1. INTRODUCTION

Polymer flooding results from adding a high-molecular-weight water-soluble polymer to waterfloods to increase oil recovery by decreasing the water/oil mobility ratio [1]. Partially hydrolyzed polyacrylamide (HPAM) is the most widely used synthetic polymer for EOR purposes, but it is susceptible to high salinity, temperature, and shear forces which leads to notable loss of its thickening power, affecting adversely its performance in EOR (1). Scleroglucan (SG) is considered the best environmentally-friendly substitution for polyacrylamides because of their high tolerance to harsh conditions [2].

The limitation of the use of SG for EOR processes is its susceptibility to microbial degradation. Polymer biodegradation depends on the chemical and physical properties of the polymer. These properties are key because they affect the biodegradation efficiency of microorganisms. The enzymes responsible for polymer degradation are generally extracellular depolymerase and intracellular depolymerase. These enzymes are involved in the degradation of complex polymers to simple units such as monomers and dimers. The degradation of polymers under anaerobic conditions produces organic acids, H2O and gases (CO2 and CH4) [3]. Under aerobic conditions, the biodegradation of the polymer forms CO2 and H2O in addition to the cellular biomass of the microorganisms. Deep subsurface petroleum reservoir ecosystems harbor a high diversity of microorganisms, which can use SG as a carbon source, promoting their proliferation and biocorrosion of oil infrastructures [4,5]. The microbial degradation of SG was investigated by Kozlowicz et al. (2020 )[6]. Their results showed that the risk of anaerobic biodegradation of SG decreases significantly at temperatures above 60°C and salinities greater than 7 wt%. They also recommended that antimicrobial controls must be targeted to the near-wellbore zone.

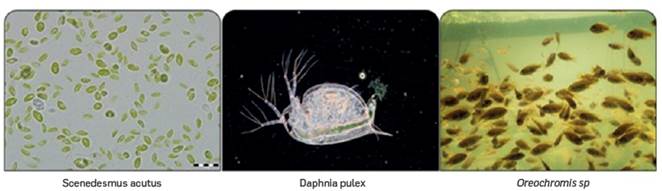

The possibility of SG reaching natural water systems downstream of its application is another concern because aquatic ecosystems are very prone to contamination [7,8]. Aquatic toxicity is determined with organisms representing the three trophic levels: Algae or plants (representing primary producers), invertebrates (e.g., crustaceans, representing primary consumers/secondary producers), and vertebrates (usually fish, representing secondary consumers). There are acute and chronic endpoints in aquatic toxicity. Acute toxicity tests (short-term exposure tests) assess concentrations that produce 50% death in a given group of individuals [9]. The results from these tests are expressed by the Lethal Concentration (LC50) [10]. Chronic toxicity is about longer-term exposure and includes effects on the hatching, growth, and survival of the individuals. This test is used to determine NOEC (No Observed Effect Concentration) values or LOEC (Lowest Observed Effect Concentration) [9].

To the best of the authors’ knowledge, there are no literature reports on the anaerobic biodegradation tests for SG, and studies of the acute and chronic toxicity of SG on aquatic organisms. For this reason, this study aimed to evaluate the biodegradation of SG under aerobic and anaerobic conditions, the effect of SG on the hatching and survival rate of Daphnia pulex and its lethal concentration (LC50) in Daphnia pulex, Scenedesmus acutus and Oreochromis sp.

MATERIALS

The biopolymer solutions were prepared with commercial SG (MW≈4-5 MDa), injection brine (RW) from a Colombian field (pH = 8.17 and conductivity = 2480 µS/cm) and a synthetic brine (SB). The synthetic brine was prepared with sodium chloride (NaCl, 99.5% pure, Merck Millipore, USA), potassium chloride (KCl, 99.5% pure, Merck Millipore, USA), magnesium chloride (MgCl2.6H2O, 99% pure, Merck Millipore, USA), and calcium chloride (CaCl2.2H2O, 99% pure, Merck Millipore, USA). Sodium acetate (C2H3NaO2, 99% pure, Merck Millipore, USA) was used as a positive control in the biodegradability tests. The concentration of SG was determined by using phenol (C6H6O, 99.5% pure, Merck Millipore, USA) and sulfuric acid (H2SO4, >95% pure, Merck Millipore, USA).

