Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

CT&F - Ciencia, Tecnología y Futuro

versão impressa ISSN 0122-5383

C.T.F Cienc. Tecnol. Futuro vol.5 no.3 Bucaramanga jul./dez. 2013

COLLOIDAL DISPERSION GELS (CDG) TO IMPROVE VOLUMETRIC SWEEP EFFICIENCY IN WATERFLOODING PROCESSES

INYECCIÓN DE GELES DE DISPERSIÓN COLOIDAL PARA EL MEJORAMIENTO DE LA EFICIENCIA DE BARRIDO VOLUMÉTRICA EN PROCESOS DE INYECCIÓN DE AGUA

Rubén-Hernán Castro-García1*, Gustavo-Adolfo Maya-Toro1, Jorge-Eduardo Sandoval-Muñoz1 and Lia-Margarita Cohen-Paternina2

1Ecopetrol S. A. - Instituto Colombiano del Petróleo (ICP), A.A. 4185 Bucaramanga, Santander, Colombia

2UT UP Consultorias, Bucaramanga, Santander, Colombia

E-mail: rubenhe.castro@ecopetrol.com.co

(Received: Dec. 17, 2012; Accepted: Dec. 04, 2013)

*To whom correspondence should be addressed

ABSTRACT

A viable option for the sustainability of hydrocarbon supply in the short and medium term is increasing the expected ultimate oil recovery factor through Enhanced Oil Recovery processes (EOR).

The purpose of this paper is to describe a methodology to evaluate EOR technologies developed at the Instituto Colombiano del Petróleo (ICP) of ECOPETROL S.A. in 2012. The methodology includes theoretical evaluation, design (geological analysis, engineering analysis, laboratory static and dynamic tests and numerical simulation, among others), field implementation and surveillance of Colloidal Dispersion Gels (CDG) injection. CDG is an EOR method that consists in the co-injection of high molecular weight polymer and a crosslinker, to generate microgels in the reservoir. This technology has become an alternative to polymer flooding.

This paper describes a field application in Dina Cretáceos Field (Dina) supported by the proposed methodology, which corresponds to the first chemical enhanced oil recovery pilot implemented in Colombia by ECOPETROL S.A. Results of this study show an increase in volumetric sweep efficiency due the improvement of the mobility ratio, increasing in oil production and decreasing in water production. Based on the results of this pilot, which started in June 2011, the feasibility of expanding the use of CDG technology in Dina and others fields of Colombia is being assessed at present.

Keywords: Colloidal Dispersion Gels (CDG), Enhanced Oil Recovery (EOR), Chemical injection, Polymer, Numerical simulation.

RESUMEN

Una opción viable para garantizar la sustentabilidad del suministro de hidrocarburos a corto y mediano plazo es el incremento del factor de recobro último de los yacimientos, mediante la implementación de métodos de recobro mejorado (EOR, por sus siglas en inglés).

Este artículo tiene como objetivo describir una metodología para evaluar tecnologías EOR desarrollada en el Instituto Colombiano del Petróleo (ICP) de ECOPETROL S.A. en el año 2012. La metodología comprende una evaluación teórica, diseño (análisis geológico, análisis de ingeniería, pruebas estáticas y dinámicas a nivel de laboratorio y simulación numérica), ejecución en campo y monitoreo de procesos de inyección de geles de dispersión coloidal (CDG, de sus siglas en inglés), CDG es un método EOR que consiste en la co-inyección de polímero de alto peso molecular con un agente entrecruzador que permite la generación de microgeles en la formación. Esta tecnología se ha convertido en una alternativa a los procesos de inyección de polímero.

En este trabajo se incluye un caso de aplicación en el Campo Dina Cretáceo (Dina) de la metodología propuesta, que corresponde al primer piloto de recobro químico en Colombia realizado por ECOPETROL S.A. Los resultados de este estudio muestran un incremento en la eficiencia volumétrica de barrido debido a la mejora de la relación de movilidad, dando lugar a un aumento en la producción de petróleo y una disminución de la producción de agua. Con base en los resultados de este piloto, que inició su ejecución en Junio de 2011, actualmente se evalúa la factibilidad de expandir el uso de la tecnología CDG en Dina y otros campos de Colombia.

Palabras clave: Geles de dispersión coloidal, Recobro mejorado de petróleo, Inyección de químicos, Polímero, Simulación numérica.

RESUMO

Uma opção viável para garantir a sustentabilidade do fornecimento de hidrocarbonetos a curto e médio prazo é o aumento do fator de recuperação última das jazidas, mediante a implantação de métodos de recuperação melhorada (EOR, por suas siglas em inglês).

Este artigo tem como objetivo descrever uma metodologia para avaliar tecnologias EOR desenvolvida no Instituto Colombiano do Petróleo (ICP) de ECOPETROL S.A., em 2012. A metodologia compreende uma avaliação teórica, desenho (análise geológica, análise de engenharia, provas estáticas e dinâmicas em nível de laboratório e simulação numérica), execução em campo e monitoramento de processos de injeção de géis de dispersão coloidal (CDG, de suas siglas em inglês), CDG é um método EOR que consiste na co-injeção de polímero de alto peso molecular com um agente entrecruzador que permite a geração de micro géis na formação. Esta tecnologia converteu-se em uma alternativa aos processos de injeção de polímero.

