Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

CT&F - Ciencia, Tecnología y Futuro

Print version ISSN 0122-5383

C.T.F Cienc. Tecnol. Futuro vol.5 no.1 Bucaramanga July/Dec. 2012

PARTICLE MATTER FROM A DIESEL ENGINE FUELED WITH JATROPHA CURCAS OIL BIODIESEL AND ULTRA-LOW SULPHUR DIESEL

MATERIAL PARTICULADO EN MOTORES OPERADOS CON BIODIESEL DE ACEITE DE JATROPA CURCAS Y DIESEL DE BAJO CONTENIDO DE AZUFRE

Helmer-Rodolfo Acevedo-Gamboa1* and Elkin-Gregorio Flórez-Serrano2

1Universidad Nacional de Colombia, Bogotá, Cundinamarca, Colombia

2Universidad de Pamplona, Pamplona, Norte de Santander, Colombia

E-mail: hracevedog@unal.edu.co

(Received Jul. 24, 2012; Accepted Nov. 02, 2012)

*To whom correspondence should be addressed

ABSTRACT

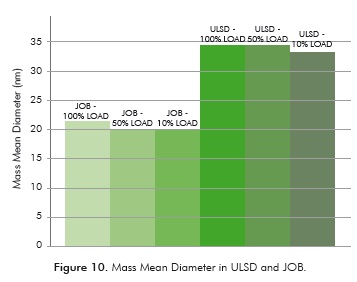

Biodiesels are promoted as alternative fuels due to their potential to reduce dependency on fossil fuels and carbon emissions. Research in this field has focused on the study of the emissions of light duty vehicles. However, particle matter and gaseous emissions emitted from heavy-duty diesel engines fueled by Jatropha Oil Biodiesel (JOB) and Ultra-Low Sulphur Diesel (ULSD) has not been studied. The objective of this study is to explore the performance and emission levels of a Cummins 4-stroke, 4.8 liter, 4-cylinder diesel engine with common rail fuel injection, equipped with a cooled Exhaust Gas Recirculation (EGR). There was a substantial reduction by the use of JOB in unburned hydrocarbons (- 45%), carbon monoxide (- 75%), and particulate matter (- 25%) compared to emission from diesel fuel. At mid and high loads, NOx emissions were higher for JOB compared to ULSD. Most of the particles (64%) for ULSD were in a range of between 40 and 560 nm. On the other hand, most of the particles (94%) for JCB mode were between 6 and 40 nm. In the range between 6 and 40 nm, mass mean diameters in ULSD were 34.4, 34.7 and 33.3 nm while for JOB they were 21.3, 18.2 and 20.1 nm for 100, 50 for a 10% load, respectively.

Keywords: Diesel engines, Alternative biofuels, Particle size distribution, Nanoparticles of biodiesel, Emissions.

RESUMEN

El biodiesel se ha promocionado como un combustible alternativo para reducir la dependencia de los combustibles fósiles y emisiones de carbono. La investigación en este campo se ha enfocado en el estudio de emisiones de vehículos de baja capacidad. Sin embargo, no se han estudiado las emisiones de vehículos de trabajo pesado operados con Biodiesel de Aceite de Jatropa (BAJ) y Diesel de Bajo Contenido de Azufre (DBCA). El objetivo de este estudio fue explorar el desempeño y los niveles de emisión de un motor Cummins de 4 tiempos, 4.8 litros, 4 cilindros, en ciclo diesel, con un sistema de inyección de riel común, dotado de un inter-enfriador con válvula de recirculación de gases (VRG). Se observó reducción sustancial con el uso de BAJ en los hidrocarburos sin quemar (-45%), en el monóxido de carbono (-75%), y el material particulado (-25%). Muchas partículas (64%) para DBCA estuvieron en el rango entre 40 y 560 nm. Por otro lado, muchas de las partículas (94%) para BAJ estuvieron entre 6 y 40 nm. En el rango entre 6 y 40 nm, el diámetro medio másico para BDCA fueron 34.4, 34.7 y 33.3 nm, mientras que para BAJ fueron 21.3, 18.2 y 20.1 nm para 100, 50 y 10% de carga, respectivamente.

