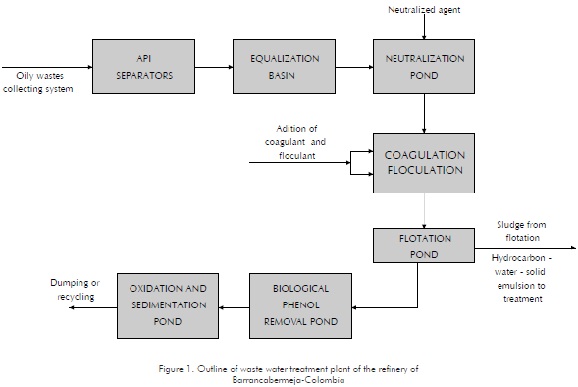

At the end of the 1970's, a Waste Water Treatment Plant was built in the Refinery of Barrancabermeja (Figure 1) designed to carry out the treatment of the outlets coming from the refinement and petrochemical processes. The oily sludge coming from the physical-chemical separation carried out in this plant were stored temporarily in tanks and then pumped toward these oily marshes.

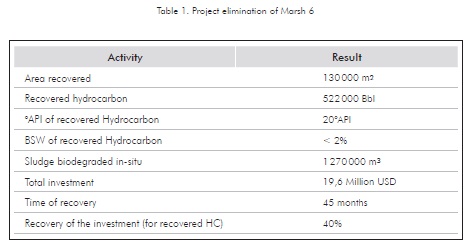

The biggest oily pond (former marsh) known as the Marsh 6, was eliminated using diverse methodologies of treatment of oily wastes in the period 1993 - 1997 (Instituto Colombiano del Petróleo, 1997). The work done at this contaminated site is summarized in Table 1. The project ended in 1997 with the recovery of the area and the elimination of the potential source of contamination to superficial waters and groundwater.

The problem of the elimination of this source of contamination was solved through the implementation of a complex system of technologies. A solid-liquid separation scheme allowed the recovery of an important volume of hydrocarbon, and that scheme eased the intensive and stimulated biodegradation of oily sludge (Table 1).

Additionally the recovery technologies have been applied successfully in several other oil production fields where nearly 2 000 000 m3 of polluted oily sludge have been treated, recovering more than 1 000 000 m2 of land (Instituto Colombiano del Petróleo, 2000; Marve, H. and Bagaasen, L., 1997).

DESCRIPTION OF THE PROBLEM

Starting from the elimination of the Marsh 6 and the other oily marshes at the refinery of Barrancabermeja, it became imminent and necessary to implement a treatment and disposal process of the oily wastes coming from the industrial waste water treatment plant and other sources of the refinery (cleaning of tanks, API separators, pools, process equipment, etc); due to the low capacity for oily wastes storage, the refinery required an option that is environmentally acceptable and economically profitable to allow the continuous treatment of the oily sludge generated in the normal operation to avoid the requirement for new oily marshes.

CONTINUOUS TREATMENT OF OILY SLUDGES-PROCESS DESCRIPTION

Oily sludge come from different sources in the refinery: API separators, storage tanks oily bottoms, floating sludge from industrial waste water treatment plant. These residues can contain supernatant oil, free or emulsified water and solids impregnated with hydrocarbons. Depending on the characteristics and quality of each one of these sources, they should be subjected to one or several processes for their total purification.

The first treatment stage consists of a gravitational and thermal dehydration, using vapor injection, with the purpose of destabilizing the emulsion, facilitating the separation of the oil impregnated in the solids, separation of the free water and a part of the emulsified water which is drained. The second stage of the treatment process is done on the oily phase, with high solid and emulsified water contents. It receives the injection of a polymer followed by centrifugation to obtain three separate phases: hydrocarbon, water and solids. The hydrocarbon outlet from centrifugation is taken to a later stage of thermal and electrostatic dehydration, depending upon its quality, and lastly it is pumped to tanks for storage or sent to the plants.

The outlet water resulting of each stage of the process is drained toward the industrial waste water treatment plant where neutralization, coagulation, flocculation and clarification processes are conducted. These processes remove solids and organic compounds present in the waste waters. These waters are further treated for phenol and hydrocarbons removal by biological processes (Grosso et al., 1995a), for final treatment prior to discharge or recycle to the process plants.