Neste trabalho inclui-se um caso de aplicação no Campo Dina Cretáceo (Dina) da metodologia proposta, que corresponde ao primeiro piloto de recuperação química na Colômbia realizado por ECOPETROL S.A. Os resultados deste estudo mostram um aumento na eficiência volumétrica de varrido devido à melhoria da relação de mobilidade, dando lugar a um aumento na produção de petróleo e uma diminuição da produção de água. Com base nos resultados deste piloto, que iniciou sua execução em junho de 2011, atualmente avalia-se a factibilidade de expandir o uso da tecnologia CDG em Dina e em outros campos da Colômbia.

Palavras-chave: Géis de dispersão coloidal, Recuperação melhorada de petróleo, Injeção de químicos, Polímero, Simulação numérica.

1. INTRODUCTION

The increase in the recovery factor of existing reservoirs has become an option in the short and medium term to ensure the sustainability of the hydrocarbon supply and it is expected to contribute to ECOPETROL'S MEGA of 1.3 million barrels of oil equivalent per day by 2020.

The study of the injection of Colloidal Dispersion Gel (CDG) is an alternative to polymer injection processes that also increase volumetric sweep efficiency in conventional waterflooding processes. The techno-logy consists in the co-injection of a high molecular weight polymer (partially hydrolyzed polyacrylamides or HPAM) and a crosslinker (i.e. Aluminum Citrate) to generate CDGs in situ to improve the mobility ratio with the potential additional benefit of increasing Residual Resistance Factor (RRF) to water in high conductive thief zones, diverting injection fluids through unswept zones, thus increasing the oil recovery factor.

Essentially, the main advantage of CDG injection compared to polymer injection is that CDG systems can reach higher viscosities with low polymer concentrations that can generate higher Resistance Factors (RF) and RRF increasing volumetric sweep efficiency. CDG also offer a higher operational flexibility and injectivity than conventional polymer injection. Additionally, CDG projects rarely produce chemical in offset producers, generating a minimum impact on the separation and treatments of produced fluids. Over the last decade, the number of CDG injection projects has increased in countries such as Argentina and the United States, and it has shown an increased interest in China, the North Sea, Russia and most recently in Colombia.

This paper introduces a methodology developed to evaluate the feasibility of applying chemical recovery processes to improve volumetric sweep efficiency and the water/oil mobility ratio in order to increase the recovery factor in Colombian reservoirs through CDG injection. The methodology consists of a reservoir engineering analysis stage, technical, conceptual and experimental assessments, and numerical modeling in which innovative strategies of numerical simulation were integrated and developed, followed by a stage of execution and monitoring of pilot test.

This paper presents a description of the first pilot of chemical EOR implemented by ECOPETROL S.A. After more than 2 years of evaluation, results show excellent technical-economic indicators, generating increases in oil production up to 300%, and a 10% decrease in water cuts. As a result of the analysis and implementation of the methodology developed, there was an incremental recovery factor of 2%.

2. THEORETICAL FRAMEWORK AND STATE OF THE ART

Waterflooding is one of the most common oil reco-very processes in the world. However, the application of the technique is not completely efficient in swee-ping viscous oils. Therefore, the implementation of Enhanced Oil Recovery (EOR) methods is necessary to increase volumetric and displacement sweep efficiency in order to increase the recovery factor.

According to Sorbie (1991), a partially hydrolyzed polyacrylamide (HPAM) solution is made up of polymer chains with a hydrodynamic radius that depends on the salinity thereof. In distilled water, the polymer groups (charged negatively) repel each other, and the polymer molecules spread out, obtaining the highest possible volume of solution. On the other hand, when there is salt present, the polymer molecules curl up, causing a reduction in solution viscosity.

In the presence of divalent or trivalent ions (crosslinker), two or three polymer groups (carboxyl) are generated, which can bond to just one cation, generating intramolecular cross-linking. At different concentrations of polymer and crosslinker, a continuous network of cross-links give rise to the formation of microgels known as CDG (Spildo, Skauge, Aarra & Tweheyo, 2008; Spildo, Skauge & Skauge, 2010). CDGs are prepared with low concentrations of HPAM (typically between 100 and 1000 ppm) of high molecular weight (>22 million Dalton) and aluminum citrate (or Chromium Acetate) as a crosslinker (metal ion), consisting of almost spherical particles with sizes in the range of nanometers (50-150 nm).

Skauge, Spildo and Skauge (2010) showed that CDGs can play an important role in EOR by diver-ting the microscopic flow and increasing macroscopic sweep in the reservoir. The success of field applications suggest the improvement of volumetric sweep in reservoirs with adverse mobility, as reported by Mack and Smith (1994); Smith (1995, 1999) and Fielding Gibbons and Legrand (1994). According to the authors, the CDGs act as a polymer without a crosslinker near the injection wellbore, showing good injectivity due to the viscoelastic nature of polyacrylamide solutions (Seright, 1983). Due to the fact that the cross-linking reaction has not taken place, the gel structures prevent from forming at early stages on injection. Deeper in the formation, when the microgels have had time to form and the differential pressure has dropped, the colloids expand, increasing solution viscosity and modifying the permeability of the area influenced (increasing RF and RRF), according to Ghazali and Willhite (1985).

In more than 40 historic cases, operators have reported incremental recovery factors of up to 10% of the Original Oil In Place (OOIP) (Demin, Yingjie, Yan & Xuping, 2002; Chang et al., 2004; Norman, De Lucía & Turner, 2006; Sandoval et al., 2010; Castro et al., 2013). CDG technology is used to improve volumetric sweep efficiency that can be affected by the heterogeneity of the reservoir and the adverse mobility ratio in waterflooding processes.