Palabras clave: Motores diesel, Biocombustibles alternativos, Distribución de tamaño de partículas, Nanopartículas de biodiesel, Emisiones.

RESUMO

Obiodiesel tem se promovido como um combustível alternativo para reduzir a dependência dos combustíveis fósseis e emissões de carbono. A pesquisa neste campo tem se enfocado no estudo de emissões de veículos de baixa capacidade. Entretanto, não se estudou as emissões de veículos de trabalho pesado operados com Biodiesel de Óleo de Jatropha (BAJ) e Diesel de Baixo Conteúdo de Enxofre (DBCA). O objetivo deste estudo foi explorar o desempenho e os níveis de emissão de um motor Cummins de 4 tempos, 4.8 litros, 4 cilindros, em ciclo diesel, com um sistema de injeção de trilho comum, dotado de um inter-resfriador com válvula de recirculação de gases (VRG). Observou-se redução substancial com o uso de BAJ nos hidrocarbonetos sem queimar (-45%), no monóxido de carbono (-75%), e o material particulado (-25%). Muitas partículas (64%) para DBCA estiveram na categoria entre 40 e 560 nm. Por outro lado, muitas das partículas (94%) para BAJ estiveram entre 6 e 40 nm. Na categoria entre 6 e 40 nm, o diâmetro médio mássico para DBCA foram 34.4, 34.7 e 33.3 nm, enquanto que para BAJ foram 21.3, 18.2 e 20.1 nm para 100, 50 e 10% de carga, respectivamente.

Palavras chave: Motores diesel, Biocombustíveis alternativos, Distribuição de tamanho de partículas, Nanopartículas de biodiesel, Emissões.

1. INTRODUCTION

Over the last few decades, the great worry has been that petroleum-based fuels will soon no longer be available. Therefore, one of engineering's main goals for this century is to discover and/or develop new sources of energy that may one day replace petroleum-based fuels. In order to achieve this goal, it must also be taken into account the fact that the emission gases of regular fuels currently used are the main agents that have contributed to global warming and have polluted most urban areas affecting the environment. Particularly this has affected the health of the people, not only those who live near factories, but in much wider areas, since these fuels are also used to provide energy for most of the means of transportation. Biodiesel is a generic term that refers to various fatty-acid mono-esters that can be used for diesel fuel. It is made from the conversion of triglyceride (vegetable oil and animal fats) to esters (primarily methyl esters) via various esterification processes (Graboski & Mccormick, 1998). On the one hand, biodiesel has physical properties very similar to those of conventional diesel fuel (Babu & Devaradjane, 2003); but it is renewable, non-toxic, and biodegradable. Biodiesel is the only alternative fuel to have fully passed the health-effects testing requirements of the Clean Air Act.

Biodiesel can be blended in any proportion with petroleum diesel fuel and blended biodiesel, mainly in blends of 20% (B20) or less, and can be used in most conventional diesel engines with little or no modification. However, only a few manufacturers recommend operating their engines with blends higher than B5.

One of the most important advantages of using biodiesel is the reduction of emissions. Emissions of total Particle Matter (PM), Carbon Monoxide (CO), and Hydrocarbons (HC) are reduced by using biodiesel fuel (Bagley, Gratz, Johnson & McDonald, 1998; McDonald, Purcell, McClure & Kittelson, 1995), while those of particle-bound volatile organic material (organic carbon) are increased (Purcell, Mcclure, Mcdonald & Basu, 1996), and those of NOx are slightly higher (McDonald et al., 1995; Bagley et al., 1998).

Studies on humans and animals show that short-term or acute exposure to Diesel emissions may cause eye, nose and pharynx irritations, as well as inflammatory responses in the air tract and lungs. They may cause allergic and immunologic effects; in worse-case scenarios even cancer. In general it is thought that biodiesel has a less adverse effect on human health than petroleum-based diesel fuel. For example, the mutagenicity of biodiesel particulate emissions is much lower than that of petroleum-based fuel (Schröder, Krahl, Munack, Krahl & Bünger, 1999; Krahl, Munack, Schröder, Stein & Bünger, 2003). On the other hand, small particles have higher specific surface areas and they are more toxic than coarse particles. In addition, small particles are more likely to be inhaled and deposited in both respiratory tracts and the alveolar region, and cause symptoms in the respiratory system (Pope et al., 1995; Health Effects Institute, 2002).

