Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería y Universidad

versão impressa ISSN 0123-2126

Ing. Univ. vol.18 no.1 Bogotá jan./jun. 2014

Analysis of Nutritional and Functional Properties of Dry Guava1

Análisis de las propiedades nutricionales y funcionales de la guayaba seca2

Diana Vásquez-Osorio3

Lina María Vélez Acosta4

Gustavo A. Hincapié5

1Reception date: April 23rd, 2013. Acceptance date: February 13th, 2014 This paper comes from the investigation project called Efecto de la temperatura de secado sobre el contenido y las propiedades funcionales de la fibra dietaria y los niveles de vitamina C en la guayaba, developed by The Grupo de Investigaciones Agroindustriales from The Universidad Pontificia Bolivariana, Medellín, Colombia.

2Fecha de recepción: 23 de abril de 2013. Fecha de aceptación: 13 de febrero de 2014. Este artículo se deriva de un proyecto de investigación denominado Efecto de la temperatura de secado sobre el contenido y las propiedades funcionales de la fibra dietaria y los niveles de vitamina C en la guayaba, desarrollado por el Grupo de Investigaciones Agroindustriales de la Universidad Pontificia Bolivariana, Medellín, Colombia.

3Ingeniera agroindustrial, Universidad Pontificia Bolivariana, Medellín, Colombia. E-mail: dianacarolina.vasquez@alfa.upb.edu.co.

4Ingeniera de alimentos, Corporación Universitaria Lasallista, Medellín, Colombia. Magíster en Desarrollo, Universidad Pontificia Bolivariana, Medellín, Colombia. Docente investigadora, Facultad de Ingeniería Agroindustrial, Universidad Pontificia Bolivariana. Correo electrónico: lina.velez@upb.edu.co.

5Químico, Universidad del Quindío, Armenia, Colombia. Magíster en Ingeniería Ambiental, Universidad Pontificia Bolivariana, Medellín, Colombia. Docente investigador, Facultad de Ingeniería Agroindustrial, Universidad Pontificia Bolivariana. E-mail: gustavo.hincapie@upb.edu.co.

Abstract

Overproduction of guava (Psidium guajava L.) causes postharvest losses and it has negative impacts on the environment and the economy. Drying is a method that allows to prolong the lifetime of the product and facilitates the transport and storage of it; but, it can also cause changes in the physicochemical and functional properties of some of its components. We studied the drying kinetics under forced convection with hot air at 30 °C, 40 °C, 50 °C, 60 °C, and 70 °C, with a constant air speed of 3 m/s. The vitamin C content was evaluated by the method of the 2-nitroaniline; and the sugar content by High Performance Liquid Chromatography (HPLC). We also studied the technical and functional properties of the dietary fiber. The tests were performed bytriplicate and the Tukey test was applied to the results. The drying time decreases with increasing temperature. The highest content of vitamin C and saccharose was presented at 40 °C. The highest content of glucose and fructose, and the best properties of the dietary fiber were obtained at 70 °C.

Keywords: Guava, Psidium guajava L., drying, vitamin C, sugars, dietary fiber.

Keywords plus: Guavas —drying, fruit processing, fiber in human nutrition, fruit dried.

Resumen

La sobreproducción de guayaba (Psidium guajava L.) causa pérdidas en la poscosecha y tiene impactos negativos en el medio ambiente y la economía. El secado es un método que permite prolongar la vida útil del producto, facilita su transporte y almacenamiento, y puede ocasionar modificaciones en las propiedades fisicoquímicas y funcionales de algunos de sus componentes. Se estudió la cinética de secado por convección con aire caliente a 30 °C, 40 °C, 50 °C, 60 °C y 70 °C, con velocidad del aire constante de 3 m/s. Se evaluó el contenido de vitamina C por el método de la 2-nitroanilina, el contenido de azúcares por cromatografía líquida de alta resolución (HPLC) y las propiedades técnico-funcionales de la fibra dietaria. Las pruebas se realizaron por triplicado, y a los resultados se les aplicó la prueba de Tukey. El tiempo de secado disminuye al incrementar la temperatura: a 40 °C se presentó el mayor contenido de vitamina C y sacarosa, a 70 °C se obtuvo el mayor contenido de glucosa y fructosa, a 70 °C se presentaron las mejores propiedades de la fibra dietaria.

Palabras clave: Guayaba, Psidium guajava L., secado, vitamina C, azúcares, fibra dietaria.

