Introduction

Adequate pre-slaughter logistics is vital for the animal to arrive in good condition at the slaughterhouse (Miranda de la Lama, 2013). Livestock transportation has been considered an essential element in the supply chain and one of the most stressful events for animals (Gallo et al., 2018; Miranda de la Lama, 2013). Poor transportation can lead to dehydration, loss of body weight, bruising, deterioration of the immune system, and increased morbidity and mortality (Coffey et al., 2001, as cited in Cernicchiaro et al., 2012; Knowles, 1998). Compared to other species, sheep are remarkably tolerant of transportation, food, and water deprivation due to their status as ruminants and tend to have a lower overall mortality rate (Knowles, 1998).

Additionally, animals are usually affected by handling, fasting, load densities, vibrations, vehicle design, trip duration, when they get on and off the truck, handling by inexperienced people, and weather conditions, among others. These factors not only affect animal welfare but are also reflected in losses, impacting product quality and safety (De Vries et al., 2014; Gallo et al., 2018; Miranda de la Lama, 2013).

Therefore, animals are exposed to physical, environmental, and psychological stressors from their departure from farms to the slaughterhouses. Adequate pre-slaughter handling under the concept of animal welfare (AW) as the central line of the process will have a positive impact on the profits of producers, distributors, and retailers because these activities significantly influence the price of animals, product quantity and quality, and consumer satisfaction (Gallo et al., 2018).

Implementing strategies to improve sheep management in the production stage and antemortem is necessary to reduce the consequences of damage to the final product quality. In Colombia, specific regulations were recently approved on welfare for sheep production: Resolution 000136/2020 (Ministerio de Agricultura [MinAgricultura], 2020). Regulations such as Decree 1500 have also been created for meat processing plants, which must follow acceptable animal treatment practices (Ministerio de Ambiente [MinAmbiente], 2007), just like Law 1774/2016 (MinAmbiente, 2016) that intends to improve AW.

Furthermore, the importance of good human-animal interaction must be considered since poor interactions can result in stress and accidents for both animals and handlers (De Boyer des Roches et al., 2016). This study aims to evaluate the commercial transport of sheep, pre-slaughter animal handling, and carcass quality as indicators of AW at a slaughterhouse in the Córdoba Department, Colombia.

Materials and methods

A cross-sectional study was conducted between May 2017 and July 2018 in a bovine slaughterhouse (SH) located in the Cereté municipality (Córdoba, Colombia), at an altitude of 22 MAMSL, average temperature of 28 °C, and relative humidity of 85%. The annual average rainfall is 1,340 mm; the rainy season lasts from April to November, reporting approximately 85% of the rainfall, and the dry season from November to mid-April.

The SH is authorized to slaughter sheep by the competent authority (Instituto Nacional de Vigilancia de Medicamentos y Alimentos [Invima], Registration Code 007OC) since it meets the sanitary requirements established by Colombian legislation (Invima, 2018). The sampling was non-probabilistic for convenience. We evaluated nine slaughters for three days in a row (day 1 = animal reception; day 2 = slaughter; day 3 = cold chambers).

The survey carried out was a structured document tested in slaughters before the start of the study. We assessed transportation, handling, and animal variables during pre-slaughter, as well as carcass quality indicators related to AW. We recorded transportation and load data through structured surveys addressed to the drivers or personnel in charge of the animals during the trip, who were previously informed of the research’s objective. Vehicle and ante mortem handling information was obtained by visual inspection. The distance traveled in kilometers was estimated using Google Maps.

Regarding transportation, we documented the type of loading infrastructure of the farm, estimated distance from gathering pens to loading areas, location of the farm, and estimated travel speed. As to the transportation logistics in the SH and animal variables, we recorded the estimated travel time, waiting time to unload at the SH, unloading time (María et al., 2004), number of unloaded animals, weight, sex, age by dental chronometry, and phenotype of the animals (local, cross, other breeds).