The acute ecotoxicological bioassays of SG were carried out on the Scenedesmus acutus organisms (Microalgae-primary producer), Daphnia pulex (Cladocera-primary consumer) and Oreochromis sp. (fish-secondary consumer). The chronic bioassays were performed with Daphnia pulex.

POLYMER SOLUTION PREPARATION

The 2000 ppm stock SG solutions were prepared by dissolving the SG powder into the aqueous phase under mechanical stirring (500 rpm). Then, the solutions were stirred at 800 rpm and heated at 40°C for 10 min. Finally, the solutions were homogenized for 20 min by using a high-performance immersion blender (IKA™ T 25 Digital Ultra-Turrax) [11]. The aqueous phases used were synthetic brine (SB), injection brine (RW) or sterile injection brine (RSW) filtered through a 0.45 µm MCE membrane filter (Merck Millipore, USA). A synthetic brine (SB) containing 0.829 g/L sodium chloride (NaCl, 99.5% pure, Merck Millipore, USA), 0.035 g/L potassium chloride (KCl, 99.5% pure, Merck Millipore, USA), 0.069 g/L magnesium chloride (MgCl2.6H2O, 99% pure, Merck Millipore, USA), and 0.331 g/L calcium chloride (CaCl2.2H2O, 99% pure, Merck Millipore, USA). To perform the tests, the stock solutions were diluted until reaching a concentration of 930 ppm.

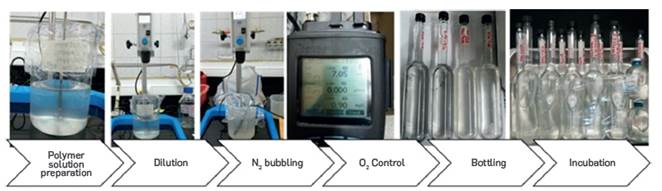

ANAEROBIC BIODEGRADATION OF SCLEROGLUCAN

The solutions and brines presented in Table 1 were used to determine if SG undergoes biological degradation under anaerobic conditions.

To perform the tests, the solutions were flushed with sterile nitrogen until the concentration of the dissolved oxygen was ~ 0 mg/L. Subsequently, aliquots of 100 mL of each SG solution were contained in 150 mL glass bottles with plastic caps fitted with butyl rubber septum. The samples were flushed again with nitrogen to ensure an oxygen-free system (Figure 1). All samples were assayed in duplicate. A concentration of 100 ppm of a commercial glutaraldehyde-based biocide (B) was used for these tests.

The viscosities of the SG solutions were measured in a DV2T Viscosimeter (Brookfield Ametek, USA) at 30°C and 7.3s-1. The uncertainty of the reported value remained between ±1 to 5%.

The initial microbial load of the RW was 1.0E+03 total anaerobic bacteria/mL. The total anaerobic bacteria count was obtained with the serial dilution technique in thioglycollate medium [12]. The incubation process was carried out for 30 days at 60 °C and 100 rpm.

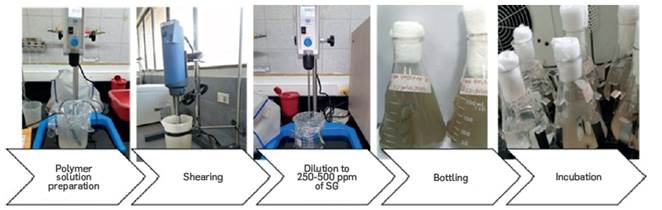

AEROBIC BIODEGRADATION OF SCLEROGLUCAN

Figure 2 shows the methodology used to determine the aerobic degradation of SG by microbial growth. The tests were performed with 930 ppm SG solutions prepared in RW and RSW, which were sheared with an Ultra-turrax IKA T50 (Ika laboratory equipment, Germany). The sheared samples were diluted to obtain solutions of 100 ppm and 200 ppm (considering that 10.8% and 21.5% of the injected polymer concentration remains in the production water) (9,11). After that, 200 mL of these solutions were contained in Pyrex® baffled Erlenmeyer flasks. The initial concentration of total aerobic bacteria was 7.4E + 04 CFU/mL. The bacteria count was obtained as described by Herigstad et al. (2001) [13]. The samples were incubated for 15 days at 30°C and 150 rpm. The concentration of SG was determined through the phenol-sulfuric acid method using an EPOCH microplate spectrophotometer (BioTek Instruments Inc., USA). For this procedure, 1 mL of the phenol reagent solution (5 g of phenol in 100 g of distilled water) is added to 1 g of SG solution. Then, 6 mL of concentrated sulfuric acid are added to the solution. This sample is allowed to stand for 10 minutes at room temperature. After that, the warm sample is shaken and placed in a water bath at 25 °C for 15 minutes. The absorbance is measured within 30 seconds at 485 nm with the instrument set at zero absorbance with the reagent blank [14].