Palabras Clave: Guayabas, procesamiento de frutas, fibra en la nutrición humana, frutas deshidratadas.

D0I:10.11144/JAVERIANA.IYU18-1.APNF

Introduction

Guava is a pyriform, ovoid or round berry. Itsexocarp and mesocarp vary between green, pink and yellow (Gélvez Torres, 1998). The mesocarp can be thin or thick and the endocarp can have few or many seeds, these are rounded, triangular and very hard. The fruit can weigh from 25 to 500 g, its polar diameter varies between 3 and 12 cm and the equatorial from 3 to 5 cm (Sánchez-Urdaneta et al., 2007). It is rich in vitamins, standing out for vitamin C content, which is higher than some citrus. Its moisture content makes it highly perishable. During maturation increases the sugar content and the skin softening (Bashir and Abu-Goukh, 2003) affecting their appearance and quality (García et al., 2010); further, the overripe fruits are a target for phytosanitary problems (Insuasty, 2007). In Colombia fruit production has not been technified, which has caused social, economic and environmental problems due to the high post-harvest losses and accentuating the problems caused for ripe and overripe fruits. Drying is a preservation technique who acts reducing the moisture content of the fruit, which contributes to the reduction or inhibition of microbial growth and enzymatic reactions, consequently decreses the volume and final weight, economizesand facilitates the transport and storage, and increases its shelf life (González Díaz, 2007). Moreover, drying contributes to the implementation of good agricultural practices, and in general, benefits economically the productive chain. However, drying can cause changes in the fruit compounds (Femenia et al., 2007), affecting the texture, color, density, porosity, materials absorption (Krokida and Maroulis, 2001), also enables overall hardening and shrinkage of the fruit (Zartha, 2001).

Vitamin C, common in vegetables and fruits, is an antioxidant that must be supplied in the diet because the human body does not have the ability to synthesize (Horton and Moran, 2008) and it is required for proper absorption of nutrients and strengthening the immune system. This compound can be easily oxidize when it is in a solution, in processes catalyzed by heat, pH (Illera et al., 2000), oxygen, light (Mazza, 1998), also during handling and storage (Coultate, 2007). Sugars are a source of easily available energy, are mainly found in sugar cane, milk, beet and fruits, from where it is named fructose (Pérez y Zamora, 2002). The sugars provide sweetness to foods generating pleasure and satisfaction to consumers (Fricker et al., 2004); drying temperatures do not affect the molecular structure of the sugars because Maillard reactions or caramelization occurs at temperatures above 100 °C (Badui, 2006). Moreover, dietary fiber contributes to the proper functioning of the digestive system, acts as a prebiotic and it can encapsulate harmful substances for the body (Jenkins et al. , 1998); itstechnical and functional properties are related to its molecular structure (Figuerola et al., 2005), also by its content of pectins, gums, mucilages and soluble hemicelluloses (Raghavendra et al., 2006), it also has antioxidant properties due to its polyphenol content (Jiménez-Escrig et al., 2001). In this research the effect of drying temperature on vitamin C, the technical and functional properties of dietary fiber and sugar content of guava (Psidium guajava L.) were studied, and the data obtained by cubic spline interpolation and least squares regression were refined.

1. Materials and Methods

The present study was conducted in the Universidad Pontificia Bolivariana Agroindustrial Engineering Laboratory, at an average temperature of 23 °C and a relative humidity around 58%.

1.1. Material

Guava (Psidium guajava L.) pear variety was acquired from a recognized chain of supermarkets in the country. It was selected at degree of ripeness 6 employing colorimetric table presented by Gélvez Torres (1998), and by measurement of °Brix from direct reading of ABBE refractometer, previously calibrated.

1.2. Guava pear Variety Physicochemical Analysis

It was measured the moisture, protein, total fat, ash, calories, total dietary fiber, soluble dietary fiber, insoluble dietary fiber and raw fiber content according to AOAC methodologies.

Vitamin C content was determined using the colorimetric method of the 2-nitroaniline (Bernal, 1998). To the fresh sample was added oxalic acid 0.15% in order to extract ascorbic acid. The absorbance was read by means of a Shimadzu UV - 1601PC UV-VIS spectrophotometer at a wavelength of 540 nm.