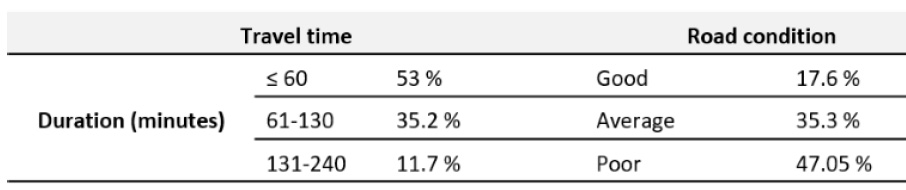

Concerning infrastructure and animal handling, we noted the unloading ramp characteristics; holding pens, general observations of animal behavior in holding pens; entry passageway of the SH, handlings indicators such as animal mobilization from holding pens to the slaughter room; stunning type and effectiveness. The slaughter was generally carried out the day after animal reception. Upon entering the SH, we evaluated whether the animal entered on their own or tried to escape, whether it slipped or backed away (María et al., 2004), or whether a cattle prod was used to move the animals (Grandin, 2013) (table 1).

Table 1 Animal handling and behavior indicators before entry

Source: Adapted from Grandin (2013) and María et al. (2004)

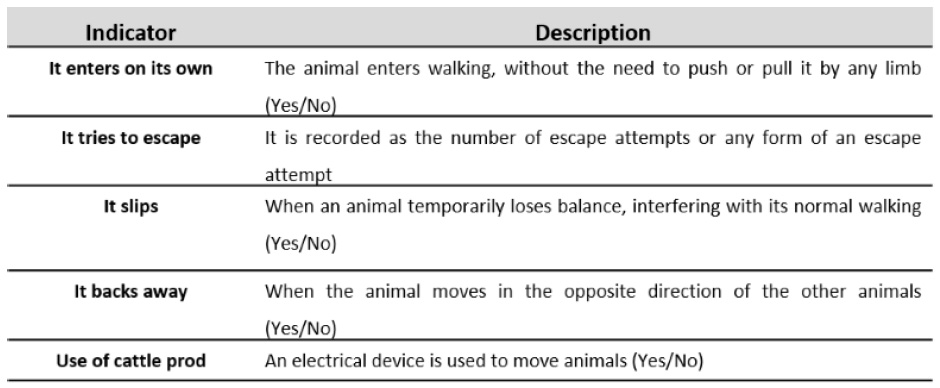

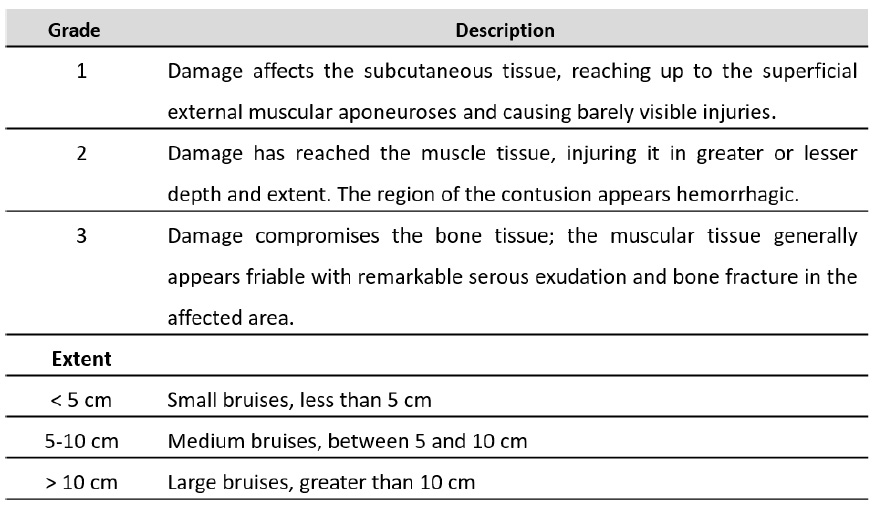

In the slaughter room, we inspected the carcasses and found bruises (contusions), as described by Tarumán and Gallo (2008) (figure 1, table 2).

