Introduction

Historically, the use of fossil energy sources has been and is the driving force behind the economic development and prosperity of nations, in such a way that in 2017 these represented around 80% of the world production of primary energy, with a contribution of 32% for oil, 26% for coal, and 21% for natural gas (International Energy Agency [IEA], 2019). However, its exploitation and intensive use have several disadvantages, among them the certainty of its extinction in the medium term and its substantial contribution to the emission of polluting gases, which, in turn, produce large environmental and climatic imbalances in all fields (Tang, 2013). In this context, the need to develop alternative energy supply mechanisms that largely overcome the disadvantages mentioned above is clear (Reboredo, 2015). Thus, renewable energy sources and their derived vectors have a growing share in sectors of the world market. In 2017, these accounted for 18.2% of the world's energy consumption and 26.5% of the electric power generation; bioenergy is, however, the one with the highest contribution with 12.8% of the global consumption (46.4 EJ) (REN21, 2019).

Of the different bioenergy use routes, the one related to biofuels is one of the most attractive, given the substitution capacity of fossil fuels, the possibility of opening new markets for agricultural producers and the recovery of residual biomass of different origin used in its production (Gupta & Verma, 2015). Accordingly, in 2017, the total world production of biofuels amounted to 143 billion liters (4.5 EJ), with the US and Brazil as the main producers, contributing with 57% and 27%, respectively (REN21, 2019).

In the case of liquid biofuels, bioethanol is the primary vector, with 112 billion liters produced in 2018 and a growth of 7%, compared to 2017. Besides, it represents 67% of the world production destined to the transport sector for its use pure or mixed with gasoline in different proportions (REN21, 2019).

There are several advantages of using bioethanol compared to gasoline: (i) a reduction in the CO and aromatic compound emissions due to its O2 content (35%), an element that is absent in gasoline and also allows increasing the combustion efficiency (Gupta & Verma, 2015); (ii) easy integration to the fuel distribution logistic systems (Zabed et al., 2017); (iii) improvement in the octane rating of the fuel mixture and its compression ratio, and (iv) increase in the power output of the internal combustion engine, due to higher volumetric efficiency as a result of a higher vaporization heat. Therefore, bioethanol obtained from agricultural residues constitutes a promising second-generation vector for sustainable mobility (Escobar et al., 2009).

Bioethanol production processes vary according to the type of residual biomass and its chemical composition. For lignocellulose biomass, a pre-treatment must be carried out to improve the overall process performance by reducing the amount of lignin and hemicellulose, decreasing the crystalline cellulose, and increasing the accessible surface area for the subsequent enzymatic hydrolysis stage (Tian et al., 2018). The methods and techniques of this pre-treatment are of a different nature: physical (grinding, ultrasound, microwaves, and hydrothermolysis), chemical (acid or alkaline hydrolysis, solvents, and ozone), physicochemical (fiber explosion with ammonium or with CO2), and biological (fungi, bacteria, and microbes), each with its advantages, disadvantages, and scope (Chiaramonti et al., 2012). Among all of these, acid hydrolysis has been widely studied and applied industrially, especially the one that uses diluted acids, due to its simplicity and low costs, which makes it commercially attractive (Solarte et al., 2019a). This is the type of pre-treatment included in the model for estimating the potential for bioethanol production from cacao husks in Ecuador.

