Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

CT&F - Ciencia, Tecnología y Futuro

Print version ISSN 0122-5383On-line version ISSN 2382-4581

C.T.F Cienc. Tecnol. Futuro vol.2 no.3 Bucaramanga Jan./Dec. 2002

1Corasfaltos, UIS Sede Guatiguará, Km.2 Vía al Refugio, Piedecuesta, Santander, Colombia. Tel.: 7655-08-06

e-mail: info@corasfaltos.com

ABSTRACT

The influence that saturated compound fractions -and, specifically, heavy paraffins- have on the chemical composition of asphalts and their asphaltic properties was assessed through the use of a complex asphalt produced in Barrancabermeja (CIB). Phenomena caused by the aforementioned substances on ductility, penetration, softening point, rheological curve, humidity susceptibility (TSR), and deformation resistance (DSR) of CIB asphalt were identified. The identified effects were explained in light of the changes in the asphalt's colloidal system.

Keywords: Heavy paraffins, effects on asphalt.

RESUMEN

La influencia de la fracción de los saturados y, precisamente, parafinas pesadas, en la composición química de los asfaltos, sobre propiedades asfálticas fue estudiada utilizando el asfalto complejo de Barrancabermeja (CIB). Fueron aclarados los fenómenos que provocan las sustancias mencionadas sobre la ductilidad, penetración, punto de ablandamiento, la curva reológica, susceptibilidad a la humedad (TSR) y la resistencia a la deformación (DSR) del asfalto CIB. Los efectos observados fueron explicados desde el punto de vista de los cambios en el sistema coloidal del asfalto.

Palabras clave: Parafinas pesadas, efectos en el asfalto.

INTRODUCTION

The influence saturated compound fractions -and, specifically, heavy paraffins- have on the chemical composition of asphalts and their asphaltic properties has been studied for many years now. Currently, it has been agreed that the admissible amount of these substances in asphalt should be, according to several authors, of 3 to 6% w/w , and, according to several others, of 1% w/w (Durrien and Vail-lant, 1985; Khudiakova et al., 1989; Rostler, 1979; Rozental et al., 1979).

Modern surveys on effects caused by paraffinic substances, including those within the boiling interval of 370-540°C (and, preferably, that of 430-480°C), are reflected on several patents (US Pat. 5580376, 5904760, 5961709, 6027557, 6048447), where recommendations are made to use such substances as additives that improve asphaltic properties at low temperatures (< 0°C). It shall be pointed out that the presence of paraffin ("slack wax") in an asphalt, in concentrations of 1 to 5% w/w, increases resistance to thermal cracking and elevates the Performance Grade (PG). Light paraffins (Boiling point > 177°C , Fusion point 48,9-58,1°C , Specification 9-0120, Ecopetrol), are also used to modify certain asphaltic properties (U.S. Pat. 5911817, 5397459), (Rozental et al., 1979). Increases in their concentration levels lower the Softening Point, Ductility and Fragility Temperature, while elevating Penetration rates.

Assays to determine the influence of heavy paraffins on the basic properties of the type of asphalt produced by the Barrancabermeja Complex (CIB) were carried out at the Corasfaltos facilities.

OBJECTIVE

The objective of this research was to clarify the phenomena caused by the presence of heavy paraffins, when added to the asphalt being produced by Ecopetrol in the Barrancabermeja Refinery - Colombia (CIB, for its acronym in Spanish).

METHODOLOGY

Asphalt CIB and heavy paraffins from the Barrancabermeja Refinery were used as study materials, as per specification N° 9-0160, Fusion point > 71°C . The content of heavy paraffins in this particular asphalt was of 0,75% w/w .

Ten (10) samples were prepared blending CIB asphalt and paraffins in different proportions (between 0,5 and 5% w/w).

Preparation conditions:

- Addition and blending temperature: 130°C

- Blending time: 15min

- Stirring: 800 rpm

Basic properties for the CIB asphalt, such as Softening Point, Penetration, Ductility, Rheological Curve, and Deformation Resistance (DSR) were assessed, as well as certain properties of asphaltic blends (modified asphalt+minerals), such as the Blend's Susceptibility to Humidity (TSR), in accordance with the respective ASTM standards.

Measurements were performed three times for all assays, except for TSR. The average value for these measurements was included in the survey's results.

