Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO -

Access statistics

Access statistics

Related links

-

Cited by Google

Cited by Google -

Similars in

SciELO

Similars in

SciELO -

Similars in Google

Similars in Google

Share

Ingeniería y Universidad

Print version ISSN 0123-2126

Ing. Univ. vol.13 no.1 Bogotá Jan./June 2009

Evaluation of Environmental Impact Diminution when Recycled Material is Used for Threaded Unions*

Evaluación de la disminución del impacto ambiental con el uso de material reciclado en elementos de unión de tubería**

Avaliação da diminuição do impacto ambiental com o uso de material reciclado em elementos de união de tubulação***

Carlos Eduardo Fúquene-Retamoso ****

Nazly Bibiana Córdoba-Pinzón *****

Jaime Andrés hara-Borrero******

Sandra Méndez-Fajardo*******

**** Ingeniero industrial, Pontificia Universidad Javeriana, Bogotá, Colombia. Master of Environmental Management, Portland State University, Portland, Estados Unidos. Profesor asistente, Pontificia Universidad Javeriana. Correo electrónico: cfuquene@javeriana.edu.co.

***** Ingeniera industrial, Pontificia Universidad Javeriana, Bogotá, Colombia. Joven investigadora, Departamento de Procesos Productivos, Pontificia Universidad Javeriana, Bogotá, Colombia. Correo electrónico: nazly.cordoba@javeriana.edu.co.

****** Ingeniero civil, Pontificia Universidad Javeriana, Bogotá, Colombia. Maestría en Ingeniería y Gestión Ambiental, Universidad Politécnica de Cataluña, Barcelona, España. Doctorado en Ingeniería de Caminos, Canales y Puertos, Universidad Politécnica de Madrid, Madrid, España. Profesor asistente, Pontificia Universidad Javeriana. Correo electrónico: laraj@javeriana.edu.co.

******* Ingeniera civil, Pontificia Universidad Javeriana, Bogotá, Colombia. Máster en Ingeniería Civil, Universidad de los Andes, Bogotá, Colombia. Profesora asistente, Pontificia Universidad Javeriana. Correo electrónico: sandra.mendez@javeriana.edu.co.

* Date of submission: August 25, 2008. Date of acceptance for publication: March 9, 2009. This article is based on a research project called Applying Product Life Cycle Management as a Support Tool in Decision Making when Selecting Materials for Manufacturing Screw Joints for Piping, financed by Pontificia Universidad Javeriana through its 2005 internal call for project support, registration N° 000425.

** Fecha de recepción: 25 de agosto de 2008. Fecha de aceptación para publicación: 9 de marzo de 2009. Este artículo está basado en el proyecto de investigación denominado Aplicación del análisis del ciclo de vida de producto como apoyo a la toma de decisiones en la selección de materiales para la fabricación de elementos de unión roscados para tubería, financiado por la Pontificia Universidad Javeriana a través de la convocatoria interna de apoyo a proyectos 2005 con número de registro 000425.

*** Data de recepção: 25 de agosto de 2008. Data de aceitação para publicação: 9 de março de 2009. Este artigo baseia-se no projeto de pesquisa denominado Aplicação da analise do ciclo de vida do produto como apoio à tomada de decisões na seleção de materiais para a fabricação de elementos de união roscados para tubulação, financiado pela Pontificia Universidad Javeriana através da convocatória interna de apoio a projetos 2005, com número de registro 00425 da Vicereitoria Acadêmica da Pontificia Universidad Javeriana.

Abstract

This research performs life cycle analysis of threaded unions manufactured in PVC. The analysis proposes two scenarios according to the amount of recycled material used in the process. One of the scenarios is based on 45% of recycled material and the other one is based on 100% of raw virgin material usage. The analysis was made by means of the software tool Simapro® version 7.0, establishing the environmental impact rating by the Ecoin-dicator 99 methodology. Data were collected from databases, observation and measurement of an industrial process, specific prototype development under laboratory conditions and interviews with experts. When a composition of 100% of virgin raw material was used for the product, significant effects observed during the product's life cycle were related to fossil fuel consumption and the generation of inorganic materials in suspension. For a product composition with 45% of recycled material, the most significant effects were related to the generation of inorganic materials in suspension and climate change. Environmental impact diminution was observed in the fossil fuel consumption, acidification / eutrophication, inorganic materials in suspension and climate change categories. Using recycled material in this product lowers the contribution of fossil fuels to the environmental impact from 56% to 5%, compared to the contribution of the other impact categories.

