Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ciencia y Tecnología Agropecuaria

Print version ISSN 0122-8706On-line version ISSN 2500-5308

Cienc. Tecnol. Agropecuaria vol.20 no.2 Mosquera May/Aug. 2019

https://doi.org/10.21930/rcta.vol20num2art:1459

Economía y desarrollo rural

Development of natural rubber suppliers in the Papaloapan River basin, Mexico: progress and limitations

1Estudiante de doctorado, Universidad Autónoma Chapingo (UACh), Centro de Investigaciones Económicas, Sociales yTecnológicas de la Agroindustria y la Agricultura Mundial (Ciestaam). Chapingo, México.

2Profesor investigador, Universidad Autónoma Chapingo (UACh), Centro de Investigaciones Económicas, Sociales y Tecnológicas de la Agroindustria y la Agricultura Mundial (Ciestaam). Chapingo, México.

3Profesor investigador. Universidad Autónoma Chapingo (UACh), Centro de Investigaciones Económicas, Sociales y Tecnológicas de la Agroindustria y la Agricultura Mundial (Ciestaam). Chapingo, México.

4Investigador, Universidad Autónoma Chapingo (UACh), Centro de Investigaciones Económicas, Sociales y Tecnológicas de la Agroindustria y la Agricultura Mundial (Ciestaam). Chapingo, México.

5Corporación Colombiana de Investigación Agropecuaria - Corpoica

Mexico has optimal conditions for the cultivation of natural rubber but imports more than 80 % of its consumption. The model of development suppliers through Innovation Management Agencies (agi, for their acronym in Spanish) was implemented to improve this situation. This work analyzed the achievements of technical assistance services provided by two agi to two rubber agro-industries (ai) and their suppliers located in the Papaloapan River Basin, Mexico. From 2011 to the beginning of 2014, the Agencies generated reports and databases about technical, productive, organizational and commercial parameters of both rubber producers and agro-industries. With this information, global databases were constructed to analyze changes in production, supply, and innovation adoption. The results show that the intervention of the Agencies was relevant and effective in improving production and post-harvest parameters. The production of coagulated rubber also increased as well as the availability of raw material to the agro-industries. Moreover, production costs were able to be reduced, and the quality of the rubber was improved. However, the fall in rubber prices at the end of 2013 caused setbacks in the adoption of innovations and the agriculture-industry integration, showing the fragility of supplier development, as well as of the ai involved serving as lead and trailblazer companies in their suppliers’ networks.

Keywords agricultural extension; agroindustry; Hevea brasiliensis; innovation adoption; technology transfer

México posee condiciones óptimas para el cultivo del hule natural; sin embargo, importa más del 80 % para su consumo. Para mejorar esta situación se implementó un modelo de desarrollo de proveedores a través de Agencias de Gestión de la Innovación (agi). Este trabajo analizó los logros de los servicios de asistencia técnica proporcionados por dos agi a dos agroindustrias (ai) de hule y a sus proveedores ubicados en la Cuenca del río Papaloapan, en México. De 2011 a inicios de 2014, las agi generaron informes y datos sobre parámetros técnicos, productivos, organizativos y comerciales, tanto de productores como de ai. Con la información se construyeron bases de datos globales para analizar los cambios en producción, abasto y adopción de innovaciones. Los resultados muestran que la intervención de las agi fue pertinente y eficaz en la mejora de parámetros productivos y de poscosecha. Además, se incrementó la producción de hule coagulado y la disponibilidad de materia prima para las ai. También se lograron reducir los costos de producción y mejorar la calidad del hule. No obstante, la caída del precio del hule a fines de 2013 provocó retrocesos en la adopción de innovaciones y en la integración agricultura-industria, lo que evidenció la fragilidad del desarrollo de proveedores, así como de las ai involucradas para fungir como empresas tractoras.

Palabras clave adopción de innovaciones; agroindustria; extensión agrícola; Hevea brasiliensis; transferencia de tecnología

Introduction

Natural rubber (Hevea brasiliensis (Willd. Ex A. Juss.) Müll. Arg.) belongs to the Euphorbiaceae family and is an agricultural commodity with great industrial importance, because some of the products that are made with it do not have a synthetic substitute of the same quality (De Dios de la Cruz, Lesher Gordillo, Gallardo Álvarez, Molina Martínez, & Jiménez Gómez, 2015). Its price is established in the world market and is very variable due to the instability of its demand in the major consuming countries, changes in the production in the main supplying countries, and the fluctuations in the price of crude oil, from which its main substitute —synthetic rubber— is produced (Aguirre Ríos & Santoyo Cortés, 2013; Coelho Junior, Pereira de Rezende, Coimbra Borges, & Donizette de Oliveira, 2009).

According to data from the Food and Agriculture Organization (fao), 2018, worldwide, Thailand and Indonesia occupy the first and second places in the production of natural rubber with 4.5 and 3.2 million tons produced in 2016, respectively. Likewise, these countries have the largest harvested area, Indonesia with 3.6 million hectares and Thailand with 3.1 million hectares.

Nonetheless, the cultivation of rubber in Mexico occurs on a smaller scale. According to data from Servicio de Información Agroalimentaria y Pesquera (siap) (2018), in 2016, 62,351 tons of natural rubber was produced in 23,099 hectares of plantations with an average yield of 2.7 t/ha, a higher amount compared to the major producing countries. Data provided by siap (2018) also shows that Oaxaca was the fourth rubber producer state in the country (6,313 t) in 2016, and contributed with 7 % of the 685.6 million Mexican pesos (mxn) of the rubber production value in Mexico; further, Veracruz occupied the first place (35,938 t) and, therefore, it is the state that contributed most to the production value with 43 %.

In 2013, 27 processing agro-industries (hereafter ai) were established in Mexico, of which 15 were in operation: five in the state of Veracruz, six in Oaxaca, one in Chiapas, and three in Tabasco (Aguirre Ríos, 2012). These four states are the leading rubber producers in the country. Besides, Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias (Inifap) (2012) of Mexico reported that there are 35,827 hectares with optimal conditions for the development of this crop, of which 11,988 are located in Oaxaca, 11,229 in Veracruz and 10,628 in Tabasco.

Regarding the features of the rubber producers in Mexico, these are elderly and mostly over 50 years old; they have low levels of education as they have not finalized their basic education; however, they have more than 13 years of experience cultivating rubber in areas of little more than four hectares (Aguilar Gallegos, Muñoz Rodríguez, Santoyo Cortés, & Aguilar Ávila, 2013).

Particularly in the state of Oaxaca, 79.6 % of the plantations have an area between 0.5 and 3.5 hectares, located mainly in the Papaloapan River basin region. In this region coagulated rubber is produced (agglomeration of the hydrocarbon particles of rubber that is formed by adding formic, acetic or citric acid) and is marketed in three different channels: 58.1 % of the producers sell it to regional-type processors, 40.2 % do so with regional intermediaries, and only 1.7 % sell it to organizations outside the production region (Oficina Estatal de Información para el Desarrollo Rural Sustentable [Oeidrus], 2011).

