Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Citado por Google

Citado por Google -

Similares em

SciELO

Similares em

SciELO -

Similares em Google

Similares em Google

Compartilhar

Ingeniería y competitividad

versão impressa ISSN 0123-3033

Ing. compet. vol.16 no.2 Cali jul./dez. 2014

Ball bearing vibrations model: Development and experimental validation

Modelo de vibraciones de un rodamiento de bolas: Desarrollo y validación experimental

Jairo A. Grajales

E-mail: ntc1687@hotmail.com

Juan F. López

E-mail: juanferll@utp.edu.co

Héctor F. Quintero

E-mail: hquinte@utp.edu.co

Mechanical Engineering Faculty, Universidad Tecnológica de Pereira, Pereira, Colombia

Eje temático: MECHANICAL ENGINEERING / INGENIERIA MECáNICA

Recibido: 09 Septiembre de 2013

Aceptado: 22 Febrero de 2014

Abstract

The experimental validation of a mathematical ball bearing model with localized outer race defects is presented in this paper. The bearing is considered as a mass - spring - damper system, considering each rolling element as a contact spring - damper pair, based on Hertz equations for contact deformation, moving along the races. In accordance with the obtained results, in this work a bearing model is validated with a purpose built test bench. To compare the vibration signals from the real system and the model, spectral and high frequency analysis is used, particularly techniques commonly used on commercially available vibration analysis equipment, such as envelope and Peak Value analysis. The studied model shows a frequency behavior similar to that of the experimental data and the envelope and Peak Value analysis clearly reveal the characteristic frequencies of the studied type of defects.

Keywords: Ball bearing, envelope, peak value, vibrations.

Resumen

En este trabajo se presenta la validación experimental de un modelo matemático de rodamiento de bolas, en el que se incluye fallas en la pista externa. En el modelado se considera el sistema como un conjunto masa - resorte - amortiguador, tomando los elementos rodantes como conjuntos amortiguador - resorte de contacto, basados en las ecuaciones de Hertz para la deformación en contacto, desplazándose sobre las pistas. Acorde con los resultados obtenidos, en este trabajo se valida un modelo de rodamiento mediante un banco de pruebas construido para tal fin. En la comparación de las señales de vibración del sistema real y del modelo se utiliza análisis espectral y el análisis de alta frecuencia que se emplea en equipos comerciales de análisis de vibraciones, tales como análisis de envolvente y Peak Value. Se muestra entonces que el modelo estudiado presenta un comportamiento en frecuencia similar al ensayo experimental y que los análisis de envolvente y de Peak Value revelan con claridad las frecuencias características del tipo de fallos estudiados.

Palabras clave: Rodamiento, envolvente, peak value, vibraciones.

1. Introduction

On industrial applications, ball bearings are considered critical mechanical components. If, during normal service, a failure occurs in them, it may cause noise, vibrations, malfunction or even complete failure of the machine (Tandon & Choudhury, 1999; Patil, Mathew, Rajendrakumar & Desai, 2010; Tadina & Boltezar, 2011; Liu, Shao & Lim, 2012), unless those defects are detected on time.

That is the reason why ball bearings have received a lot of attention in the field of machine condition monitoring (Kiral & Karagulle, 2003), which is a fundamental piece in the operation of preventive maintenance programs, and is considered an essential part of every modern manufacturing plant. Proper monitoring allows the prediction of a possible failure before it actually occurs (Patil, Mathew, Rajendrakumar & Desai, 2010).