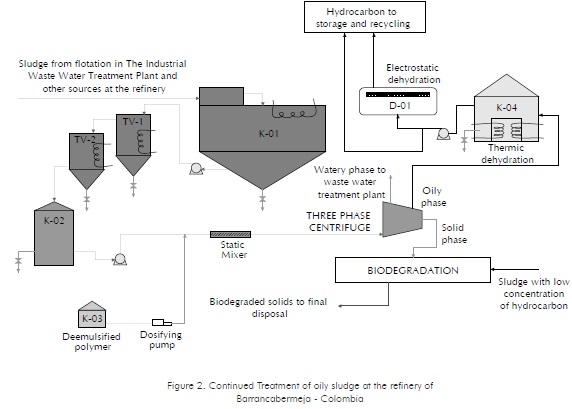

The oily solids coming from the centrifugation process are treated in a continuous process of stimulated and intensive biodegradation. This process has been implemented at the refinery, using hydrocarbon-specific microorganisms for the biodegradation of soils and waters resulting from the petroleum industry. These microorganisms have been isolated and tested in the laboratory and used at pilot plant scale at The Colombian Petroleum Institute (Vargas, M. C. et al., 1996). The isolated bacteria are native species from contaminated soils and sludge in the tropical areas of Colombia; these bacteria are enhanced to improve treatment efficiency. As a final step, the remaining solids with very low hydrocarbon contents are sent to final disposal, according to the general waste management plant for the Barrancabermeja refinery. Figure 2 shows the flow-process diagram of the continuous treatment of oily sludge at the refinery of Barrancabermeja - Colombia.

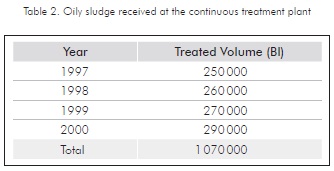

The volumes of oily sludge received and treated using the process presented in Figure 2 are summarized in Table 2.

SEPARATION PROCESS

The gravitational and thermal separation is carried out simultaneously in tanks K-01 and K-02, and in the chutes TV-01 and TV-02 showed in Figure 2. These equipment have internal serpentines circulating fluid steam at 345 kPa of pressure; the supply of heat is constant maintaining the oily sludge at a temperature that oscillates between 70 and 80°C . The heating also favors the later process of separation by centrifugation.

The determination of the temperature of dehydration at industrial level, involves diverse variables, some of them favor the process, other restrict it. The tests at pilot plant report that higher temperature increases the efficiency of the centrifugation process, but the increase of the temperature favors the evaporation of the light fractions, increases deterioration of the equipment and requires additional isolation requirements of pipes, among others efects.

Through the gravitational and thermal separation process, approximately 40% - 50% of the water contained in the emulsion of oily sludge is separated; this water is drained to the equalization basin of the industrial waste water treatment plant. The emulsion passes to the following stage of the process: injection of deemulsifier polymer and later on to centrifugation.

DE-EMULSIFIER AND CENTRIFUGATION

The outlet emulsion of the gravitational and thermal separation train receives an amount of a quick action de-emulsifier polymer, througth a dosing pump. The added polymer is selected by means of a technical-economical evaluation of several different products at pilot plant scale. The contact between the demulsifier polymer and the emulsion is improved by means of an on -line mixing device- (static mixer), located in the feeding pipe to the centrifuge.

The centrifugation is carried out using a HYSEP® three-phase centrifuge that operates at minimum speed of 3500 rpm processing approximately 35 BPH (barrels per hour).