The focus of this work is to investigate the effects on particle size distribution of a compression ignition engine when it is fuelled by JOB in comparison to those of ultra-low sulphur diesel. Emissions of total PM are reduced by using biodiesel fuel (Bagley et al., 1998; McDonald et al., 1995). However, recent work suggests that the particles coming out from a diesel engine fueled with biodiesel fuel are smaller compared to ultra-low sulphur diesel (Tsolakis, 2006). This paper investigates the particle size distribution of JOB and ULSD in a range of between 5 and 560 nm (nanoparticles).

2. EXPERIMENTAL SETUP

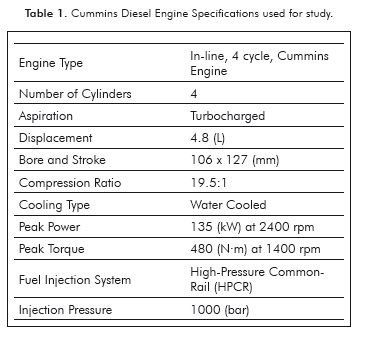

Diesel Engine and Instrumentation

The engine used in this study was a 2005 Cummins diesel engine (meets EPA2004). Specifications of this engine can be seen in Table 1. The engine was loaded with a dynamometer for load control. It was operated at three different speeds 1400, 1900 and 2400 rpm under 0, 10, 25, 50, 75 and 100% loads. The dynamometer, a Siemens DC Electric Dynamometer, which applies a load to the engine, was equipped with a load sensor to measure the torque and fuel flow by the Red Lion volumetric flow system with the uncertainty of (±1 cm3/s). Air flow was measured using a Sierra Instruments Mass Flow Meter (±0.1SCFM). All these measurement devices are connected to a National Instruments Data Logger coupled with PC. The mass fractions of different chemical components in the exhaust gases were measured by a Horiba gas analyzer. The emission bench was conformed of an 02 gas analyzer (± 0.1 %, non-disperse infrared-NDIR), a C02 gas analyzer (± 0.05 %, NDIR), a CO gas analyzer (± 0.01 %, NDIR), a M9X gas chemiluminescence analyzer (± 1 % full scale), JUM engineering heated FID analyzer (± 10ppm), and a Beckman industrial flame ionization detector (± 1ppm).

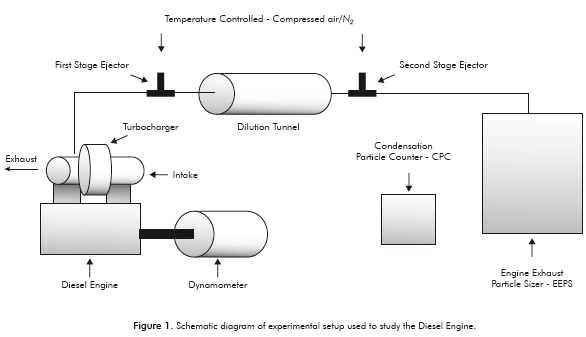

A Horiba micro soot sensor (Photo Acoustic Soot Sensor, PASS) was used to measure soot concentration in a diluted exhaust from the Cummins diesel engine. The measuring range and the detection limit of the Horiba are 0-50 mg/m3 and < 10 ug/m3, respectively. The Engine Exhaust Particle Sizer (EEPS) was used for size distribution analysis. The EEPS measures the mobility of equivalent particle diameters in the diameter range of 5.6-560 nm. The exhaust was sampled 25 cm downstream of the turbocharger exit and, was diluted in a two-stage, ejector type, variable residence time dilution tunnel, similar to the one described by (Jung, Kittelson & Zachariah, 2006) (Figure 1).