In addition to agroclimatic conditions, its industrial value and proximity to the main consumption centers are characteristics that encompass the interest that exists for the development of this crop (Rojo Martínez, Martínez Ruiz, & Jasso Mata, 2011). However, despite having adequate soil, climate and technology conditions to be selfsufficient in natural rubber and even to export this product, Mexico imports between 80 % and 90 % of its rubber consumption (Aguirre Ríos & Santoyo Cortés, 2013). In other words, the demand for natural rubber in Mexico is not covered (Moctezuma López et al., 2015), so there is an opportunity for rubber production, especially concerning the substitution of imports (Moctezuma López, Ortiz Cervantes, Hernández Cruz, Díaz Fuentes, & Velázquez Fragoso, 2017).

To encourage and strengthen the production of natural rubber in Mexico, the federal government, through Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación (Sagarpa), subsidized technical assistance services (including productive, management and organization issues) for several crops in the region of the Mexican humid tropics, including rubber. This was done through Agencias de Gestión de la Innovación para el Desarrollo de Proveedores (agi) [Innovation Management Agencies for Supplier Development], to improve productivity and integration between producers and the ai (Sagarpa, 2011). The agi were formed by teams of professionals oriented to promote the adoption of better technical and organizational practices, through the technical assistance of specialists, who motivated the interaction of actors from different chains at a territorial level (Aguilar-Ávila, Santoyo-Cortés, Muñoz-Rodríguez, Aguilar-Gallegos, & Martínez-González, 2015), and under a network approach (Aguilar-Gallegos et al., 2017).

In this sense, this work has the aim of analyzing the intervention strategy of the agi to specify to what extent the technical assistance services provided were an efficient intervention to improve the rubber producers link, the supply networks and the integration between the rubber suppliers and the ai they supply.

Reference framework

Operation of the Innovation Management Agencies (agi)

The innovation management agencies (agi, for their acronym in Spanish) were considered as a model of agricultural extension that operated in Mexico from 2004 until 2014 (Aguilar-Ávila et al., 2015) to promote agricultural innovation through the interaction between farmers and other actors. The executing agencies of the agi model were Instituto Nacional para el Desarrollo de Capacidades del Sector Rural (inca Rural) and Universidad Autónoma Chapingo (UACh). These agencies launched a public call for agro-industrial companies with schemes for the development of suppliers to hire Specialized Technical Groups for the accompaniment and technical assistance to agro-industrial crop producers; further, in this process, each group contracted formed an agi (Sagarpa, 2011).

During their operation, the agi identified key actors (leading producers) to accelerate the dissemination of information and knowledge. They also selected the best production, administration, and organization practices to be promoted and adopted by producers. Its intervention focused both on promoting relevant practices and on working with key actors for the dissemination and structuring of networks for the exchange and distribution of information and knowledge (Aguilar-Ávila et al., 2015; Aguilar-Gallegos et al., 2017). As part of the activities of an agi, a catalog of the best practices that a producer —in this case, a rubber producer— should adopt to improve their productivity was developed, some of which were selected and disseminated through innovation networks. To this end, a diagnosis was first made of both the producers and the ai through a baseline survey, and with their analysis, an intervention strategy was developed, which was implemented in a period of eight to ten months per year through the operation and hiring processes of the agi.

Within the strategy, those that provide technological, economic, organizational or social solutions that are not necessarily novel in a global context, but that are locally based, were considered as best practices. New or adapted practices were also included, as well as the conditions for these to be adopted and, thus, a favorable change in their productive activity.

The above is based on innovation management, aimed at organizing and directing the available resources aiming at increasing the creation of new knowledge and ideas that generate wealth, either through the acquisition of new products, processes and services or improvements to existing ones (Birkinshaw, Hamel, & Mol, 2008; Muñoz Rodríguez, Aguilar Ávila, Rendón Medel, & Altamirano Cárdenas, 2007). It should be noted that the term “innovation management” was used referring to the professional technical assistance provided by the agi in the selection and dissemination of best practices, aiming at their adoption and thus, achieve an impact on the objectives of the development of suppliers, one of them being the integration between producers and agro-industries.

The agi motivated the coordination and interaction of the farmers with the ai because it has been observed that a higher degree of integration reduces the use of intermediaries in the chain, decreases the uncertainty of supply and demand, and protects the purchase against price fluctuations. Furthermore, it strengthens value-added activities, it raises farmers' income and provides an incentive to increase agricultural productivity and improve product quality (Mendoza-Robles, Parra-Inzunza, & de los Ríos-Carmenado, 2010; Porter, 1980; Reddy, 2013).

Key concepts

The integration between agriculture and industry is related to the links established by the ai and the suppliers to carry out the purchase and sale of raw materials and can be found with different degrees of associative organization or integration (Santacoloma, Suárez, & Riveros, 2005). The degree of integration is measured by the ownership, level of participation, risk and reward shared by partners in the business (Vermeulen & Cotula, 2010). Hence, we can distinguish three degrees of integration between a company and its suppliers: 1) purchase in the open market (spot market), which typically occurs in agricultural commodity chains; 2) vertical coordination (chain coordination) through the establishment of purchase and sale agreements and contracts, and 3) vertical integration, in which the company is responsible for producing its own raw material or carries out the stages of its productive process under the same direction and guidelines (Castellanos, Rojas, Villarraga, & Ustate, 2001; Economic Comisión Económica para América Latina y el Caribe [Cepal], Deutsche Gesellschaft für Internationale Zusammenarbeit [gtz], & Food and Agriculture Organization [fao], 1998; Da Silva, 2005; Vermeulen & Cotula, 2010).

The development of suppliers is a coordination mechanism that companies use to work with their suppliers and ensure that they have the necessary capabilities to support their position in the supply chain (Arroyo López & Sánchez Maldonado, 2009). The development of suppliers is considered as any set of activities carried out by a purchasing company to improve the performance or capacity of the supplier so that it can meet the short and long term needs of the purchasing company (Krause, Handfield, & Scannell, 1998). This effort is essential because suppliers are a source of innovation and competitiveness for companies (De Jong & Hulsink, 2012; Porter, 1980).

In this sense, several authors (Arroyo López & Sánchez Maldonado, 2009; Miglierini & Treviño, 2012) have pointed out that the relevance of suppliers lies in the fact that the products and services supplied influence the quality, cost and delivery times of the products manufactured by the buying company, hence, the need to develop these.

Intervention strategy

Based on the concepts mentioned above, the agi implemented intervention strategies based on the initial diagnosis and baseline indicators to improve them and, thus, increase rubber yield per hectare, promote agriculture-industry integration, reduce production costs and improve the quality of raw materials through technical assistance. This included the dissemination of best practices among producers and the accompaniment of the ai to promote the articulation between this and its suppliers. To do so, they applied the methodology proposed by Aguilar-Ávila et al. (2015), which consists of five stages: 1) definition of the baseline: measuring indicators that account for the starting point; 2) management strategy design: best strategic, tactical and operational practices to be carried out to modify the baseline indicators; 3) monitoring system: processes and instruments to confirm, verify and communicate that the baseline indicators are being modified; 4) operation: implementation of the management strategy and monitoring system, and 5) evaluation: objective assessment of the degree of compliance of the activities, products and results proposed.