Softening point - (ASTM D-36 Standard). Measured through the use of two horizontal asphalt discs which have been discharged into two brass rings and heated at a controlled speed in a liquid bath, while each one supports a steel ball. The softening point is reported as the measurement of the temperature at which both discs soften enough to allow each ball covering the asphalt to fall a 25 mm distance.

Ductility - (ASTM D-113 Standard). A test tube containing the asphaltic material is subject to a traction assay, at specific speed and temperature conditions, in a water bath with the same density. Ductility is then defined as the maximum distance (in centimeters) the test tube extends until it reaches the instant of rupture.

Penetration - (ASTM D-5 Standard). Measurement of the consistency of a bituminous material, expressed as the distance (in tenths of millimeters) a standard needle vertically penetrates a sample of asphalt, under defined load, time and temperature conditions.

Rheological curve - (ASTM D-4402 Standard). Viscosity of asphalts is determined in mPa.s or cP, at different temperatures. The equipment applies torque by means of a needle that rotates inside the asphalt sample, at a defined temperature. The material's viscosity is measured, based on the resistance such material offers to the flow; thus, it is possible to identify the behavior of the material in light of the variations in temperature observed.

Resistance to deformation - (AASHTO TP5 Standard). The dynamic slice rheometer (DSR) measures the complex module (G*) and the phase angle (δ), when the sample undergoes oscillating slice tensions; this allows for the calculation of the sample's response to deformation. These values are used to determine the maximum temperature an asphalt may resist prior to plastic deformation.

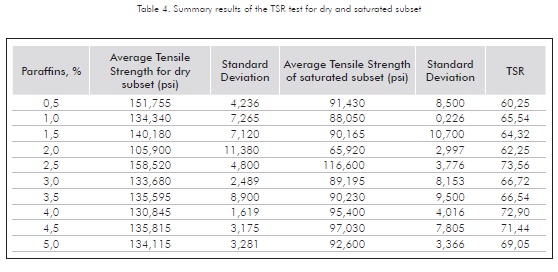

Susceptibility to humidity (TSR, Tensile Strength Ratio) - (AASHTO T 283-89 Standard). The susceptibility to humidity for the asphaltic sample being analyzed is determined by calculating compatibility and affinity values for the aggregate and the binder. The assay is carried out through the preparation of six (6) test tubes with vacuums of 6 to 8%. Half of these samples are saturated and conditioned. Then, the assay on resistance to indirect traction is performed for all test tubes (both, humid and dry) and the TSR value is determined as the percentage ratio between the measurement result for indirect traction on humid samples and the measurement result for indirect traction on dry samples.

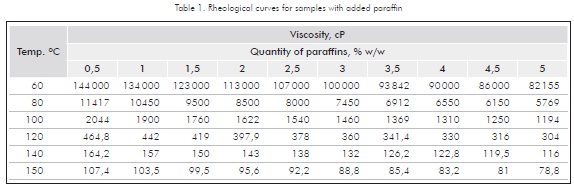

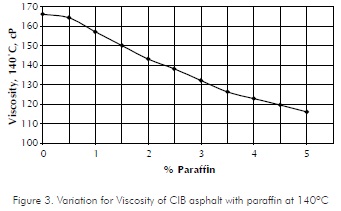

The rheological curve values for the various samples are included in Table 1, showing a clear fluidization of the products as the content of paraffins increases. Then, it is concluded that through the increase of paraffin quantities, the asphalt's viscosity decreases for all temperature ranges applied.

RESULTS

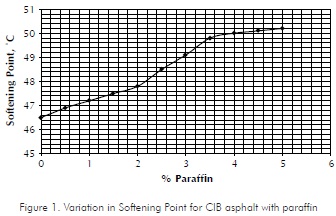

Figure 1 shows Softening Point variations against paraffin percentages.

As the quantity of paraffin increases, so does the Softening Point.

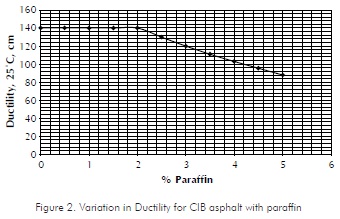

Ductility, in turn, remains at respectively high values, and the first decrease is observed at experiment conditions, with the presence of 2,5% w/w of added paraffin. Ductility variation is shown in Figure 2.

The rheological curve values for the various samples are included in Table 1, showing a clear fluidization of the products as the content of paraffins increases. Then, it is concluded that through the increase of paraffin quantities, the asphalt's viscosity decreases for all temperature ranges applied.