Theoretical ball bearing models help understand the mechanisms that generate vibration signals, additionally they allow to study the influence of several parameters, such as load and force transmission paths, to better comprehend the vibration generated at the beginning of an incipient defect (Tandon & Choudhury, 1999; Patil, Mathew, Rajendrakumar & Desai, 2010). Different models have been created for the simulation of the ball bearing movement in the presence of a localized defect. The model proposed by Tandon & Choudhury (1999) simulates the acceleration signal as the sum of vibration modes due to each different component and defect. Kiral & Karagulle (2003) performs a finite element simulation of the system. There have also been models based on Newton's equations (Patil, Mathew, Rajendrakumar & Desai, 2010; Liu, Shao & Lim, 2012). Signal analysis has been done mainly with frequency domain transformations (Patil, Mathew, Rajendrakumar & Desai, 2010; Liu, Shao & Lim, 2012), although time domain analysis such as rms and kurtosis have also been applied to ball bearings (Kiral & Karagulle, 2003). Analytical and numerical models are usually validated with three different methods: Comparison with literature references (Tandon & Choudhury, 1997) and experimental validation of two types: In-situ measurements (Wang & Kootsookos, 1998) and test bench experiments (Patil, Mathew, Rajendrakumar & Desai, 2010; Mcfadden & Toozhy, 2000; Siegel, Al-Atat, Shauche & Liao, 2012; Randall & Antoni, 2011; Pan & Tsao, 2013; Cong, Chen, Dong & Pecht, 2013).

The main motivation for the present work is the validation of the analytical model signal analysis algorithms developed by the research group. Although investigations have already been done (particularly in countries like India and China), our main problem focuses in the lack of properly classified and identified ball bearing vibration data bases, to support further research in vibration monitoring and fault detection in the region.

The relevance of the present work lies in conducting the experimental validation of a theoretical ball bearing model for the prediction of characteristic frequencies in the presence of localized defects, based on Newton's equations, considering the ball bearing as a mass - spring - damper system where rolling elements are simulated as a contact spring - damper group following Hertz equations for contact deformation. Envelope and Peak Value signal analysis techniques, commonly used in commercially available vibration analysis equipment, are used to detect a localized defect on the outer race. To validate the model, these techniques were applied to the mathematical model and on the analysis of the experimental data obtained from a purpose built test bench to study ball bearing failure. The test bench was designed and built by the research group for the mechanical vibrations laboratory, to be used on ball bearing vibration monitoring research and to support teaching activities. This bench will allow future implementation and validation of different models that include additional or alternative characteristics and conditions to those presented in this paper, and the mathematical bearing model will support further researches in the field of bearing vibrations monitoring, serving as the baseline for more complex models considering other types of defects, additional parameters and increase the reliability and functionality of the model thus expanding the regional knowledge in the area of vibration and fault monitoring of rotating machinery.

The development of the mathematical model and defect generation is presented in the first part of the paper. In the second part the spectral and high frequency analysis techniques are showed and used in the comparison between the model and the experimental data. In the third part, results are presented for the analysis of experimental data of a ball bearing with an outer race defect and these are compared with the response of the model. In the fourth part conclusions are presented.

2. Methodology

2.1. Ball bearing model

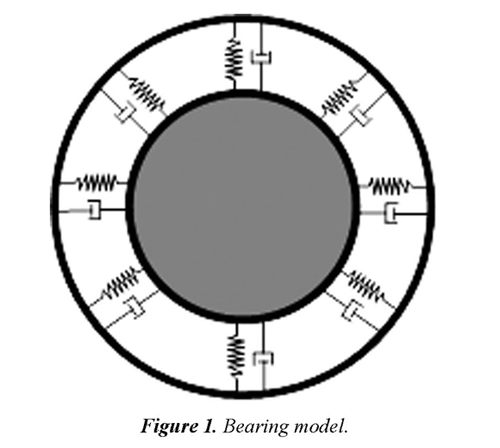

To determine the vibrations generated in a ball bearing, a model must be created to find the equations that define its movement. The model used in this paper is based on the works of Patil et al. (2010) & Liu et al. (2012). The bearing is considered as a spring - damper - mass system, as shown in Fig. 1, with an applied radial load, and considering the radial clearance between the elements. The shaft and inner race (rigidly fixed) are the lumped mass, while the outer race is considered rigidly fixed to the housing, therefore it doesn't rotate. The rolling elements (which transmit the force between inner and outer races) are modeled as a damper - contact spring pair, because they are in constant relative motion with the races.

