Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

CT&F - Ciencia, Tecnología y Futuro

Print version ISSN 0122-5383On-line version ISSN 2382-4581

C.T.F Cienc. Tecnol. Futuro vol.3 no.3 Bucaramanga Jan./Dec. 2007

DESIGN AND APPLICATION OF FLOTATION SYSTEMS FOR THE TREATMENT OF REINJECTED WATER IN A COLOMBIAN PETROLEUM FIELD

Diseño y aplicación de sistemas de flotación para tratamiento de agua de reinyeccion en un campo petrolero colombiano

Jorge-Enrique Forero1, Olga-Patricia Ortiz2, and José-Javier Duque1

1Ecopetrol S.A.- Instituto Colombiano del Petróleo, A.A. 4185, Bucaramanga, Santander, Colombia To whom correspondence may be addressed

2Universidad Industrial de Santander, UIS - Escuela de Ingeniería de Petróleos, Bucaramanga, Santander, Colombia e-mail: jorge.forero@ecopetrol.com.co

This document presents the application of a new flotation process, developed by Ecopetrol S.A., for the treatment of produced or residual production waters for injection. Recently, treatment costs of these waters have increased due to stricter quality specifications, especially in the content of suspended solids and emulsified oils, which should be eliminated to minimum levels (less than 5 ppm). In the same way, in the increase of the volumes to be treated, which have elevated –in some cases- more than 100 times. Considering the industrial results obtained, we observed that the application in this flotation process in production fields is a valuable treatment alternative, with advantages over the conventional processes, in terms of efficiency, energy, financial and of process.

Keywords: separation, oil, water, flotation, emulsion, waste water, produced water, oil-fields, produced water re-injection, induced gas flotation.

En este articulo de presenta la aplicación de un nuevo proceso de flotación, desarrollado por Ecopetrol S.A., para el tratamiento de agua de producción o residual para inyección en campos de producción de petróleo. Últimamente el costo de tratamiento de estas aguas se ha incrementado debido a condiciones de calidad mas estrictas, especialmente en el contenido de sólidos en suspención y/o hidrocarburos en emulsión, los cuales deben ser tratados hasta niveles muy bajos (menores a 5 ppm). Además también se han incrementado considerablemente el volumen de agua a tratar, en algunos casos, hasta en 100 veces. Considerando los resultados obtenidos de la aplicación industrial de este proceso de flotación, se observó que es una alternativa muy valiosa, con ventajas sobre los procesos convencionales, especialmente en términos de eficiencia, consumo de energía, costos y de proceso.

Palabras clave: separación, aceite, agua, flotación, emulsión, agua residual, agua de producción, campos de producción, reinyección de agua de producción, flotación por gas inducido.

INTRODUCTION

The injection and re-injection of produced water is a widely used process in petroleum production fields, since it is a relatively economical way of improving the recovery factor of the hydrocarbons in a reservoir, since it establishes external propulsion mechanisms and because it is an element to maintain the system pressure. Also, it is an alternate disposition mechanism of produce waters (Abou-Sayed, 2005).

The mechanism of injection or re-injection of water generally duplicates the amount of oil recoverable reserves. However, there exists a factor that is of vital importance to achieve the virtues this technology has to offer in an effective manner, and it is the quality of the water to be injected.

In general, the water should be oxygen free -which causes corrosion within injection tubing equipment – and of solid or liquid particles – which cause clogging in the reservoir-. All this causes damages of such magnitude that would severely limit the production of hydrocarbons, generate irreversible losses at the reservoir or significantly increase the injection costs; to such a point that they could cause the abandonment of the field with a recovery factor less then they could obtain with a primary recovery process (Abou-Sayed, 2005).

In this article we present the experiences of the San Francisco field in Colombia, in which the re-injection of production water at the reservoir is used, as an improved recovery activity. The treatment process of production water used at this field is typical of these systems, whereby separation through gravity procedures are employed - for sediment forming compounds-, and filtration in sand and vegetable layers –for suspended particles-.