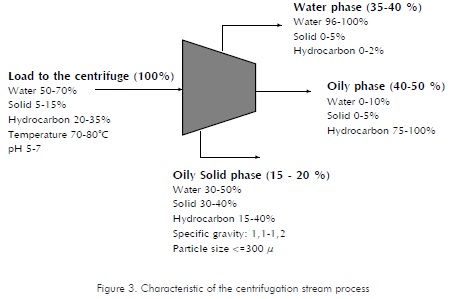

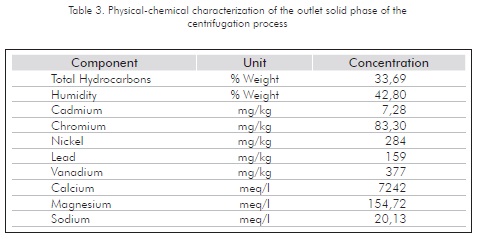

The typical characteristics of the centrifugation stream process are presented in Figure 3 and the typical physical-chemical characterization of the outlet solid phase is presented in the Table 3. Up to 50% of the oil can be recovered from the oily phase and the amount of solid to be treated decreased up to 15% of the load making the subsequent biological treatment more efficient and cheaper.

The outlet oily phase of the centrifugation process is sent to a later stage of thermal and electrostatic dehydration (see Figure 4), using an 24 000 V electrostatic field to produce the final separation of the watery and oily phases. The dehydrated hydrocarbon, containing less than 0,5% of BSW, is pumped to fuel storage tanks or is loaded to plants for recycling.

BIODEGRADATION

The solid phase resulting from the centrifugation process is then transported to a specific area designated to carry out the continuous treatment using biodegradation techniques.

The stimulated and intensive biodegradation consists of the addition of microorganisms to the oily solids, previously prepared with nutrient and acidity modifiers (Eweis et al., 1998).

The aeration of the soil-organism mixture is carried out, once or twice a week, using conventional earth-moving machinery (excavators, tractors, dozers, etc.), in cells appropriately designed (see Figure 4).

In order to increase the efficiency of the process and the contact between the microorganism and the hydrocarbon, the initial oil content of the soil-sludge mixture was adjusted to 15% (Eweis et al., 1998).

The amount of nutrient and acidity modifiers added depends of its characteristics. In order be to push pH near neutrality, Calcium Oxide (CaO) is commonly used; to satisfy the microorganisms nutrition necessities, mixtures containing Nitrogen, Phosphorus and Potasium (N:P:K) are used. The diet recommended for the microorganisms optimal metabolism is given by the relation C:N:P:K 50:14:3:1. (Eweis et al., 1998).

This biological process is the result of the scaling up from laboratory to pilot plants of the research done at ICP, on the influence of the type of microorganisms, nutrient contents, aeration mechanisms, water content, form and frequency of microorganism addition, thus allowing a considerably reduction of the treatment costs and biodegradation time.

The microorganisms used to carry out the processes of biodegradation of hydrocarbons have been identified, isolated and strengthen at ICP's laboratories from native species taken from samples of the same oily sludge to be treated (Vargas et al., 1996).

The handling of microorganisms in the open atmosphere is supported by bio-safety studies that guarantee its appropriate manipulation and application, eliminating all risk for the operator and the surrounding environment and ecological resources.

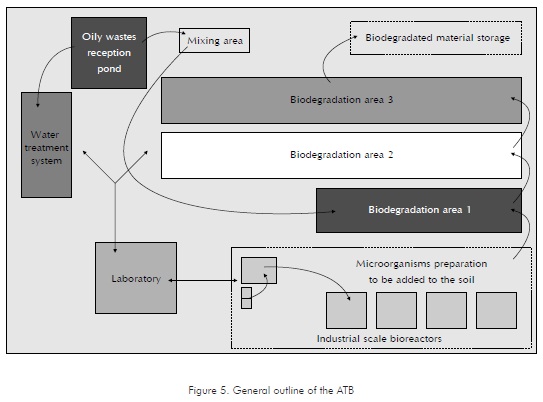

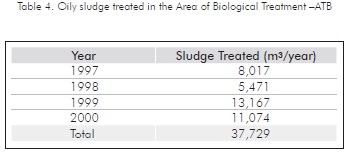

The Area of Biological Treatment - ATB used for the continuous treatment of the oily solids by stimulated and intensive biodegradation (Figure 5) has a high density polyethylene (HDEP) lining system, segregation and water treatment facilities and quality control monitoring microbiological and physical-chemical aspects. The amount of sludge treated at the ATB is summarized in Table 4. 40% of oily sludge teatred come from the centrifugation process and 60% from other sources at the refinery, oily production fields nearby and other adjacent facilities.