Table 2 Description of the record of bruises according to grade and extent

Source: Taken from Tarumán and Gallo (2008)

Source: Adapted from Tarumán and Gallo (2008)

Figure 1 Anatomical regions considered for bruise location in sheep carcasses

In a cold chamber, the hydrogen potential (pH24h) was measured using an insertion pH meter for meat (HANNA HI99163) between the semitendinosus and biceps femoris muscles (leg) at 24 h post mortem, following Carter and Gallo’s (2008) procedure. The pH meter was calibrated in cold chambers before use with control solutions (pH 4 and 7 buffers, at 4 °C) and recalibrated every 8-10 measurements.

Statistical analysis

The carcass quality parameters were analyzed with descriptive statistics, obtaining averages, intervals, deviations, and percentages. For data analysis, we created databases and used Excel 2016 and InfoStat tools. A . test was performed to compare the pH variable by sex, first checking that the variances between groups were equal. The normality assumption was evaluated by graphical review of the residual distribution in frequency diagrams and pp-plot using SAS®, version 9.4. Besides, we carried out the analysis of correlations between some points considered risk factors of stress and AW indicators in carcasses but found no relationship, so they were ultimately excluded from the research.

Results and discussion

Transport logistics

During the study period, we analyzed 18 loads or transports. All the animal loads came from municipalities in Córdoba (Lorica 44,4%, San Pelayo 16,6%, Moñitos 11,11%, Canalete 11,115%, Sahagún 5,55%, San Andrés de Sotavento 5,55%, no answer 5,55%), at an approximate distance of 58.9 km; therefore, they were short trips. Eight hundred eighty-three sheep arrived at the SH; 84.3% were male and 15.7% female. The mean live weight was 26.8 ± 6 kg.

Photographs: Sandra Perdomo (a) and Lorena Aguayo (b)

Figure 2 Cargo vehicles used to transport sheep to the SH. a. Pickup truck with an open bed. b. Stake truck

The animals transported in a non-suitable vehicle for the animals since they travel lying down and tied up are shown in figure 2a. A vehicle suitable for transporting sheep are shown in figure 2b.

As to animal loading, 11.8% of the properties had a passageway, and 23.5% had a pier or loading ramps for the animals. Before loading, most animals were close to the truck, less than or equal to 20 meters (94.4%), but others were up to 600 meters away (5.6%). The limited on-farm loading infrastructure favors inappropriate handling during animal loading, causing farm workers to use force and putting both animal and worker welfare at risk.

The vehicles that arrived at the SH with sheep during the study period had a rigid body, two axles, a mechanical suspension system, and run on ACPM (Diesel). 94.1% of the vehicles had stake bodies with an average height of 1.27 m, allowing for better ventilation and favored thermoregulation of confined animals during transportation. We identified only one animal load in an unsuitable vehicle, a pickup truck with an open bed (low walls) where the animals were in lateral decubitus position and tied by the limbs so that they could not escape, preventing the attenuation of vehicle movements during transportation (figure 2a). Most load compartments of the sheep transporting vehicles were suitable (figure 2b) and had average areas of 8.38 m2, which is much smaller than the standard size of the vehicles transporting cattle, that is, a capacity of 14-16 animals with an average weight of 455 kg (Romero, Uribe-Velásquez, et al., 2013).

Moreover, regarding the use of bedding during transportation, only six trucks (35.3%) used some type of bedding, the most common being rice bran, leaves, or sawdust. This percentage is much lower than that found by Romero, Sánchez y Gutiérrez (2011), who evaluated cattle transport in two plants in western Colombia; they found that 96.4% of the trucks used some bedding to transport the cattle. This low percentage may be due to the drivers’ unawareness of the benefits of its use, both for hygienic- sanitary issues during the trip by preventing manure from leaving the compartment and for the stability it provides to the animal in motion (Organización Mundial de Sanidad Animal [OIE], 2010). It should be noted that bedding is a requirement under Resolution 002341/2007 specific to bovines and buffaloes (Instituto Colombiano Agropecuario [ICA], 2007). For sheep, there is still a legal gap that is currently being solved with the article 5 of 000136 Resolution of 2020 which indicates that it must follow the provisions of the Animal Welfare Manual in the transport of live animals issued by the Ministry of transport and the Colombian Agricultural Institute (Instituto Colombiano Agropecuario [ICA] & Ministerio de Transporte [MinTransporte], n.d ). On the other hand, bedding materials are part of the international recommendations of the OIE (2010), which are the basis for farm animal transportation.