Since 1957, 19 commercial waterflooding projects have been implemented in Colombia, along with 6 pilots that are currently underway. However, the development of EOR strategies has been incipient. Based on the above, there is an opportunity to implement EOR processes to increase the recovery factor in Colombian reservoirs, which is currently 18% on average. The implementation of EOR can definitively contribute, achieving the MEGA of ECOPETROL´s Business Group, which is targeting by 2020 the production of 1.3 million barrels of oil equivalent per day.

The Instituto Colombiano del Petroleo (R&D Center) of ECOPETROL S.A. invested 1.5 years from the screening up to the implementation of a CDG pilot injection in a Dina field. The optimal CDG formulation was selected based on the development of new experimental procedures (Castro, 2011).

While developing the CDG formulation at lab scale, a numerical simulation model was generated in commercial software to predict the performance of the pilot based on CDG injection, updating the result with the laboratory tests and incorporating innovative numerical simulation strategies.

Finally, in June 2011 the pilot test was implemented in the field. Operational indicators such as water quality, power generation and non-productive time, improved on a constant basis, achieving a continuous injection of more than 437000 barrels of CDG, controlling operational setbacks and most importantly, without safety, health or environmental incidents. During the first two years of CDG injection, the pilot project reported an increase in the recovery factor of approximately 2% of the OOIP.

3. METHODOLOGY

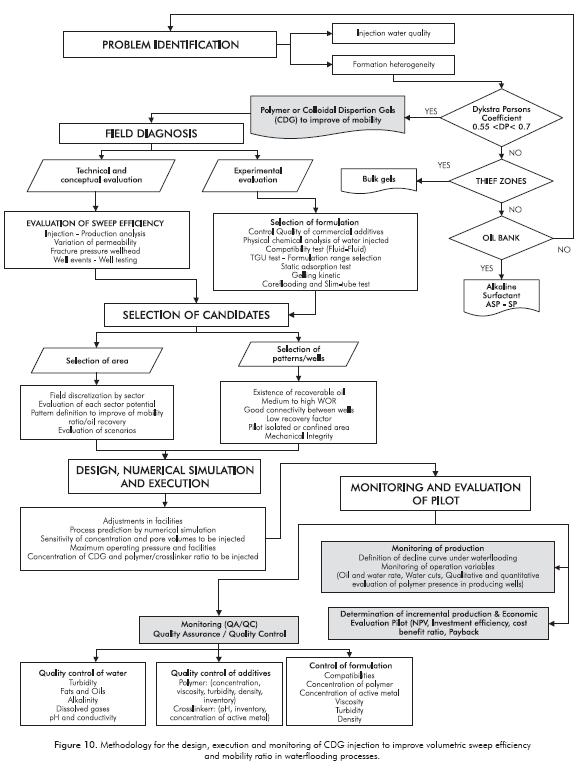

The implementation of enhanced recovery technologies in the field is not a common practice in Colombia. Therefore, ECOPETROL S.A. makes its best effort to implement this type of processes in Colombian reservoirs (Castro et al., 2010). In this sense, the ICP created a methodology that includes an initial technical, conceptual and experimental assessment, followed by detailed numerical simulation studies, the design, implementation and evaluation of the CDG process. The following sections will summarize the main stages of the methodology developed.

Identification of the Problem

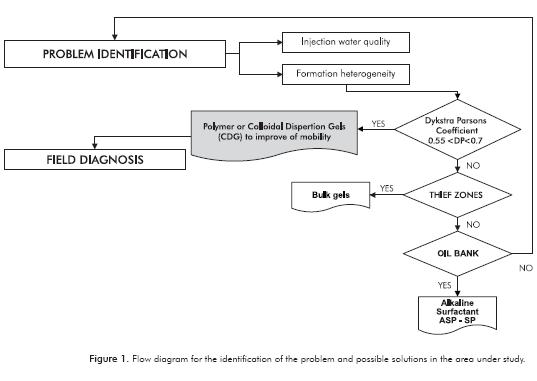

The technical analysis and assessment of a field under waterflooding process begins with the identification of the problem existing in each area of study. These problems and the possible causes are evaluated representing the starting point to determine possible solutions for each individual case. This stage is focused on a detailed analysis of the characteristics and the petrophysical and fluid properties of the reservoir. This analysis is integrated with any existing problems regarding the secondary recovery project, such as injection water quality or formation heterogeneity, which generates treatment alternatives for thief zones, oil banks or improved mobility. The determination of the Dykstra Parsons coefficient represents a key step to guide the decision making process of possible solutions to improve the performance of waterflooding. Once the problem and the potential negative effects on the waterflooding project are diagnosed, the zones affected in the area of study of the reservoir are identified. Figure 1 illustrates the most important parameters, including the stage to identify potential problems and needs/solutions of the reservoir under analysis.

Field Diagnosis

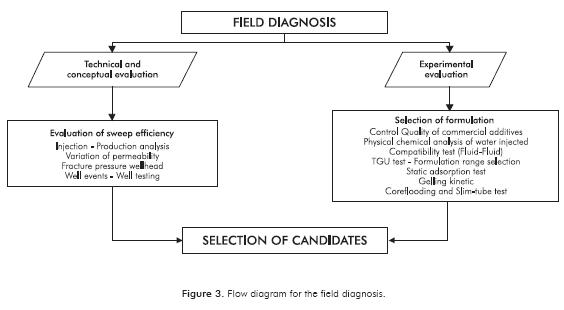

During the field diagnosis stage, a technical, conceptual and experimental assessment is carried out. Therefore, the performance of the waterflooding process has to be reviewed and analyzed in order to determine sectors candidate for the application of the EOR technologies. Once the EOR technology is identified, an experimental study is also conducted to determine any possible incompatibility between the CDGs, with the formation and/or reservoir fluids.