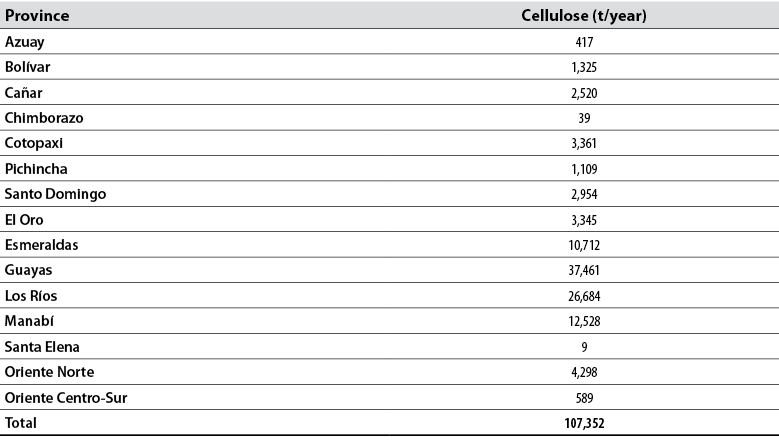

The kinetics of acid hydrolysis is relatively complex as it occurs in several phases and is strongly influenced by the operating conditions and the concentration of the acid used, usually diluted. To facilitate its study, explain and predict the structural changes in the compounds involved in this kinetics, Saeman (1945) formulates a simplified model in terms of two first-order irreversible pseudo-homogeneous reactions in series. In the first, cellulose is hydrolyzed to glucose, while in the second, glucose is degraded to third products. A second simplification consists of not considering the diffusive processes or the crystallinity of glucose (Tsoutsos, 2010). However, this constitutes a theoretical approach with a good degree of fit with the experimental results (Vegi & Shastri, 2017), which makes it the basis for more complex models and can later be extended to biomass polysaccharides (Orozco et al., 2013). Therefore, it can be widely used for different lignocellulosic biomass (Acosta et al., 2018; Liu et al., 2012). Therefore, and considering the main aim of this study, the preliminary estimation of the potential for bioethanol production from the use of the cacao husks in Ecuador is the kinetic model adopted.