Key words: Environmental impact analysis, waste utilization, joints (engineering).

Resumen

La investigación analiza el ciclo de vida de uniones roscadas fabricadas en PVC y propone dos escenarios de acuerdo con la cantidad de material reciclado utilizado en el proceso: (1) una composición de producto con 45% de material reciclado y (2) el uso de 100% de materia prima virgen. Para el análisis se usó la herramienta informática Simapro® versión 7 y el grado de impacto se estableció por medio del uso del Ecoindicador 99. Los datos se recolectaron de bases de datos, observación y medición de un proceso industrial, desarrollo de un prototipo específico en condiciones de laboratorio y entrevistas con expertos. Cuando se utilizó una formulación de producto con 100% de material virgen, los mayores efectos ambientales del producto se asociaron con el consumo de combustibles fósiles y la generación de material inorgánico respirable en suspensión. Para un producto con una formulación correspondiente al 45% de material reciclado, se asociaron los mayores impactos ambientales a la generación de material inorgánico respirable en suspensión y al cambio climático. Se observó una disminución del impacto ambiental en las categorías del consumo de combustibles fósiles, lluvia ácida/eutroficación, material inorgánico en suspensión y cambio climático. En consecuencia, el uso de material reciclado en este producto disminuye la contribución del impacto ambiental de los combustibles fósiles de un 56% a un 5% en comparación con la contribución de las diferentes categorías de impacto.

Palabras clave: Evaluación del impacto ambiental, aprovechamiento de residuos, uniones (ingeniería).

Resumo

A pesquisa analisa o ciclo de vida de uniões roscadas fabricadas em PVC e propõe dois cenários de acordo com a quantidade de material reciclado utilizado no processo: (1) uma composição de produto com 45% de material reciclado e (2) o uso de 100% de matéria prima virgem. Para a análise utilizou-se a ferramenta informática Simapro® versão 7 e o grau de impacto estabeleceu-se por meio do uso do Ecoindicador 99. Os dados se coletaram de bases de dados, observação e medição de um processo industrial, desenvolvimento de um protótipo específico em condições de laboratório e entrevistas com especialistas. Quando se utilizou una formulação de produto com 100% de material virgem, os maiores efeitos ambientais do produto associaram-se com o consumo de combustíveis fósseis e a geração de material inorgânico respirável em suspensão. Para um produto com una formulação correspondente a 45% de material reciclado, associaram-se os maiores impactos ambientais à geração de material inorgânico respirável em suspensão e a mudança climática. Observou-se uma diminuição do impacto ambiental nas categorias de consumo de combustíveis fósseis, chuva ácida/eutroficação, material inorgânico em suspensão e mudança climática. Como conseqüência, o uso de material reciclado neste produto diminui a contribuição do impacto ambiental dos combustíveis fósseis de 56% a 5% em comparação com a contribuição das diferentes categorias de impacto.

Palavras chave: Avaliação do impacto ambiental, aproveitamento de resíduos, uniões (engenharia).

Introduction

The city of Bogota generates approximately 5.880 Ton/day (Ministerio de Desarrollo Económico, Superintendencia de Servicios Públicos, 2008, p. 46) of solid residues. From this amount, around 30% of total residues, composed by organic matter, plastics and paper, could be reincorporated into productive cycles instead of ending up in landfills.

Traditional plastics have become a material of interest because of their long time to decompose, their low weight/volume ratio and the very little commercial use of biopolymers. It has become a challenge the search of alternatives for minimizing the generation of plastic residues.

According to the Commission of European Communities it was estimated that in 1999 the total annual PVC waste quantity was about 4.1 million tons in the Community and around one million tons of PVC is present in the construction and demolition waste stream. In addition to that it is expected that the volume of PVC waste will increase significantly by 30% in 2010 and by 80% in 2020, in particular due to the important increase of waste quantities from long lifespan products (Commission of European Communities, 2000).