Figure 3 shows a decrease in viscosity for samples at a temperature of 140°C.

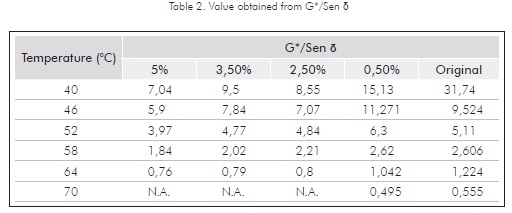

Table 2 shows the results for the influence of paraffin contents on resistance to deformation values, taking into consideration the complex module (G*) and the phase angle between the liquid response and the solid response (δ) of each asphalt.

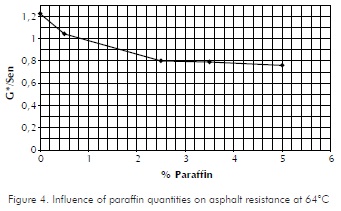

Figure 4 shows results for changes in the permanent deformation for different paraffin quantities at a temperature of 64°C.

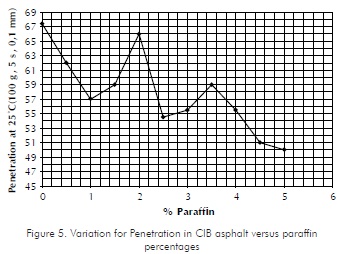

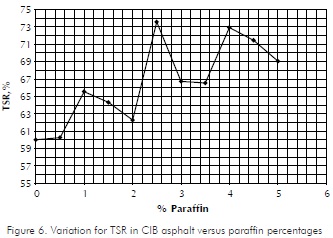

Figures 5 and 6 show variations in Penetration and TSR, respectively.

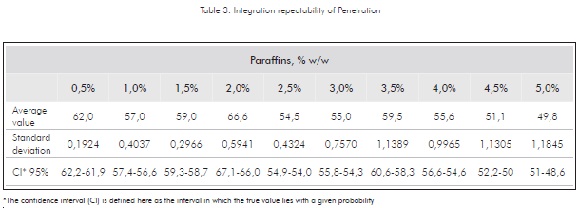

These data show a complex dependence on quantities of added paraffin. It is worth mentioning that the TSR value is inversely proportional to the Penetration value for each paraffin concentration, and that dependence exists exactly up to the point where the percentage of added paraffin reaches the 4,0% w/w mark. Furthermore, it should be noted that Penetration of the original paraffin used in assays, as measured under the same conditions, as per ASTM D - 1321 standard, has a value of 16 mm/10. Tables 3 and 4 (Annexes) show some dates of repeatability in the test of Penetration and TSR - test. The Penetration test was realized after the cooling at the samples during 1h in air at 25°C and then in water bath during 1h at 25°C , too. The repeatability was defined by annealing to reduce possible effect of steric hardening. The Table 3 presents the data of 10 parallel masurments.

DISCUSSION

It is known that bitumens are colloidal systems (Pfeiffer and Saat, 1940; Pfeiffer, 1950) that have a structure type depending on the chemical composition and proportionality of their components (Pfeiffer and Dormaal, 1940; Pfeiffer and Labout, 1936). Depending on the concentration of asphaltenes and "micelle" formed, they interact with one another and organize a disperse, condensed or coagulated free structure (Kolbanovskaya, 1973, 1968). Oils and resins, both of which are not part of the solvatic layer of asphaltenic "micelle", are present in the bitumen's disperse medium and also form associations among themselves. Therefore, any bitumen's disperse phase may be composed, aside from asphaltenic "micelle", by associations of other types of molecules (Khudiakova, 1991). Under certain thermal conditions, these may be covered with a solvatic layer, forming complex structural units. According to applicable literature, (Kolbanovskaya and Mihailov, 1973), asphalt has a structural state made up of different inter-molecular associations, at the time it forms a film on a mineral aggregate.