In this context, this article also helps to show to what extent an intervention strategy that considers a methodological design, the selection of activities to be developed, as well as indicators for its measurement, can improve farmers' performance and articulation with the ai.

Materials and methods

The intervention of the agi object of this study was developed in the Papaloapan River basin region of the state of Oaxaca, Mexico. The achievements of the work carried out by two agi located in the municipality of San Juan Bautista Tuxtepec were evaluated. However, the names of the ai are not included to ensure the confidentiality of the information. Each agi collaborated with a natural rubber processing ai, offering technical assistance to part of its coagulated rubber suppliers. agi A gave support to a processing ai property of a cooperative (from now on aic) and 180 of its randomly selected suppliers; on the other hand, agi B gave support to a private-owned processing ai (hereinafter aip), as well as to 120 of its suppliers who were directly selected by the ai and theagi.

The information analyzed was obtained from the annual reports prepared by the agi and stated to the executing agencies of Sagarpa as proof of their operation, as well as from the databases that the same agencies generated from baseline surveys and end line data. The surveys for producers were divided into four main sections: 1) attributes of the producer and its production unit, including age, experience in the cultivation of rubber, education, size of the plantation, yield, production costs, marketing channels, and volume delivered to the ai; 2) dynamics of innovations with technical and organizational parameters, such as carrying out best cultivation and harvesting practices; 3) social, technical and commercial networks; and 4) other aspects of interest of the chain.

With this information, a database with 524 records was built, from which the changes of the variables mentioned in the study period were analyzed, i.e., at the beginning of the annual technical assistance cycle of the year 2011 (baseline) and at the end of the service in the year 2014 (end line).

The surveys designed for the ai were divided into three sections: 1) general data, which indicate the rotation, location and organizational structure of the ai; 2) features of the operation, such as the production process, customers, and sources of financing, support, and assistance; and 3) the supply and provider network, which emphasized in the number of suppliers, collection centers and capacity used.

Furthermore, information from semi-structured interviews including four technical advisers (two from each agi), one manager from each ai, and operative personnel from the processors (one worker from each ai) were analyzed. These interviews had a different format depending on the actor and were designed according to the scope of their participation in the intervention of the agi.

The value network of the agi was analyzed to validate the relevance of the intervention strategies implemented by the same, and based on what was proposed by Brandenburger and Nalebuff (1997). Following what other authors have indicated about the study of agri-food value networks (Barrera Rodríguez, Baca del Moral, Santoyo Cortés, & Altamirano Cárdenas, 2013; Muñoz Rodríguez, 2010), the central problem and the causal complex of the ai were identified to complement the information of the value network.

To measure the adoption of the best practices that were disseminated by the agi and adopted by the producers, an indicator proposed by Muñoz Rodríguez et al. (2007) called the index of adoption of innovations (InAI) was calculated. This index has been widely used to measure adoption in different agricultural activities, such as beekeeping (Martínez-González et al., 2018), tropical plantations (Aguilar-Gallegos et al., 2016; Aguilar-Gallegos, Muñoz-Rodríguez, Santoyo-Cortés, Aguilar-Ávila, & Klerkx, 2015), sheep and goat production (Aguilar-Gallegos et al., 2017; Martínez-González et al., 2011), and also in the horticultural sector (Avendaño-Ruiz, Hernández-Alcantar, & Martínez-Carrasco-Pleite, 2017; García Sánchez, Aguilar Ávila, & Bernal Muñoz, 2011), among others. For each producer, the level of adoption of practices before and after the intervention of the agi was measured. The calculation of the inai is usually done by innovation or practice category (health, nutrition, among others), and at the end, a general indicator is calculated. When doing so by category, the practices adopted by the producer are accounted compared to the total number of practices contained in that category; subsequently, for the general InAI, the InAI of the categories are averaged. With this indicator, it is possible to measure the adopting capacity of the producers, i.e., with a higher InAI the adoption is also higher and vice versa (Aguilar Gallegos et al., 2013).

The statistical package sas® sas, 2004) was used to establish the significance of the increase in the adoption of practices during the analysis period. The improvements in the productive parameters of producers were estimated through the changes achieved in yield, quality, and costs, mainly.

The coagulated rubber collection networks of both processors were identified to study the dynamics of the supply networks of each ai, and the evolution of the number of suppliers, the volume of raw material collected, the number of collection centers and the capacity used by the ai during the study years were analyzed.

Consequently, the activities promoted by the agi were analyzed to encourage the establishment of links between suppliers and ai, such as the number of contracts signed with suppliers and the delivery of economic incentives or vegetative material for the establishment of new plantations; with these data, the changes occurred during the intervention period were evaluated.

Finally, between July and August 2015 and between June and July 2016, six semi-structured interviews were conducted with those persons directly involved in the operation and scope of each agi model, i.e., to the director general of each ai, and to the manager and to a technical advisor of each agi, to learn about their activities after the intervention of the agi model. With this, it was possible to evaluate the permanence and sustainability of the actions carried out, as well as the influence of various environmental changes on the ai.

Results and discussion

The results are addressed in five areas: 1) the relevance of the intervention strategies developed by the agi is analyzed; 2) the improvements achieved in the productive base of the suppliers are examined; 3) the changes reached in the supply networks are shown; 4) the changes in the integration between the rubber producers and the ai are presented; 5) all the advances made are discussed analyzing the limits to the progress of suppliers in products such as coagulated rubber.

The relevance of the intervention strategies developed by the agi

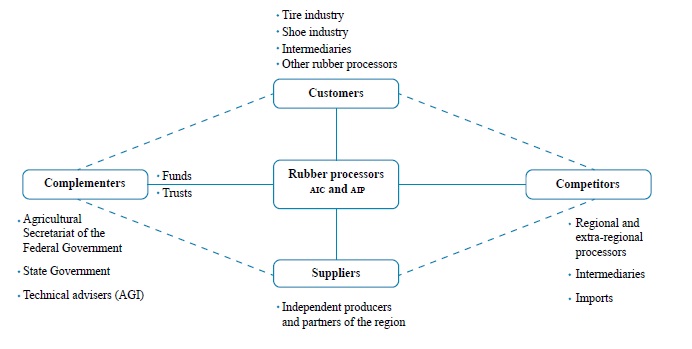

Both ai assessed produce dry granulated rubber. The aic has an installed capacity of 3,600 t/year of which only 42 % was used in 2011. On the other t/year, of which only 65 % could be used. Figure hand, the aip had an installed capacity of 480 t/ 1 shows how its value network is integrated. The year in 2011, of which 80 % was used; however, characteristics of the nodes in this network are only one year later, in 2012, it increased to 720 discussed below.

Suppliers: This node includes producers of coagulated rubber that are located in the basin of the Papaloapan River. In 2011, 56.2 % of 300 producers attended by the agi reported lower than average yields compared to the total number of producers surveyed in the baseline (2.29 t/ha/year) study, mainly due to the lack of implementation of health, nutrition, harvest and postharvest management practices, which is also reflected in the low quality obtained in the field and during processing. Therefore, the potential to improve returns is essential and is more associated with knowledge problems than with economic resources, which agrees with what was pointed out by De Dios de la Cruz et al. (2015). These authors consider that the lack of support for small producers and the lack of knowledge on specialized techniques for cultivating and harvesting natural rubber are limiting factors for the development of this tropical crop.

