Introduction

Corn, Zea mays L. (Poaceae), is either fresh or processed (Parera, 2017). Floury corn kernels contain high amounts of starch (70-72%) and proteins (7%) (Corn Refiners Association [CRA], 2006). Tender kernels contain 70-75% water, and the texture of corn grains is soft (Suslow & Cantwell, 2012). In the early stages of development, corn ears have a higher total soluble solids content. As grain maturity advances, the proportion of starch increases, and the sugar content decreases (Ospina, 2015).

Corn ears continue their biological activity after harvest, and physiological changes during storage are reflected in respiratory activity. Temperature affects the metabolism of fresh, stored vegetables. When temperature increases, the respiration intensity increases, along with the consumption of sugars; therefore, the effect of conservation decreases, and quality deteriorates more rapidly, especially in perishable foods, such as fresh corn ears (Kader, 2013).

Increased firmness in corn ears results in the hardening of grains, which is associated with the loss of water and in turn with the structure and composition of grains, temperature, and storage time (Gonk et al., 2017). Therefore, it is essential to harvest corn ears before physiological maturity and maintain the appropriate environmental conditions during the postharvest period to guarantee and prolong conservation.

Using fresh food packaging improves consumer acceptance with an appreciable quality and color and also decreases microbial action (Sandarani et al., 2018; Santos et al., 2012); however, little research addresses refrigeration and storage time for fresh corncobs. Therefore, the objective of this study was to evaluate the effect of storage temperature, packaging type, and husk presence on post-harvest quality parameters in corn.

Materials and methods

Plant material and postharvest treatments

Sabanero floury corn was collected from two commercial plots in the municipalities of Rosal and Mosquera (Cundinamarca, Colombia). Sabanero is a regional variety of corn adapted to cold climate production zones in Colombia, above 2500 MASL, with an average temperature of 14ºC, annual rainfall close to 900 mm, solar radiation of 14.2 MJ m−2 day−1, and relative humidity of 74%. This variety was widely cultivated by the Muiscas, the indigenous inhabitants who selected it for its culinary quality and large grain size; therefore, this corn variety has been highly accepted in Andean cities (Ligarreto, 2017). The material was processed in the Laboratorio de Calidad y Poscosecha de Productos Agrícolas at Universidad Nacional de Colombia, Bogotá. Two storage temperatures, 4 °C and 15 °C, were used. Packaging consisting of 2-gauge polyethylene bags, 22.5 cm long and 35 cm wide, with 5 mm micro perforation at the center of the bags was evaluated. A control treatment without packaging was used.

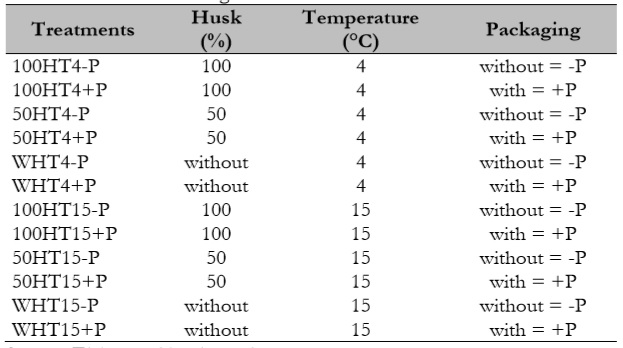

First, an experiment determined physicochemical variables with destructive tests: total soluble solids, titratable acidity, and firmness. Each sampling unit consisted of three ears, with five repetitions, for 180 evaluated corn ears. A second experiment was carried out to investigate respiration intensity, weight loss, and color. The second experiment consisted of two corn ears, with four repetitions, for a total of 96 corn ears. Both experiments had the same treatments as described in Table 1.

A complete randomized design with 12 treatments was used in a 3 x 2 x 2 factorial arrangement. The first factor was the corn ear aspect (100% husk, 50% husk, and without husk), the second factor corresponded to temperatures (4 °C and 15 °C), and the third factor was the use or not of polyethylene packaging. Measurements were repeated over time at 8 and 18 days for total soluble solids and titratable acidity variables and at 5, 10, 15, and 20 days for firmness, respiration intensity, weight loss, and color as an intrasubject factor that affected the response variable (Davis, 2002). Considering previous studies by Sánchez and Villamizar (2003), the two temperatures were plotted separately with their respective trends in corn ear and packing over time to view the interaction of the main effects on the physicochemical variables.