However, due to the increase of the abundant water to be treated, the process began presenting limitations on the quality of water to be injected (with a content of oil and/or suspended solids, > 3 mg/dm3) making it especially difficult in the separation of suspended particles, which are principally separated by filtration layers. Therefore, considering the economics of the system, the general efficiency should be increased limiting the growth in the filtration process capacity. Due to the high operational cost and complexity of the filtration process, since the capacity has increased in more than 100% from its initiation, in previous projects of improvement of the treatment process of water for re-injection.

With this purpose Ecopetrol proposed the use of a new flotation system, developed at the Instituto Colombiano del Petróleo (ICP) (Forero, 1999) after of evaluated different process in pilot plant, with the goal of reducing the content of suspended particles in the water (hydrocarbons, solids) which are sent to filtration and whose objective is to increase the operation cycle of this phase and minimize the material to be separated through filtration.

Due to this development being preliminarily evaluated under laboratory conditions and at the pilot plant, it should be adjusted to the real physical-chemical conditions of the fluids at water treatment plant of the San Francisco field. Therefore, the flotation process efficiency of the fields own waters were evaluated and the most appropriate operational conditions for this system in particular are determined (pH, pressure, residence time, turbulence, bubble size , collision process, number of bubbles, and others) (Al-Shamran, 2001; Matijevi, E., 1981). It is important to take into account that the behavior of a separation process completely depends on the characteristics of the mixture water-crude, specifically of the physical-chemical properties of crude oil and the diameter of the suspended particles (Plebon, 2004a), and on the dynamic conditions of contact suspended particles/gas bubbles in the particular tanks available in this case. (Pyke, 2004; Lee, 2003; Lee, 2002).

Once these conditions were determined, the process was installed in the transference tanks in each of the plants that are currently found operating. The results obtained show that with the installation of this system, an efficiency of 70% of the hydrocarbons separation is easily reached instead 10% to 15% of separation by action of gravity, in a skimmed conventional tank available in the previous process at the San Francisco field.

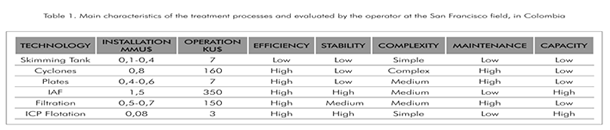

It is essential to highlight that the system developed at Ecopetrol-ICP, was selected by the field operator after evaluating other renowned processes and technologies taking into account factors such as costs, dependability, efficiency, maintenance, control, among others, as shown in Table 1.

THEORICAL BACKGROUND

The San Francisco field uses the injection mechanism of a mixture of production water and water from an external source as a method of enhanced oil recovery. The water necessary for this process should be previously treated with the objective of complying with some minimum prerequisites for this field, in reference to solid content and hydrocarbon content (< 3 mg/dm3). To reach these conditions a demanding and expensive treatment is needed, especially in waters of this quality that under normal conditions present a concentration of suspended particles before filtration greater than 200 mg/dm3.

Many technologies exist throughout the world available for processing this type of water (Plebon, 2004b). For the system conditions, factors were evaluated such as installation and operating costs, efficiency, sensitivity to changes to the load, maintenance, complexity, among others. The system considered most appropriate was the flotation process developed by Ecopetrol-ICP; the information for the decision-making is summed up in Table 1.

The system designed by Ecopetrol-ICP, is based on the injection of air or production gas using water as the driving fluid through the injector nozzles. Under these conditions, the flotation kinetic is similar to a process of Dissolved Air Flotation (DAF) but with less energy consumption, similar to the Induced Air Flotation (IAF) process.

This system, as well as being efficient, is also flexible, which allows it to be adaptable to specific geometric conditions and to additional processes such as the removal of absorbed gases, aeration and homogenization, among others. Given the high content of hydrocarbons present in water associated with the production of crude of the San Francisco field, it was necessary to develop an alternate technique from the cost/benefit point of view, to achieve its separation to permissible levels; in such a way that the water that is re-injected does not cause damage to the production formation and does not affect the recovery process. This technique is an adaptation of the flotation system designed by Ecopetrol-ICP, in accordance with the particular characteristics of the fluids and infrastructure available in the treatment deposits at the San Francisco field.