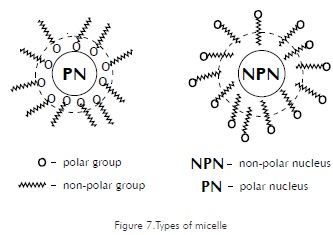

Since Penetration reflects the colloidal state of an asphalt, it may be concluded that paraffin has an influence on the molecular structuring of the bonder. It is probable that within the colloidal system of the asphalt being used, added paraffins participate as gathering centers. Their crystals, as they cool down, form units with the solvatic layers. However, orientation of molecules in these layers should be opposite to that of the asphaltene layers; in this case, this means that the nucleus of the complex unit is non-polar and the molecules around it should be oriented with their polar groups outside and their non-polar groups towards the center. This colloidal chemistry phenomenon is schematically described in Figure 7, which shows the formation of different types of micelle.

When grouping is taking place and new structural units are formed, a decrease in Penetration values is observed. Simultaneously, TSR values increase, thus implying an increase in resistance to water and, therefore, an increase in adherence. These dependences are observed until paraffin is added up to a proportion of 4,0% w/w . Adherence may increase also due to hydro-phobization of the surface of aggregates produced by paraffinic substances. Nonetheless, it is hard to expect such a drastic change in hydrophobization during the investigation. It is only possible to conclude that such characteristic is reflected on the common trend for TSR change (meaning adherence), as compared against the original asphalt, continuing to increase as paraffin proportions increase. At the same time, trends for penetration change head the opposite way.

However, it would be exaggerated to suppose that all heavy paraffin molecules are grouped and form structural units with their solvatic layers. As seen in the corresponding results (Figures 5 and 6) for our case, the value of 4% w/w of added paraffins identifies a limit at which structuring processes leading to the formation of non-polar nucleus micelle predominate in the asphalt being used (CIB). For quantities exceeding this value, other tendencies of heavy paraffins in asphalt composition are manifested, such as their activities as saturated organic fillers or asphalt plasticizers.

It is difficult to explain such a considerable variation in data for Penetration and TSR at the paraffin variation range. Reference should be made to the strength and nature of bonds formed in the system's structuring process, as well as to the effects that have a direct impact on this process, since the oil molecules state is a function of the inter-molecular interactions proportion and the energies of thermal movement. It should also be noted that up to the 4% w/w mark for added paraffins, the CIB asphalt complies with Ductility requirements (> 100 cm) for road asphalts (specification by INVIAS, Figure 2). Furthermore, the highest impact the structuring process has on the asphalt is observed when 2% w/w of paraffins is added.

The Softening Point variation process (Figure 1) only shows an increase of the phase that softens at higher temperatures. The Softening Point for the CIB asphalt featuring a 4% w/w presence of heavy paraffins is found at a temperature of 50°C , falling within the specification requirements mentioned for road asphalts. It does not exceed such specifications when using the whole range of paraffins added, in all the assayed samples.

Results for Brookfield viscosity show a proportional reduction in this characteristic as paraffin presence increases. These data correlate with that on Ductility, Softening Point and, particularly, DSR analysis, since they reflects, to a certain degree, the plasticity (higher deformability) of the asphalt under high temperatures and while undergoing the application of forces. (Figures 3 and 4, Tables 1 and 2). Based on these results, it should be accepted that molecule thermal movements have a higher impact on associations formed in the asphalt's colloidal system, and that paraffin used should be qualified as a plasticizer. The DSR values at 64°C do not change significantly when 2,5% w/w of paraffin is added, and they drastically fall after exceeding the 0,5% w/w mark. For results on DSR values at 40 and 46°C, with 2,5% w/w of paraffins, it is possible to suppose an unbalance in inter-molecular bond energies at non-polar micelle and in bond energies at self-associations of parafins with no solvatic layers. In other words, the asphalt's colloidal system houses polar and non-polar micelle, paraffinic molecules associated among themselves, and free paraffin molecules, among others; we will suppose that, at the aforementioned conditions (2,5% w/w of paraffins, and temperatures of 40 and 46°C), most of the paraffinic molecules are grouped in non-polar micelle, as confirmed by data for TSR (maximum resistance to humidity at 25°C). In order to destroy this system, only the solvatic layers should be destroyed. With an increase of paraffins in the asphalt, up to a 3,5% w/w proportion, bonds in paraffin self-associations appear; these bonds also demand energy to be destroyed. However, this explanation is only valid for the phenomenon at the 3,5 and 2,5% w/w values; for quantities exceeding these values and while at higher temperatures, the molecule thermal movements effect predominates.

The aforementioned effects should vary, according to the asphalt's chemical composition (that is, to its nature or origin). Restructuring of the asphalt's colloidal system through the addition of heavy paraffins is observed in the changing of the asphalt, from "sol"-type to "gel"-type. This effect shall be more noticeable for asphalts that feature a disperse phase with higher polarity values.