Technical and Conceptual Evaluation

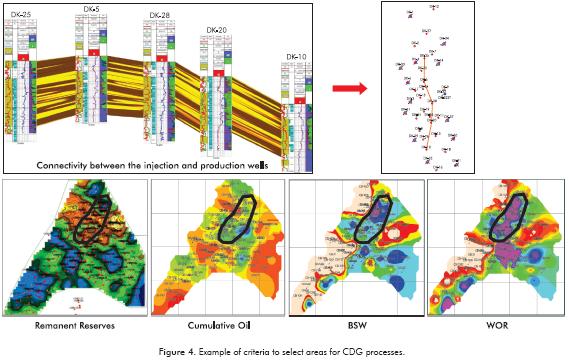

The review of standard maps (incorporating petrophysical properties, accumulated water injection, oil production and recovery factors) provides a high level overview of the field, indicating the zones with good petrophysical properties, low recovery factor and high mobile oil saturation, among others.

An injection-production analysis should be conducted for each field, injection sector and finally by injection pattern or well pairs if necessary. Injection sectors are selected based on the location of injection wells and the analysis of production curves (Water Oil Ratio (WOR) analysis, WOR vs. Time, WOR vs. Cum. Production or Np, production and injection diagrams vs. time, etc.). Reservoir zonation might be necessary in order to correlate production wells response with the associated injector and to evaluate the effect of an injection well on offset producers.

The analysis and interpretation of the diagrams mentioned above (Figure 1) are essential in identifying the connectivity between injection and production wells, analyzing the production response obtained from water injection and identifying areas with low volumetric sweep efficiency requiring further optimization.

After identifying the problem, analyzing the production data, fracture pressure and well events, and identifying the target patterns of the field, the conceptual analysis is conducted for a more detailed selection of the injection patterns that are most likely to succeed to carry out the process.

Experimental Evaluation

During this stage, the chemicals to be used are selected by evaluating its performance at reservoir conditions. Since there is no experimental standard test to evaluate CDG performance, a procedure was developed at the laboratories of ICP. The protocol consist in the integration and analysis of different experimental tests consulted with experts evaluating in this type of processes or similars (Hirasaki and Pope, 1974; Walsh et al., 1983; Seright, 1994; Ranganathan et al., 1997-1998; Smith, Liu and Dong, 2000; Sydansk, 2005 and Skauge et al, 2010).

The experimental evaluation starts with the cha-racterization of the products used to prepare the CDGs (polymers, crosslinkers and oxygen scavengers).

In the case of polymers, infrared spectroscopy analysis is carried out to identify the type of polymer. The percentage of humidity and hydrolysis is determined in order to estimate the approximate number of acrylic acid monomers present in the macromolecule. The molecular weight is also calculated based on the measurement of intrinsic viscosity.

For the crosslinker, pH values are measured to verify the oxidation status of the active metal present in order to calculate the concentration. After that, an infrared spectroscopy analysis is carried out to identify the chemical nature of the crosslinker. Finally, the oxygen scavenger undergoes infrared spectroscopy analysis.

After characterizing the products, stock solutions are generated based on which the CDGs are prepared at different concentrations. After that, compatibility tests are conducted with reservoir fluids (crude, production and injection water) and the possible CDG formulas to be implemented. Following the compatibility testing, CDGs that does not show incompatibilities or precipitates undergo rheological evaluation at different shear rates. In addition, gel time and dynamic viscosity vs. maturation time of the microgel are tested for different polymer and crosslinker concentrations.

Gel time tests, also known as microgel flow rate tests, are conducted in the time gel unit - TGU proposed by Smith (1989). The TGU consists of a pipe with a pa-cking made up of 5 100-mesh strainers located at the top of the cylindrical body and a pressure control system where the chemical (i.e. polymer and CDGs) solution are tested as illustrated in Figure 2. This test is run to evaluate the consistency and flowing times of the CDG after 24 hours, 1 to 2 weeks and 1 month or longer if necessary. CDG performance can be also compared with polymer solutions at different concentrations to evaluate potential benefits (or not) of CDG.

The CDG formulas with the best stability, rheological performance and transition pressures greater than 5 psi at the end of the Fluid-Fluid compatibility analysis, are tested in different porous media. Berea or composite reservoir core plugs and sand packs or slim tubes (1 to 40 ft) are the most common systems used to evaluate CDG flow and oil recoveries in porous media based on the proposed methodology.

Essentially, CDG formulas with high RRF are evaluated to find data on gelling kinetics with the experimental tests designed based on this methodology considering the studies reported by Klaveness and Ruoff (1994) and generating static and dynamic adsorption data in Berea or reservoir rock, if available. Figure 3 summarizes the most important parameters of the field diagnosis stage, which includes technical, conceptual and experimental evaluation.

Selection of Candidates

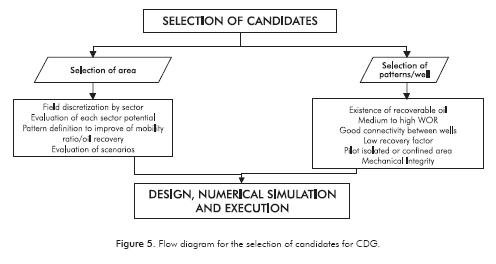

A detailed reservoir and injection/production data analysis is required to identify and select candidate areas and wells in the reservoir under evaluation. Basically, there should be recoverable oil, proper connectivity between injector(s) and producer(s), a low recovery factor, a high WOR and the area should preferably be isolated or confined.