Bioethanol in Ecuador

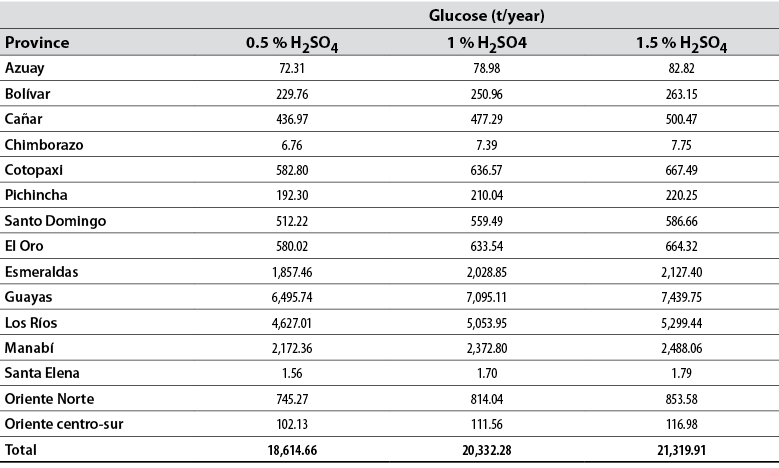

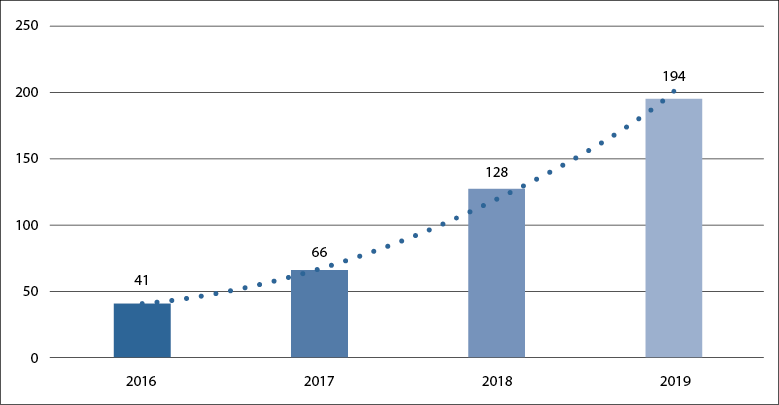

In 2010, in the province of Guayas, the Ecopaís pilot plan began with the purpose of testing the E5 fuel mixture, comprised of 5% (v/v) of bioethanol and 95% of gasoline, which ended in the year 2014 (Paredes, 2015). In 2016, the proposal was to extend the use of E5 to the entire country and, later, increase the percentage of bioethanol in the mix to 10 and 15%, to replace the demand for extra-type gasoline in 2019 entirely. This type of gasoline represents 79% of the gasoline consumption and around 46% of the demand for liquid fuels in the country by 2014 (Ministerio Coordinador de Sectores Estratégicos, 2015). For this, the production of bioethanol should increase by a figure close to 200% in the period 2017-2019 (figure 1), which shows the magnitude of the challenge to overcome and to which this study aims to contribute by proposing an alternative production route of bioethanol to the one commonly used based on sugarcane cultivation (García et al., 2013).

Source: Elaborated by the authors based on Paredes (2015)

Figure 1 Current and projected production of bioethanol in Ecuador (Mml)

Studies in Ecuador on the production of bioethanol have considered different types of biomass: García et al. (2014) estimated the potential for bioethanol production from agricultural residues of rice, banana, and sugarcane, and were supported by a predictive model and by locating the production plants according to the energy potential of the region. For their part, Prado and Cervantes (2017) analyzed the main variables that affect the cultivation of sugarcane for the production of bioethanol; these authors concluded that the planted area is the variable with the highest incidence in crop efficiency. Guerrero and Muñoz (2018) used the life cycle approach to estimate environmental sustainability and demonstrate the ability to reduce greenhouse gases (GHG), with favorable results in both cases. Unproductive species have also been studied, such as the Peruvian feathergrass, paja ichu or paja de páramo (Stipa ichu) as a primary source for the production of bioethanol with promising results (Albarracín et al., 2015).

Likewise, the potential of a specific crop and province has been estimated. In the province of Chimborazo, the production of bioethanol from potatoes has been evaluated. This alternative use has been assessed in response to the overproduction of this crop, which causes a 50% decrease in the commercialization price and even the use of waste or out-of-specification products (Pérez et al., 2017). Finally, in the province of Imbabura, the production of bioethanol from corn waste has been studied (Hernández-Rueda et al., 2018).

Regarding the use of residual cacao biomass for energy purposes, Kuglarz et al. (2018) evaluated the potential for biogas production by anaerobic digestion for the Balao canton, a region with the highest residual cacao biomass production density. In this canton, biogas is used for electricity generation that could satisfy 88% of its energy demand.

From this documentary review, it can be seen that the study of the use of cacao residues for the production of bioethanol has not been studied much in Ecuador, such as the use of kinetic models to estimate the potential for bioethanol production of a specific lignocellulosic residue. In this context, the aim of the current work was to estimate the theoretical potential of bioethanol in Ecuador from the residues of the cacao husks through acid hydrolysis and fermentation. To this end, a mathematical simulation model was formulated based on official information on national cacao production and the application of Seaman's kinetic model.

The purpose was to contribute to the basic knowledge on an alternative route of bioethanol production in Ecuador, strategically convenient and that also allows the valorization of an agro-industrial waste positioned in fifth place in the country related to the generated volume and energy content (Ministerio de Electricidad y Energía Renovable, 2014). The main result was the identification of the provinces of the country with an attractive bioethanol production potential to carry out more detailed feasibility studies that include environmental and economic dimensions. All these elements constitute the main contribution of the work.

Estimation of bioethanol production potential

The estimation of bioethanol theoretically obtainable from the residual biomass of cacao in Ecuador is carried out in three stages: (i) establish the amount of cacao husk residues generated annually in the provinces of the country, and determine the amount of corresponding cellulose based on the lignocellulosic analysis; (ii) quantify the glucose generated in the hydrolysis of the cacao husks applying the kinetic model of Saeman (1945), and (iii) estimate the production of bioethanol by fermentation of the glucose generated in the provinces and regions of Ecuador.