Physicochemical tests

Total soluble solids (TSS): 20 kernels were randomly taken through zig-zag sampling from each ear (BBCH-scale 79), a methodology described by Lancashire et al. (1991), with an average weight of 12 g. Subsequently, the grains were crushed, and two drops of filtered juice were added to a digital refractometer (Hanna brand, HI 96801, USA), ranging from 0 to 85%, with an accuracy of 0.1 Brix. The content of TTS was expressed as a percentage

Titratable acidity (TA): The method adopted by Ramírez (2006), was used. The corn kernels were crushed in a manual blender (Osterizer brand, model 4655, UK), 1 g of juice was obtained, to which 5 mL of distilled water were added (1: 5 v/v). Three drops of phenolphthalein were added as an indicator using a Class A precision digital burette, Titrette, and acid-base titration with sodium hydroxide at (0.099 meq mL-1) (Ladino & Valencia, 2014TA was expressed as a percentage with Rozo-Romero et al’s. (2015) equation.

Grain firmness (GF): It was estimated with a digital texturometer (Lloyd LS1 brand, Bognor Regis, UK) with a 1 kN load cell, 3 mm cylindrical punch, and Nexygen plus software. A sampling point located at the central part of the cob was selected using an input force of 5 N (Ladino & Valencia, 2014), an input speed of 5 mm seg-1, and a 7 mm depth.

Weight loss (WL): It was determined using a precision analytical balance with an approximation of 0.01 g, OHAUS-Pioneer, USA; the applied methodology considered the final weight compared to the initial weight.

Respiration intensity (RI): It was determined with a Vernier Labquest 2 (USA), with a PVC chamber 31 cm long and 12 cm wide. The volume by displacement of water (cm³) and the weight according to precision balance (g), with which the specific weight (g cm- 3) was calculated as described by Sánchez and Villamizar (2003), were used to calculate the slope of RI and was expressed in mg CO₂ kg-1 h-1 (Balaguera et al., 2015).

The color was determined with the CIE Lab colorimetric system using a Minolta CR 410 digital colorimeter (Konica Minolta brand, Hong Kong). The coordinate L represented the color change, light to dark.

Statistical analysis

Analysis of variance was performed to determine the effect of the treatments and their interactions and the effect of time x treatments on the variables studied. Tukey’s means test was used to verify the existence of significant differences between treatments’ (p ≤ 0.05). The applied software was Statistix v 9.0 (analytical software, Tallahassee, FL).

Results and discussion

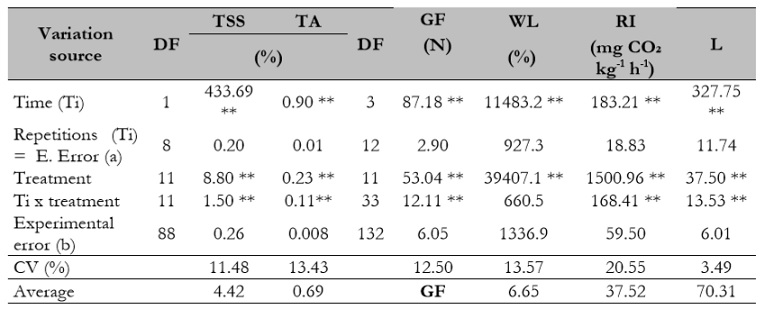

The analysis of variance showed statistical differences for the main effects and their interactions (data not shown) and revealed differences between the storage time of corn ears, treatments, and the interaction of time per treatment on the variables: TSS, TA, GF, WL, RI, and luminosity, as shown in Table 2.