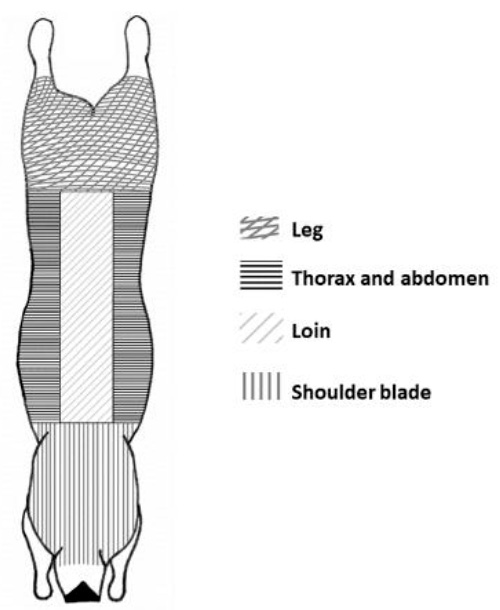

As estimated by the drivers, the average speed of the trip was 54.7 km/h. 47.1% stated that the roads used were in poor condition, 35.3% in fair condition, and 17.6% in good condition. This finding may be because, despite the short distances, 35% of the trips lasted 61-130 minutes and 11.7% 131-240 minutes (table 3).

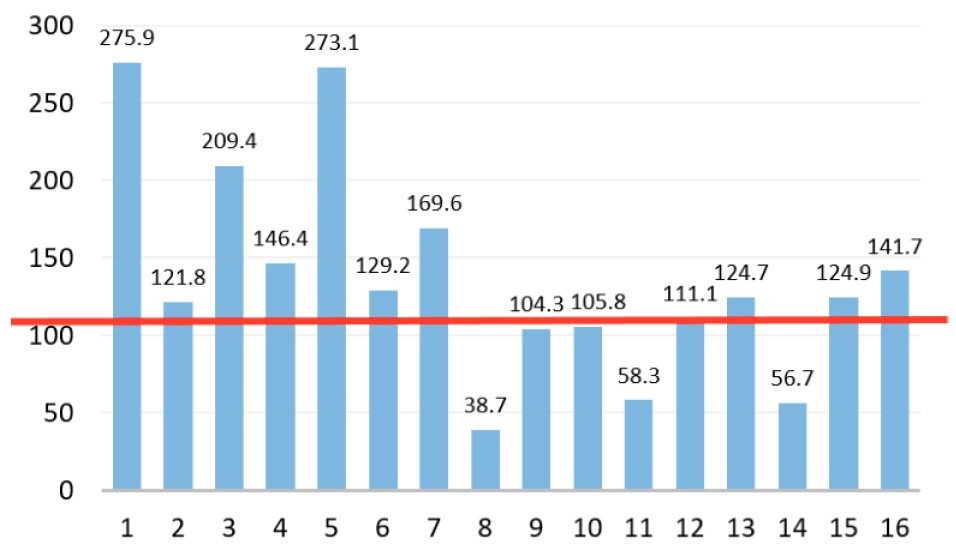

Load density

The load density is another relevant factor to assess the well-being or comfort with which the animals travel and is determined by the area that the animals have inside the vehicle, according to their number and weight; it directly affects their ability to maintain balance within the moving vehicle (Gallo et al., 2018; Romero, Toro, & Sánchez, 2011; Warriss et al., 2003). It can only be calculated if the animals’ total weight and the floor area are known (Warriss et al., 2003). The load density in this study had a minimum and maximum range of 38.7-275.9 kg/m2 and an average of 138.5 kg/m2 are shown in figure 3, which exceeds authorities’ recommendations (113 kg/m2 for animals weighing 25 kg on average) (Instituto Colombiano Agropecuario [ICA] & Ministerio de Transporte [MinTransporte], n.d.).