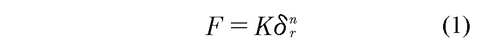

In the interaction between rolling elements and races, an elastic deformation occurs, which is modeled as a nonlinear relationship between force and deformation, based on Hertz equations for contact deformation:

Where δr is the spring deformation, K is the load - deformation factor or Hertzian elastic contact deformation constant, and n is the load - deformation exponent which is: 3/2 for ball bearings and 10/9 for roller bearings. The load - deformation factor K is considered as a single value for each rolling element, but it must be considered that there are two elastic deformation contacts for each element, one with the inner race, and the other with the outer race, therefore the total effect is that of two springs in a serial configuration, which gives:

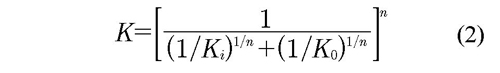

Where Ki and K0 are the contact coefficients for the inner and outer race, respectively, which are determined based on Harris equations (Harris & Kotzalas, 2007):

Where ∑ρ is the curvature sum, which is calculated using the radii of curvature of a couple of principal planes that pass through the point of contact. δ* is the dimensionless contact deformation based on curvature difference (Harris & Kotzalas, 2007).

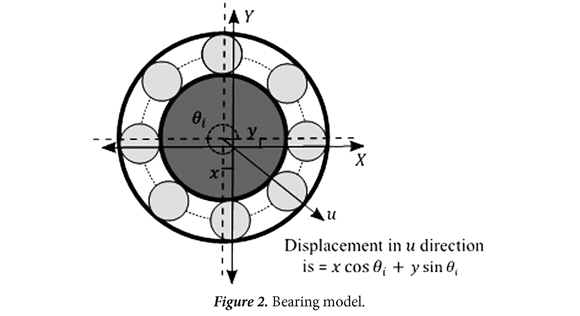

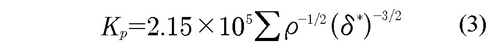

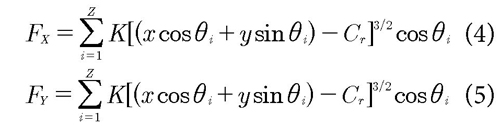

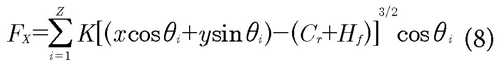

Given that contact stress happens only during compression, the springs in the model operate only in that condition. To calculate the deformations, the conventions shown in Fig. 2 are used, considering the presence of radial clearance, and the forces produced by every spring are calculated, for the x and y directions, as:

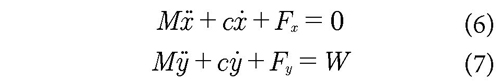

Where Cr is the radial clearance and θi the angular position of i element. By applying Newton's equations for the shaft - inner race group in the x and y directions, the motion equations are obtained:

Where M is the mass of the system, C is the damping coefficient.

2.2. Model of the localized defect

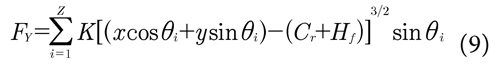

In the presence of a localized defect, the model is affected in the calculation of the forces in the springs. For the present document a localized defect in the outer race is modeled. The presence of this defect affects the deformation calculation of the spring, in the same way as radial clearance.

The localized defect is modeled, in this case, as a half - sinusoidal wave. By introducing it in the spring force calculation expressions Eq. (8), (9) and (10) are obtained:

Therefore, when a rolling element passes over a defect, the forces must be calculated by these new equations, whereas the rest must be calculated with Eq. (4) and (5).