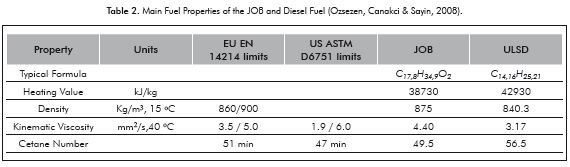

Fuel Properties

A ULSD and JOB were used in this study. Although it is unusual to use more than 20% biodiesel (B20), in this study 100% JOB was used to allow a comparison to be made with pure fuels. ULSD was selected as the base fuel. Specifications for both fuels tested are shown in Table 2. It can be seen that the heating value of JOB is lower compared to ULSD. However density and kinematic viscosity of the JOB are higher than the ULSD. Higher density and kinematic viscosity changes the fuel flow along injection system considerably and modifies the combustion process. Tuning injection systems should be addressed in order to improve fuel atomization with the use of JOB.

Statistical Analysis

Errors and uncertainties in the experiments can arise from instrument selection, condition, calibration, environment, observation, reading and test planning. Uncertainty analysis is needed to prove the accuracy of the experiments. Percentage uncertainties of various parameters like total fuel consumption, brake power, brake specific fuel consumption and brake thermal efficiency were calculated using the percentage uncertainties of various instruments used in the experiment. For the typical values of errors of various parameters given in the section Diesel Engine and Instrumentation section, using the principle of propagation of errors, the total percentage uncertainty of an experimental trial can be estimated as ± 2.3%.

3. RESULTS

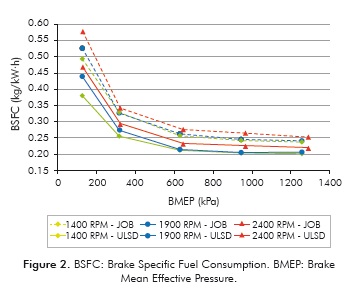

Brake Specifc Fuel Consumption (BSFC) and Thermal Effciency

Specific fuel consumption is one of the important parameters of an engine and is defined as the consumption per unit of power over a unit of time. Test results showed that the obtained minimum specific fuel consumption values were in the vicinity of the maximum power area. As shown in Figure 2, the minimum specific fuel consumption values were 0.21 kg/kW.h with ULSD at 2400 rpm, and 0.25 kg/kW.h with JOB at 2400 rpm. The higher specific fuel consumption values in the case of Jatropha oil methyl ester (+19.04%) are due to their lower energy contents. In order to maintain the same brake power output, the BSFC of Jatropha-biodiesel blends would be increased to compensate the reduced chemical energy in the fuel. The calorific value of Jat-ropha oil is lower than that of conventional diesel, this characteristic causes a higher specific fuel consumption. However the higher oxygen content should improve the combustion quality in optimum mixing conditions as a greater quantity of fuel is oxidized (Pramanik, 2003; Chaunan, Kumar & Muk, 2012).

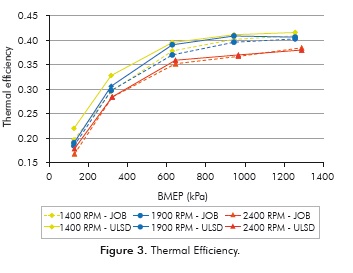

The variation of brake thermal efficiency with respect to load for different fuels considered for the present analysis is presented in Figure 3. In all cases, brake thermal efficiency has the tendency to increase with an increase in applied load. This is due to the reduction in heat loss and an increase in the power caused by an increase in load. The maximum brake thermal efficiencies obtained are 44.1% for diesel fuel and 40.9% for JOB. This lower brake thermal efficiency obtained for B100 (-7.33%) could be due to the reduction in calorific value and increase in fuel consumption as compared to diesel fuel. This complies with the increase of BSFC for JOB (+19.04%). Similar results were reported in Agarwal and Agarwal (2007).