Amount of residual cacao husks in the provinces and regions of Ecuador

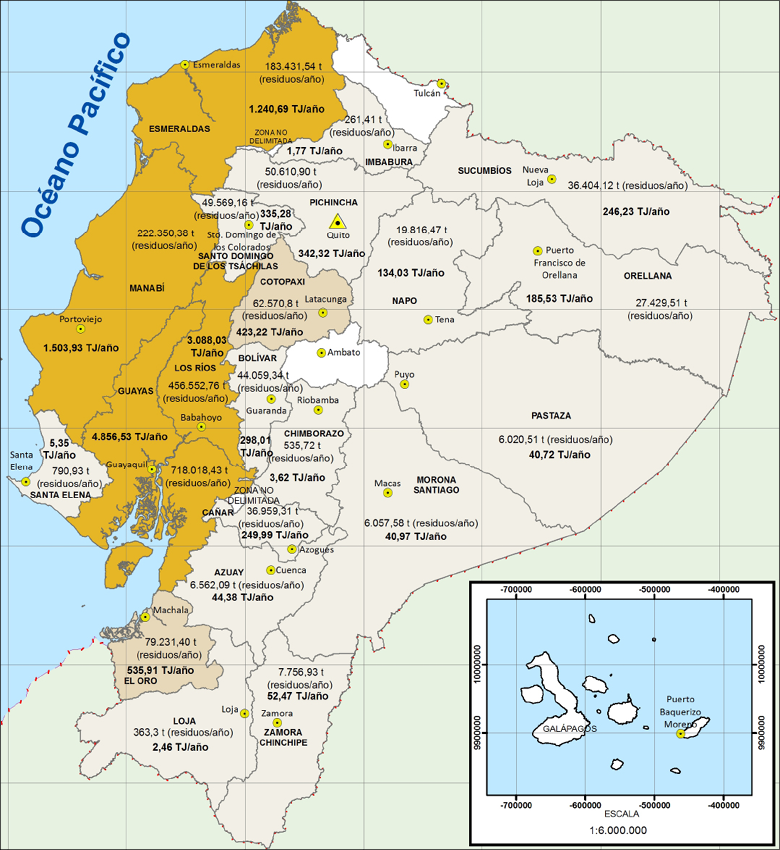

The Bioenergetic Atlas of Ecuador is the primary source of information on the amount of residues from cacao cultivation, estimated at 2,015,353 t/year for 2014 (Ministerio de Electricidad y Energía Renovable, 2014). Its geographical distribution (figure 2) shows that the provinces of the coastal region are the ones with the highest contribution, with approximately 87% of the total waste.

Source: Ministerio de Electricidad y Energía Renovable (2014)

Figure 2 Geographic distribution of the cacao cultivation residues in Ecuador

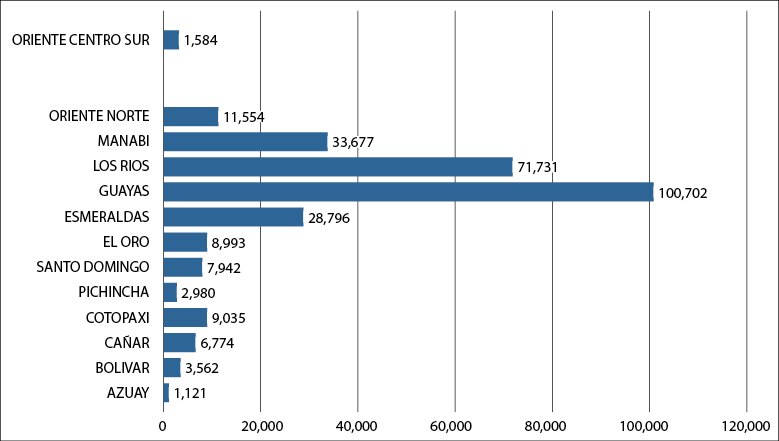

The residues corresponding to cacao husks represent 14.32% (by weight) of the total residues of this crop (Sánchez, 2013), equivalent to 288,580 t/year. In figure 3 are shown the regions and provinces with a significant contribution to generate energy. The eastern region has been divided into two subregions: Oriente Norte [West North], comprised of the provinces of Napo, Orellana, and Sucumbíos; and Oriente Centro-Sur [West Center-South], formed by the provinces of Pastaza, Morona, and Zamora.