On the other hand, "the world market potential for biopolymers in 2010 could be between 4 million and 12.5 million tons which would be only a 1.5%-4.8% share of the entire plastics market" (Michael, 2003, s. p.). Mentioned aspects have motivated the development of this research project with the purpose of evaluating in what proportion and on which impact categories an environmental impact is minimized when using recycled materials in plastic materials.

One way for evaluating if recycling has positive impact on the environment and quantifying its benefits can be done by means of product Life Cycle Analysis (LCA). Results from this kind of analysis have concluded that the less a product is recycled the more the environmental load related to it (Choi et al., 2006). On the other hand, "when comparing risks regarding dumping and incineration, recycling becomes the strategy for solid residue management" (Lund, 2006, p. 1.10).

In order to reincorporate recycled materials into the supply chain, it is imperative to take into account some essential variables such as identification, materials processability, recovering technology to be used, conditions of recycled materials, generated environmental effects and ways for disposing, during the design process. Life Cycle Analysis (LCA) constitutes as well as an objective, an effective way to determine which existing or under development materials favors the environment, allowing products to become a green alternative.

This article is focused on the Life Cycle Analysis (LCA) of threaded union for pipes, manufactured in PVC. The analysis proposes two scenarios according to the amount of recycled material used in the process. One of the scenarios is based on a 45% of recycled material and the other one is based on a raw virgin material usage.

The reason for the selection of this material is related to the high dynamism, of plastic sector, for the past three decades in Colombia, with an annual growth of 7% for this industrial sector (Ministerio de Medio Ambiente, Vivienda y Desarrollo Territorial, 2004) and the fact that it is possible to recycle it.

For evaluating environmental impact, it was used a methodology for product Life Cycle Analysis (LCA), which among others, allows the determination of environmental aspects and potential impacts associated to a specific product by means of: compilation of the inventory of the system's inputs and outputs, the evaluation of the potential environmental impacts related to these inputs and outputs, and the interpretation of the results coming from the impact and inventory phases related to the objectives of the study (Norma Técnica Colombiana ISO 14040, 2003). Inputs and outputs of each phase of the product life cycle were identified and documented, including those related to the raw material extraction, production, usage and final disposal.

According to UNEP, there are some barriers, in developing countries, to LCA implementation: "absence of a perceived need, lack of LCA expertise and know-how, lack of funding for LCA and lack of appropriate data and methodologies". In general, industry in developing countries has to reinforce preventive actions for avoiding pollution taking into account that "typically neither recycling nor end-of-pipe measures are employed" (Arena, 2000, s. p.).

Furthermore, "during the World Summit on Sustainable Development in Johannesburg in September 2002, opposition emerged from delegates from developing countries against the concept of life-cycle management and in particular also against the use of LCA" mainly because of perception as technical barriers to trade (Udo de Haes, 2004, p. 8).

Protection to environment cannot be seen as opposite to protection to trade. It is required to optimize processes, improve product design and control of operations to be more competitive and environmentally responsible at the same time. Being a developing country is not an excuse for enhancing responsibility to nature.

Furthermore, "Despite higher manpower input and despite higher (informal) recycling, the environmental burdens in developing countries are... per functional unit, higher than those in industrialized countries" (Udo de Haes, 2004, p. 9). Related to the importance of evaluating product environmental impacts in developing countries, Ortiz states that:

... although financial supports, technology and technical assistance play a significant role when applying LCA throughout industrial activities in developing countries, in developed countries LCA is the cornerstone for most industrial activities. It is, therefore important to apply the nascent LCA methodology in both developed and developing countries to allow sustainable development. (Ortiz, 2009, p. 35)

This study contributes to perform an environmental evaluation to a specific case in Colombia. From this perspective information collected and resulting analysis will support future research related to recycling materials composition in final products and its impacts along life cycle.

1. Methodology

For study case, analysis was made by means of Ecoindicator 99 methodology and the software tool Simapro® version 7.0. Ecoindicator 99 corresponds to a methodology developed in Europe and according to previous studies there are some differences between assignation rules for European model and the Colombian specific environmental problems.

For the ecoindicators calculation it is taking into account three different variables: Specific value for the impact (inventory), contribution factor (characterization) and priorities among the environmental problems (evaluation). Specific impact value for the impact, which is measured for specific processes, varies according to process under study. Contribution factor and priorization are defined under the assignation rules (Ministry of Housing, 2000).