In order to quantify the sugars content was weighed ± 4.00 g of fresh sample in a beaker of 250 ml, then 75 ml of distilled water was added, followed by stirring for 5 minutes. The dilution was decanted into a 100 ml florence flask and was gauged with distilled water. It was stirred vigorously and then was gravity filtered through filter paper MUNKTELL grade 388. The sugar content was determined to the filtrate using the Azucares.Icm method, standardized in the Centro de Estudios y de Investigación en Biotecnología (CIBIOT) UPB using a High Performance Liquid Chromatography (HPLC) Shimadzu Prominence with refractive index detector RID — 10 A.

1.3. Drying Kinetics

Selected guava was cut into slices of 3-5 mm thick, submitted to convection drying under forced air to five (5) different temperatures; 30 °C, 40 °C, 50 °C, 60 °C, and 70 °C with a constant air speed of 3 m/s. The initial weight was ± 1500 kg disposed over a mesh of 0.48 m2. The drying process was continuous. The dryer was connected to a computer, which controls and records parameters as time, weight, and drying temperature. In order to obtain the drying curves the Equation 1 were performed (Geankoplis, 1998). Then the drying weight of the product was calculated. The process was conducted until the product reached a moisture content of about 0.12 kg H2O/kg of dry matter (DM).

Where pt is the dry weight over time, p is the wet weight over time, ps is the product dry weight, and DM is dry matter.

1.4. Obtained Product Analysis

The dried sample was processed in a CORONA manual disk mill in order to reduce its size to 0.18 mm; then, it was refined using a SUELOS e ING vertical eccentric to tapo and passing through a # 80 sieve, standard series PYSIS.

1.4.1. Vitamin C

The dried and ground sample were taken and analyzed using the method described in 1.2 for analysis of this compound to the fresh sample.

1.4.2. Sugar Content

The dried and ground sample were taken and analyzed using the method described in 1.2 for analysis of this compound to the fresh sample.

1.4.3. Technical and Functional Properties of Dietary Fiber

The analyzed properties were: swelling (SW), water retention capacity (WRC), fat adsorption capacity (FAC) and solubility. It was used the method describe by Femenia et al. (1997). Those properties were measured from the Alcohol insoluble residues (AIRs), following the described procedure by Nunes et al. (2009).

1.4.3.1. Swelling (SW)

In a 10 ml preweighed graduated cylinder was added ± 0.25 g of dry AIR sample. The occupied volume was measured and then hydrated up to 10 ml with distilled water. After 24 hours the volume occupied by the sample was measured, the SW is the volume difference and it is expressed as ml water/g of AIR.

1.4.3.2. Water Retention Capacity (WRC)

In a preweighed centrifuge tube were added ± 0.25 g of dry AIR sample and 10 ml of distilled water. After 24 h, it was centrifuged at 3000 rpm for 10 min, the supernatant was decanted and the tube was weighed. The WRC is expressed as g water/g of AIR.

1.4.3.3. Fat Adsorption Capacity (FAC)

In a preweighed centrifuge tube were added ± 0.25 g of dry AIR sample, and 10 ml of sunflower oil. After 24 h, it was centrifuged at 3000 rpm for 10 min, the supernatant was decanted and the tube was weighed. The FAC is expressed as g oil/g of AIR.

1.4.3.4. Solubility

The centrifuge tube containing the wet sample, after decanting the water at the end of the WRC test, is led to a drying oven at 100 °C until constant weight is reached. Solubility is determined by weight difference and expressed as% w/w.

1.5. Statistical Treatment

The experimental design was completely random. The statistical analysis corresponded to a one-way analysis with five (5) treatments and three (3) repetitions. The response variables measured were: the technical and functional properties of dietary fiber (SW, WRC, FAC, and solubility), sugars content (glucose, fructose and saccharose) and vitamin C content. To the fresh sample only vitamin C and sugars content were measured because the technical and functional properties of dietary fiber are just measured for dehydrated products. For the data treatment and analysis SAS V 8.0 program was used and the Tukey test was applied with a P value < 0.05.

2. Results

2.1. Selection

Guava used in this studied were found in mature state, showed an average 9.4 °Brix; Gélvez Torres (1988) reports that it should be between 9.5 and 10.5 ° Brix.