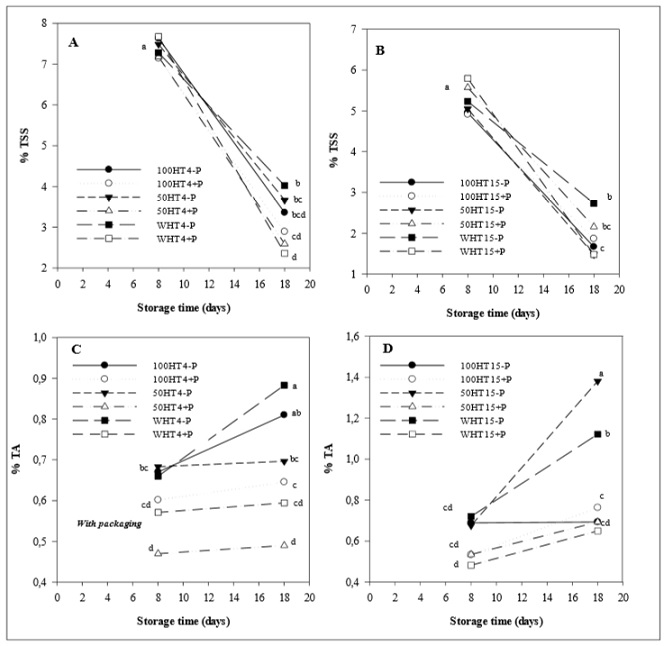

The corn ears stored at 4 °C with the husk were stable at 18 days (Figure 1A). The corn ears without the husk or packaging reached a TSS value of 4.02%, whereas the treatments with packaging showed a value of 2.89% with 100% husk and 2.59% with 50% husk. On the other hand, in the corn ears stored at 15 °C (Figure 1B), the treatment with the lowest concentration of soluble solids (1.48%) was that with packaging but no husk.

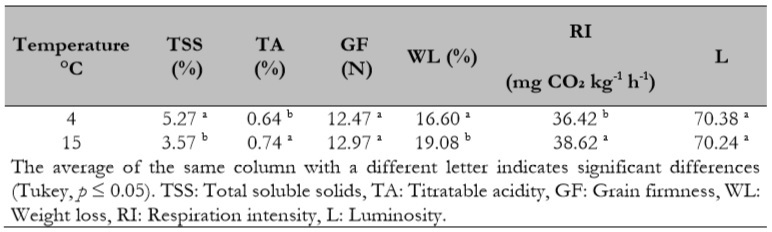

When comparing the effect of temperature on the TSS in the corn stored, it was found that, at 15 °C, there was a significantly lower percentage of TSS during storage (Table 3). Source: Elaborated by the authors TSS ranged from 7.14 to 7.67% in the cobs refrigerated at 4 °C, whereas, at 15 °C, the effect of temperature on TSS was appreciable, which decreased to 4.91 and 5.79% after eight days of storage. Similar results were found by Ladino and Valencia (2014), who pointed out that, under refrigeration and packaging, the TSS was in a range between 6.5 and 8.0%; however, during storage, the sugar content drops as a result of turning into starch (Machado et al., 2018) or being used in respiration. The results showed a decrease in TSS at 4 °C, between 2.36 and 4.02%, in 18 days of storage. This result coincides with Shao and Li (2011), who stated that the sugar content at 4 °C decreased to 2.4% in 25 days of storage.

Table 2 Mean squares of measurements repeated over time on the studied variables

** Significance at p ≤ 0.01. DF: Degrees of freedom; TSS: Total soluble solids; TA: Titratable acidity; GF: Grain firmness; WL: Weight loss; RI: Respiratory intensity; L: Luminosity.

Source: Elaborated by the authors

The TSS values at 15 °C decreased as a result of the maturation of the grains, with values close to 1.48 and 2.73%, similar to those reported by Sánchez and Villamizar (2003), who observed that the TSS content of floury corn from the municipality of Simijaca (Cundinamarca) decreased to 1.7 and 2.3%.

The packaging effect differed significantly for the TA, as noted in the two groups: with or without polyethylene (Figure 1C). The ears with husks and without packaging under refrigeration at 4 °C had the most significant increase in the percentage of TA (0.88%), whereas a lower value of 0.49% after 18 days of storage was reached with 50% husk and packaging.