Ecoindicator methodology could be a restriction for not European studies if there have not been developed local indicators at the specific region where study is developed because of the possible differences with the assignation rules that are in use.

In Colombia, there have been developed some ecoindicators like those mentioned by Van Hoof in his research. For achieving them there were conducted a survey with people from different environmental sectors in Colombia. It is good to take into account, though, that threaded unions' study do not pretend to specify only the specific impact load of a product but how a recycling strategy can affect in a positive way the environmental impacts of a product by having different scenarios with recycled material composition. Under this premise, what is under analysis is the evaluation of environmental impact diminishment when recycled material is used for threaded unions and not the single impact by itself. Even if the assignation rules could affect the specific value of the indicator, the percentage comparison between different recycle composition scenarios impact categories could have a similar approach for different regions under study.

Ecoindicator 99 is based on the evaluation of three main categories related to resources consumption, human health and ecosystem quality. Human Health includes the number and duration of diseases and life of years lost, due to premature death from environmental causes. These years are expressed as Disability Adjusted Life Years (DALY's) which corresponds to an index that is also used by the World Bank and the World Health Organization. This category includes impacts associated with climatic change, ozone layer depletion, carcinogenic elements and nuclear radiation, among others. Damage to ecosystem quality is expressed as the loss of species over a certain area over a certain time. This category includes impacts associated with ecotoxicity, eutrophication and acid rain ant it is expressed as potentially disappeared fraction (PDF) of species over a certain area during a certain time. Finally, resources category includes surplus energy needed for future generations to extract lower quality mineral and fossil resources (Ministry of Housing, 2000).

1.1 Product Description and Functional Unit

The selected product corresponded to threaded unions for PVC pipes of V inches used for junctions of sewage piping systems, weighting 46.44 g, composed of a female and a male element. In most cases, these products are manufactured with polymers or non corrosive metals. For this case polymer unions were analyzed.

1.2 System Boundaries

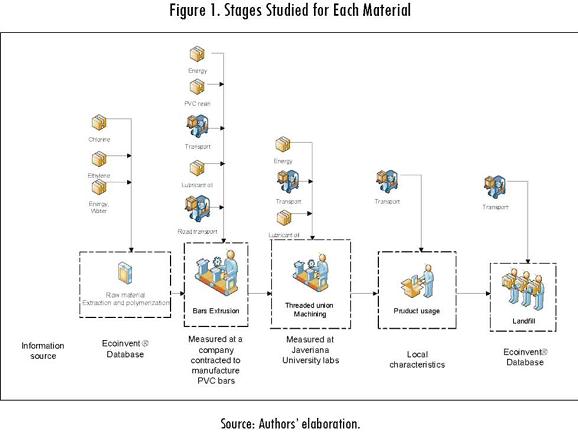

For the analysis, the stages of extraction and transformation of raw material, bars extrusion, preparation, machining, use of the union and disposal were all taken into account (see Figure 1).

The inventory of the extraction stage was acquired by one that was predefined in the Ecoinvent® database, through the informatics tool SIMAPRO® version 7. To study this first stage, it was included the analysis of the extraction of oil and chlorine, their transformation into a monomer and finally its polymerization by means of a suspension process. In Colombia, PVC monomer is imported and arrives at Cartagena' s port where a company makes the polymerization process. In this stage, facts such as inputs and outputs inherent to the manufacturing process as well as impacts caused by transportation of the monomer to the port and its subsequent transport to Bogotá were all considered. Ecoinvent® database is based on research and cooperation between The Swiss Federal Offices and research institutes of the ETH (Frischknecht etal., 2005), containing 2,500,000 datasets of products and services from the energy, transport, building materials, chemicals, pulp and paper, waste treatment and agricultural sector from different continents (Frischknecht et al., 2005).

Data from the extrusion stage was acquired from a small company, contracted to manufacture the PVC bars based on the requirements of this project and the two scenarios of material composition. At this company, it was possible to obtain information about supplies and energy consumption, as well as residues generated from the extrusion process. In terms of water usage, it is important to indicate that because of the cyclic cooling systems, water dumping was assumed negligible.

Continuing with the productive process, for the stages of preparation and machining, it was developed a prototype product at the Technological Center of Industrial Automation, part of the School of Engineering at Pontificia Universidad Javeriana. Blueprints of the female and male part of the union were made on CAD (Computer Aided Design) software and machining process was made on a CNC (Computer Numerical Control) lathe. Data, at this stage, were collected from the operation conducted at the labs.