Source: Elaborated by the authors

Figure 3 Residues of cacao husks (t/year) in the main provinces and producing regions

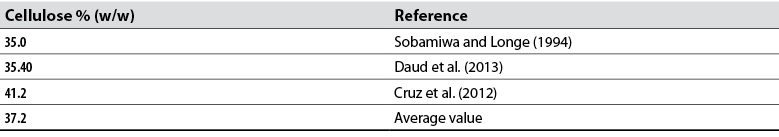

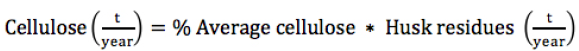

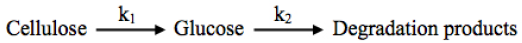

The cellulose fraction present in the cacao husks, in dry weight, is the basis for calculating the amount of cellulose and is taken as the average of the values reported in various studies (table 1).

The amount of hydrolyzable cellulose generated in the provinces and regions of Ecuador is obtained from equation 1 and is shown in table 2.

Kinetic modeling of cellulose hydrolysis

The reaction of cellulosic materials with acids is complex: on the one hand, the different series and parallel chemical reactions that take place, and, on the other hand, the presence of two phases in them. Therefore, the global reaction mechanism has not been entirely established due to the practical difficulties of measuring the reaction rate of individual reactions (Carrasco & Roy, 1992). In this situation, an approach to understand and predict the behavior of the acid hydrolysis reaction in the crystalline fraction of cellulose is to consider it as a first-order pseudo-homogeneous reaction, with apparent rate constants.

The pioneering development of this approach is carried out by Saeman (1945), supported by experiments on the degradation of wood at moderate temperatures with diluted sulfuric acid. Its model has been used for various types of residual biomass and operating conditions (Carrasco & Roy, 1992; Thompson & Grethlein, 1979) and has also been applied to the hydrolysis of the hemicellulose fraction (Lu et al., 2008; Téllez et al., 2002).

This model is used to establish the amount of glucose obtained from the cellulose present in the residues of the cacao husks and considers that glucose is the sugar with the highest interest in lignocellulosic hydrolyzates, and from whose fermentation bioethanol is obtained (Paredes, 2015).

Reaction rate

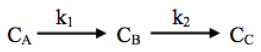

The simplified schematic representation of the hydrolysis of cellulose is as follows:

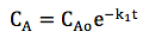

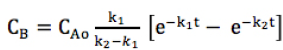

The solution of this reaction system, for zero initial conditions, is CA = CB = 0, and is represented like this:

Where k1 is the rate constant in glucose production (s-1); k2 is the rate constant in the breakdown of glucose (s-1); CA is the cellulose concentration (%); CB is the glucose concentration (%), and CA0 is the initial cellulose concentration (%).

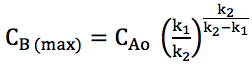

By mathematically manipulating equations 2 and 3, the expressions for the maximum glucose concentration (CBmax) and the time it takes to occur (tmax) are obtained. These are useful for calculating the maximum efficiency of the conversion of cellulose to glucose and the amount of bioethanol generated through fermentation.

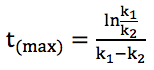

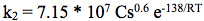

The mathematical expressions of the constants of the reaction rates and the numerical values of the parameters present in them must be established to complete the kinetic model. In the first case, compliance with Arrhenius's law has been corroborated in several experimental studies. Furthermore, considering Saeman’s model, in the pre-exponential factor, a term that quantifies the effect of the diluted acid concentration is incorporated (Aguilar & Canizales, 2004; Suárez et al., 1985; Thompson & Grethlein, 1979). Its generic mathematical expression is shown below:

Where Cs is the concentration of diluted sulfuric acid (%).