BIODEGRADABILITY TEST OF SCLEROGLUCAN

The biodegradation of SG was evaluated according to the OECD 301 test guideline (1992) [15] by measuring the CO2 production with a WTW respirometric OxiTop® IS (Xylem Analytics, Germany). The tests were carried out by adding 100 ppm of SG to a mineral solution containing 21.74 g/L K2HPO4, 8.50 g/L KH2PO4, 1.70 g/L NH4Cl, 44.60 g/L Na2HPO4 ∙ 12H2O, 22.5 g/L MgSO4∙7 H2O, 0.25 g/L FeCl3∙6 H2O, and 27.5 g/L CaCl2 [15]. The pH value of all solutions was adjusted to 7. For the control of endogenous respiration, the oxygen uptake rate was measured by using the inoculum and a mineral medium. The sludge from the wastewater treatment plant (WWTP) of the ICP was used as the inoculum. The samples were incubated for 28 days at 20°C ± 1. Sodium acetate served as a positive control, and to verify the performance of the inoculum. According to the OECD guidelines (OECD 301), the sodium acetate must exhibit dissolved organic carbon (DOC) removal >70% in 28 days, otherwise, the test should be repeated using an inoculum from a different source [15].

At the end of the tests, the percentage biodegradation of SG at each time was compared to that obtained for the sodium acetate [16]. This percentage was calculated by the following equation:

Where Ct is the mean concentration of DOC in the inoculated culture medium containing test substance at time t (mg DOC/l), Co is the mean starting concentration of DOC in the inoculated culture medium containing the test substance (mg DOC/l), Cbl(o) is the mean starting concentration of DOC in blank inoculated mineral medium (mgDOC/l), and Cbl(t) is the mean concentration of DOC blank inoculated mineral medium at time t (mgDOC/l).

TEST ORGANISMS

Daphnia pulex, Scenedesmus acutus and Oreochromis sp. were the organisms used in the ecotoxicological assays of the SG solutions [17-19]. The SG stock solution was prepared in RW at 1000 ppm. Then, the stock solution was diluted with the appropriate amount of RW to obtain five samples with different concentrations of SG (100%, 50%, 25%, 12.5% and 6.25% v/v). The Scenedesmus acutus and Daphnia pulex organisms were obtained from a stock culture available at the biotechnology laboratory at ICP, while the Oreochromis sp. were bought from a local supplier. Before the tests, the Oreochromis sp. organisms were acclimated to pure water for 9 days, according to the OECD 203 test guideline [18,20].

The bioassay data for inhibition of the Scenedesmus acutus (algae) was used to determine the toxic effects of the samples on primary producers. The samples required for these tests were prepared in 250 mL Erlenmeyer flasks, containing 50 mL of the study solution and 5 mL of bristol culture medium [21]. First, the algal density in each sample was determined using a Neubauer chamber. Then, a standard volume of inoculum was added to each flask to obtain an initial concentration of 5.0E + 03 cells/mL. Each sample was tested in triplicate. The samples were incubated in a chamber with controlled temperature (24 ± 2°C), light (6,000-7,000 lux), and constant shaking (100-150 rpm). The cells density in each flask was determined at 24, 48 and 72h.

The acute toxicity tests with Daphnia pulex were used to determine the toxic effects of the study samples on aquatic invertebrates. This bioassay was conducted in an environmental cabinet at constant temperature (22 ± 1°C), moderate light intensity (2000-6000 lux) and 16/8h light/dark regime. The bioassays were carried out in 50 mL glass beakers, containing 30 mL of the studied solutions. For the experiments, five neonates of Daphnia pulex were introduced into each beaker. Four replicates of each sample were prepared. The living organisms of Daphnia pulex were determined at 24 and 48h. Control samples containing 20 individuals were divided into 4 groups and kept in dilution water. After 48-hour incubation, the number of live organisms was registered and used to obtain the lethal dose 50 (LD50).