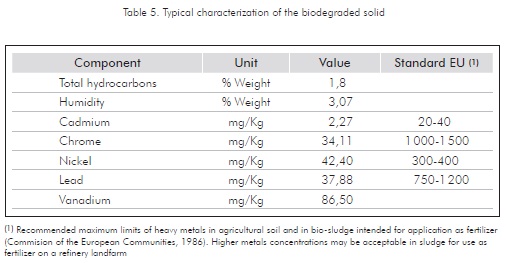

The biological process at ATB obtain removal efficiencies higher than 90% of initial hydrocarbon content in less than 90 days. Part of the biodegraded material is used several times as recharge material to mix with new oily sludge that enters to the process; other portion of the treated solids is taken for final disposal as filling material. The typical characterization of the biodegraded solid is showed in Table 5.

CONCLUSIONS

- A unique technological package implemented by ICP at the Refinery of Barrancabermeja has been an environmental solution for the problematic of handling, treatment and elimination of oily wastes avoiding to form contaminated sites (such as oily marshes); because that wastes from different refinery and petrochemical process can be treated in a continuous way using a combination of several technologies to achieve acceptable standards and prevent further environmental damage.

- Using a continuous treatment system of oily sludge coming from refining waste water treatment plant, it is possible recover up to 50% of hydrocarbon present in the sludge by centrifugation and up to 20% of oily solids can be treated using stimulated and intensive biodegradation.

- The pre-treatment of oily sludge using separation and de-emulsification facilitate the treatment by biodegradation because it is possible to reduce the volume of hydrocarbons to be treated up to 85% of the initial volume.

- The treatment of the oily solids using stimulated and intensive biodegradation technique, obtain removal efficiencies higher than 90% in less than 90 days of treatment.

- The oily wastes stored during years in open pits can be treated by means of economically viable and environmentally acceptable technologies. Using stimulated and intensive biodegradation combined with several oil recover technologies the cost of the treatment is close to US$ 15 per cubic meter of oily sludge.

- The continuous treatment, using a combination of several technologies, solves the environmental problems caused by inappropriate treatment and disposal of oily wastes.

BIBLIOGRAPHY

Arnold, K. and Stewart, M., 1986. "Surface production operations". Houston, GPC. [ Links ]

Commission of the European Communities, 1986. "Council directive on the protection of the environment, and in particular of the soil, when sewage sludge is used in agriculture". Directive 86/278/EEC. [ Links ]

Eweis, J., Ergas, S., Chang, D. and Schoerder, E., 1998. "Bioremediation principles", New York, McGraw Hill. [ Links ]

Grosso, J. L., Díaz, M. P. and León, G., 1995a. "Biodegradación de fenoles en aguas residuales de la industria petrolera". CT&F - Ciencia, Tecnología y Futuro, 1(1): 5-15. [ Links ]

Grosso, J. L., Cáceres, O., Vidales, H., Echeverría, V., Díaz M. P., Castro, A. and Ramírez, N., 1995b. "Sistema Integral para el tratamiento de lodos aceitosos y aguas residuales de la industria del petróleo". Memorias Codicid, Bucaramanga, Colombia. [ Links ]

Instituto Colombiano del Petróleo, 1997. "Remediation of 13 Ha contaminated area in Colombia's largest Petroleum Refinery". Technical Report, Ecopetrol - ICP. [ Links ]

Instituto Colombiano del Petróleo, 2000. "Remediation of hydrocarbon-contaminated sites: Ecopetrol Comprehensive Approach". Technical Report, Ecopetrol - ICP. [ Links ]

Marve, H. and Bagaasen, L., 1997. "Select a site cleanup technology". Chemical Engineering Progress, August, pp 22-43. [ Links ]

Vargas, M. C, Ramírez, N. E., Rueda, S. M. and Sánchez, F. N., 1996. "Isolation of microorganism with capability to degrade polycyclic aromatic hydrocarbons (PAH'S)". CT&F - Ciencia, Tecnología y Futuro, 1(2): 45-53. [ Links ]