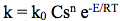

In the second case, to specify the values of the parameters k0, n, and E (equation 7), associated with the hydrolysis of the cacao husk residues, a documentary search was carried out without favorable results. However, considering the purpose of this study, the quantification of bioethanol that would be obtained theoretically from the processing of the cacao husks available in Ecuador, the values of these parameters reported in Carrasco and Roy (1992) were taken for the hydrolysis of wheat straw. This selection was made under the following considerations: (i) the similarity in the cellulose content of both species, 38.7% and 37.2% for cacao and wheat straw, respectively, and (ii) equality under operation conditions, such as temperature and concentration ranges of diluted sulfuric acid. Therefore, these are the expressions for the rate constants:

Carrasco and Roy (1992) recommended empirical models to simulate the hydrolysis mechanisms of lignocellulose materials. From this, Aguilar and Canizales (2004) established the k1 and k2 values based on experimental data obtained from acid hydrolysis, where k0 and E were statistically determined using least squares regression.

With the previous equations, the kinetic model is completed and will serve as a mechanism for calculating the glucose produced from the residual cacao biomass and, later, in the bioethanol obtained.

Glucose production

The procedure for calculating glucose production is based on determining the operating conditions that allow obtaining the maximum conversion of crystalline cellulose to glucose and its minimum conversion to third products or degradation products, is comprised of the following steps:

-

Establish the initial concentration of cellulose and operating ranges of the temperature of the diluted acid concentration, as follows:

CA0 = 37.5 % T (°C): (120 to 210) CS (%): (0.5; 1.0; 1.5)

Set the first value of Cs in the operating range.

Vary the T in the operating interval and calculate for each T: tmax, CBmax, CA, and CC, using equations 6, 5, 2, and 4.

Specify the T value for which the highest value of CBmax is obtained, for later use in the calculation of the bioethanol that will be obtained for the fixed Cs.

Repeat the procedure for the next Cs value in the study range until all its values are completed.

Bioethanol estimation

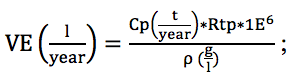

Equation 10 is used to calculate the bioethanol resulting from the fermentation of glucose with a theoretical yield (Rtp) of 0.49 g ethanol/g glucose, i.e., an average value used in other studies (Albarracín et al., 2015; Ballesteros et al., 2004).

where VE is the ethanol volume, l/year; 𝜌, bioethanol density, 790g/l; 1E6, the conversion factor from grams to tons, and Cp is cellulose by province, t/year.

It should be mentioned that the estimation of ethanol production is carried out for ideal conditions or theoretical yields for the fermentation stage in the global ethanol production process. Therefore, it is expected that the actual production that will be obtained will be less when considering the yields and efficiencies in the handling, adaptation, and conversion processes involved in the overall process. From the literature review, no values have been found on the efficiency of the global process for obtaining bioethanol for the residual biomass studied. Only the values of the global yield of bioethanol production from other biomasses, such as rapeseed straw of 12.2% (Kuglarz et al., 2018) and olive oil residues of 11.8%, can be referenced (Solarte et al., 2019b). Both percentages were calculated in terms of the ratio of the bioethanol weight respect to the initial raw material weight. In this scenario, the need to carry out experimental cutting studies is appreciated allowing to obtain specific and conclusive information on this bioethanol production route, which considers the yields and efficiencies of the global process from the suitability of the raw material to the purification of bioethanol in vehicle fuel grade.