Lower TA values were found in the cobs stored at 15 °C with 100% husk without packaging and 50% husk with packaging. TA increased to 1.38% with 50% husk and without packaging, a significant difference, and the value was 0.65% in the cobs without husks and with packaging (Figure 1D), which suggests that as grain ripening increases, TA increases.

Source: Elaborated by the authors

Figure 1 Effect of temperature, husk presence, and packaging on total soluble solids and titratable acidity during storage for corn ears under two temperatures. A) TSS at 4 °C, B) TSS at 15 °C, C) TA at 4 °C, D) TA at 15 °C. Points are the average of three data. Averages with the same letter at any storage time were not significantly different (Tukey, p ≤ 0.05).

It was generally observed that, under both storage temperatures, the cobs with packaging had lower TA; at 4 °C, these values were considerably lower than with storage at 15 °C (Table 3). Sánchez and Villamizar (2003) reported TA values of 0.18-0.38% at 18 °C during 21 days of storage. The TA values in this study were higher, indicating an increase in TA concerning the temperature and storage time of the ears.

Table 3 Average values of the effect of storage temperature on the studied variables

Source: Elaborated by the authors

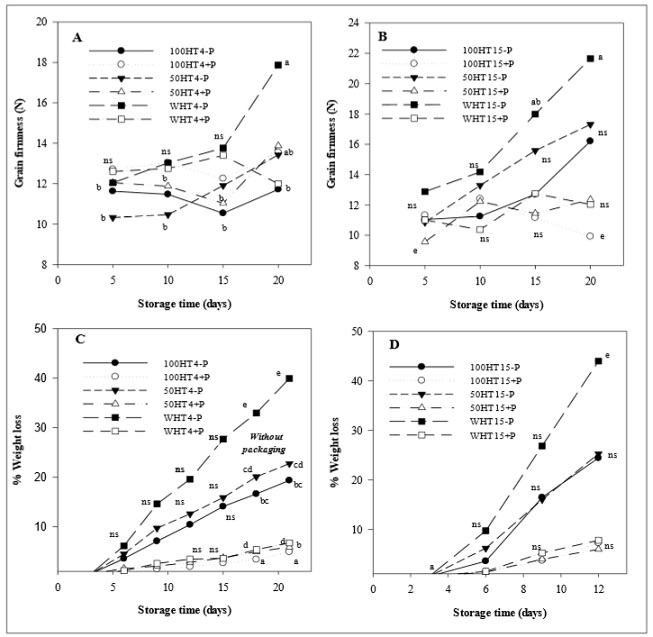

The less firm grains remained close to or below 12 N, while the hardest were above 14 N, observed in the ears with husks and without packaging. The firmness increased the maturation state of the corn ears, as observed in Figure 2A, with notable effects of the storage conditions on GF.

At 4 °C, the lowest GF corresponded to ears with 100% husk and without packing, while the harder grains occurred in the corn ears without husks and packaging. At 15 °C, the cobs with 100% husk and with packaging had a lower GF value (Figure 2B). The hardest cobs were those stored without husks and packaging at 20 days of storage, which suggests that the husk and packaging play an essential role in conserving corn ears. The hardening of grains is attributed to an increase in the thickness of the pericarp (Choe, 2010) and loss of water. Therefore, the force required to penetrate the grain increases over storage time as the grain dries (Gonk et al., 2017).

The hardness is determined by factors such as structure, size, and shape of the grain (Centro Internacional de Mejoramiento de Maíz y Trigo [CIMMYT], 2016). Similarly, a direct relationship exists between WL and GF; lower WL represents tender kernel preservation with higher moisture content. Other studies have reported that using low-density polyethylene (PEBD) packaging reduces the hardening of the cob during 21 days of storage (Ladino & Valencia, 2014).

Gradual WL was evaluated in two groups: with and without packaging during storage (Figure 2C). The ears stored at 4 °C with 100% husk obtained the lowest WL, followed by 50% husk and without husk, while the most significant WL was seen in the ears without husks and packaging, significantly different from the other treatments. On the other hand, at 15 °C, the WL was considerable in the cobs without husks and packaging compared to the cobs with packaging (Figure 2D). When comparing the cobs stored at 4 and 15 °C, there was a significant difference at 4 °C, with a lower percentage of WL (Table 3).