Customers: This node includes all stakeholders that use rubber to manufacture tires, balls, hoses, and shoes, mainly. The total production of the ai is sold in the domestic market where it competes primarily with imports from Guatemala and Malaysia. Therefore, the rubber producers can place any additional production to the one obtained in the study years (considering that there is an unmet demand for this material) that complies with the established standards, as long as they are competitive in costs compared with the imports.

Complementers: The functions of these actors are to help improve the competitive positioning of the ai, and these include government agencies at the municipal, state and federal levels that complement the suppliers through subsidies for investments and technical agricultural assistance services. They also complete the processing through subsidies or credits to improve their operation and infrastructure. In general, their role is linked to public programs, and its influence is not coherent, except for the Humid Tropic Program while it operated (Sagarpa, 2011). In this node, the absence of rubber producer organizations is noteworthy, which limits their ability to negotiate the definition of public policies for this sector. On the other hand, the ai do not usually commit to the credit institutions because they do not have a regular raw material supply that gives them the security to pay off the debt.

Competitors: synthetic rubber is the primary substitute and competition of natural rubber, so the prices of the latter are highly correlated with oil prices. The ai compete with imports of dry rubber, which meet international quality standards, but the strongest competition is the collection of raw material with other regional or extra-regional processors located in municipalities of Veracruz and Guatemala, mainly. This competition is given through a network of local agents who collect the rubber and compete with others by giving advance payments, better prices and cash payment to the producers, or diminishing the quality requirements of the coagulated rubber. This significantly reduces rubber availability for the processors in the region.

The above data shows that the value network of the rubber ai has a central problem: insufficient availability of natural coagulated rubber in the region, which limits the collection of raw material from the processors, causing them to operate below 50 % of their installed capacity. Consequently, the production unit costs increases as the fixed costs are divided between the lower dry rubber production volumes. This low level of operation is not a consequence of market problems, as the ai can sell their production while accepting the dry rubber prices fixed by imports. The essential cause is the low availability of the raw material that arises from the weaknesses of the suppliers’ node, as inadequate plantation and harvest management —due to ignorance and little investment— that cause low yields and high production costs (Vargas-Canales, Palacios-Rangel, Acevedo-Peralta, & Leos-Rodríguez, 2016). Also, the use of inadequate tapping systems, poor post-harvest management and the lack of price differentiation generates lowquality raw material with low industrial yields. Finally, the atomization of production and the low level of integration between suppliers and the ai make the collection of coagulated rubber more expensive.

The analysis also showed a weak competitive position of the value network of the ai studied and the relevance of focusing the intervention strategy of the agi in improving the productive base of the suppliers, strengthening the supply networks and improving the integration between the ai and its suppliers.

In this regard, it has been found that the payment of better prices for rubber delivery regularity to producers and the guarantee of raw material supply for companies are examples of incentives that can motivate both actors to participate in supplier development activities. In the case of companies, they will be driven in uncertainty contexts with perceived risk in their supply, but also by competition with other companies; on the other hand, providers would be willing to participate in this type of scheme if they perceive advantages such as access to financing, a secure market and access to inputs (Cepal et al., 1998; Miglierini & Treviño, 2012). Later, the presence or absence of these incentives is analyzed and discussed.

Improvements in the productive base of suppliers

The providers assisted by the agi had, on average, 57.4 years of age, 23 years of experience as natural rubber producers, four years of education and 2.5 hectares of plantations; similar results were reported by other authors (Aguilar Gallegos et al., 2013). The main difference between the suppliers of both processors was found in the yield of coagulated rubber obtained in the field, in which the producers of the aip stood out with 2.6 t/ha; meanwhile, the suppliers of the aic obtained a slightly lower amount (2.1 t/ha).

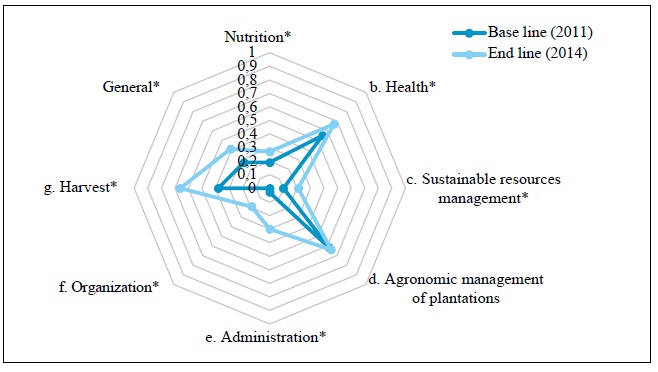

During its operation, the agi promoted production practices for plantations related to nutrition, health, and sustainable management of resources, agronomic management of plantations, administration, organization, and harvesting. The promotion of these improvements was made through direct technical assistance in the plantations of the producers, classroom sessions and training events, as well as the delivery of technical brochures and direct accompaniment to the producers in their plantations, which are common activities in the agi model as reported by Aguilar-Ávila et al. (2015). The increases in adoption levels are shown in figure 2, in which the InAI is compared at the beginning and the end of the agi intervention.

Source: Elaborated by the authors

Figure 2. Adoption of best practices by category.* The changes between the baseline and the end line are highly significant (p <0.001).

The results showed that there were important advances in the level of adoption of practices in the categories "g. Harvest", focused on the correct extraction of latex and its post-harvest handling, and on "e. Administration", referring to the production unit, i.e., registries of practices, income, and expenses of the activity. Both categories are characterized by including practices with high relative progress and being simple to perform, features that are desirable to increase the adoption of practices and innovations (Rogers, 2003).

In descending order, the category "c. Sustainable management of resources" includes practices for the management of agrochemical containers and the use of organic acids for the coagulation of latex. These types of practices had lower levels of adoption, both initial and final because they are perceived as complex or difficult to carry out, in addition to the fact that these are not commonly carried out by the producers of the region, characteristics that reduce the possibility of adoption (Rogers, 2003). In the case of the category "f. Organization", practices to improve the interaction between producers such as the realization of joint purchases that reduce input costs or sales consolidated with the ai were promoted. However, the adoption of practices in this category requires the confluence of several actors and joint participation with the ai, so they had a lower level of adoption.

The practices of the category "b. Health" related to the monitoring and prevention of pests and diseases, despite starting from relatively high levels of adoption, these also had statistically significant increases in their levels of adoption.

Finally, the category "a. Nutrition ", which includes improvements such as foliar and soil analyses as well as the application of fertilizers, had the lowest increases in adoption since it is necessary to invest in laboratory analyses as well as in fertilizers; however, the changes remained statistically significant.