Results and discussion

Kinetic model

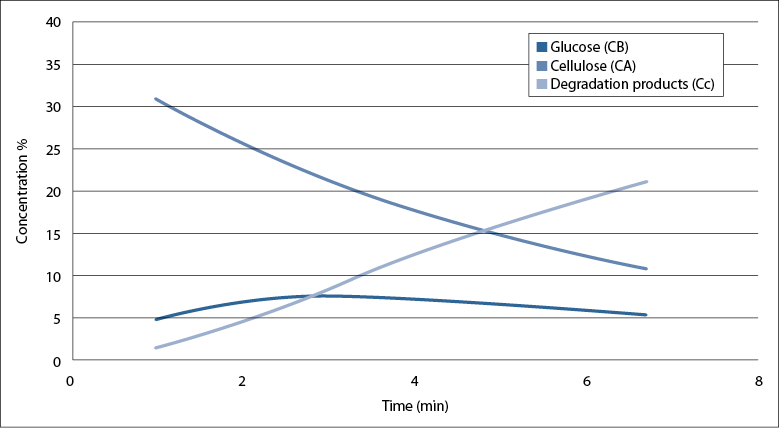

The dynamics of the change of reactants and products for T = 190 °C and Cs = 1% (figure 4) shows behavior following the kinetic theory for irreversible reactions in series with k1 >> k2, and also with the results of several similar studies for other types of residual biomass (Suárez et al., 1985; Thompson & Grethlein, 1979). Also, in figure 4, the maximum operating point (tmax, CBmax) can be located. The continuous growth of degradation products and the existence of a maximum value of the glucose concentration indicate the need to ensure that the process operates around this operating point.

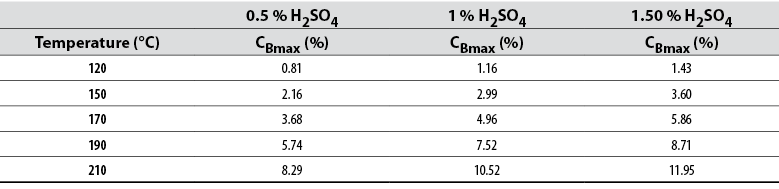

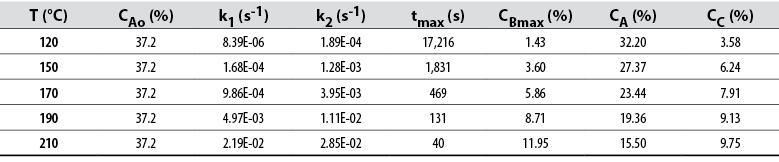

Table 3 presents the results of the procedure followed to establish the maximum conversion to glucose for the specified initial conditions. The high sensitivity of the optimum point value is appreciated (tmax, CBmax) with temperature.

Table 3 Summary of the results of the kinetic model for Cs =1.5 s%

Source: Elaborated by the authors

One aspect to analyze is having reached the optimal point of glucose yield for the most rigorous (or extreme) operating conditions. Nonetheless, these also favor its decomposition to products that could interfere with the alcoholic fermentation, which means that there is a compromise relationship between opposing effects. Another aspect to consider is the decrease in residence time as operating conditions increase in value until reaching a very short residence time of the reaction mixture, very difficult to implement in practice for a scale larger than that of the pilot. Also, in economic terms, the cost of neutralization increases with increasing acid concentration.

The large increase in the reaction rate of glucose with the acid concentration, which reaches increases of over 100% in CB, are in correspondence with those obtained in similar studies. Mathematically, these are explained by the strongly non-linear nature of the reaction rate caused by the product of a power-type term with another of an exponential type.

Glucose production

The glucose production for T and Cs ranges are presented in table 4. The effect of both variables on CBmax is notorious due to the non-linear nature of the relationship of each variable with CB, so the effect of T is higher due to its exponential variation, in contrast to the power-type variation of Cs. Clearly, the maximum maximorum corresponds to the highest values of the range of T and Cs, which is T = 120 °C and Cs = 1.50 %, with which a CBmax = 11.95 % is obtained. It should also be noted that a more representative indicator of the increase in the conversion of the variable of interest consists of measuring the degree of conversion with respect to its initial value; thus, for the CBmax value of 11.95 %, the conversion percentage is 32 %.