During the analysis of the product usage, two variables were included: the distance that a client needs to accomplish for buying a threaded union and the transportation of the union to the site where it is going to be used (10 km in total).

Finally, once the union has accomplished its life cycle and needs to be replaced, the union is transported along with other residues and debris to the city landfill, the inventory of this stage was acquired by one that was predefined in the Ecoinvent® data base.

2. Results

2.1 Scenario. PVC (100% virgin raw material)

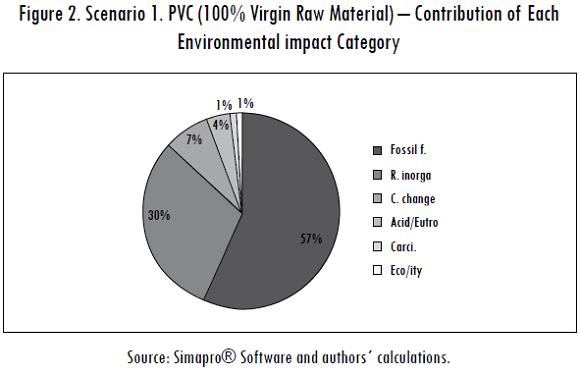

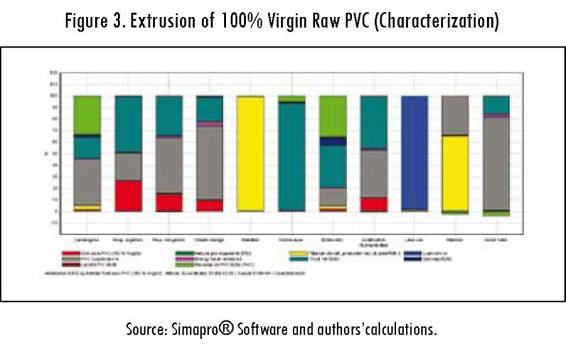

The greater effects were related to fossil fuels consumption and the generation of inorganic materials in suspension (Figure 2). The fossil fuel consumption is associated to the PVC production (polymerization by suspension) and fuel used in vehicles for the polymer transportation (Figure 3). As far as the inorganic material generation, this is due to nitrogen oxides (55%), sulfur oxides (25%) and particles (9%); all of them generated by raw material transportation and PVC production (polymerization by suspension) (Fuquene, 2007). Raw material manufacturing and polymer transportation constitute a product impact key point, taking into account that the monomer is based on ethylene extraction coming from fossil fuels and the transportation of monomer from the US to the port in Colombia and the final transportation of the polymer across the country from the port to Bogotá. These environmental impact matters represent a logistic problem to be solved by the supply chain management. Distances among distributions and/or buying centers, types of means of transportation and fuels used by those transport systems compromise the environmental performance of the product as well.