The set of adoptions achieved explains the increase in yield, which went from 2.29 to 2.84 t/ha per year on average and the reduction of production costs of 15,948 to 13,368 mxn/ha. According to Ortiz Hernández (2011), the average yield of a rubber tree begins with 1,237 kg/ha in the first year of harvest and increases progressively to 3,845 kg/ ha in the thirteenth year of production, stabilizing afterward. Therefore, for the assessed producers, there is still an opportunity gap to increase yield. In terms of production costs, the same author mentions that on average, it increases to 14,076 mxn/ha, so the decrease in production costs was significant in the case study.

The quality of the coagulated rubber received by the AI was also improved as reported by the aic, in which the content of impurities decreased from 0.25 to 0.20 %, the weight of the clots also diminished from 70 to 50 kg, and the moisture content was reduced from 52 to 48 %. According to the requirements of the ai, the content of impurities must be equal to, or less than 20 %, the moisture content equal to or less than 50 %, and the weight of the clots must be maximum 50 kg.

Also, it could be noted that the adoption of the practices was greater when dealing with technical aspects of the crop that resulted in better production parameters because according to some authors (Aguilar-Gallegos et al., 2015), the adoption is related to higher levels of production and value generation. On the other hand, the socioeconomic characteristics of the producers assisted are also related to adoption levels; several authors (Aguilar-Gallegos et al., 2015; Cárdenas-Bejarano et al., 2016; Garrido-Rubiano, Martínez-Medrano, Martínez-Bautista, Granados-Carvajal, & Rendón-Medel, 2017; Martínez-González et al., 2011) have reported that the adoption of practices and technologies is positively associated with education and the scale of production, but also inversely with the age of the producers, among other variables.

In sum, the intervention of the agi was effective in improving the productive parameters by allowing the producers to know and carry out better production practices, as well as the best use of their resources. With this, they were able to improve their yields, reduce their production costs and improve the quality of the rubber they produce.

Changes in supply networks

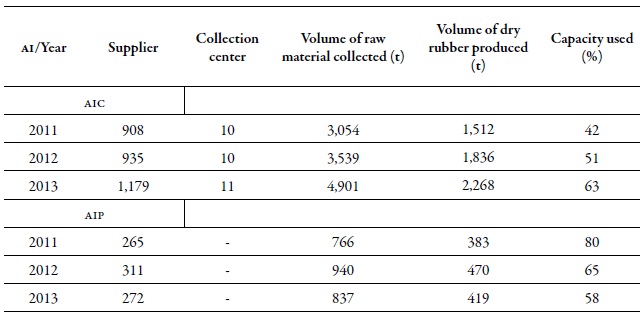

Table 1 shows the dynamics of the ai supply network. First, in the aic, the growth of the stockpile in the period analyzed was almost 30 % per year, as a result of an increase in the number of suppliers and in the average individual contribution, which went from 3.4 t per supplier in 2011, to 3.8 t in 2012, and then to 4.2 t per supplier in 2013. This, in turn, was a consequence of the improvements in yields that producers achieved due to the adoption of best practices. In the aip, the relationship between the volume of raw material collected and the number of suppliers was 2.9 t per supplier in 2011, 3.0 t in 2012, and 3.1 t in 2013, confirming what was stated by Moctezuma López et al. (2017). These authors consider that the technological development and the implementation of innovations can significantly benefit the primary sector and that this benefit is radiated to the agro-industrial sector; in this case, improving the collection of raw materials. As mentioned, the aip expanded its installed capacity from 480 to 720 tons of dry rubber in 2012, the only year in which the number of suppliers increased; for this reason, although it was possible to increase the stock of raw material by almost 10 % in the period analyzed, the use of the utilized capacity in 2011 could not be reached. In addition to the already mentioned low availability of raw material for the processors, in 2013 the number of suppliers and, consequently, the amount of raw material collected by the aip decreased due to two situations that affected the commercialization of dry rubber: the entry of foreign rubber with a lower price and higher quality, and second, the purchase and sale contracts with their customers. Furthermore, they were also affected by the drastic drop in the price of rubber at the end of 2013 and its prevalence until 2015. For this reason, the aip demanded a lower amount of raw material, stopping the stockpile in the first months of 2014. In this sense, the scheme of commission-type stockholders used by the aip with variable routes does not facilitate the loyalty of its suppliers, increasing its price and, possibly, also explains its greater vulnerability in the face of falling prices.

Changes in the integration between rubber producers and the ai

The supply strategy of both ai assessed consists of purchases in the open market, either in the ai itself, in collection centers or their collection routes. Because there are no formal commitments to buy and sell with producers, the patterns of their supplier are very variable and imprecise. However, with some of their most trusted suppliers, they maintain stronger links through the delivery of inputs, harvest materials or loans on account of raw materials.

Therefore, within the work programs of the agi, actions were considered to improve the relationship between the ai and the suppliers. Thus, in 2011, the aic, advised by the agi, distributed free of charge, vegetative material to a part of its suppliers for the establishment of new plantations and, in 2012, delivered vegetative material at 50 % of the production cost. In this way, a total of 166 contracts were signed with the benefitted producers, wherein return they undertook to deliver the coagulated rubber from the first three years of production.

Also, as a strategy to improve the supply before the intervention of the agi, the aic that was paying $1.0/kg of additional remnant to the rubber supplied by the partners from the intervention in 2011, also paid $0.5/kg of remnant to the rubber of non-members; from 2012, the remnant was $1.0/ kg of rubber delivered by its suppliers, regardless of whether they were partners or not. However, with the fall in rubber prices towards the end of 2013, this scheme could no longer be sustained and disappeared.

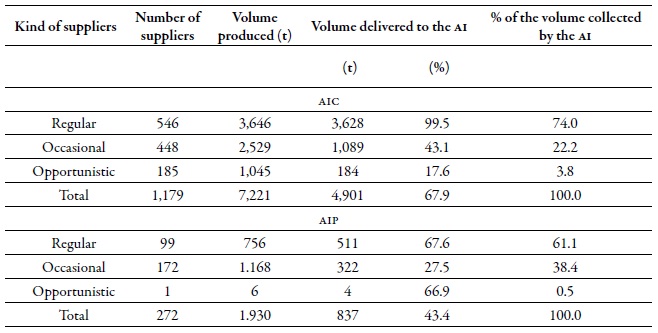

The activity of the agi contributed to the aic having higher knowledge of its suppliers and was able to identify that 48% of the total suppliers delivered raw material on a regular basis, 36 % on an occasional basis, and the remaining 16 % were only opportunists, i.e., those that deliver less than 20 % of their production to the processors, sporadically. In terms of volume, the first group contributed with 74 % of the supply (table 2).

Table 2. Types of suppliers of the processors identified by the agi in 2013

Source: Elaborated by the authors

Note:Regular producers deliver more than 60% of their production to the ai; occasional producers, from 20% to 60%; and opportunistic producers, less than 20%.

Likewise, the best knowledge of its suppliers allowed the aic to specify that in 2013, of its 1,370 shareholder producers, only 403 members continued to supply their own processors. These delivered 2,000 of the 2,600 tons of coagulated rubber produced in that year, which indicates that a significant part of the partners no longer produces rubber, or that the production of the partners is marketed to other processors or intermediaries.