Eleven of 17 loads (64.7%) exceeded the recommended load density; five of them were above 160 kg/m2 and another three below the recommendation (51.2 kg/m2 on average). Nonetheless, we omitted a load since the animals arrived in an unconventional vehicle and were tied, so the load density could not be estimated. Tarumán and Gallo (2008), when evaluating sheep transportation to a meat processing plant in southern Chile, reported commercial load densities of 106.8-225.4 kg/m2 for sheep and 112.1-216.4 kg/m2 for lambs, whose maximums are lower than that found in the present study. This result is consistent with Warriss et al.’s (2003) study, which reported loads of 121-214 kg/m2 in commercial transportation in the United Kingdom. It is noteworthy that most vehicles used in the latter have a large capacity and at least two decks.

Source: Elaborated by the authors

Figure 3 Sheep load density transported to a processing plant in Córdoba, Colombia. The red line represents the load density of 113 kg/m2 recommended by ICA and MinTransporte (n.d.) for animals that average 25 kg

It should be emphasized that both the shortage and excess space available during transportation can affect AW. A high load density (less space availability) increases the chances that, when animals fall, they will have difficulty getting back up, increasing the risk of being trampled and causing contusions and additional energy costs that translate into pH alterations in meat (Varón et al., 2014). A low load density (excess space) decreases the animal’s physical support and produces a rebound effect that can cause loss of balance, falls, suffering, pain, and fear when moving together at high speed. So, considering the roads, great importance must be given to adjusting the animal load. Regarding surface area per animal, an average of 0.2 m2 was found, with a minimum and maximum of 0.1 and 0.6 m2, respectively. The area recommended by the Food and Agriculture Organization (Heinz & Srisuvan, 2001) is 0.4 m2 per sheep transported.

Unloading time

Regarding the waiting time before unloading, 86.7% of the unloadings took longer than recommended, with an average of 21.7 minutes. We observed that one of the factors that delayed animal unloading was related to pen infrastructure and the lack of specialization of the SH in sheep slaughter. When slaughtering cattle, procedures such as herding towards the bovine stunning box physically interrupted sheep unloading towards the weighing scale; therefore, sheep had to wait for the cattle to go through the passageway towards the stunning box to be unloaded, sometimes delaying operational processes.

The unloading took an average of 38.7 minutes (min. 9-max. 80), which was long, probably due to such a process overlapping between herding towards cattle slaughter and sheep unloading. At the beginning of the study, we also observed that the SH had an inadequate open unloading ramp, which allowed the animals to see to the sides and towards the ground and could cause fear and difficulty during unloading. Subsequently, the SH made a change to this ramp, installing a closed one both on the sides and on the ground, which considerably facilitated the unloading. Pérez et al. (2017) reported an average unloading time in cattle of 2.8 minutes; Huertas and Gil (2008) recorded an average unloading time of 5.4 ± 0.2 minutes, similar to that found by Romero, Cobo y Gonzales et al. (2013) with an average of 4.52 minutes. Meanwhile, Miranda de la Lama et al. (2010), who studied the critical points of the pre-slaughter logistics chain of the sheep sector (Aragon, Spain), found that the waiting time until unloading ranged from 5 to 20 minutes while unloading reported a time range of 5-22 minutes; the vehicles used in this study were specialized three-deck trucks. According to a stress rating scale during loading and unloading developed by María et al. (2004), unloads are appropriate if they are below 15 minutes.

Antemortem handling at the SH

The waiting time in pens averaged 19.4 hours (maximum 26 hours). Considering that animals are generally locked up the day before transportation without food, it could be said that sheep spend about 32 hours fasting before slaughter. This aspect could be significantly affecting AW due to weight loss, especially during the first 12 hours of fasting.