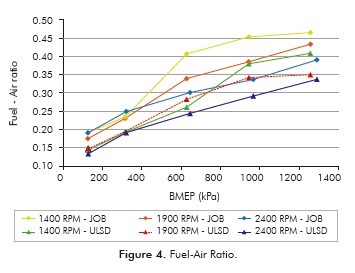

The thermal efficiency combines the effects of gross thermal efficiency, combustion efficiency (Combustion efficiency is defined as the fraction of the fuel energy supplied which is released in the combustion process), pumping efficiency, and friction. From an ideal perspective, thermal efficiency is affected by the compression ratio and the thermody-namic properties of the working mixture. The compression ratio naturally remained fixed in this study (19,5:1); thermodynamic properties of the mixture, however, changed for a couple of reasons. The first reason was the fuel-air ratio shown in Figure 4 that increases with biodiesel for most of the studied points. An increase in fuel-air ratio decreases the mixtures ratio of specific heats, which in essence decreases the potential to convert the mixtures' thermal energy to work energy. The second reason the thermodynamic properties of the mixture change with the use of biodiesel is a small change in the Exhaust Gas Recirculation (EGR) level. An increase in the EGR level, like an increase in fuel-air ratio, decreases the mixtures ratio of specific heat (Heywood, 1989).

Gaseous Emissions

The biodiesel fueled engine emits several regulated and unregulated pollutant species. This study is limited to investigating the regulated gaseous emissions. The emissions were recorded using the raw exhaust gas emission analyzer described in the Experimental Setup section.

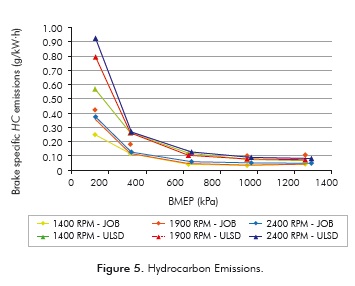

Hydrocarbon Emissions

It is observed from Figure 5 that JOB has lower HC emissions as compared to ULSD at low, mid, and high loads. This is because biodiesel is an oxygenated fuel having 10-11 % oxygen content by weight (Heywood, 1989). A general trend is that by increasing the engine load, HC mass emissions decrease, which is due to increasing pressure and temperature in the combustion chamber, which, in turn, improves the combustion of the fuel (Mazumdar & Kumar, 2008). At higher loads, JOB shows comparable emissions with ULSD.

HC emission reduction is explained by the high oxygen content of Jatropha Biodiesel which allows a better and more complete combustion, thus a greater quantity of fuel is burnt (Elango & Senthilkumar, 2011).

Although PM emission measurements were not frequently encountered within the reviewed literature, it is constantly mentioned that through jatropha biodiesel use PM emission reductions are achieved as there is a more complete combustion and thus the proportion of HC and soot emitted is reduced (Knothe, Krahl & Van Gerpen, 2010).

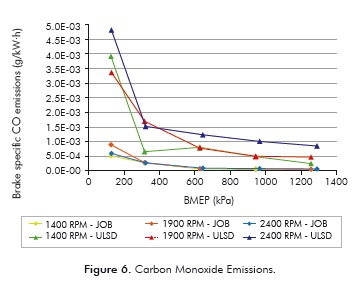

Carbon Monoxide Emissions

From Figure 6 it is clear that JOB shows significantly lower CO emissions compared to diesel fuel. JOB shows the lowest CO emissions for all engine-operating conditions. Although CO emissions are higher for diesel fuel, it is interesting to note that, in particular, the engine emits more CO using diesel fuel at low and mid loads. At low and mid loads, CO emissions from the engine fueled with diesel fuel increase due to lower availability of oxygen (Figure 4). On the contrary, CO emissions of diesel engines fueled with pure JOB are lower due to intrinsic oxygen contained by methyl esters (Sureshkumar, Velraj & Ganesan, 2008).

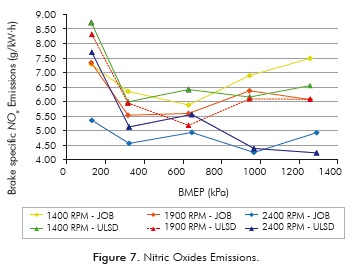

Nitric Oxides

Figure 7 shows NOx emissions for both fuels tested at the three different engine speeds and all load conditions. NOx emissions depend upon the temperature of the combustion chamber and oxygen availability (Heywood, 1989). At 1400 and 1900 rpm and a low load (up to 25%) NOx emissions are higher for ULSD than JOB. At these engine speeds and mid and high loads, NOx emissions are higher for pure JOB. At 2400 rpm, except for full load, NOx emissions are higher for ULSD compared to JOB. The magnitude of the NOx biodiesel increases concords well with previous studies (Graboski, McCormick, Alleman & Herring, 2003; Mc-Cormick et al., 2005) (Karavalakis, Stournas & Bakeas, 2009). Generally, NOx is closely related to the rate of heat release during engine operation. Consequently, the NOx emissions of biodiesel are higher than that of diesel, because the heat release rate of biodiesel is higher (Kyu, Gu & Sik, 2008). This agrees well with Prasad, Krishna, Reddy and Mohan (2012) who reported a reduction when using Jatropha oil in Low Heat Rejection diesel engines.