The presence of insoluble elements in residual water for re-injection, such as: oil, grease and solids in the final phases of the residual waters treatment processes are generally found in the form of stable suspended particle systems. These propose a challenge to the conventional physical-chemical treatment technologies, based on separation by density differences, gravity and the use of binding additives or common coagulants.

When the stability of these suspensions is high, the separation efficiency of the conventional systems is very low, generating high costs and low reliability.

The stability of these suspensions is favored by physical factors as well as chemical ones. Among the most important and frequent can be found the following:

- The presence of surfactant substances.

- The small diameter of suspended particles.

- The low concentration of suspended elements.

- The low density difference between the system phases.Given that quality restrictions for the use of water as an injection fluid are getting more demanding, and that generally in production fields water flow increases as time passes, conventional treatments can become a significant proportion in the economics of the process, which can even make it so there is no real incentive to operate these surface facilities.

Therefore, the objective of this document is to continue with the development of a technology that has been evaluated at a laboratory and pilot plant scale, but that it be useful in the treatment of waters in real industrial scenarios like those mentioned here.

Basic theory of separation

The removal of oil, grease and solids from production waters can be achieved using various well known and accepted techniques. However, the application of each of these technologies depends on the quality, characteristics and conditions of the particular water-oil mixture.

The majority of the current techniques for the realization of this separation treatment are based on the difference in density, the separation is measured by the Stokes Law, and which establishes that the separation velocity (Vs) is a function of the square of the particles diameter.

Where:

Vs = Particle separation velocity

g = Gravity’s acceleration

ρa = Water density

ρo = Oil density

d = Particle diameter (oil /solid)

μ = Continuing phase viscosity (water)

According to this law, we can see that the size of the particle is the most important factor in designing water-oil separator systems, because of the significant impact on separation velocity value. The majority of conventional technologies currently in use only manipulate this variable by means of increasing resident time, or by the use of binding agents and/or coagulants. However, with less importance but as an influential factor in the separation velocity, there are factors such as the density difference, the viscosity and even gravity acceleration.

Consequently, the bigger the droplet, the less will be the separation time of the suspended particles, the oil could be present in the water as a free or emulsified oil. In general, free oil can be defined as a particle whose size is greater than 500 microns, and which –under normal conditions- can always separate quickly when there are acceptable values in the density differences. This does not always manifest itself, especially when the residual waters come from the treatment of heavy crudes.

It is considered that when suspended particles in water from oil and solids have a diameter of less than 150 microns, you have an emulsion. This is because the separation time is of a magnitude that makes the conventional method of water treatment not economically viable. When the size of the particles in suspension are less than 50 microns, the application of standard systems of separation by gravity are inefficient in the treatment of water.

These emulsions can be classified into two main categories: emulsions from mechanical processes,and those from chemical processes. The chemical emulsions are formed through the presence of substances that act in the oil and/or solid/water interface, eliminating the forces of attraction between the suspended particles and establishing the equilibrium between the different phases.

These particular conditions of water and oil mixtures, considered stable emulsions in the residual water treatment processes, are the points of interest in the development of this document; therefore, the principal objective in these conditions is to destabilize the system in a way that the particles can be separated through the effects of gravity in conventional systems.

Separation technologies

The main gravity separation systems are API separators, Parallel Plate Interceptors (PPI) and Corrugated Plate Interceptors (CPI). It is generally considered that the efficiency of this equipment under normal operating conditions is enough to separate suspended particles larger than 150 µ.

Another common method of separation is to manipulate the difference of density in phases to be separated, associating gas to suspended particles, which decreases total particle density and causes separation speed to increase.