Moreover, during the arrival at the holding pens, we noticed a considerable mixture of groups since the animals were not separated by the lot of origin, category, or sex; commonly, two of the four pens available were used. This circumstance led to repeated social interactions between animals, such as males attempting to mount other males and some females, and conflicts between males. Something similar was described by Miranda de la Lama et al. (2012) in a study of behavior and stress evaluation during the first days of social mixing. They identified that social mixing between unknown animals alters the group’s social structure and increases agonistic interactions that resulted in establishing a new social hierarchy, adversely affecting AW and product quality. Bianchi and Garibotto (n.d.) recommend that sheep be taken to large, covered, and lighted holding pens and that they be separated by lots of origin to avoid fights over hierarchies.

All the evaluated slaughters were carried out the day after the reception. During the entrance to the slaughter room, 88.3% of the animals did not do it on their own, that is, they were pulled by some limb or carried by the operator; other behavioral events observed were escape attempts, backward movements, slides, and bleats (27.8%, 20.1%, 14.7% and 9.8%, respectively). Several authors have shown that the use of devices such as flags, bells, and even plastic bags, without physical contact, help animal mobilization to be quick and effective, facilitating the operational processes of the SH (Ceballos et al., 2018; Gallo et al., 2018; Grandin, 2013); however, in the SH where the study was carried out, no devices were used for adequate animal mobilization.

Regarding SH infrastructure, González et al. (n.d.), in an analysis of the Argentine sheep chain at the livestock, transportation, and meat processing plant level, recommended that the animals be taken to the stunning room through passageways that meet minimum conditions, such as the non-slip floor, closed walls, and proper design of the circuit that facilitates movement. Furthermore, Grandin (1991) highlighted the importance that the infrastructure for animal handling be adequate, preventing animals from falling or slipping. Passageways should allow animals to move smoothly; have good lighting at the entrance to the stunning room and in SH facilities in general; avoid high-frequency noises, and prevent animals from seeing people, shadows, or any other distraction in their path.

The SH where the evaluation was carried out lacked the majority of the recommended infrastructure to transfer sheep to the stunning room. The main shortcoming at this point was the lack of a closed-walled passageway, adjusted to sheep size, blocking visual distractions from the outside. Regarding animal stunning or desensitization, 97.5% of the animals fell at the first shot, considered acceptable according to Grandin’s (2013) guidelines; nevertheless, 1.8% of the sheep (16 out of 911 animals) showed some sign of consciousness, which is above this author’s recommendation (maximum 1 out of 500 animals).

The average time between stunning and bleeding (throat-cutting) was 74 seconds (1 min and 14 sec), which could be considered excessive since it should be kept to a minimum; even 13.1% of the animals were bled after 2 minutes. The SH exceeded the time recommended by Warriss (2004, as cited in Gallo & Tadich, 2008), who suggests that this process should take less than 30 seconds when it comes to specific stunning techniques in which they can regain consciousness more quickly, and the animal can feel pain and fear. The technique used by the SH was the captive bolt pistol (100%); so, the animals did not have the possibility of regaining consciousness unless the procedure was poorly performed. Despite this, the time should be kept to a minimum to avoid possible quality problems of the meat product caused by internal bleeding in the animals.

Post mortem evaluations: Carcass quality indicators associated with AW

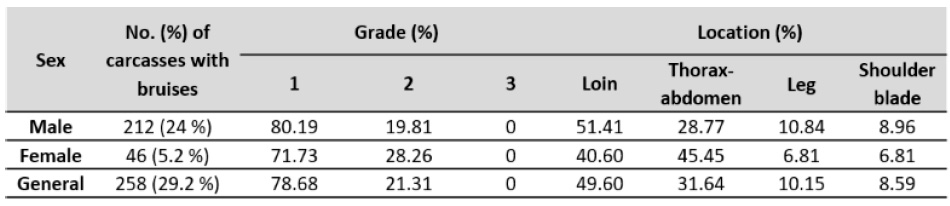

The study found that most 883 evaluated carcasses came from young males (lambs), younger than one year (74,17% without tooth shedding). The carcasses’ average weight was 11.1 kg (CV: 24.3%), with an average centesimal yield of 41.5%. Of all the carcasses observed, 29.2% had some bruising (table 4).