2.2. Physico-Chemical Analysis

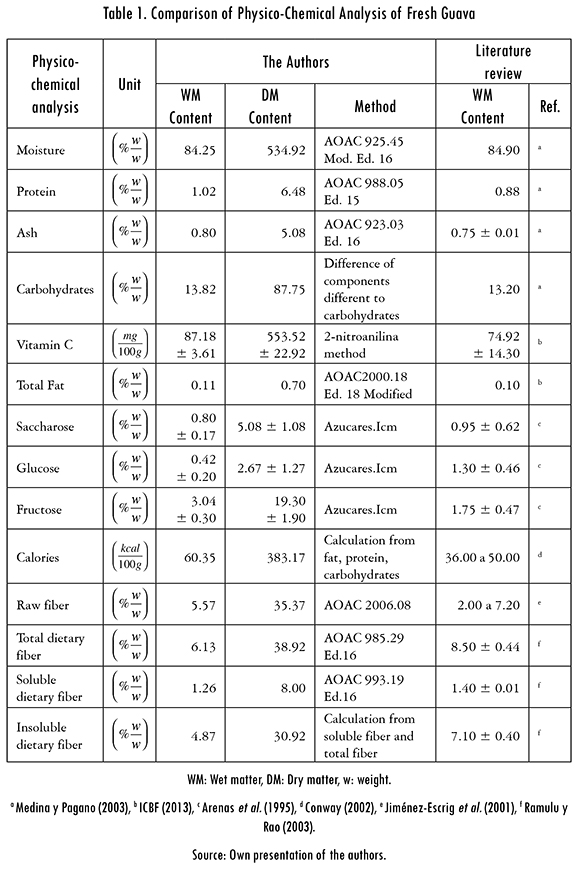

The results of physicochemical analysis of fresh samples and the data reported in other studies are presented in Table 1. It can be seen that the obtained results in this study showed values close or even within the ranges reported by other authors for some compounds, allowing us to validate the used methods for analysis. It is observed that the moisture content of guava is very high. The sugar content also makes it susceptible to be attacked by microorganisms and insects; for this, the use of technological treatments to prolong its life is an essential reason. Guava is a good source of vitamin C; it beats the orange 202,623 mg/100 g DM (FAO, 2013b) and mandarin 145,337 mg/100 g DM (FAO, 2013a).

The content of insoluble dietary fiber (IDF) is four times greater than the soluble dietary fiber (SDF), which enables us to state that the obtained fiber from guava has a high technical and functional potential as these properties are presented primarily in IDF, as it was shown by Jimenez-Escrig et al. (2001). Also, in the study by Ramulu and Rao (2003) to 25 fruits including plum and apple, commonly known for their high fiber content, guava was only surpassed in their total dietary fiber by the sapote, which presented 2.40 g more in a sample of 100 g. In the case of sugars studied by Arenas et al. (1995) the presented values correspond to the lower content found in ripe guava since the average values were higher than those reported in this study. This difference may be due to agronomic and climatic conditions of the planatation as Ramulu and Rao (2003) mentioned in their study.

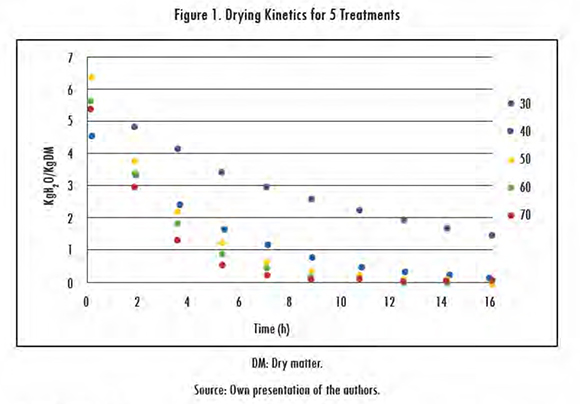

2.3. Drying Kinetics

Figure 1 shows the drying kinetics of the five used treatments. After 12,5 hours of operation all drying curves showed a moisture content below 0,40 kg HzO/ kg of DM; except for the 30 °C curve, that in the laboratory conditions did not reach a moisture content below 0.12 kg H^O/kg DM, which is required for the preservation of the dry product. It can be seen that as the operating temperature increases the drying time is reduced, a similar behavior occurring in the curves corresponding to 40 °C and 50 °C, as the 60 °C and 70 °C; the results are equivalent to those presented by Chua et al. (2000). This behavior occurs by the water evaporation rate increase from the surface of the sample, and is due to the rapid distribution and migration of moisture from the surface during the adaptation period of the 5 treatments and generated higher heat sensitivity in response to increased temperature.