In the end, these criteria will lead to the selection of the best areas in accordance with the evaluation of the potential to increase oil recovery in each sector, as well as an evaluation of scenarios to define the best patterns to implement the CDG process.

During the stage to evaluate the potential of each sector of the field, the patterns with the highest mobile oil saturation that can be recovered if sweep efficiency is improved are defined. Another selection criterion includes the patterns (active wells) with the largest number of sands open to injection-production in each reservoir with a low secondary recovery factor. Figure 5 illustrates the most important parameters of the candidate selection stage.

Design, Numerical Simulation and Execution

The design of the process should include the injection rates, volume and concentration of the chemicals to be injected. Since the main objective is to increase volumetric sweep efficiency by improving mobility ratio, chemicals should be injected at the lowest possible flow rate. Injection rates should not exceed the formation fracture gradient or the operational limit of the injection facilities. All aspects mentioned regarding to injection rates are directly related to the concentration of chemicals (polymer and crosslinker). In general, the higher the concentration the lower the flow rate in order to inject large volume of chemicals below or close to the maximum operating pressure.

According to Alvarado and Manrique (2010), the feasibility studies to implement an EOR process should include screening analyses, identification of similar fields and numerical simulation of reservoirs in order to estimate the potential of the recovery process in a given reservoir, supporting risk-management decision and provide guidance for a possible field implementation. With respect to the numerical simulation of CDG processes, there is no commercial software that includes special fluid modeling modules to evaluate changes in CDG (i.e. pressure build up due to viscosity increase and/or mechanical trapping) when the microgels have had time to form in the formation. To simulate CDG, the gel option of CMG (Computer Modeling Group) was used in Dina field.

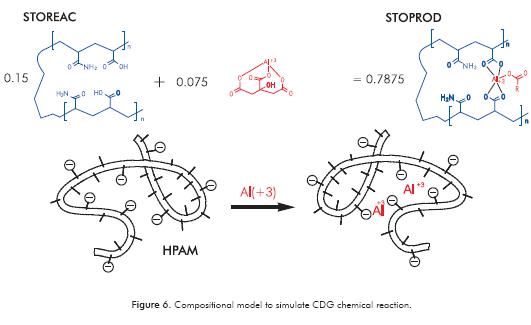

The proposed methodology included the development of innovative strategies of compositional simulation combining the injection of two or more components (i.e. HPAM and aluminum citrate-reagents in the simulation), that generates another component (CDG), using gelling kinetics (Figure 6) and the numerical adjustment of laboratory tests obtained in previous phases (Castro, 2011).

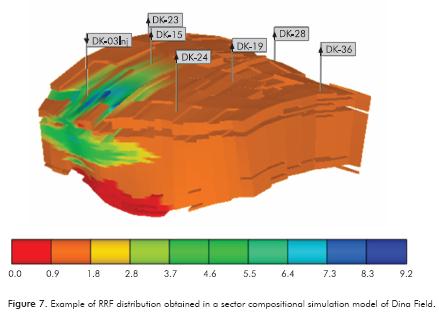

Therefore, numerical simulation is required to support an initial design, generating the chemical volume to be injected in a given application (Dina Field in this case), in addition to the concentration and polymer-crosslinker ratio. Figure 7 illustrates the RRF obtained using a compositional numerical simulation model based on the proposed approach.

During the execution stage, the resources required for injection of the CDG treatment consist of a water supply, electric power and a material stockroom, in addition to specialized technicians to operate and monitor the operation on a continuous basis.

Surface equipment should include a system for storing water (i.e. FracTank), a power line or generator and an automated injection facility, that should have a polymer feed hopper, a crosslinker dosing system, a mixer of the fluids to be injected (water, polymer and crosslinker), a triplex pump and, ideally, an oxygen scavenger system if not included in the water treatment of the main water injection facility.

The injection system should start pumping water in order to stabilize well flow and define injection pressure base line. Once the injection has been stabilized, the co-injection of HPAM and crosslinker (Aluminum Citrate in this case) should start based on the procedure described in previous sections. It is important to keep in mind that the injection of chemicals, its concentration, injection rates and times are based on the treatment design supported by the experimental and numerical simulation studies.

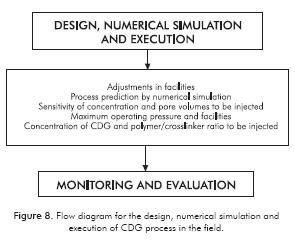

However, changes in injection strategies needs to be adjusted based on injection performance sustaining the injection of chemicals close or below maximum operating pressure. Generally, polymer concentration and polymer:crosslinker ratio are the most common variables adjusted during CDG projects. Figure 8 illustrates the most important parameters of the design, numerical simulation and execution stage.