The nature of interphasial forces is also changed, and this increases attraction forces for suspended particles in order to bind them, increasing their size of the suspended bodies. To do this it is common to employ substances such as binding agents, demulsifiers, aluminum and iron compounds, cationic poly-electrolyte that in general improve the efficiency of separation systems, either by gravity or by flotation.

The gravity acceleration variable is also manipulated in systems where particles are subject to centrifugal forces, which increase the gravitational field at different levels of magnitude (generally between two and four). This is enough to obtain a separation of particles between 10 and 15 μ in hydrocyclones and between 3 and 7 μ in high-efficiency centrifuges. Centrifugal forces cause the heavy phase to concentrate on the separator walls and a lighter particles to concentrate on the central part with lower pressure, where they can be recovered.

Filtering is thought to be the other alternative for water – oil separation processes; however, its use is limited due to its high maintenance costs. Oil and solids are retained in the filtering medium, which makes this process discontinuous because when the medium is saturated it must be replaced or regenerated . It is common to use multiple layer systems; the most common materials used are sand, anthracite and oleolific materials such as nutshells and pecan. In these systems the regeneration periods are generally between 24 and 72 hours.

It is also possible to perform the water treatment with active carbon systems and membrane filtering. These processes are used in very specific situations due to their high installation and operating costs.

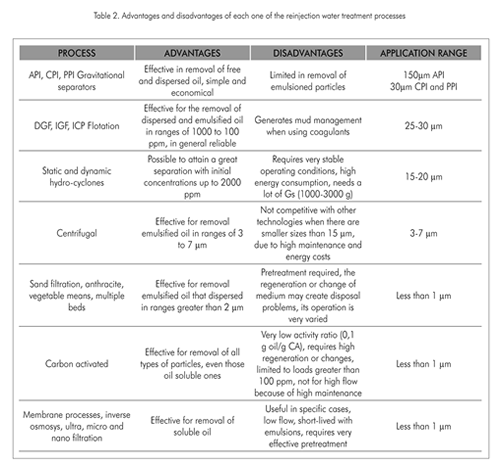

Table 2 shows the main advantages and disadvantages for each of the previously mentioned systems.

Industrial experimental evaluation

This paper evaluates the main operating conditions for the flotation system, designed by Ecopetrol-ICP for the treatment of residual waters in an oil-producing field, destined for reinjection and in order to improve fluid recovery from the formation.

This work takes the operating conditions recommended in the prior work (Forero, 1999), bearing in mind that this system was evaluated under pilot plant conditions, in a closed system and using a synthetic mixture of crude oil in water, with average particle sizes vary in between 30 and 150 μm. Basically, the best operating conditions were determined for optimizing the bubble size, considering injector flow and pressure conditions. For this case, it was necessary to determine the influence of operating conditions, like those of the true industrial scale system, such as:

- Residence time.

- Bubble density (function of the relation of water circulation to the flotation tanks).

- Bubble diameter (pressure function for injectors).

- The use of binding additives and pH control.

Experimental methodology for industrial plants

The methodology used is basically the same reported in the evaluation of the plant pilot (Forero, 1999). Nevertheless, further on some necessary differences are mentioned to determine variables common to a continuous system:

- Adapting a flotation cell with similar geometry to the real tank available.

- Time of constant residence (50 min.).

Description of industrial system

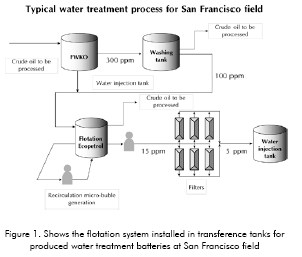

Figure 1 shows a scheme of the industrial treatment system for water injection.

The flotation tanks, whose general scheme is shown in Figure 2, have a capacity of 477 m³ (3000 barrels). The adjustments and/or modifications that were performed on these tanks were the following:

- Installation of a central distributor, allowing the water loaded into the flotation tank to generate a piston-like flow pattern, keeping a distribution of the residence time, stable and least for 95% of the flow to be treated. This is due to the fact that the available array this distribution was dispersed, since the water entering the system was quickly suctioned by the transference pumps. Through this line the water from the Gun Barrels enters the Free Water Knock Out (FWKO) (treatment load). This is located 2,40 m (8 ft) from the bottom of the tank.