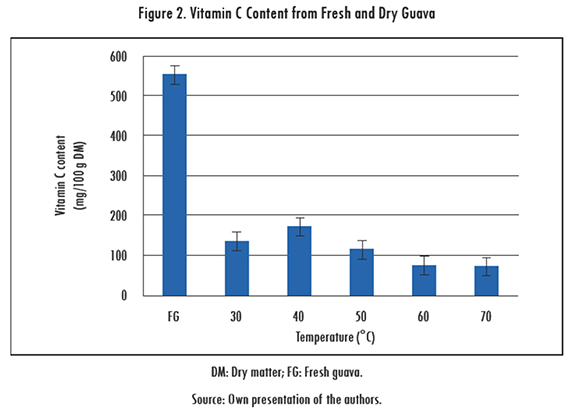

2.4. Vitamin C

In Figure 2 is shown the vitamin C content present in the samples subjected to different treatments; taking into account the obtained results, the percentage of vitamin C loss was determined at each temperature using as parameter the evaluated fresh guava content, at 30 °C loses the 75.48% at 40 °C the 68.73%, at 50 °C the 79-35%, at 60 °C the 86.51% and at 70 °C the 86.80%.

The increase in temperature decreases the vitamin C content starting from 40 °C; this behavior is similar to that presented in the kiwi (Kaya et a¡,, 2010) and guava (Chua et a¡,, 2000). At 30 °C lower content is preserved than at 40 °C; this is mainly due to drying time for the samples subjected to 30 °C was twice that for those at 40 °C. Previous studies have shown that temperature and drying time are the main factors of ascorbic acid degradation (McMinn and Magee, 1997), which is accentuated by the process conditions, since the used dryer is not isolated from the natural light (Ma2Za, 1998). The standard deviations within the same treatment are high, may be due to the postharvest condition of the fruit and, handling during the investigation at which the product is subjected (Coultate, 2007).

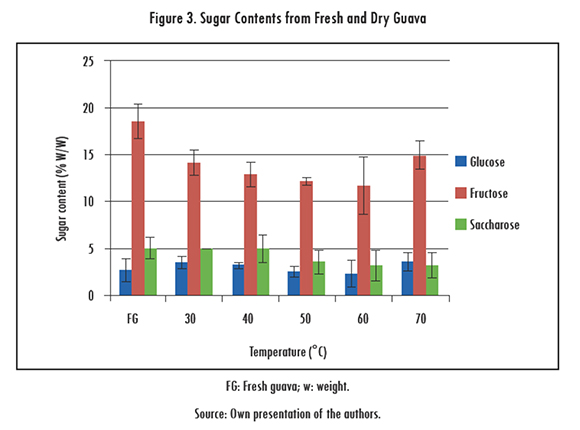

2.5. Sugars

The results for the sugars contents (glucose, fructose and saccharose) for fresh guava and for those subjected to 5 treatments are observed in Figure 3- It identifies that the drying promotes the conditions for synthesis of invert sugar which requires an aqueous and acidic medium, and temperature as catalyst (Badui, 2006); experimentally this process is performed at 68 °C (Gomez, 1985). During the drying, acids and sugars present in the guava dissolve in the unbound water and the temperature catalyzes the production; Moreover, it is considered water as the limit reagent because sugars and acids present in the dehydrated product do not have a continuous medium in which to react.

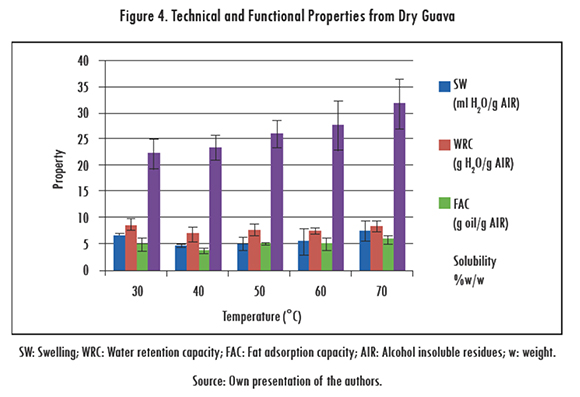

2.6. Technical and Functional Properties of Dietary Fiber

In Figure 4 are shown the results obtained for the technical and functional properties of the dietary fiber in the samples subjected to the 5 treatments. The SW, WRC, and FAC do not have a linear trend with respect to temperature increase, while the solubility presents a definite upward trend. In the dehydrated guava study (Ramirez and Pacheco, 2009), it shows that this has ahigher content of soluble and insoluble fiber and better fiber properties regarding soursop and pineapple. Then, a comparative analysis of the obtained results for dry guava with those obtained for citrus pulp (Hincapié et al., 2010), apple guava (Hincapié et al., 2011) peel and orange pulp (Garau et al., 2007) are presented, as the technical and functional properties of the fiber are analyzed using the same methodology.