Monitoring and Evaluation

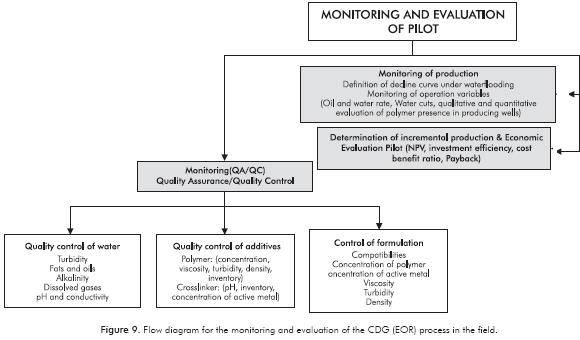

This stage begins during the pilot implementation. According to Maya, Castro, Pachón and Zapata (2012), reservoir and well performance should be verified on a permanent basis including if the chemical dosage (i.e. polymer concentration and polymer: crosslinker ratio) of design are met at wellhead of the injector. Verifying this point based on permanent QA/QC monitoring is essential to the success of the CDG process. Quality control of injection water and additives used for water treatment, including a continuous control of the chemical (CDG) injected, are fundamental for a proper monitoring process.

An early detection of the injected polymer in offset producers represents a negative factor requiring the adjustment of chemical injection and/or injection rates at the injection well. Polymer production in CDG projects have been rarely reported in previous field experiences. CDG is expected to remain in the reservoir due to adsorption, mechanical and hydrodynamic entrapment, depending on the pore volume of chemicals injected.

Injection pressure during treatment water and oil rates in production wells will be key parameters to evaluate project performance. Monitoring production is fundamental for this and any oil recovery process. During this stage, water and oil production baseline must be established defining a clear decline curve that will be used to evaluate incremental oil recoveries of CDG injection. The definition and agreement of a decline curve will be key to determine the incremental production and the economic evaluation of the process implemented (NPV, efficiency of the investment, cost-benefit ratio and recovery period of the investment). Figure 9 illustrates the most important parameters of the monitoring and evaluation stage of the process.

The purpose of the developed methodology is to design and execute EOR processes systematically by CDG injection, starting with the reservoir engineering analysis stage, experimental testing and numerical modeling, followed by a stage of execution and monitoring of the process Figure 10 provides a summary of the most important parameters of the proposed methodology.

4. DISCUSSION

The developed methodology was used in the first pilot project of chemical EOR (CDG flood) in Colombia by ECOPETROL S.A. at the Dina Cretáceos Field located in Upper Magdalena Valley Basin.

Dina Field was discovered in 1969 and is operated by ECOPETROL S.A. The main producer formation of the field is Monserrate, whose contribution to the overall production of the field is approximately 94%. These flow units are highly heterogeneous (Dykstra Parsons Coefficient > 0.7), with permeabilities ranging between 50 and 200 mD and porosities between 14 and 18%. Rock wettability is mixed, but there is a slight preference for oil. Reservoir depth is between 5000 and 7000 ft, and the initial pressure was 2800 psi at temperature of 152ºF.

Peripheral water re-injection started in 1985, sho-wing good oil production response. However, water cuts increased from 30% to current values of 96%. High water cuts are mainly attributed to permeability contrasts and unfavorable mobility ratios (M > 4). The recovery factor of the field is estimated at 32% of the OOIP.

The selection of CDG technology and the pilot area in the Dina Cretáceos Field is the result of geological analysis (i.e. stratigraphic correlations, mapping of petrophysical properties, determination of permeability variation coefficient, etc.), engineering analysis (i.e. standard maps, analysis of injection/ production history, ILT tests, fracture pressure, etc.), analysis of well events (i.e. mechanical states, influxes, etc.), filter screening, conceptual simulation and laboratory analyses, based on which the technical/economic feasibility of CDG injection was concluded by ECOPETROL, S.A. 1.5 years were dedicated from the screening phase to the pilot implementation, followed by a detailed injection and reservoir monitoring.

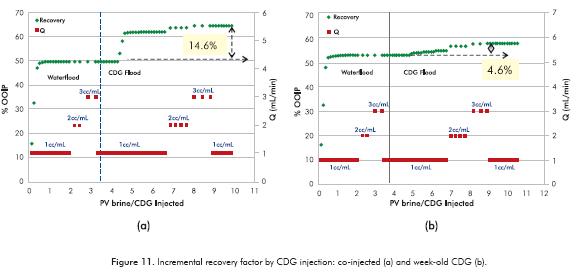

The optimal CDG formulation (polymer concentration and polymer-crosslinker ratio) was selected based on the design and testing of gel time (TGU), viscosity, dynamic viscosity vs. gel maturing time, displacement tests in consolidated and unconsolidated (slim tubes or sand packs) porous media. Figure 11 illustrates the results of the displacement tests conducted for the field (Castro et al., 2013) with co-injecting HPAM (600 ppm) and aluminum citrate (20:1) (a) and one week aged CDG (b).

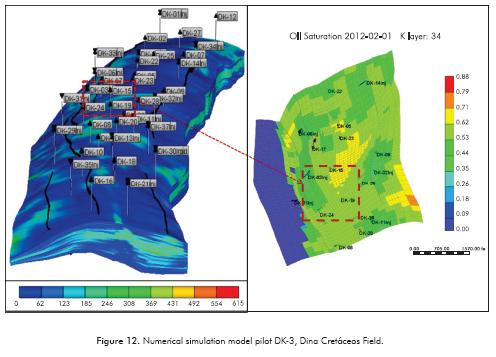

While selecting the optimal CDG system, a compositional numerical simulation model was generated (commercial software), incorporating chemical reaction and the results of the laboratory tests, which allowed the prediction of pilot performance under CDG injection (Figure 12). Numerical modeling validated the technical/economic feasibility of implementing the techno-logy (incremental recovery factor of 5% with rapid oil response times and incremental production).