2.2 Scenario 2. PVC (45% recycled material)

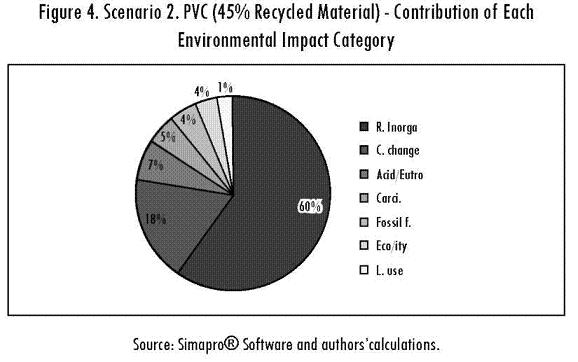

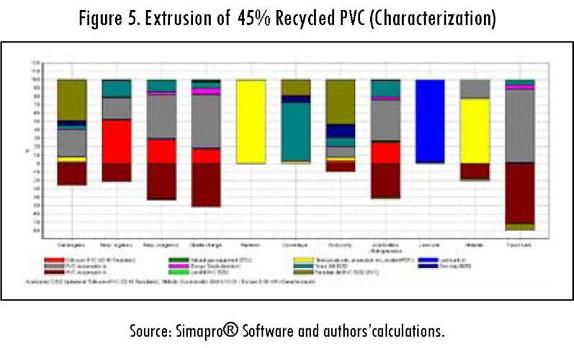

The biggest effects were related to the generation of inorganic materials in suspension and climate change (Figure 4). The biggest contribution to the inorganic material generation was made by sulfur oxides (39.4%), followed by nitrogen oxides (34.6%) and nitrogen dioxides (11.6%). The firs two caused by PVC production and the extrusion process. Nitrogen oxides are caused by the use of energy through the processes within union life cycle. The highest contribution to the climate change corresponded to the CO2 (92.7%) and CH4 (5.5%). The fist one is affected by polymerization, extrusion, transportation of the monomer to the plant and transportation of the polymer to the extrusion company (Figure 5).

2.3 Comparison of the Two Scenarios

Using recycled material lowers the contribution of fossil fuels to the environmental impact from 56% to 4.69% comparing to the contribution of the other impact categories (see figures 2 and 4). Therefore, oil consumption in shifted from the first to the fifth place in the scale of contributors to environmental and global impact.

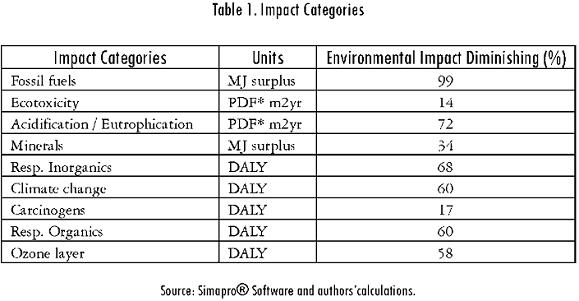

The environmental impact analysis of the product for each one of the categories, in terms of human health effects, ecosystems quality and natural resources exhaustion measured in Disability Adjusted Life Years (DAYS), Potentially Disappeared fraction (PDF) and MJ for the two scenarios considered; found an improvement for each one of the above categories when the formulation included recycled materials over the raw virgin material formulation. Specifically speaking, the level impact caused by fuels improved by 99%, breathable inorganic particles improved by 68% and climate change improved by 60% (see Table 1).

On the other hand, this significant improvement was possible by lowering fossil fuel consumption, which in most part is related to materials extraction and use in production of the monomer (Ethylene) and transporting of the monomer.

3. Conclusions

When comparing the two scenarios, raw virgin material and recycled material (scenarios 1 and 2) for the PVC product, it was found that there is an 84% improvement in the product environmental performance, in terms of Pt indicator, when recycled material is used. Recycling plastics is a valid alternative not only for minimizing the impact of a product at the end of its life cycle but also for reducing consumption of a scarce resource such as oil. The usage of recycled materials in productive processes contributes to the environmental improvement of products in two different perspectives. One of them has to do with lowering the amount of natural resources needed to be used as raw materials and the second one is focused on the diminishing of final disposal of the finished product, by incorporating it into the productive cycle again. On the other hand, the usage of recycled material, according to the organization of the supply chain, could contribute to lower material costs. This must be a variable to be considered at the moment of selecting materials composition for the productive process.

Additionally, when using recycled material it is required to adequate process variables in order to maintain product quality and to guarantee customer protection and satisfaction.

What is the importance of this project? The main objective of this project is to illustrate that a low impact production performance can be achieved, trough recycling, trying to tame the rule that still prevails in some sectors in which the market survival overrules the environmental culture and to highlight the importance of carrying out conclusive actions in developing countries towards sustainability that include a complete diagnostic trough LCA and the review of the design phase of products.

What are the limitations of the study? It is recommended to continue working on the construction of processes databases according to the Latin American current situation. The lack of this information puts some burdens on studies study based on the LCA methodology. On the other hand, it is imperative to involve the private companies into the LCA studies, with the purpose of developing and promote projects focused on sustainable production, taking into account not only costs and material properties, but also this kind of variables, and with the same amount of importance and relevance.

For specific study case, limitations were related to companies' information access, use of international databases and environmental evaluation trough application of international ecoindicators which can differ from local evaluation perspectives.

It is imperative for Colombia to develop a joint strategy among the government, universities and manufactures of PVC pipes and accessories, to explore new alternatives in the development of new products with less environmental impacts including recycled material into the productive processes. Here it would be important to take into account legislation related to human health in order to fulfill all the product and regulatory requirements. Furthermore, it would be important to review the usage of recycled materials for specific products such as the sewer systems case.