The acute toxicity tests with Oreochromis sp. were used to determine the toxic effects of the study samples on aquatic vertebrates. The tests were carried out in an air-conditioned room at constant temperature (20±3°C), moderate light intensity (2000-6000 lux) and 16/8h light/dark regime. The bioassays were carried out in 3L fishbowls, containing 2L of the studied solutions. For the tests, five fingerlings of Oreochromis sp. were introduced in each container with a hand net. Two replicates were prepared for each SG concentration. The living organisms of Oreochromis sp. were determined at 24, 48, 72 and 96 h. Injection (RW) and potable water were used as positive and negative control samples, respectively.

The effect of SG solutions on the reproductive output of Daphnia pulex was evaluated through chronic toxicity bioassays. For this purpose, young females of Daphnia pulex were exposed for 21 days to different concentrations of SG. At least, 10 organisms were added to each sample and the water was changed every 72h. The tests were carried out in an environmental cabinet at constant temperature (22 ±1°C), moderate light intensity (1000 - 4000 lux) and 16/8h light/dark regime. During the test, the total number of live offspring produced by each parental organism was determined.

The toxicological classification of the samples was based on the treaty established by the European Economic Community (EEC), which determines the criteria for assessing risks to the environment and human health associated with hazardous substances (Directive 67/548/ EEC). The risks classification is shown in Table 2 [22].

STATISTICAL ANALYSIS

The results of the acute toxicological tests were analyzed using the Probit program v2.5 [23]. The lethal concentration (LC50) was calculated following the USEPA guidelines (2002) [24]. The anaerobic biodegradation of the SG solutions was determined through the viscosity changes of the solutions, while the aerobic biodegradation was calculated with the changes in the SG concentration. The biodegradability tests were validated since the deviation of the measured values of the biological replicas was less than 20%.

One-way Anova was used in the chronic toxicological tests with Daphnia pulex to determine if there were significant differences (p>0.05) in the reproduction rate between the negative and positive controls and the SG solutions. Tukey's test was performed to confirm the statistical significance of the data [25].

For the anaerobic and aerobic tests, one-way Anova was used to determine the statistical significance (p>0.05) of the changes in the viscosity and the concentration of SG in the solutions, respectively. Subsequently. Tukey´s test was performed.

3. RESULTS

ANAEROBIC BIODEGRADATION OF SCLEROGLUCAN.

Figure 4 shows the viscosity changes of the SG solutions as a function of time. The p-value of the abiotic controls in sterile water (RSW/SG) and synthetic brine (SB/SG) showed that there were no significant differences in the viscosity changes of the SG solutions after 5 weeks (p = 0.345 and 0.242, respectively). This result was attributed to the non-ionic nature of SG, which made it salt-resistant [26].In contrast, the viscosity reduction of the biotic control (RW/SG) was 92% (from 49.5 to 3.9 cP, p=0.001), suggesting that the bacteria use SG as a substrate. However, the viscosity reduction of biotic control with the biocide (RW/SG/B) was 34% (from 49 to 32.3 cP).

Figure 4 Viscosity as a function of time of the SG solutions in injection water with (RW/B) and without biocide (RW), sterilized injection water (RSW), and synthetic brine (SB) at 7.3 s-1 and 30°C.

The anaerobic bacterial count in the RW/SG solution increased from 1.0E +02 to 1.0E+03 bacteria/mL at week 5 (Table 3). The bacterial count of the RW/SG/B solution at time 0 was <10 bacteria/mL, but from week 3 an increase to 1.0E+01 bacteria /mL was observed. It indicates that the biocide was not 100% effective. The initial bacterial count of RW brine was 1.0E+02 bacteria/mL and decreased to <10 bacteria/mL in week 5, due to the lack of carbon sources that enable the bacterial growth. In the abiotic controls with sterile water (RSW/ SG) and synthetic brine (SB/SG), the initial bacterial count was <10 bacteria/mL.

The bacterial growth and the decrease in viscosity of the SG solutions were attributed to the fact that bacteria can use the biopolymer as a carbon source. It has been reported in the literature that the metabolism of glucans occurs because the glucanase enzymes produce by bacteria break βdown biopolymers. For SG, the glucanase enzymes break down the β -d-(1-3)-glucopyranosyl chain [27,28] and their link with the -d-(1-6)-glucopyranosyl groups, depolymerizing SG.

AEROBIC BIODEGRADATION OF SCLEROGLUCAN.