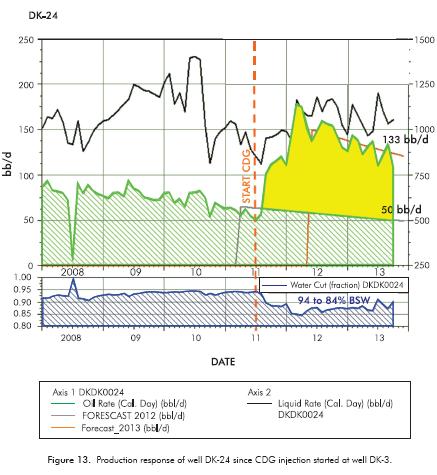

The CDG injection pilot began on June 9 th 2011 at the injector DK-3. The initial injection rate was established at 1500 barrels per day of CDG, using a polymer concentration of 400 ppm and a polymer-crosslinker ratio of 40:1. The main objective of CDG injection in the Dina Cretáceos Field was to increase the oil recovery factor of the pilot area by 5% in 5 years. According to the results of the pilot, it has been recorded that oil production increases up to 300%, decrease in water cuts up to 10% and incremental recovery factor of 2% du-ring the first two years of CDG injection. As a result, a continuous injection of more than 437 000 Barrels of CDG was achieved, without the presence of the polymer produced in the producing wells. Based on the results of the CDG pilot, the expansion of the technology was approved for Dina Field and triggers the evaluation of CDG in other fields in Colombia.

Figure 13 illustrates the decline curve under waterflooding in the pilot area and the incremental oil obtained in one of the offset wells (DK-24) of the wells influenced by the CDG injection process. DK-24 represents the well with the largest oil production of the pilot area.

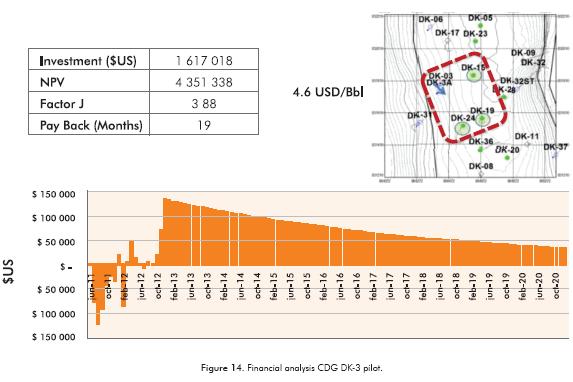

Based on total costs and financial analysis that includes conventional cash flow, pilot production response show the economic benefits of the project. In terms of Net Present Value (NPV) and investment efficiency, resulting values are $ U.S. 4.35 million and 3.88 respectively. At the time of this evaluation, the cost per incremental barrel of oil was estimated approximately in $ U.S. 4.6. Figure 14 illustrates cash flow and the economic benefits of the project.

5. CONCLUSIONS

- A methodology was developed to increase the probability of success of applying enhanced oil recovery treatments by CDG injection to improve sweep efficiency and mobility ratio in waterflooding processes.

- According to the results of the DK-3 pilot, CDG technology represents a viable option to increase oil recovery in mature waterfloods. The results of the pilot area are largely attributable to the implementation of the methodology developed and discussed in detail in this paper.

- This study not only enabled the implementation of the first pilot of chemical EOR technology in Colombia by ECOPETROL S.A., but it also allowed the incorporation of laboratory protocols, engineering analyses, and numerical simulation strategies necessary to make the technology viable, providing another option for increasing the oil recovery factor of reservoirs in Colombia.

ACKNOWLEDGEMENTS

The authors would like to thank ECOPETROL S.A. for allowing the publication of these results and for its generous support throughout the project. Special thanks to the Reservoir Management (GDY), Huila - Tolima Superintendence (SOH) and the Instituto Colombiano del Petroleo (ICP).

We would also like to thank TIORCO, especially to Ph.D. Eduardo Manrique, for its assistance, monitoring and support throughout the process.

REFERENCES

Alvarado, V. & Manrique, E. (2010). Enhanced oil recovery: Field planning and development strategies. USA, Elsevier. [ Links ]

Castro, R., Maya, G., Mercado, D., Trujillo, M., Soto, C., Pérez, H., Lobo, A., Ordóñez, A. & Sandoval, J. (2010). Enhanced Oil Recovery (EOR) Status - Colombia. SPE Latin American and Caribbean Petroleum Engineering Conference, Lima, Perú. Paper SPE 139199. [ Links ]

Castro, R. (2011). Análisis de un proceso de inyección de Geles de Dispersión Coloidal (CDG) usando ensayos de laboratorio slim tube y simulación numérica Campo Dina Cretáceo. Tesis de maestría Fac. Ingenierías Fisicoquímicas, Universidad Industrial de Santander, Bucaramanga, Colombia, 219pp. [ Links ]

Castro, R., Maya, G., Sandoval, J., León, J., Zapata, J., Lobo, A., Villadiego, D., Perdomo, L., Cabrera, F., Izadi, M., Romero, J., Norman, C. & Manrique, E. (2013). Co-lloidal Dispersion Gels (CDG) in Dina Cretáceos Field: From pilot design to field implementation and performance. 2013SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia. Paper SPE 165273. [ Links ]

Chang, H., Sui, X., Xiao, L., Guo, Z., Yao, Y., Xiao, Y., Chen, G., Song, K. & Mack, J. (2004). Successful field pilot of in-depth Colloidal Dispersion Gel (CDG) technology in Daqing Oilfield. SPE Reservoir Evaluation & Engineering, 9(6), 664-673. [ Links ]