- Installation of a line that rests on the tank wall, which allows gas from the gas blanket system to pass through the nozzles, by means of derivation collars and high-resistance hoses.

- Installation of a recirculation system that allows part of the treated water to reenter the system as moving fluid for the process of generating gas bubbles. This system is made up of a distributor tank, fixed to the floor by supports, from which dispense tubing branch out. These supports hold the micro bubble generating nozzles, according to the geometric pattern established.

The majority of the elements installed were made of fiberglass, although some accessories installed were manufactured from PVC and Kynar.

System operation

Water to be treated enters the transference tank from gun barrels and from the FWKO through the central distributor. Bearing in mind the results obtained in this study for the plant pilot (Forero, 1999), the operation of the flotation system requires recirculating part of the treated water. For this reason, discharge water was taken from the transference pumps, so that 15% of the water was recirculated, and no recirculation was taken from the 30% to 40% range because of system pumping capacity. Generation of these micro-bubbles constitute a key factor for the flotation process, because as reported by Strickland (1980) and Sander (1994) it is necessary that micro bubbles generated are distributed throughout the body of water to be treated, colliding with the material to be removed and this mixture rise facilitating its separation. With the elements installed a hydrocarbon layer may be obtained floating on the surface of the water being treated, which is removed by the floating skimmer.

Analysis of results

Although, due to operation factors, the system was operating under conditions different to those contemplated in the original design (more load and a higher oil content to be removed, less residence time, less recirculated water, without the use of additives, without pH control) removal efficiency higher than 50% has been achieved.

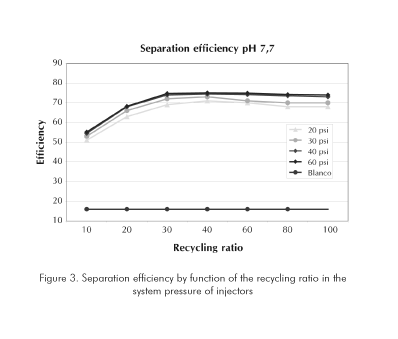

Figure 3 shows the influence of the recycling ratio, that is the percentage of treated water recycled flowing into the test tank, maintaining a residence time of 50 minutes. These gravity separation conditions only show an efficiency of nearly 16%, with regard to the flotation system. It can be observed that with low recirculation ratios (low density of bubbles) the flotation efficiency is low, fluctuating between 50 and 60%. This increases until achieving a recycling ratio between 30 and 40%, after which growth is not representative and on the contrary, when the ratio surpasses 60% values, a small reduction in efficiency may be seen, which is more noticeable at low pressures. This may be explained by the fact that the turbulence/density ratio for bubbles increases when recycling water flow is higher, causing bubble unions and suspended particles to become unstable, thus decreasing separation efficiency.

As it may be observed, the pressure of the injection system proposed is highly influential in separation efficiency. The higher the pressure, the more the efficiency; however, after 40 psi pressure increase does not seem to have great impact on separation efficiency, since even though the pressure increases, this increase does not compensate for the energy increase required to reach pressures above the 60 psi. Another tendency observed is that with ratios over 40%, separation efficiency does not increase noticeably and just the opposite, under some operating conditions it decreases. It is important to highlight that this consideration depends on residence time in the system, and possibly with lower residence times – not evaluated in this paper – the optimum recycling ratio may be higher than that found here.

According to these results, adequate operating pressure for this system is considered to be between 30 and 40 psi.