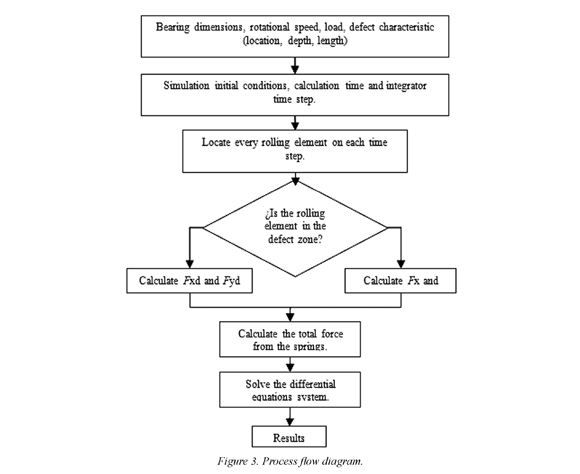

The resulting differential equations systems are transformed to state space variables, and their solution is obtained by a numerical integrator, a fourth - order Runge - Kutta method.

The solution to the system is obtained, according to the flow chart in Fig. 3.

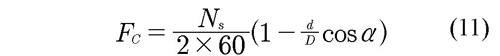

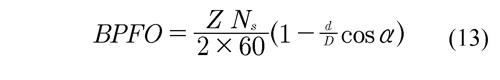

The characteristic frequencies that appear in the vibration signal of a ball bearing are mainly the rotating frequency of the shaft, cage frequency, the BPFO and BPFI. The cage frequency is:

The BPFI is the frequency in which a rolling element passes over a point on the inner race, and can be calculated as:

And the BPFO is the frequency in which a rolling element passes over a point on the outer race:

Where D is the pitch diameter, and is the average between the inner and outer race diameters, d is the rolling element diameter, α is the contact angle and NS is the shaft speed in rev⁄min.

2.3 Experimental validation

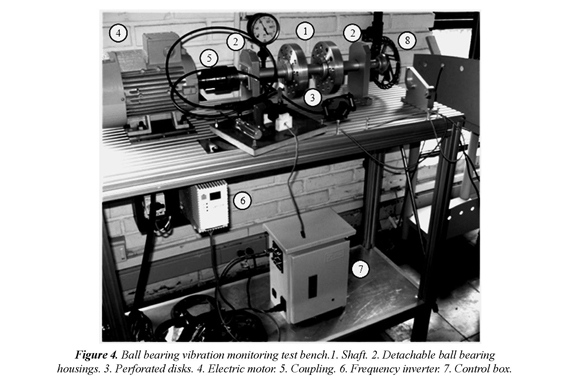

To validate the results from the mathematical model, experimental results were obtained from a purpose built test bench designed and built by the research group, to study ball bearing failure and vibration monitoring. Fig. 4. Shows the test bench built in the laboratory.

The module consists of a shaft supported by two single row ball bearings, (in this case the bearings used are SKF reference 6005 2ZNR) mounted on detachable housings. In the middle of the shaft a perforated disk is mounted (holes located in two rows and spaced 30 degrees between each other), allowing testing of unbalance loads by using screwed weights. To move the module an asynchronous electric motor is connected through a flexible coupling, the motor is controlled via a frequency inverter that communicates with a computer to manipulate precisely its speed and operating characteristics. In order to simulate load in the shaft (torsion) a hydraulic brake is installed. Vibration measuring is performed with a vibration measuring and analyzing device currently being developed by the research group, and for this work, consists of a couple of piezoelectric accelerometers, one mounted horizontally and the other vertically over one of the ball bearings, a data acquisition device connected to a computer and a program designed and created (in house) to collect, analyze and display the digital signal obtained, is used here to store the signal data for further processing. An artificially induced outer race defect on the ball bearing was used to simulate the conditions of damage due to wear, and to be able to compare the obtained signal with the mathematical model. A rotary tool was used to carve the outer race of the bearing.