In this study, dry guava has a lower SW than the citrus at the different temperatures; (Hincapié et al., 2010) also the tendency differs with respect to the temperature trend. In the study by Garau et al. (2007), orange pulp has a greater SW at a drying temperature of 40 °C and the lowest value at 60 °C; while the orange peel is not affected by the temperature increase; dry guava presented a similar behavior, being not affected by the different treatments.

Dry guava has greater a WRC compared to citrus pulp (Hincapié et al., 2010) and to apple guava (Hincapié et al., 2011). The tendency of this property in the dry guava regarding temperature is the same as obtained in citrus pulp, but differs with the obtained trends in apple guava. In the orange case (Garau etal., 2007) both the pulp and the peel have higher values than those obtained in this study. In orange pulp, the WRC do not have significant variation from 30 °C to 50 °C; it has the maximum value at 60 °C and decreases to 70 °C; while the peel has increased from 30 °C to 40 °C and decreases from 40 °C to 70 °C.

Dry guava has a greater FAC compared to citrus pulp (Hincapié et al., 2010) and to apple guava (Hincapié et al., 2011). A variation of this property in the dry guava regarding temperature is not observed, this tendency is the same as obtained for the citrus pulp and for the apple guava. In the orange case (Garau et al., 2007) shows higher FAC values in the pulp (5.0 to 6.5 g oil/g AIR) that in the peel (values around 3 g oil/g AIR). In the pulp, the FAC has increased from 30 °C to 50 °C where it reaches its maximum value and then decreases.

The dried guava presents an upward trend in the solubility versus temperature (22.3 % to 31.7 %). In contrast to the results in the orange peel (Garau et al, 2007) which has values between 27.3 % and 37.8 %, the tendency increases from 30 °C to 40 °C and then descends. In the case of orange pulp (Garau et al., 2007) has values between 25.9 % and 38.5 %, the tendency increases from 30 °C to 60 °C and then falls

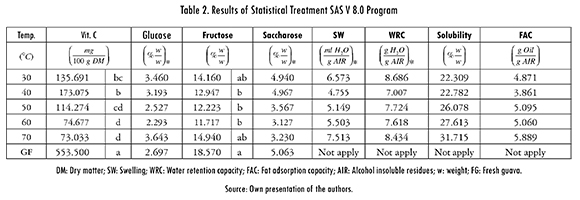

2.7. Statistical Treatment

The means with the same letter within each treatment do not shown statistically significant difference according to Tukey test (p value < 0.05). The asterisk (*) indicates not statistically significant difference between any of the treatments. It means that only vitamin C and the fructose content exhibited statistically significant difference on the different operating temperatures. The obtained results by performing the statistical treatment are shown in Table 2.

Conclusions

In drying process, temperature and long exposure times contribute significantly to the decreasing ofthe vitamin C content present in the pear guava (Psidium guajava L.). At 40 °C occurs its lowest decreasing.

The glucose and saccharose contents do not exhibit any statistically significant variation due to the drying treatment; however, fructose does. Drying at 70 °C promotes the hydrolysis of saccharose in its early stages.

The contents of glucose and saccharose do not exhibit any statistically significant variation due to drying treatment, while fructose if presented. Drying at 70 °C promotes the hydrolysis of saccharose in its early stages.

The technical and functional properties of dietary fiber do not show statistically significant variation to any treatment. Nevertheless, there was a trend in which at 70 °C the highest values are found for the 4 analyzed properties, meanwhile at 40 °C the lowest values for SW, WRC and FAC were found.