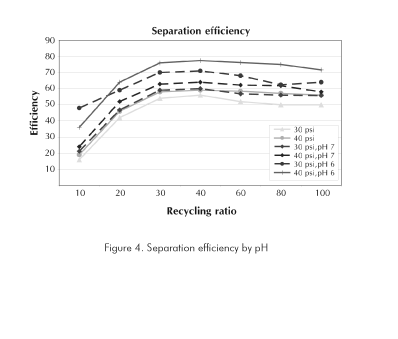

Figure 4 shows the influence of pH on separation efficiency for the evaluation sample. The pH was modified for these experimental conditions in the sample with the 0,1N hydrochloric acid solution. It can be seen that separation efficiency is markedly improved when pH becomes slightly acid (pH 6,0). This result suggests that due to the nature of the natural emulsion evaluated, it is maintained by the basic natural surfactants that are neutralized by the acid. In this case, controlling pH has an important impact on efficiency of the entire system, rendering improvement between 10 and 15%.

Regarding the use of binding additives, two types of commercial aluminum and polymer salt-based binding agents were evaluated for this experiment, using a concentration of 500 ppm. It may be seen that the polymer’s action on separation is very important. Under these experimental conditions, it may be observed that the influence of additives used (Figure 5) may represent a 15 to 25% increase in efficiency. According to results obtained, there is a marked difference with the incidence of the type of additives used, since the changes of efficiency are different (5%-10%). Nevertheless, no marked difference was detected in system pressure for the range of work.

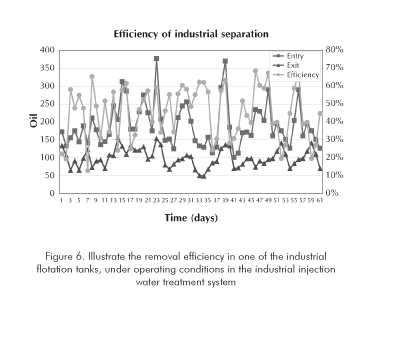

Figure 6 illustrate the removal efficiency in one of the industrial flotation tanks, under operating conditions in the industrial injection water treatment system.

It is evident that on the average efficiency is very variable (30%-70%), especially due to the unstableness of the flow and system pressure. However, there is a 50% measure that represents an efficiency increase in this system specifically of more than four times with regard to separation by gravity.

In order to determine if the increase in oil removal was caused by the flotation system or by gravity, recirculation was eliminated in such a way that it was inoperable in the flotation system. This test was initially run for 24 hours, time during which hydrocarbon content removal in the water decreased remarkably, with hydrocarbon content in treated water going from 55 ppm to 200 ppm, on the average.

It was thus determined that the flotation system in an industrial tank greatly favors oil content reduction in a body of treated water.

Figure 7 shows the effect of the operation in the new flotation system for processing re-injection water. This effect shows that when the process is set in place, the quality of injection water reached recommended parameters. Furthermore, it also illustrated that the maintenance period for the filtration systems increased more than 2,5 times, which reflect the least mud production, making the system operation more economical and efficient.

CONCLUSIONS

-The flotation system proposed shows an average 75% separation efficiency under operating conditions (50 min. residence time), in production water that when undergoing separation by gravity only exhibit an average 16% separation efficiency.

- One of the most influential variables for flotation system efficiency is the recycling ratio, which under evaluation conditions exhibits a growing proportional efficiency, until this ratio reaches values of 60%. The higher the recirculation ratios, the more efficiency remains constant and even diminishes.

- The reduction in separation efficiency to recirculation ratios greater than 60%, are more evident at lower pressures, may be due to the fact that the turbulence/ density of bubbles ratio in regard to recycling water flow.

- The pressure in the bubble generating system positively influences the separation efficiency, and it is recommended to operate at 40 psi. Nevertheless, the increase in pressure from this point is not of major importance for separation efficiency, since the increase is not compensated by energy consumption required to achieve pressures greater than 60 psi.

- It can be seen that separation efficiency is markedly improved when pH becomes slightly acid (pH 6,0). In this case, controlling pH has an important impact on efficiency of the entire system, rendering improvement between 10 and 15%.

- The influence of additives in separation is very important, and it may mean an efficiency increase between 15 and 25% under evaluation conditions.