2.4 Vibration signal analysis

Once the vibration signal is obtained from the mathematical model, and the measurement done in the test bench, a special mathematical treatment must be performed to be able to clearly identify in the signals, the characteristics that allow the identification of the condition of operation of the ball bearing.

Time - frequency transformations are amongst the most useful tools for vibration signal analysis. Many of the commercially available vibration analysis devices use these transformations, when delivering the results to the user. Two fairly common of these tools, normally used on commercial equipment, are the envelope and Peak Value analysis.

A. Envelope analysis:

The process of the analysis begins by obtaining the time domain vibration signal. That signal goes through a rectifier and a low band pass filter, with parameters determined based on the constructive characteristics and working conditions of the ball bearing, aiming at eliminating unnecessary and unwanted signal components. Once filtered, an envelope detector is used. In the same way, the envelope detector is executed in a particular way based on the conditions of the ball bearing. A fast Fourier transformation (FFT) is used on the envelope signal, to obtain the final spectrum of the envelope of the signal.

B. Peak Value Analysis:

The analysis begins by taking the measured time domain signal of the vibration and getting it through a high band pass filter, then the filtered signal passes a process of segmentation in time, then the maximum value for each segment and subsample is determined. The processed signal is then transformed to frequency domain using the FFT, obtaining the final result.

2.5 Model simulation

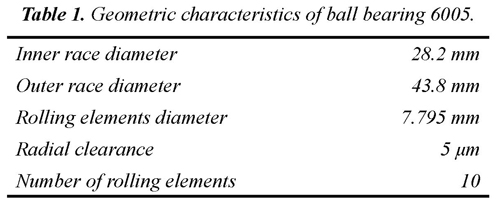

For the simulation, the selected inputs for the model are the characteristics of the same ball bearing used in the test bench, under the same operating conditions (rotational frequency of 1800 rpm, with a localized outer race defect). The bearing used is reference 6005 from SKF, whose geometric properties are presented in Table 1.

For the model, the load - deformation factor is estimated at K = 8.375 GN⁄m3⁄2 , whilst the damping constant has a value of C = 200 Ns⁄m. A radial load is assumed as W = 20 N and a mass of M = 0.6 kg.

Initial conditions for the integration algorithm are assumed zero for the speeds in the x and y directions, and equal to 1 µm for each position.

3. Results and discussion

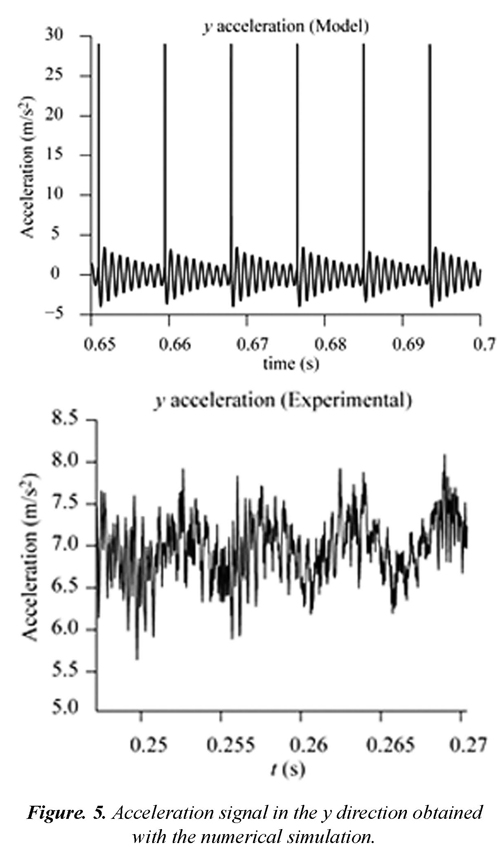

For the model validation, the numerical simulation of the equations previously shown is performed. The conditions for the defect are selected arbitrarily in terms of length and depth, because the objective of the present analysis is the frequency response. Therefore the selected parameters of the defect are: length 40 µm, depth 40 µm, and it's located in the outer race's lowest position (270° measured counterclockwise from the positive x axis). The analyses were performed on the vibration signals (model and experimental) in terms of acceleration, and the numerical results of the model, in the y direction, are shown on Fig. 5.