Source: Elaborated by the authors

Figure 2 Effect of temperature, husk presence, and packaging on the changes associated with grain firmness and weight loss under two temperatures. A) GF at 4 °C, B) GF at 15 °C, C) WL at 4 °C, D) WL at 15 °C. Points are the average of three data. Averages with the same letter at any storage time were not significantly different (Tukey, p ≤ 0.05).

The results indicated that WL was affected by temperature, presence or absence of husk, and packaging. The ears without husks and packaging at 15 °C had a WL of 43.94%; at 4 °C, it was 39.95% at 21 days of storage. Similar observations were made by Ávila et al. (2007) and Lopes et al. (2016), who pointed out that WL increases concerning storage period and depends on the attached husk proportion. Sánchez and Villamizar (2003) reported that in ears without husks, the loss increased to 66.6 % without packaging and, with 50% husk, up to 65.62%. WL was 49% in the commercialized husk form at 18 °C with 70% relative humidity. Other research has indicated that the optimum temperature is 4 °C with 95% relative humidity, which allows for 12 days of storage (Escobar et al., 2014). Therefore, packaging plays a vital role in preserving fresh corn ears; it reduces WL and facilitates the gas permeability for oxygen and carbon dioxide (Fernández et al., 2015).

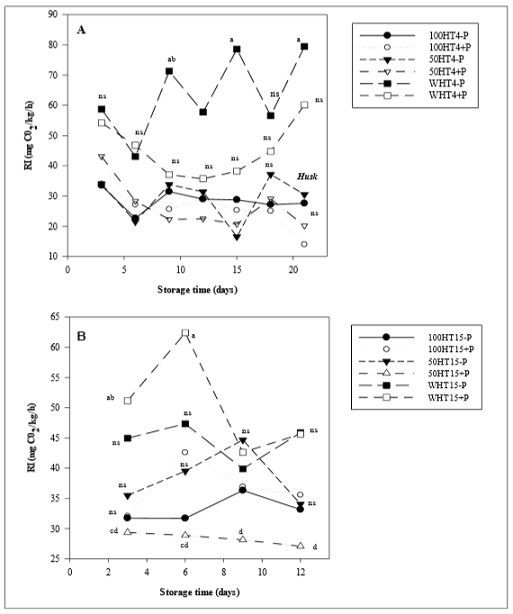

Under both storage temperatures, the cobs with a lower RI remained near or below 35 mg CO₂ kg-1 .-1. The RI increased above 40 mg CO₂ kg-1 .-1 in the ears without husks, with and without packaging. The cobs stored at 4 °C had a lower RI when they had 100% and 50% husk and with packaging and achieved stability during storage. The physiological function of the husk produces an effect that prolonged postharvest conservation (Figure 3A).

On the other hand, at a temperature of 15 °C, the highest values of RI were seen in the ears without husks, with and without packing. At the same time, the RI was lower and more stable in the cobs with 50% husk and packaging, with significant differences concerning the other treatments (Figure 3B). The effect of RI on storage temperature was also observed (Table 3).

RI decreased from 20 mg CO₂ kg-1 .-1 to 38 mg CO₂ kg-1 .-1 in precooled and uncooled ears packed at 4 °C (Ladino & Valencia, 2014). This range was maintained in the treatments with 100% and 50% husk when packaged at 4 °C and stored for 21 days. This approach was consistent with a report by Pengelly et al. (2011), who pointed out a decrease in RI in ears with husks. Low refrigeration temperatures delay the metabolic reactions involved in physicochemical changes in terms of the consumption of carbohydrates, such as starch, and directly influence quality parameters such as firmness, sugar content, and flavor (Thompson & Kader, 2009); however, the opposite situation was also reported (Suslow & Cantwell, 2012) when ears were subjected to 15 °C, with a RI increase between 207.09 and 240.00 mg CO₂ kg-1 .-1.