On the other hand, it was found that the aip was less inclined to articulate more with its network of providers. In 2011, it supported some suppliers with polyethylene bags for planting seedlings in small nurseries. In 2013, five of its suppliers received specialized technical assistance for the production of nursery plants and, in the same year, the aip began to pay 1 mxn more for each kilogram of raw material that complied with the quality parameters, thus, granting this benefit to 123 of the 272 suppliers. However, in 2013, this ai could not sustain this benefit either.

The activity of the agi, which attended the aip, contributed to having a greater knowledge of its suppliers and hence, managed to identify that 36 % of the total providers delivered their product regularly, 63 % did so on an occasional basis, and only 1 % were opportunistic. In terms of volume, the first group contributed with 61 % of the supply (table 2).

The results allow arguing that the cooperative nature of the aic motivated decisions that sought to benefit most of the partner producers, meanwhile in the AIP the decision only considered its own interests; in this sense, the payment of preferential prices by the aic to its partners to collect the largest amount of raw material, and the payment of one peso more for quality to only some suppliers carried out by the aip. However, regardless of the cooperative or private nature of each AI, both were vulnerable to the falling prices in 2013. Moreover, the global crisis had long-term consequences and, for 2016, the aip ceased to operate permanently, while the aic reduced its processing capacity. In addition to the above, and with the change in the rules of operation of the federal program that supported the hiring of the agi in 2016, the ai reversed the supplier development strategy.

The limits to the development of suppliers of coagulated rubber for the ai

With the results found, it is possible to argue about the limitations that the development of suppliers has in crops such as rubber. In this sense, the insufficiency of raw material is the main problem of the ai in Oaxaca. Further, within the framework of its intervention strategy, the agi carried out technical assistance and training activities to contribute to the solution of this problem. Thus, it was possible to improve the adoption of practices for the management of the plantation, as well as the use of adequate tapping and post-harvest management systems. Likewise, the supply to the ai increased, and the quality of the raw material collected was also improved. On top, various actions were carried out to bring together and improve the articulation between the producers and the ai.

Nonetheless, this progress was quite fragile and could not materialize the current development of suppliers, since they practically disappeared with the fall of international rubber prices and the withdrawal of federal government support for technical assistance. In this sense, since the end of 2013, the global media announced that Thailand and China had a large amount of undeclared natural rubber in existence, and when it reached the markets, the international price collapsed. Faced with this situation, the regional rubber price in Oaxaca fell from almost mxn 20.0/kg of rubber coagulated in mid-2013 to nearly mxn 4.0/kg at the end of this same year. This meant that the producers reduced the plantation management and, therefore, yields fell; furthermore, the ai reduced their stockpiling, and some even stopped operating.

In relation to this, some authors (Arumugam, Fatimah, Chiew, & Zainalabidin, 2010) identified that the main incentives that motivate farmers to participate in higher levels of integration with their agro-industrial buyers are the following: stability against price volatility, recognition —via prices— of the qualities and services offered by the supplier; and access to relevant commercial information, technology (to improve agricultural, management and post-harvest practices) and inputs. These characteristics could not be sustained in the long term by the rubber ai to their suppliers.

Technical assistance from iga was concentrated on producers with relevant achievements in access to technology, and eventually, access to inputs offered by government programs, but without substantially modifying prices or quality payments, which are the main elements to encourage small producers to seek a higher level of integration with the ai (Baumann, 2000). In fact, it is known that producers have no difficulty selling their coagulated rubber while accepting the price that runs in the region; so when prices are similar, they prefer to deliver their production to the buyer that offers them better conditions, including fewer quality requirements, faster payments, proximity to deliveries, among others. Thus, the high competition for raw materials among the ai makes suppliers sell to the highest bidder with few quality requirements.

In addition to the previous, it is possible to argue that the large fluctuations in rubber prices were predictable due to the inelasticity of the demand price of the end industry due to the substantial substitution with synthetic rubber, and due to the inelasticity of the short term supply price that characterizes the plantations. Therefore, the main reason why the progress of the suppliers has not materialized and sustained satisfactorily is not attributable only to the product market; it is also because of the characteristics of the ai that were involved in the process, since they had no capacity to stabilize the price for their suppliers or to incentivize them economically to be faithful suppliers.

This is why the ai involved could not incentivize their suppliers through price improvements, since they sold an undifferentiated product such as uncertified dried granulated rubber, and are in direct competition with international suppliers. In this way, they do not operate as tractors or trailblazers that link their suppliers with more dynamic and remunerative markets, or promote innovation in traditional business models; furthermore, they are also not involved in structuring a network that captures higher value through differentiated products, which are characteristic of tractor or trailblazer companies (Lusby et al., 2008).

In this sense, Eclac et al. (1998) mention that, when there is little differentiation of prices according to the characteristics of the supply, the reasons for a greater integration decrease; thus, the ai and the producers tend to exchange their product in the market without higher fidelity among them. Furthermore, as Baumann (2000) points out, some standard raw materials do not justify a complex system to ensure quality compliance, a situation that occurs with coagulated rubber. In this sense, higher levels of integration represent higher transaction costs due to the difficulty of adequately managing the supply organization (Baumann, 2000; Vermeulen & Cotula, 2010).

Undoubtedly, the work of the agi achieved an increase in the knowledge of the ai on their suppliers, despite their geographical dispersion and their small size. On the other hand, it reduced the distrust of producers in the payment and reception systems of the ai involved. However, the fall in prices showed that these small advances were not enough to achieve stronger lasting trade integration. The distancing between ai and suppliers was also accentuated because, since 2014, the ai could only work with suppliers registered in the Mexican Tax Administration System and had to pay them through bank transfers. This caused that the producers, especially the smallest ones, preferred to sell informally to the local collectors (intermediaries) to avoid fulfilling burdensome fiscal exigencies, external situation of an institutional context that limits the development of small producers.

Conclusions

The incorporation of methodologies such as those implemented by the agi through the identification of the problem and the design of an intervention strategy allowed focusing on the technical assistance and the promotion of improvement practices, which showed positive results in productive parameters such as rubber yield and quality. Likewise, the work of the agi also allowed the ai to have greater knowledge of their suppliers and develop more proactive collection strategies, as well as the facilitation of a certain level of integration between both actors.

However, despite the increase in production and the improvement in product quality, this was partially captured by the ai involved. In this sense, two situations are highlighted: 1) the undifferentiated nature of the granulated rubber sold by the ai, and 2) that its commercial strategy was based on competing with low prices. This prevented them from giving relevant price incentives to their suppliers, which in turn, makes them very sensitive to international price fluctuations.

Therefore, we can argue that the selection of the ai (tractor or trailblazer company) and the agricultural product is vital to achieving the progress of suppliers since it requires wellpositioned companies in dynamic and diversified markets, which reward the differentiation of their products and spread commercial risks. In this sense, strategies aimed at strengthening agricultural production and where agro-industries are involved —whose raw material is a commodity— will hardly be able to make efficient supplier development and, therefore, durable, as was the case of the two rubber ai in Oaxaca, Mexico.