- There is a noticeable difference with the incidence of the type of additives used, since the changes of efficiency are different (5%-10%). Nevertheless, no marked difference was detected in system pressure for the range of work.

- This flotation system developed by Ecopetrol-ICP in closed systems represents an efficient and economical solution for the ongoing process of injection water treatment at production fields.

- Installation, operating and maintenance costs for the flotation system implemented do not exceed 30% of the most economic activities presented for treatment of injection water at the San Francisco field (cyclone, skimming tanks, plate separators, flotation cells).

- It is important to evaluate each one of the systems individually, in order to determine optimum operating conditions by physical – chemical characteristics for water, oil, solid systems.

- For the case evaluated, it is estimated that the use of the greater recirculation conditions, binding additives and pH controllers could achieve an increase in separation efficiency for the range is between 25 and 30%, making the system more efficient and economical.

ACKNOWLEDGEMENTS

The authors give special thanks to Juan F. Ardila, Carlos F. Rueda, Fredy Nariño and the Cantagallo oil field team, the for their very important support in this technology industrial application. This research was supported by Ecopetrol S.A., and the Instituto Colombiano del Petroleo (ICP).

REFERENCES

Abou-Sayed, A (2005). Produced water management strategy- saving the asset from drowning in produced water. Business Briefing: Exploration & Production: The oil & Gas Review,106-110. [ Links ]

Al-Shamran, A.A. (2001). Separation of oil from water by dissolved air flotation. Department of Chemical Engineering, Environmental Technology Centre.The University of Manchester, Institute of Science and Technology UMIST, Manchester, UK, Dec.13. [ Links ]

Forero, J.E., Diaz, J., & Blandón, V.R. (1999). Diseño de un nuevo sistema de flotación para tratamiento de aguas industriales. CTYF- Ciencia Tecnología y Futuro, 1 (5): 67-75. [ Links ]

Lee, J.E. (2003). A Study of the Bubble Properties in the Column Flotation System. HydroLab Institute, Sum-Jin EST Company, School of Mechanical Engineering, Pusan National University, San 30, Changjeon-Dong, Keumjeong-Ku, Busan 609-735, Korea; April 17. [ Links ]

Lee, J.E. (2002). Effect of Microbubbles and Particle Size on the Particle Collection in the Column Flotation. HydroLab Institute, Sum-Jin EST Company, Songjeong-Dong, Gangseo-Gu, Busan 618-270, Korea. Department of Mechanical Engineering, Pusan National University, Pusan, Korea. [ Links ]

Matijevi, E. (1981). Interactions in mixed colloidal systems (heterocoagulation, adhesion, microflotation). Pure & Appl.Chem., 153: 2167-2179. Institute of Colloid and Surface Science and Department of Chemistry, Clarkson College of Technology, Potsdam, New York, USA. [ Links ]

Plebon, M.J. (2004a). Advances in Total Oil Remediation and Recovery system for Produced Water. EARTH -Canada- Corporation, Montreal, Quebec, Canada. [ Links ]

Plebon, M.J. (2004b). Advances in produced water oiling utilizing a recently developed technology which removes recovers dispersed oil in produced water 2 microns and larger. EARTH -Canada- Corporation, Montreal, Quebec, Canada. [ Links ]

Pyke, B. (2004). Bubble-Particle Capture in Turbulent Flotation Systems. (B. App.Sci.(Hons), B. Bus), Ian Wark Research Institute, University of South Australia, Adelaide, Australia. [ Links ]

Sander, E., De Rijk., Jaap, H.J.M., Van D.G.,y Jan, G.D. B. (1994). Bubble size in flotation thickening. Delft University of Technology, Faculty of Civil Engineering and Water Managemente, Delf, The Netherlands, 465-473. [ Links ]

Strickland, T. Jr. (1980). Laboratory results of cleaning produced water by gas flotation. SPE Journal 7805, Shell Development Co., 175-190. [ Links ]

(Received May 30, 2007; Accepted Oct. 12, 2007)