References

ARENAS, L.; MARÍN, M.; CASTRO, C. and SANDOVAL, L. Determinación por HPLC de los azúcares en los frutos de guayaba (Psidium guajava L.) de una plantación comercial del municipio Mara. Revista de la Facultad de Agronomía. 1995, vol. 12, no. 4, pp. 467-483. [ Links ]

BADUI DERGAL, S. Química de los alimentos. 4 ed. México: Pearson, 2006. [ Links ]

BASHIR, H.A. and ABUGOUKH, A.-B.A. Compositional changes during guava fruit ripening. Food Chemistry. 2003, vol. 80, no. 4, pp. 557-563. [ Links ]

BERNAL, I. Análisis de alimentos. 3 ed., vol. 2. Bogotá: Guadalupe, 1998. [ Links ]

CONWAX IP Tree medicine: A comprehensive guide to the healing power of over 170 trees. n.p.: Piatkus Books, 2002. [ Links ]

COULTATE, T. P. Manual de química y bioquímica de los alimentos. Londres: Acribia, 2007. [ Links ]

CHUA, K. J.; CHOU, S. K.; HO, J. C.; MUJUMDAR, A. S. and HAWLADER, M. N. A. Cyclic air temperature drying of guava pieces: effects on moisture and ascorbic acid contents. Food and Bioproducts Processing. 2000, vol. 78, no. 2, pp. 72-78. [ Links ]

FAO. Mandarina [document online]. Chile: FAO, [2013a]. <http://www.rlc.fao.org/es/conozca-fao/que-hace-fao/estadisticas/composicion-alimentos/busqueda/?clave=C299>. [Consultation: 28-1-2013] [ Links ].

FAO. Naranja [document online]. Chile: FAO, [2013b]. <http://www.rlc.fao.org/es/conozca-fao/que-hace-fao/estadisticas/composicion-alimentos/busqueda/?clave=C387>. [Consultation: 28-1-2013] [ Links ].

FEMENIA, A. High-value co-products from plant foods: cosmetics and pharmaceuticals. In K. WALDRON Handbook of waste management and co-product recovery in food processing. Cambridge: Woodhead Publishing Ltd, 2007, pp. 470-501. [ Links ]

FEMENIA, A.; LEFEBVRE, A. C.; THEBAUDIN, J. Y; ROBERTSON, J. A. and BOURGEOIS, C. M. Physical and sensory properties of model foods supplemented with cauliflower fiber. Journal of Food Science. 1997, vol. 62, no. 4, pp. 635-639. [ Links ]

FIGUEROLA, F.; HURTADO, M. a. L.; ESTÉVEZ, A. M. a.; CHIFFELLE, I. and ASENJO, F. Fibre concentrates from apple pomace and citrus peel as potential fibre sources for food enrichment. Food Chemistry. 2005, vol. 91, no. 3, pp. 395-401. [ Links ]

FRICKER, J.; DARTOIS, A.-M. and FRAYSSEIX, M. D. Guía de la alimentación del niño. Madrid: Blume, 2004.

GARAU, M. C.; SIMAL, S.; ROSSELLÓ, C. and FEMENIA, A. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chemistry. 2007, vol. 104, no. 3, pp. 1014-1024.

GARCÍA MOGOLLÓN, C.; CURY RENGO, K. I. and DUSSÁN SARRIA, S. Evaluación poscosecha y estimación de vida útil de guayaba fresca utilizando el modelo de Weibull. Acta Agronómica. 2010, vol. 59, no. 3, pp. 347-355.

GEANKOPLIS C., J. Procesos de transporte y operaciones unitarias. 3a ed. México: Compañía Editorial Continental, 1998.

GÉLVEZ TORRES, C. J. Manejo post-cosecha y comercialización de guayaba: Psidium guajava L. vol. 9. Bogotá: IICA, 1998.

GÓMEZ, M. J. Química orgánica. Bogotá: Universidad Nacional de Colombia, 1985.

GONZÁLEZ DÍAZ, E. E. Análisis comparativo de las propiedades organolépticas de zanahoria deshidratada con y sin pretratamiento osmótico. Pregrado Universidad de San Carlos de Guatemala, 2007.

HINCAPIÉ, G. A.; BARAJAS, J. A. and ARIAS, Z. Evaluación del secado por convección de la guayaba (Psidium guajava L.) variedad manzana. Revista Investigaciones Aplicadas. 2011, vol. 5, pp. 42-53. [ Links ]

HINCAPIÉ, G. A.; OMAÑA, M. M.; HINCAPIÉ, C. A.; ARIAS, Z. and VÉLEZ, L. Efecto de la temperatura de secado sobre las propiedades funcionales de la fibra dietaria presente en la citropulpa. Revista Lasallista de Investigación. 2010, vol. 7, no. 2, pp. 85-93. [ Links ]

HORTON, H. R. y MORAN, L. A. Principios de bioquímica. 4 ed. México: Pearson, 2008. [ Links ]

ICBF. Tabla de composición de alimentos colombianos. Guayaba entera, Palmira ICA1 [document online]. Bogotá: ICBF, [2013]. <http://alimentoscolombianos.icbf.gov.co/alimentos_colombianos/principal_alimento.asp?id_alimento=1150>. [Consultation: 28-1-2013] [ Links ].