Figure 5 shows the change in concentration of 100 and 200 ppm SG sheared solutions prepared in RW and RSW. For abiotic controls, there were no significant changes in SG concentration (7% and 5% for RSW / SG solutions of 100 ppm (p = 0.511) and 200 ppm (p = 0.733), respectively). However, in the presence of bacteria, the SG concentration of the 100 ppm and 200 ppm RW / SG solutions was reduced by 48% (p = <0.001) and 27% (p = <0.029), respectively. Additionally, the aerobic bacteria count increased in SG solutions prepared in RW and decreased in RW brine after 15 days (Figure 6). As mentioned before, the decrease in the concentration of SG in solution is attributed to the fact that this biopolymer can be used as a substrate for the metabolism of microorganisms [29].

Figure 5 SG concentration of the 100 and 200 ppm SG solutions prepared in injection water (RW) and sterilized injection water (RSW) as a function of time.

BIODEGRADATION OF SCLEROGLUCAN.

Figure 7 shows the biodegradation of SG and sodium acetate as a function of time. The sigmoid behavior of the data and the biodegradation of the sodium acetate (~100%) confirmed the validity of the tests [30]. Additionally, the deviation of the measured values of the biological replicas was less than 20%. The biodegradation of SG was 75.8% after 23 days. According to the OECD 301 test guideline (1992), SG can be classified as a biodegradable polymer.

ACUTE TOXICITY TESTS

The result of the toxicity test and the physicochemical parameters of the RW/SG solution are presented in Table 4. The method validation was carried out according to the OECD 201 test guideline (2011) (19). For this, it was determined that the coefficient of variation between replicas was less than 35% and the biomass of Scenedesmus acutus. increased by 16% in the control bioassays after 72h.

According to the OECD guidelines established for this test (OECD 202, 2004 [26] and OECD 203, 2019), the sample was classified as not harmful to the environment. However, the toxicity test showed that SG could have deleterious effects on Scenedesmus acutus. population based on the LC50 values (Table 4). The mean survival percentage of Daphnia pulex and Oreochromis sp. was above 90%. Therefore, the RW/SG sample does not show acute toxicity for both types of organisms.

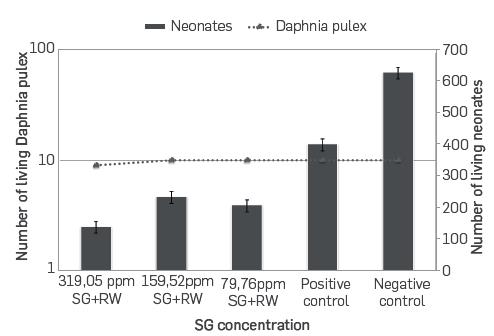

The chronic bioassay with Daphnia pulex in the RW/SG was performed to evaluate the effect of sublethal concentrations of SG on the survival and reproduction of the cladoceran. It was observed that the survival of the Daphnia pulex was not significantly affected by SG (Figure 8).

Regarding the reproduction of Daphnia pulex, the number of neonates was considerably lower at higher SG concentrations (Figure 8). The statistical analysis showed that there were significant differences (p=0.007) between the SG samples and the negative control. This difference may be related to the high conductivity of the RW (2500 μs/ cm), which affects the metabolism of the Daphnia pulex. In contrast, there were no significant differences (p=0.16) between the SG solutions and the positive control (RW).

CONCLUSIONS

In the biodegradation tests, it was observed that the bacteria grew in the RW/SG, leading to the reduction of the SG concentration and the lost viscosity of the solutions because bacteria use the biopolymer as an energy and carbon source. Additionally, it was found that the biocide did not mitigate the bacterial growth in the RW/SG/B solution. The biodegradation of SG was 75.8% after 23 days. The acute ecotoxicological bioassays of the RW/SG solution showed that there was no evidence of acute deleterious effects of SG on the Scenedesmus acutus, Daphnia pulex and Oreochromis sp. microorganisms, according to the OECD (201, 202, 203) guidelines established for these tests. Therefore, the sample was classified as not harmful to the environment. It was concluded from the chronic ecotoxicological bioassays that there was no effect of SG on the mortality of Daphnia pulex, regardless of the tested SG concentrations. The proposed experimental protocol was validated through the tests performed in this study. This protocol can be applied to evaluate the biodegradation and toxicity of other natural and synthetic polymers.