What are the recommendations for future research? Future research work could continue in complementary directions related to the optimization of reverse logistics in order to take back products, quality measurements on laboratory for identifying resistance performance for different recycled composition formulation and evaluation of economic benefits for industries and consumers as a result of using recycled materials formulation.

In addition to that it should be developed an industries market research in order to identify likeliness of managers to perform studies towards classification of life cycle environmental impacts and life cycle costs due to processes inefficiencies.

References

ARENA, A. Spreading life-cycle assessment to developing countries: lessons from Argentina. Journal of Industrial Ecology. 2000, vol. 4, núm. 3, pp. 3-6. [ Links ]

CHOI, B.; SHIN, H-S; LEE, S-Y and HUR, T. Life Cycle Assessment of a Personal Computer and its Effective Recycling Rate. The InternationalJournal of Life Cycle Assessment. 2006, vol. 11, núm. 2, pp. 122-128. [ Links ]

COMMISSION OF THE EUROPEAN COMMUNITIES. Green Paper: Environmental Issues of PVC [Documento en línea]. Bruselas: 2000. <http://ec.europa.eu/environment/waste/ pvc/en.pdf > [Consulta: 09-2008]. [ Links ]

FRISCHKNECHT, R.; JUNGBLUH, N.; ALTHAUS, H.-J. et al. Code of Practice: Ecoinvent Report No. 2. Dübendorf: Swiss Centre for Life Cycle Inventories, 2003. [ Links ]

FRISCHKNECHT R.; JUNGBLUH, N.; ALTHAUS, H.-J. et al. The Ecoinvent Database: Overview and Methodological Framework. The International Journal of Life Cycle Assessment. 2005, vol. 10, núm. 1, pp. 3-9. [ Links ]

FÚQUENE, C. and CÓRDOBA, N. Selection of Materials Trough the LCA* for Pipes' Threaded Unions. Third International Conference on Life Cycle Management, August 27 to 29, 2007. LCM 2007, p. 1-196. [ Links ]

FÚQUENE, C. et al. Aplicación del análisis del ciclo de vida de producto como apoyo a la toma de decisiones en la selección de materiales para la fabricación de elementos de unión roscados para tubería. Bogotá: Pontificia Universidad Javeriana. 2007. [ Links ]

LUND, H. Recycling Manual. Madrid: McGraw-Hill, 2006. [ Links ]

MICHAEL, D. Biopolymers from Crops: Their Potential to Improve the Environment [Documento en línea]. En: Solutions for a Better Environment. Proceedings of the 11th Australian Agronomy Conference, Geelong, Victoria, 2-6 Feb, 2003, Australian Society of Agronomy. <http:// www.regional.org.au/au/asa/2003/c/11/michael.htm> [Consulta: 03- 2009]. [ Links ]

MINISTERIO DE DESARROLLO ECONÓMICO y SUPERINTENDENCIA DE SERVICIOS PÚBLICOS DOMICILIARIOS. Estudio sectorial aseo 2002-2005. Bogotá, 2008. [ Links ]

MINISTERIO DE MEDIO AMBIENTE, VIVIENDA Y DESARROLLO TERRITORIAL. Guía ambiental sector plásticos: principales procesos básicos de transformación de la industria plástica y manejo, aprovechamiento y disposición de residuos plásticos post-consumo. Bogotá, 2004. [ Links ]

MINISTRY OF HOUSING, COMMUNICATIONS DIRECTORATE. Ecoindicador 99 Manual for designers. The Netherlands, 2000. [ Links ]

NORMA TÉCNICA COLOMBIANA-ISO 14040. Gestión ambiental: análisis de ciclo de vida. Principios y marco de referencia. Bogotá: Icontec, 2003. [ Links ]

ORTIZ, O.; CASTELLS, F., and SONNEMANN, G. Sustainability in the Construction Industry: A Review of Recent Developments based on LCA. Construction and Building Materials. 2009, vol. 23, pp. 28-39. [ Links ]

UDO DE HAES, H. Life-Cycle Assessment and Developing Countries. Journal of Industrial Ecology. 2004, vol. 8, núms.1-2, pp. 8-10. [ Links ]