ILLERA M., M.; ILLERA DEL P, J. and ILLERA DEL P, J. C. Vitaminas y minerales. Madrid: Editorial Complutense, 2000. [ Links ]

INSUASTY B., O.; BAUTISTA D., J.; MONROY, R. A. and CUADROS M., J. Manejo integrado de moscas de la fruta de la guayaba. Bogotá: Produmedios, 2007. [ Links ]

JENKINS, D. J. A.; KENDALL, C. W C. and RANSOM, T. P. P Dietary fiber, the evolution of the human diet and coronary heart disease. Nutrition Research. 1998, vol. 18, no. 4, pp. 633-652. [ Links ]

JIMÉNEZ-ESCRIG, A.; RINCÓN, M.; PULIDO, R. and SAURA-CALIXTO, F. Guava fruit (Psidium guajava L.) as a new source of antioxidant dietary fiber. Journal of Agricultural and Food Chemistry. 2001, vol. 49, no. 11, pp. 5489-5493. [ Links ]

KAYA, A.; AYDIN, O. and KOLAYLI, S. Effect of different drying conditions on the vitamin C (ascorbic acid) content of Hayward kiwifruits (Actinidia deliciosa Planch). Food and Bioproducts Processing. 2010, vol. 88, nos. 2-3, pp. 165-173. [ Links ]

KROKIDA, M. K. and MAROULIS, Z. B. Structural properties of dehydrated products during rehydration. International Journal of Food Science & Technology. 2001, vol. 36, no. 5, pp. 529-538. [ Links ]

MAZZA, G. Alimentos funcionales: Aspectos bioquímicos y de procesado. Zaragoza: Acribia, 1998. [ Links ]

MCMINN, W. A. M. and MAGEE, T. R. A. Kinetics of ascorbic acid degradation and non-enzymic browning in potatoes. Food and Bioproducts Processing. 1997, vol. 75, no. 4, pp. 223-231. [ Links ]

MEDINA, M. L. and PAGANO, F. Caracterización de la pulpa de guayaba (Psidium guajava L.) tipo "criolla roja". Revista de la Facultad de Agronomía. 2003, vol. 20, pp. 72-86. [ Links ]

NUNES, C.; SANTOS, C.; PINTO, G.; SILVA, S.; LOPES-DA-SILVA, J. A.; SARAIVA, J. A. and COIMBRA, M. A. Effects of ripening on microstructure and texture of "Ameixa d'Elvas" candied plums. Food Chemistry. 2009, vol. 115, no. 3, pp. 1094-1101. [ Links ]

PÉREZ, F. and ZAMORA, S. Nutrición y alimentación humana. Murcia: Aula de Mayores. Universidad de Murcia, 2002. [ Links ]

RAGHAVENDRA, S. N.;RAMACHANDRA SWAMY, S. R.; RASTOGI, N. K.; RAGHAVARAO, K. S. M. S.; KUMAR, S. and THARANATHAN, R. N. Grinding characteristics and hydration properties of coconut residue: A source of dietary fiber. Journal of Food Engineering. 2006, vol. 72, no. 3, pp. 281-286. [ Links ]

RAMÍREZ, A. and PACHECO, E. Propiedades funcionales de harinas altas en fibra dietética obtenidas de piña, guayaba y guanábana. Intendencia. 2009, vol. 34, no. 4, pp. 293-298. [ Links ]

RAMULU, P and RAO, EU. Total, insoluble and soluble dietary fiber contents of Indian fruits. Journal of Food Composition and Analysis. 2003, vol. 16, no. 6, pp. 677-685. [ Links ]

SÁNCHEZ-URDANETA, A.B.; COLMENARES, C.; BRACHO, B.; ORTEGA, J.; RIVERO, G.; GUTIÉRREZ G. and PAZ, J. Caracterización morfológica del fruto en variantes de guayabo (Psidium guajava L.) en una finca del municipio Mara, estado Zulia. Revista de la Fiacultad de Agronomía. 2007, vol. 24, pp. 282-302. [ Links ]

ZARTHA S., J. W Operaciones unitarias aplicadas a la agroindustria. Medellín, Colombia: Facultad de Ingeniería Agroindustrial, 2001. [ Links ]