Acknowledgments

The authors wish to thank the two agro-industries that process natural rubber, the Innovation Management Agencies for Supplier Development (agi, Agencias de Gestión de la Innovación para el Desarrollo de Proveedores), and the suppliers that participated in this study and that provided the data. Moreover, also for facilitating the access to information and for the time spent with us during the fieldwork. We also thank the three reviewers for their time and suggestions made to the first version of this manuscript, as their comments contributed to improving this article.

REFERENCES

Aguilar-Ávila, J., Santoyo-Cortés, V. H., Muñoz-Rodríguez, M., Aguilar-Gallegos, N., & Martínez-González, E. G. (2015). Agencias de gestión de la innovación para el desarrollo de proveedores en México. En R. Compés López, J. M. García Álvarez-Coque, & J. Aguilar-Ávila (Eds.), Redes de innovación y desarrollo local en el medio rural (pp. 249-266). Madrid, España: Ministerio de Agricultura, Alimentación y Medio Ambiente. Gobierno de España. [ Links ]

Aguilar-Gallegos, N., Martínez-González, E. G., Aguilar-Ávila, J., Santoyo-Cortés, H., Muñoz-Rodríguez, M., & García-Sánchez, E. I. (2016). Análisis de redes sociales para catalizar la innovación agrícola: de los vínculos directos a la integración y radialidad. Estudios Gerenciales, 32(140), 197-207. doi:10.1016/j.estger.2016.06.006. [ Links ]

Aguilar-Gallegos, N., Muñoz-Rodríguez, M., Santoyo-Cortés, H., Aguilar-Ávila, J., & Klerkx, L. (2015). Information networks that generate economic value: A study on clusters of adopters of new or improved technologies and practices among oil palm growers in Mexico. Agricultural Systems, 135, 122-132. doi:10.1016/j.agsy.2015.01.003. [ Links ]

Aguilar-Gallegos, N., Olvera-Martínez, J. A., Martínez-González, E. G., Aguilar-Ávila, J., Muñoz-Rodríguez, M., & Santoyo-Cortés, H. (2017). La intervención en red para catalizar la innovación agrícola. REDES. Revista Hispana para el Análisis de Redes Sociales, 28(1), 9-31. doi:10.5565/rev/redes.653. [ Links ]

Aguilar Gallegos, N., Muñoz Rodríguez, M., Santoyo Cortés, V. H., & Aguilar Ávila, J. (2013). Influencia del perfil de los productores en la adopción de innovaciones en tres cultivos tropicales. Teuken Bidikay, 4, 207-228. [ Links ]

Aguirre Ríos, C. E. (2012). Estudio prospectivo de la cadena de hule. México D. F., México: Secretaría de Agricultura Ganadería Desarrollo Rural Pesca y Alimentación (Sagarpa). [ Links ]

Aguirre Ríos, C. E., & Santoyo Cortés, V. H. (2013). El cultivo del árbol del hule (Hevea brasiliensis Muell Arg.): avances y retos en la gestión de la innovación. Chapingo, México: Universidad Autónoma Chapingo - ciestaam. [ Links ]

Arroyo López, M. D. P. E., & Sánchez Maldonado, R. A. (2009). Programas de desarrollo de proveedores como estrategia para la competitividad empresarial. México D. F., México: SinncO. [ Links ]

Arumugam, N., Fatimah, M. A., Chiew, E. F. C., & Zainalabidin, M. (2010). Supply chain analysis of fresh fruits and vegetables (ffv): Prospects of contract farming. Agricultural Economic - Czech, 56(9), 435-442. [ Links ]

Avendaño-Ruiz, B. D., Hernández-Alcantar, M. L., & Martínez-Carrasco-Pleite, F. (2017). Innovaciones tecnológicas en el sector hortícola del noroeste de México: Rapidez de adopción y análisis de redes de difusión. Corpoica Ciencia y Tecnología Agropecuaria, 18(3), 495511. doi:10.21930/rcta.vol18_num3_art:740. [ Links ]

Barrera Rodríguez, A. I., Baca del Moral, J., Santoyo Cortés, H. V., & Altamirano Cárdenas, J. R. (2013). Propuesta metodológica para analizar la competitividad de redes de valor agroindustriales. Revista Mexicana de Agronegocios, 32, 231-244. [ Links ]

Baumann, P. (2000). Equity and efficiency in contract farming schemes: the experience of agricultural tree crops. Working Paper 139. Londres, Reino Unido: Overseas Development Institute. [ Links ]

Birkinshaw, J., Hamel, G., & Mol, M. J. (2008). Management innovation. The Academy of Management Review, 33(4), 825-845. doi:10.5465/AMR.2008.34421969. [ Links ]

Brandenburger, A. M., & Nalebuff, B. J. (1997). Co-opetition. Nueva York, EE. UU.: Doubleday. [ Links ]

Cárdenas-Bejarano, E., Gallardo-López, F., Nuñez-Espinoza, J. F., Asiaín-Hoyos, A., Rodríguez-Chessani, M. A., & Velázquez-Beltrán, L. G. (2016). Redes de innovación en los grupos ganaderos de validación y transferencia de tecnología en México. Agricultura, Sociedad y Desarrollo, 13(2), 237-255. [ Links ]

Castellanos, O., Rojas, J., Villarraga, L., & Ustate, E. (2001). Conceptualización y papel de la cadena productiva en un entorno de competitividad. Innovar, 11(18), 87-98. [ Links ]

Coelho-Junior, L. M., Pereira-de Rezende, J. L., Coimbra-Borges, L. A., & Donizette-de Oliveira, A. (2009). Análise temporal da borracha natural brasileira. Cerne, 15(1), 19-26. [ Links ]

Comisión Económica para América Latina y el Caribe (Cepal), Deutsche Gesellschaft für Internationale Zusammenarbeit (gtz), & Food and Agriculture Organization (fao). (1998). Agroindustria y pequeña agricultura: vínculos, potencialidades y oportunidades comerciales. Santiago de Chile, Chile: Naciones Unidas. [ Links ]

Da Silva, C. A. B. (2005). The growing role of contract farming in agri-food systems development: drivers, theory and practice. Roma, Italia: fao. [ Links ]

De Dios de la Cruz, O., Lesher Gordillo, J. M., Gallardo Álvarez, M. I., Molina Martínez, R. F., & Jiménez Gómez, F. (2015). La importancia de la detención de la variación somaclonal en el árbol del hule. Kuxulkab’, 21(40), 5-10. doi:10.19136/kuxulkab.a21n40.989. [ Links ]

De Jong, J. P. J., & Hulsink, W. (2012). Patterns of innovation networking in small firms. European Journal of Innovation Management, 15(2), 212-231. doi:10.1108/14601061211243639 [ Links ]

Food and Agriculture Organization (fao). (2018). Faostat. Food and Agriculture Organization of the United Nations [database]. Recuperado de https://www.faostat3.fao.org/download/Q/QC/E [ Links ]

García Sánchez, E. I., Aguilar Ávila, J., & Bernal Muñoz, R. (2011). La agricultura protegida en Tlaxcala, Méjico: La adopción de innovaciones y el nivel de equipamiento como factores para su categorización. Teuken Bidikay, 2, 193-212. [ Links ]