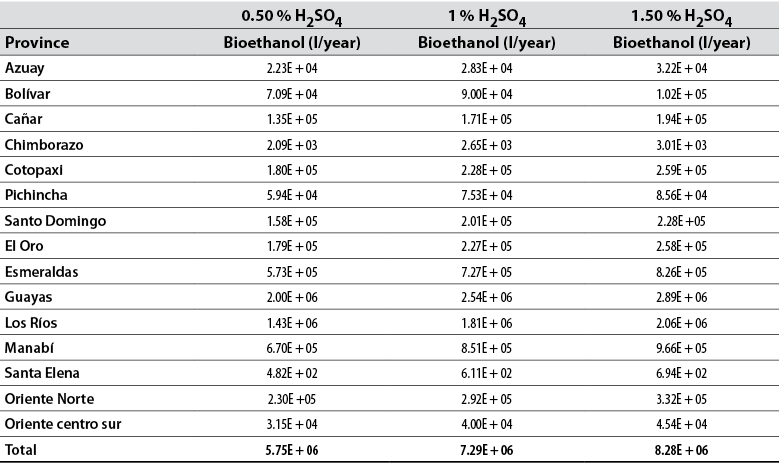

Glucose by province

The glucose produced annually in each province (table 5), corresponds to the highest value of CBmax according to the cellulose available in each province (table 2). The provinces of the coastal region (Guayas, Los Ríos, and Manabí) are the ones with the highest contribution, representing 71 % of the national glucose production, which will be repeated in the production of bioethanol.

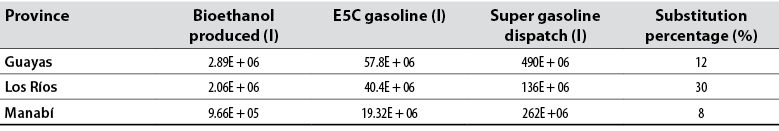

Bioethanol production

It is obtained from equation 10, and its quantities for the country and provinces are presented in table 6. The first value, 8.28 Mml, is equivalent to 10% of the national production of bioethanol for the year 2017 (Martínez, 2017). However, a more appropriate comparison results from comparing production for the same base year (2014). In this case, bioethanol from residual cacao biomass represents about 56% of the bioethanol production from sugarcane processing. However, it should be noted that bioethanol production has experienced an average inter-annual growth of 80 % in the 2014-2017 period (Martínez, 2017).

Although this study represents a theoretical model, the amount of bioethanol generated could vary depending on the lignocellulose substrate that is used, knowing that the yield has been based on a traditional fermentation process.

Production of Ecopaís E5 gasoline

The volume of E5 gasoline that would be obtained using bioethanol is 166 Mml. In comparison, the total production for the year 2017 was around 1,688 Mml (Ministerio Coordinador de Sectores Estratégicos, 2015), which means that the gasoline obtained by mixing bioethanol would contribute with around 10 % of the national production. However, a more pertinent assessment of the contribution of E5C gasoline from cacao bioethanol is to consider 2014 as the basis for comparison, bearing in mind that this is the year where the residual biomass was quantified. In this case, the contribution of E5C gasoline corresponds to 56 % of the national produced for that year.

Another dimension to assess the alternate E5 gasoline production route proposed in this study is the provincial level. Thus, when comparing the values of E5C gasoline with respect to the consumption of the three provinces with the highest contribution: Guayas, Los Ríos and Manabí (table 7), it can be observed that in these provinces the substitution of the super gasoline for the E5C mixture has a significant impact, starting from the volumes of gasoline replaced instead of its corresponding percentage, i.e., 118 Mml, which would make it attractive to undertake more detailed studies that include the economic and environmental dimensions.

Conclusions

The production of bioethanol from cacao fruit husks has been estimated, supported by a simplified kinetic model of the hydrolysis of this residual biomass that explains its behavior and appropriately predicts its products. For this, the official information on the amount of residual biomass at the national and provincial levels was used. The results indicate that the production of bioethanol and E5 from cacao residues is an alternative way to the traditional one based on the cultivation of sugarcane and sufficiently attractive from in-depth, technical and economic studies, in those provinces with a high contribution to the national production and with high volumes of E5 gasoline consumption, which would allow the diversification of the supply. In this way, opportunity niches are configured by combining high production potentials with high levels of demand. These theoretical results, based on a mathematical simulation model, must be accompanied by subsequent experimental studies that validate the results obtained and provide real knowledge about the performance and efficiency of the global process.

text in

text in