The ignition delay is influenced by the fuels ignition quality (defined by the cetane number), the compression ratio, engine speed, cylinder gas pressure, intake-air temperature and the quality of fuel atomization. A more important factor in the engine-out NOx emissions is an advance in the start of injection timing caused by the higher bulk modulus of compressibility of biodiesel fuel (Szybist, Boehman, Taylor & McCormick, 2005). The author of this research investigated the use of Palm Oil Biodiesel (POB) on unmodified heavy duty diesel engines (Acevedo & Mantilla, 2011). They found that POB causes NOx emissions to increase 15% compared to ULSD. In this study, the injection timing of Cummins Diesel Engine was adjusted (1 CAD) to get better results. The NOx emission results in this study indicate that adjusting the injection timing could diminish the impact on NOx emissions of diesel engines fueled with JOB.

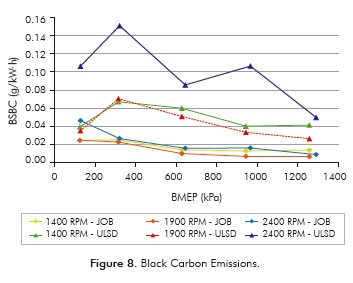

Black Carbon - Smoke Number

Brake Specific Black Carbon (BSBC) is plotted versus BMEP and can be seen in Figure 8. The mass collected on the Horiba micro soot sensor shows the Bosch number decreases with the use of JOB. This smoke number is a measure of particulate matter in the exhaust and very important in the soot reduction associated with the use of bio-diesel. In high loads and low speed applications there was essentially no soot obtained in the BSBC test. For all engine speeds and loads the use of JOB showed a drastic reduction in the black carbon emissions compared to the ultra-low sulphur diesel used in this study. Previous research (Acevedo & Mantilla, 2011) found a noted increase of BSBC of an unmodified heavy-duty diesel engine when it was fuelled by POB. Definitely advance injection timing (i.e. 1 CAD) might improve combustion of JOB in order to take advantage of JOB oxygen content.

PM is essentially composed of soot carbon, un-burned fuel, lube oil and sulfuric aerosols (Knothe et al., 2010) . The poor atomization properties of Jatropha oil could cause an increase in PM emissions particularly at high concentrations although most of the vegetable oils and their derivatives are reported to reduce them (Prasad et al., 2012).

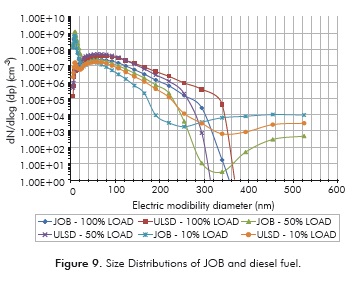

Particle Size Distribution

Emissions of total PM are reduced by using biodiesel fuel (Bagley et al., 1998; McDonald et al., 1995). However, recent work suggests that the particles coming out of a diesel engine fueled with biodiesel fuel are smaller than compared to ULSD (Tsolakis, 2006). Figure 9 shows the exhaust particle size distribution (corrected for dilution ratio) as a function of engine load at 1400 rpm using JOB and ULSD fuels. Trends seen for diesel and biodiesel fuel were similar. The concentrations of particles smaller than about 40 nm are markedly increased using JOB. The particle-size distributions in terms of the profiles of cumulative mass fractions (F) are useful in comparing the contributions of fine and coarse particles. F is 95 and 35% for particle sizes between 6 and 40 nm for JOB and ULSD, respectively. For ULSD, most of the particles are in the range between 40 and 560 nm. Mass Mean Diameters (MMD) in ULSD were 34.4, 34.7 and 33.3 nm for 100, 50 and 10% loads, respectively. On the other hand, MMDs in JOB were 21.3, 18.2 and 20.1 nm for 100, 50 and 10% loads, respectively (Figure 10). Similar results were found (Lin et al., 2008; Turrio-Baldassarri et al., 2004).