Table 4 Distribution (%) of sheep carcasses according to bruise grade and the affected anatomical region, in general, and by sex (N = 883)

Source: Elaborated by the authors

In general, we detected 258 carcasses with bruises (29.2%); the majority corresponds to a superficial contusion (78.68%) (table 4), which affects only the subcutaneous tissue (Grade 1). A lower percentage affected the muscle (21.31%, Grade 2), and no contusions were affecting the bone tissue (Grade 3). In both males and females, superficial contusion predominated. Most of the bruises were located mainly on the back, followed by the thorax-abdomen, leg, and, finally, the shoulder blade. In females, the bruises were located mainly on the thorax-abdomen. We recorded that 59.6% of the carcasses had bruises of less than 5 cm in length: 23.9%, between 5-10 cm, and 17.6%, greater than 10 cm.

These findings are slightly higher than those found in the third quality audit of the Uruguayan sheep meat chain, where 2,108 carcasses were evaluated; it was reported that 24.5% of them had some bruise (Instituto Nacional de Investigación Agropecuaria [INIA], 2017). The report also indicated that 4.1% of these carcasses with bruises were Grade 2—that is, damage to the muscle—, implying a significant loss of value for the carcass since the damage must be removed (INIA, 2017).

In Chile, Tarumán and Gallo (2008) evaluated 39,301 carcasses in one of the principal sheep slaughterhouses for export in the Magallanes region based on local transportation distance (up to 400 km) and found that 7.5% (6.1% for distances between 0 and 99 km) of the carcasses had some contusion. These findings are lower than those obtained in the present study, where the distances were classified as short. However, in another study for the same year, Carter and Gallo (2008) evaluated two types of national trips: local land trips, by unpaved paths and asphalt roads (12 h), and long-distance trips, by unpaved paths, asphalt roads, and by sea (46 h), found 25% and 33% of contused carcasses, respectively, percentages similar to those in this study.

Of note is that the relationship between distance traveled and bruises is not always direct, probably because many factors interact with each other (Tarumán & Gallo, 2008). One of them is road condition, which, as mentioned by the drivers above, was classified as poor. Most bruises were on the back; however, the most serious ones (Grade 2) were located mainly in the anatomical region of the thorax-abdomen and the leg. The loin is one of the most valuable regions of the carcass and, when Grade 2 contusions are present (or severe, as reported in Uruguay), cuts could range from small areas, where only a few grams are lost, to several kilos of meat per animal (Tarumán & Gallo, 2008).

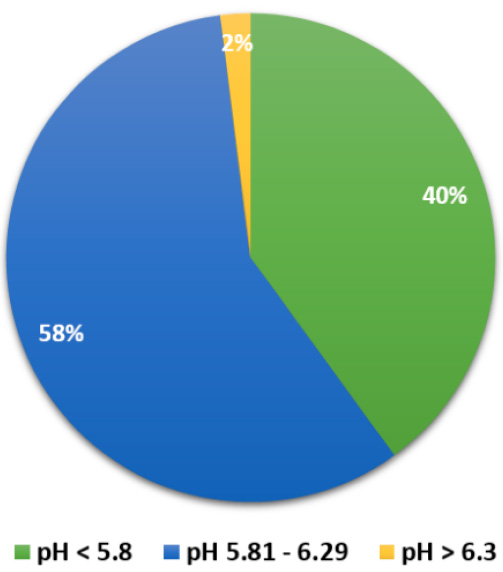

pH is one of the primary measures to monitor meat quality and AW since it is related to the depletion of glycogen reserves and the release of lactate caused by stressful handling during pre-slaughter operations (Gallo et al., 2018; Romero, Uribe-Velásquez et al., 2013). Although it is said that young sheep are less susceptible to stress before slaughter (Sañudo, 2008, as cited in Partida de la Peña et al., 2017), the pH can give clues about how the animals were handled before they died and the shelf life of their meat.