Garrido-Rubiano, M. F., Martínez-Medrano, J. C., Martínez-Bautista, H., Granados-Carvajal, R. E., & Rendón-Medel, R. (2017). Pequeños productores de maíz en el Caribe colombiano: estudio de sus atributos y prácticas agrícolas. Corpoica Ciencia y Tecnología Agropecuaria, 18(1), 7-23. doi10.21930/rcta.vol18-num1. [ Links ]

Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias (Inifap). (2012). Potencial productivo de especies agrícolas de importancia socioeconómica en México. México D. F., México: Inifap. [ Links ]

Krause, D. R., Handfield, R. B., & Scannell, T. V. (1998). An empirical investigation of supplier development: reactive and strategic processes. Journal of Operations Management, 17(1), 39-58. doi:10.1016/S0272-6963(98)00030-8. [ Links ]

Lusby, F., Derks, E., Field, M., Fries, B., Campbell, R., Nourse, T., ... Grell, S. (2008). Defining lead firms and principles of facilitation. Recuperado de https://www.actionforenterprise.org/field1.pdf [ Links ]

Martínez-González, E. G., Arroyo-Pozos, H., Aguilar-Gallegos, N., García Álvarez-Coque, J. M., Santoyo-Cortés, V. H., & Aguilar-Ávila, J. (2018). Dinámica de adopción de buenas prácticas de producción de miel en la península de Yucatán, México. Revista Mexicana de Ciencias Pecuarias, 9(1), 48-67. doi:10.22319/rmcp.v9i1.4366. [ Links ]

Martínez-González, E. G., Muñoz-Rodríguez, M., García-Muñiz, J. G., Santoyo-Cortés, V. H., Altamirano-Cárdenas, J. R., & Romero-Márquez, C. (2011). El fomento de la ovinocultura familiar en México mediante subsidios en activos: lecciones aprendidas. Agronomía Mesoamericana, 22(2), 367-377. [ Links ]

Mendoza-Robles, R., Parra-Inzunza, F., & de los Ríos-Carmenado, I. (2010). La actividad frutícola en tres municipios de la Sierra Nevada en Puebla: características, organizaciones y estrategia de valorización para su desarrollo. Agricultura, Sociedad y Desarrollo, 7(3), 229-245. [ Links ]

Miglierini, F. M., & Treviño, E. J. (2012). Factores que afectan el desarrollo de proveedores en una cadena de valor integrada. Daena: International Journal of Good Conscience, 7(2), 129-158. [ Links ]

Moctezuma López, G., Ortiz Cervantes, E., Espinosa García, J. A., Uresti Gil, J., Vélez Izquierdo, A., Jolalpa Barrera, J. L., ... Inurreta Aguirre, H. D. (2015). Potencial productivo y económico de las plantaciones de hule en el trópico húmedo mexicano. Agronomía Tropical, 65(1-2), 7-16. [ Links ]

Moctezuma López, G., Ortiz Cervantes, E., Hernández Cruz, J. M., Díaz Fuentes, V. H., & Velázquez Fragoso, L. (2017). Evaluación financiera de plantaciones de hule [Hevea brasiliensis (Willd. ex A. Juss) Müll. Arg.] en el trópico húmedo mexicano. Folleto Técnico Número 25. Ciudad de México, México: Cenid Comef, Inifap. [ Links ]

Muñoz Rodríguez, M. (2010). Identificación de problemas y oportunidades en las redes de valor agroalimentarias. En J. Aguilar Ávila, J. R. Altamirano Cárdenas, & R. Rendón Medel (Eds.), Del extensionismo agrícola a las redes de innovación (pp. 103-168). Chapingo, México: Universidad Autónoma Chapingo - ciestaam. [ Links ]

Muñoz Rodríguez, M., Aguilar Ávila, J., Rendón Medel, R., & Altamirano Cárdenas, J. R. (2007). Análisis de la dinámica de innovación en cadenas agroalimentarias. Chapingo, México: Universidad Autónoma Chapingo - ciestaam / piiai. [ Links ]

Oficina Estatal de Información para el Desarrollo Rural Sustentable (Oeidrus). (2011). El cultivo del Hule: Datos básicos 2011. Recuperado de https://www.oeidrus-oaxaca.gob.mx/pdf/12Hule2012.pdf [ Links ]

Ortiz Hernández, E. (2011). Paquete tecnológico del hule (Hevea brasiliensis Muell Arg.). Establecimiento y mantenimiento preoperativo. México D. F., México: Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias (Inifap). [ Links ]

Porter, M. E. (1980). Competitive strategy: techniques for analyzing industries and competitors. Nueva York, EE. UU.: Free Press. [ Links ]

Reddy, A. A. (2013). Training manual on value chain analysis of dryland agricultural commodities. Andhra Pradesh, India: International Crops Research Institute for Semi-Arid Tropics (Icrisat). [ Links ]

Rogers, E. M. (2003). Diffusion of innovations (5.a ed.). Nueva York, EE. UU.: Free Press. [ Links ]

Rojo Martínez, G. E., Martínez Ruiz, R., & Jasso Mata, J. (2011). El cultivo del hule en México. Libros Técnicos: Serie Forestal. México D.F., México: Universidad Autónoma Indígena de México. Colegio de Postraduados, Campus Montecillo. [ Links ]

Santacoloma, P., Suárez, R., & Riveros, H. (2005). Fortalecimiento de los vínculos de agronegocios con los pequeños agricultores. Estudios de caso en América Latina y el Caribe. Roma: Organización de las Naciones Unidas para la Alimentación y la Agricultura (fao). [ Links ]

SAS. (2004). sas/stat (R). User’s Guide, Version 9. Cary, U. S. A.: Statistical Analysis System. [ Links ]

Secretaría de Agricultura, Ganadería, Desarrollo Rural, Pesca y Alimentación (Sagarpa). (2011). Proyecto estratégico para el desarrollo rural sustentable de la región sur-sureste de México: Trópico Húmedo. Recuperado de https://www.sagarpa.gob.mx/programas2/formatos/tropico_humedo/mecanismo_tropico_humedo_2011.pdf [ Links ]

Servicio de Información Agroalimentaria y Pesquera (siap). (2018). Anuario estadístico de la producción agrícola. Servicio de Información Agroalimentaria y Pesquera [database]. Recuperado de https://www.infosiap.siap.gob.mx/aagricola_siap_gb/icultivo/index.jsp [ Links ]

Vargas-Canales, J. M., Palacios-Rangel, M. I., Acevedo-Peralta, A. I., & Leos-Rodríguez, J. A. (2016). Profitability analysis for natural rubber (Hevea brasiliensis Muell. Arg.) production in Oaxaca, Mexico. Revista Chapingo Serie Ciencias Forestales y del Ambiente, 22(1), 45-58. doi:10.5154/r.rchscfa.2015.02.005. [ Links ]

Vermeulen, S., & Cotula, L. (2010). Making the most of agricultural investment: A survey of business models that provide opportunities for smallholders. Survey of Business. Londres/Roma/Berna: IIED/FAO/IFAD/SDC. [ Links ]

Received: April 12, 2018; Accepted: February 18, 2019

text in

text in