4. CONCLUSIONS

- According to the experimental results, the BSFC values were 0.21 kg/kW.h with diesel fuel and 0.25 kg/ kW.h with JOB. The higher specifc fuel consumption values in the case of Jatropha oil methyl ester (+19.04%) are due to their lower energy content.

The maximum brake thermal effciencies obtained are 44.1% for diesel fuel and 40.9% for JOB. This lower brake thermal effciency obtained for B100 (-7.33%) could be due to the reduction in calorifc value and increase in fuel consumption as compared to diesel fuel. The use of biodiesel in a conventional diesel engine resulted in a substantial reduction of unburned hydrocarbons (-45%), carbon monoxide (- 75%), and particulate matter (- 25%) compared to emissions from diesel fuel. At mid and high loads, NOx emissions were higher for JOB compared to ULSD. Most of the particles (64%) for diesel mode are in the range between 40 and 560 nm. On the other hand, most of the particles (94%) for biodiesel mode are between 6 and 40 nm. In the range between 6 and 40 nm, mass mean diameters in ULSD were 34.4, 34.7 and 33.3 nm and in JOB were 21.3, 18.2 and 20.1 nm for 100, 50 and 10% load, respectively.

ACKNOWLEDGEMENTS

This project was funded by Departamento Administrativo de Ciencia, Tecnología e Innovación - COLCIENCIAS and Carbones del Cerrejón LLC under the contract # 789-2011.

REFERENCES

Acevedo, H. & Mantilla, J. (2011). Performance and emissions of a heavy duty diesel engine fueled with palm oil biodiesel and premium diesel. DYNA, 170: 152-158. [ Links ]

Agarwal, D. & Agarwal, A. K. (2007). Performance and emission characteristics of Jatropha oil (preheated and blends) in a direct injection compression ignition engine. Applied Thermal Eng., 27(13), 2314 - 2323. [ Links ]

Babu, A. & Devaradjane, G. (2003). Vegetable oils and their derivatives as fuels for CI engines: An overview. SAE Technical Paper, 01-0767: 1-14. [ Links ]

Bagley, S., Gratz, L., Johnson, J. & McDonald, J. (1998). Effeects of an oxidation catalytic converter and a bio-diesel fuel on the chemical, mutagenic, and particle size characteristics of emissions from a diesel engine. Environ. Sci. Technol., 32(9), 1183-1191. [ Links ]

Chauhana, B., Kumara, N. & Muk, H. (2012). A study on the performance and emissions of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy, 37(1), 616-622. [ Links ]

Elango, T. & Senthilkumar, T. (2011). Combustion and emission characteristics of a diesel engine fuelled with Jatropha and diesel oil blends. Thermal Science, 15(4), 1205-1214. [ Links ]

Graboski, M. & Mccormick, R. (1998). Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci., 24(2), 125-164. [ Links ]

Graboski, M., McCormick, R., Alleman, T. & Herring, A. (2003). The effect of biodiesel composition on engine emissions from a DDC series 60 diesel engine. Technical Report, NREL/SR-510-31461. National Renewable Energy Laboratory. [ Links ]

Health Effects Institute. (2002). Research directions to improve estimates of human exposure and risk from diesel exhaust. [ Links ]

Heywood, J., (1989). Internal Combustion Engine Fundamentals. New York: Mac Graw Hill. [ Links ]

Jung, H., Kittelson, D. & Zachariah, M., (2006). Characteristics of SME biodiesel fueled diesel particle emissions and the kinetics of oxidation. Environ. Sci.Technol., 40(16), 4949-4955. [ Links ]

Karavalakis, G., Stournas, S. & Bakeas, E. (2009). Light vehicle regulated and unregulated emissions from different biodiesels. Science of the Total Env., 407(10), 3338-3346. [ Links ]

Knothe, G., Krahl, J. & Van Gerpen, J. (2010). The Biodiesel Handbook second edition. New York: AOCS Press. [ Links ]