CONCLUSIONS

-

Results confirm the significant influence heavy paraffins have on the molecular restructuring of asphalt; that is, on the formation of the colloidal structure of the analyzed asphalt.

-

The aforementioned influence produces a change in the asphalt's properties.

-

The maximum increase in resistance to humidity was identified for the CIB asphalt at the point featuring a content of 2,5% w/w of heavy paraffins. The inverse proportion of TSR values against Penetration values at the 0,5-4,0% w/w range for added paraffins was also defined, a phenomenon that had not been mentioned in previous literature.

-

It is concluded that added paraffin acts within the asphaltic system, simultaneously as a coagulator and a plasticizer. As a coagulator, it forms micelles with a non-polar nucleus that causes, in turn, an increase in adhesiveness and is reflected in the increase of TSR values. As a plasticizer, it reduces viscosity, a fact that may prove practically valuable for efforts to reduce blending temperatures and compacting processes.

-

As per Figure 4, it was determined that for quantities exceeding 0,75% w/w of paraffins, the CIB asphalt's usage range changes, displacing it to the low-temperatures area. This means, it should be used in colder weathers.

-

Presence of heavy paraffins, at the proper quantities for each type of asphalt, should be beneficial, due to their characteristics at low temperatures, supporting the product's plasticizing. These properties should be properly verified under regulations currently in force.

-

To determine and verify the optimal quantity of heavy paraffins required for each type of asphalt, it is necessary to carry out assays with different percentages of paraffins.

REFERENCES

Durrien F. and Vaillant D., 1985. "Bull, lails Lab ponts et chaussees". Paris, N138, 124p. [ Links ]

Khudiakova, T. S., Strijev, E. F., Mashkova, I. A. and Sichev, M. M., 1989. "La adhesividad del betún como una función de la composición química y estructura". Revista de Química Aplicada, 8: 1849-1853. [ Links ]

Khudiakova, T. S., Rozental, D. A. and Mashkova, I. A., 1991. "Propiedades de adhesión de los betunes petroleros y métodos de su corrección". Química, Moscú, 40p. [ Links ]

Kolbanovskaya, A. S. and Mihailov, V. V., 1973. "Bitúmenes viales". Transporte, Moscú, 264p. [ Links ]

Kolbanovskaya, A. S., 1968. "Desarrollo de las estructuras dispersas en los modelos de betunes petroleros". Revista coloidal, 30: 393-398. [ Links ]

Pfeiffer, J. Rh., 1950. "The properties of the Asphaltic Bitumen". New York, Amsterdam, London, Elsevier, 285p. [ Links ]

Pfeiffer, J. Rh., Saat, R. N., 1940. "Journal of Physical Chemistry", 44: 39-149. [ Links ]

Pfeiffer, J. Rh. and Dormaal, P. P, 1940. "Journal of Physical Chemistry", 44: 149-165. [ Links ]

Pfeiffer, J. Rh. and Labout, J. W., 1936. "Journal of Physical Chemistry", 32: 414. [ Links ]

Rostler, F. S., 1979. "Fractional composition: Analytical y Functional Significance". Vol. 2, Asphalts, Edited by Arnold J. Holberg. Huntington, New York, Robert E. Krieger Publishing Company. [ Links ]

Rozental, D. A., Bereznikov, A. V. and Kudriavtceva, I. N., 1979. "Asfaltos, producción y modificación". Química, Leningrad, 132p. [ Links ]

US Pat. 53974459. "Process to produce lube oil basestock by low severity hydrotreating of used industrial circulating oils". [ Links ]

US Pat. 5580376. "Asphalt improvement". [ Links ]

US Pat. 5904760. "Rerefined oil or hydrofinished neutral oil for blending superpave asphalt with low temperature properties". [ Links ]

US Pat. 5911817. "Process for paving with asphalt containing mineral lubricating oil base stock". [ Links ]

US Pat.5961709. "Environmentally improved asphalt compositions and their preparation". [ Links ]

US Pat. 6027557. "Oxidized blends of asphalt and paraffinic base stock fluxing component having improved low temperature properties". [ Links ]

US Pat. 6048447. "Asphalt compositions containing solvent deasphalted bottoms and rerefined lube oil bottoms, and their preparation". [ Links ]

ANNEXES