The results showed a lower range from 27.07 to 62.39 mg CO₂ kg-1 .-1, which implies differences in the commercial quality of corn, which is better preserved at low temperatures. The increase in RI was more evident in the ears without husks, possibly related to the loss of turgidity in the grain. It caused the most significant loss of water when there was no packaging, especially in the ears without husks and with packaging, likely related to the increased moisture that accumulates inside the package, promoting early germination (viviparity) and, therefore, increased respiration.

Source: Elaborated by the authors

Figure 3 Effect of temperature, husk presence, and packaging on respiration intensity under two temperatures, A) 4 °C for 21 days, B) 15 °C for 12 days of storage. White symbols indicate the function of packaging, and black symbols indicate no packaging. Averages with the same letter at any storage time were not significantly different (Tukey, p ≤ 0.05).

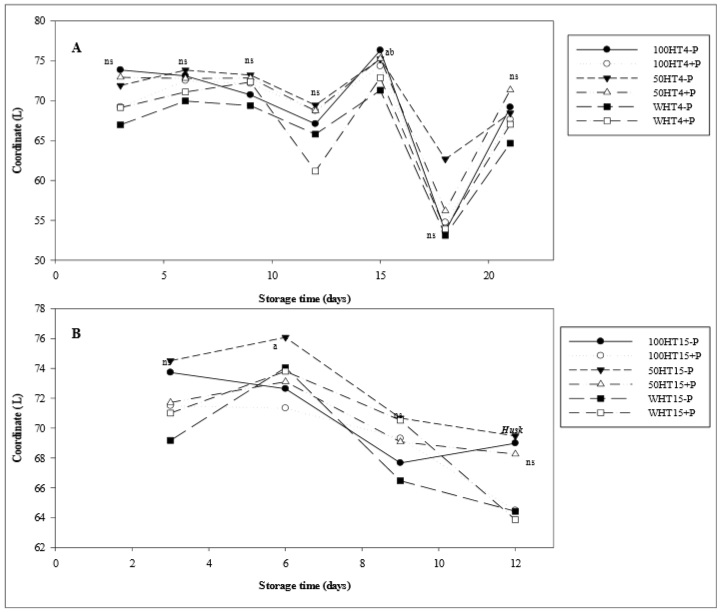

At 4 °C, the L coordinate showed that the darkest grains were found on the ears without husks, with and without packaging, while the brightest grains were found with 100 and 50% husk with and without packaging (Figure 4A). At 15 °C, bright colors demonstrated conservation of grain color, observed with 100% husk without packaging and 50% husk with and without packaging (Figure 4B).

Source: Elaborated by the authors

Figure 4 Effect of temperature, husk presence, and packaging on color. A) 4 °C, B) 15 °C. Points are the average of two data. Averages with the same letter at any storage time were not significantly different (Tukey, p ≤ 0.05).

In the present study, color behaved as a stable variable among the ears with husks, providing greater luminosity to the grains, which is consistent with the findings of Farahnaky et al. (2013). They argued that luminosity increases with the moisture content of the grain. The yellow color predominated in floury corn because of the flavonoids in the grains, which influences the color and taste and helps protect enzymes and vitamins (Falcone et al., 2012; Kumar & Pandey, 2013). The results indicate that good conservation of fresh corn cobs for up to 21 days is maintained when they are stored with bracts, polyethylene packaging, and at a refrigeration temperature of 4 ºC since WL is avoided without affecting the quality of the product grain. In perspective, there is a need to continue research on guaranteeing the shelf-life of postharvest corn cobs using low- cost and environmentally friendly packaging techniques.

Conclusions

In this study, the storage temperature significantly affected the conservation of fresh corn ears; the best treatment was 4 °C with 100% husk and packaging. This treatment decreased RI, GF, and WL. Grain hardening was associated with WL and increased temperature to 15 °C. The results suggested that the temperature should be controlled to decrease GF changes. The physiological function of the husk and the polyethylene packaging produced color stability, contributing to the preservation of the commercial quality of the ears for up to 21 days of storage. Continued research on packaging techniques with physicochemical analyses is needed to ensure the shelf-life of postharvest corn ears.