The average pH24 of the leg found in this study (5.82) was similar to the average recorded by Castro et al. (2017) in the musculus longissimus (loin) of Colombian Mora sheep. However, unlike the latter, the pH values by sex in the present study were significantly higher in females (5.9 ± 0.02) than in males (5.8 ± 0.01) (p < 0.001), which could be attributed to the fact that most females in our study were discard, older, and heavier ewes. A particular pH increase with slaughter weight has been observed, possibly due to older animals’ greater susceptibility to stress (Sañudo et al., 1998). Besides, the general pH range of the evaluated carcasses fluctuated between 5.2 and 6.8 (figure 4).

Similar to our study, Partida de la Peña et al. (2017) evaluated the pH of 1,000 sheep carcasses of various breeds in Mexico, finding a range between 5.0 and 6.5, with an average of 5.5 ± 0.2. This pH is lower than that found in the present study, which may be because in Mexico, unlike our region, diverse production systems predominate that vary according to modality, intensification, and technology, resulting in different nutrition levels; therefore, there were different degrees of muscle glycogen reserves until slaughter (Partida de la Peña et al., 2017). In Chile, Carter and Gallo (2008), during a sampling of 100 sheep carcasses that were transported at different times, found that the general average pH was 5.93; however, there were significant differences between the average recorded for the loin (average 5.75) and the leg (6.1). It is worth mentioning that these sheep and those in our region generally feed almost exclusively on extensive grazing.

Source: Elaborated by the authors

Figure 4 pH distribution in carcasses evaluated at the SH in Córdoba, according to three categories proposed by Watanabe et al. (1996): low <5.8; medium = 5.8-6.3; high > 6.3

The evaluated carcasses’ pH distribution according to three categories are shown in figure 4 (Watanabe et al., 1996): low, medium, and high. Most of the pHs in this study (58%) were between 5.8 and 6.3, classified as medium pHs; followed by low pHs < 5.8 (40%, standard) and, finally, high pHs > 6.3 (2%, undesirable due to the damage that they can cause to the final product quality). These results are quite different from those reported by the INIA of Uruguay (2017) in its quality audit, where 64.9% of the evaluated carcasses had a pH lower than 5.8 (standard), and the remaining 35.2% had a pH rated as medium (≥ 5.8).

In Colombia, pH is not a routine measurement in all meat processing plants; nevertheless, as the results of this study show, it is a quality variable to be monitored since it could indicate: a) a limitation in meat quality, impacting the shelf life of the food product, and b) an AW problem, associated with lack of food or transportation issues (high load densities, poor road conditions, driving problems, stress).

As reported by Albarracín and Sanchez (2013), the ideal pH of sheep meat should be between 5.5 and 5.7 in order for it to retain its organoleptic properties, which is consistent with that reported by Hogan et al. (2007), who mentioned that the ideal pH should be less than 5.7. A pH of around 5.8 at 24 hours post mortem translates into quality defects similar to DFD (Dark, Firm, and Dry) meat, characterized by high water retention, firm and sticky texture, and a dark red color. This occurs in highly stressful and physically demanding transport conditions, especially in climates with extreme temperatures (Gregory, 2007, as cited in Miranda de la Lama, 2013).

Conclusions

This study’s results allow us to conclude that there are a series of limitations to the welfare of sheep brought to formal slaughter in Córdoba. A lack of infrastructure that facilitates animal loading on farms; load densities during transportation that do not follow ICA’s and MinTransporte’ recommendations; poor road conditions and infrequent use of non-slip materials such as bedding; prolonged animal unloading, social mixing in holding pens, and inadequate herding to the SH are some of the limitations that, together with insufficient infrastructure for sheep, can be multifactorial sources of animal stress and damage. These aspects were reflected in a high percentage of bruises in the carcasses and pHs classified as medium, putting the final product quality at risk.

text in

text in