Krahl, J., Munack, A., Schröder, O., Stein, H. & Bünger, J. (2003). Influence of biodiesel and different designed diesel fuels on the exhaust gas emissions and health effects. SAE Transactions, 112(4), 2447-2455. [ Links ]

Kyu, H., Gu, H., & Sik, C., (2008). Spray and combustion characteristics of biodiesel/diesel blended fuel in a direct injection common rail diesel engine. J. Eng. Gas. Turb. Power, 130(3), 1123-1130. [ Links ]

Lin, Y. C., Tsai, C. H., Yang, C. R., Wu, C. J., Wu, T. Y. & Chang-Chien, G. P. (2008). Effects on aerosol size distribution of polycyclic aromatic hydrocarbons from the heavy-duty diesel generator fueled with feedstock palm-biodiesel blends. Atmosph. Environment, 42(27), 6679-6688. [ Links ]

Mazumdar, B. & Kumar, A. (2008). Performance, emission and combustion characteristics of biodiesel (waste cooking oil methyl ester) fueled IDI diesel engine. SAE Technical Papers, 2008-01-1384. [ Links ]

McCormick, R., Tennandt, C., Hayes, R., Black, S., Ireland, J., McDaniel, T., Williams, A. & Frailey, M. (2005). Regulated emissions from biodiesel tested in heavy-duty engines meeting 2004 emission standards. SAE Technical Papers, 2005-01-2200. [ Links ]

McDonald, J., Purcell, D., McClure, B. & Kittelson, D. (1995). Emissions characteristics of soy methyl ester fuels in an IDI compression ignition engine. SAE Technical Papers. 950400. [ Links ]

Ozsezen, A. N., Canakci, M. & Sayin, C. (2008). Effects of biodiesel from used frying palm oil on the performance, injection, and combustion characteristics of an indirect injection diesel engine. Energy and Fuels, 22(2), 1297-1305. [ Links ]

Pope, C., Thun, M., Namboodriri, M., Dockery, D., Evans, J., Speizer, F. & Heath, C. (1995). Particulate air pollution as a predictor of mortality in a prospective study of U.S. Adults. Am. J. Respir. Crit. Care Med., 151(3), 669-674. [ Links ]

Pramanik, K. (2003). Properties and use of Jatropha Curcas oil and diesel fuel blends in compression ignition engine. Renewable Energy, 25(2), 239-248. [ Links ]

Prasad, C., Krishna, M., Reddy, C. & Mohan, K. (2012). Perfor-mance evaluation of non-edible vegetable oils as substi-tute fuels in low heat rejection diesel engines. J. of Automobile Eng., 214(2), 181-187. [ Links ]

Purcell, D., Mcclure, B., Mcdonald, J. & Basu, H. (1996). Transient testing of soy methyl ester fuels in an indirect injection, compression ignition engine. J. Am. Oil Chem. Soc., 73(3), 381-388. [ Links ]

Schröder, O., Krahl, J., Munack, A., Krahl, J. & Bünger, J. (1999). Environmental and health effects caused by the use of biodiesel. SAE Technical Paper. 01-3561. [ Links ]

Sureshkumar, K., Velraj, R. & Ganesan, R. (2008). Performance and exhaust emission characteristics of a CI engine fueled with pongamia pinnata methyl ester (PPME) and its blends with diesel. Renew Energy, 33(10), 2294-2302. [ Links ]

Szybist, J., Boehman, A., Taylor, J. & McCormick, R. (2005). Evaluation of formulation strategies to eliminate the biodiesel NOx effect. Fuel Processing Techn., 86(10), 1109-1126. [ Links ]

Tsolakis, A. (2006). Effects on particle-size distribution from the diesel engine operating on RME-Biodiesel with EGR. Energy and Fuels, 20(4), 1418-1424. [ Links ]

Turrio-Baldassarri, L., Battistelli, C., Conti, L., Crebelli, R., de Berardis, B., Iamiceli, A., Gambino, M. & Iannaccone, S. (2004). Emission comparison of urban bus engine fueled with diesel oil and biodiesel blends. Science of the Total Environment, 327(1-3), 147-162. [ Links ]