Demin, W., Yingjie, S., Yan, W. & Xuping, T. (2002). Producing more than 75% of Daqing Oilfield's production by IOR, What experiences have been learnt?. SPE Asia Pacific Oil and Gas Conference and Exhibition, Melbourne, Australia. Paper SPE 77871. [ Links ]

Fielding, R., Gibbons, D. & Legrand, F. (1994). In-depth drive fluid diversion using an evolution of colloidal dispersion gels and new bulk gels: An operational case history of North Rainbow Ranch Unit. SPE/DOE Improved Oil Recovery Symposium, Tulsa, USA. Paper SPE 27773. [ Links ]

Ghazali, H. & Willhite, P. (1985). Permeability modification using aluminum citrate/polymer treatments: Mechanisms of permeability reduction in sandpacks. SPE Oilfield and Geothermal Chemistry Symposium, Phoenix, USA. Paper SPE 13583. [ Links ]

Hirasaki, G. & Pope, G. (1974). Analysis of factors influencing mobility and adsorption in the flow of polymer solution through porous media. PE Journal, 14(4), 337-346. [ Links ]

Klaveness, T. & Ruoff, P. (1994). Kinetics of the cross-linking of polyacrylamide with Cr(III). Analysis of possible mechanisms. J. Phys. Chem, 98(40), 10119-10123. [ Links ]

Mack J. & Smith, J. (1994). In-depth colloidal dispersion gels improve oil recovery efficiency. SPE/DOE Improved Oil Recovery Symposium, Tulsa, USA. Paper SPE 27780. [ Links ]

Maya, G., Castro, R., Pachón, Z. & Zapata, J. (2012). Polymer gels for controlling water thief zones in injection wells. CT&F - Ciencia, Tecnología y Futuro, 5(1), 37-44. [ Links ]

Norman, C., De Lucía, J. & Turner, B. (2006). Improving volumetric sweep efficiency with polymer gels in the Cuyo Basin of Argentina. SPE/DOESymposium on Improved Oil Recovery, Tulsa, USA. Paper SPE 99379. [ Links ]

Ranganathan, R., Lewis, R., McCool, C., Green, D. & Willhite, G. (1997). An experimental study of the in situ gelation behavior of a polyacrylamide/aluminum citrate "colloidal dispersion" gel in a porous medium and its aggregate growth during gelation reaction. International Symposium on Oilfield Chemistry, Houston, USA. Paper SPE 37220. [ Links ]

Ranganathan, R., Lewis, R., McCool, C., Green, D. & Willhite, G. (1998). Experimental study of the gelation behavior of a polyacrylamide/aluminum citrate colloidal-dispersion gel system. SPE Journal, 4(3), 337-343. [ Links ]

Sandoval, J., Pérez, H., Maya, G., Castro, R., Muñoz, E., Colmenares, K., León, J., Sánchez, F., Villadiego, D., Manrique, E., Romero, J. & Izadi, M. (2010). Dina Cretáceos Field chemical EOR: From screening to pilot design. SPE Latin American and Caribbean Petroleum Engineering Confe, Lima, Perú. Paper SPE 139200. [ Links ]

Seright, R. (1983). The effects of mechanical degradation and viscoelastic behavior on injectivity of polyacry-lamide solutions. SPE Journal, 23(3), 475-485. [ Links ]

Seright, R. (1994). Propagation of an aluminum-citrate-HPAM "colloidal-dispersion" gel through Berea sandstone. Report No. PRRC 94-29, New Mexico Petroleum Recovery Research Institute, New Mexico Institute of Mining and Technology. USA. [ Links ]

Skauge, T., Spildo, K. & Skauge, A. (2010). Nano-Sized Particles for EOR. SPE Improved Oil Recovery Symposium, Tulsa, USA. Paper SPE 129933. [ Links ]

Smith, J. (1989). The transition pressure: a quick method for quantifying polyacrylamide gel strength. SPE International Symposium on Oilfield Chemistry, Houston, USA. Paper SPE 18739. [ Links ]

Smith, J. (1995). Performance of 18 polymers in aluminum citrate colloidal dispersion gels. Paper SPE 28989. [ Links ]

Smith, J. (1999). Practical issues with field injection well gel treatments. Paper SPE 55631. [ Links ]

Smith, J. Liu, H. & Dong, Z. (2000). Laboratory studies of in-depth colloidal dispersion gel technology for Daquing Oilfield. SPE/AAPGWestern Regional Meeting, Long Beach, USA. Paper SPE 62610. [ Links ]

Sorbie, K. (1991). Polymer improved oil recovery. Glasgow: Blackie and Son. [ Links ]

Spildo, K., Skauge, A., Aarra, M. & Tweheyo, M. (2008). A new polymer application for North Sea Reservoirs. SPE/DOE Symposium on Improved Oil Recovery, Tulsa, USA. Paper SPE 113460. [ Links ]

Spildo, K., Skauge, A. & Skauge, T. (2010). Propagation of Colloidal Dispersion Gels (CDG) in laboratory corefloods. SPE Improved Oil Recovery Symposium, Tulsa, USA. Paper SPE 129927. [ Links ]

Sydansk, R. (2005). Polymers, gels, foams, and resins. SPE Petroleum Engineering Handbook, Texas: Sydansk Consulting Services, LLC. [ Links ]

Walsh, M., Rouse, B., Senol, N., Pope, G. & Lake, L. (1983). Chemical interactions of aluminum-citrate solutions with formation minerals. SPE Oilfield and Geothermal Chemistry Symposium, Denver, USA. Paper SPE 11799. [ Links ]