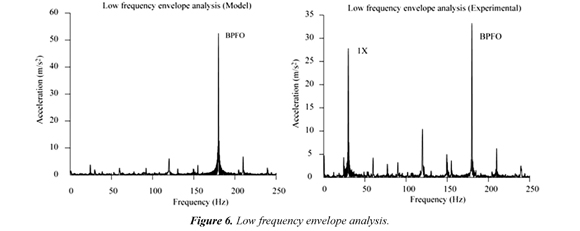

Experimental data, as previously stated, was taken on a 6005 ball bearing from SKF operating at an angular speed of 1800 rpm, with a localized defect in the outer race. Fig. 6 shows the results of the envelope analysis (low frequency) for the simulated and experimental acceleration signals. As shown in Fig. 6 a peak appears in the experimental vibration signal at a frequency equal to the rotation of the shaft (1X). This peak is a characteristic response in cases of unbalance and misalignment in the shaft that carries the ball bearing. When the ball bearing suffers a defect in the outer race, the frequency spectrum is expected to have the highest peak at the BPFO (Ball Pass Frequency Outer), since this defect generates an impulse every time the ball passes over it. As seen on the experimental signal, the highest peak appears at BPFO, indicating the presence of a defect on the outer race of the bearing. The signal from the model, since it is only affected by an outer race defect, shows a much clearer peak at the BPFO frequency.

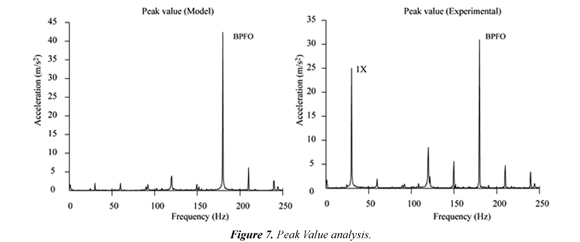

Fig. 7 shows the results of the Peak Value analyses for the experimental and simulated acceleration signals. By using the Peak Value analysis, both the simulated and experimental signals, behave in the same way as they did on the envelope analysis. For the experimental signal the highest peak shows at the BPFO, which will indicate the presence of a localized defect in the outer race of the ball bearing. A peak also appears at the rotational frequency of the shaft (1X), indicating once more the presence of unbalance or misalignment in the bearing shaft. For the analysis applied to the results from the model, a peak clearly appears at BPFO frequency because of the only defect present in the simulation (Localized outer race defect). The designed and built test bench provided a good set of data that allowed the validation of the model. With our own test bench, a lot of tests and experimentation can be done to support the development not only of the classes instructed, but the graduation and research projects in the field of bearing vibration monitoring.

In a very similar way the mathematical bearing model will support further researches in the field of bearing vibrations monitoring, and also there are a lot of possible improvements that can be done, like modeling other types of defects, consider additional parameters and increase the reliability and functionality of the model.

4. Conclusions

A mathematical model was elaborated for the determination of the vibrations of a ball bearing, in the presence of a localized outer race defect, using Newton's equations. Simulating the defect as a half sinusoidal wave it was possible to find, in the signal response, the characteristic frequency peaks for the kind of simulated defect. Obtaining, for the localized outer race defect, that there are peaks at BPFO frequency. The resulting frequency peaks are similar to those present in the experimental signal, validating the model.

Two of the most common procedures in commercially available vibration analysis equipment, Peak Value and envelope analysis, are used in this work. By using them, it was possible to find, clearly, the characteristic frequency components of the localized outer race defect, both in the experimental and simulated model data, validating its capabilities for the detection of fault signals in ball bearings.

The use of the test bench provided useful data for experimental validation of the mathematical model. The experiments were performed under controlled circumstances and the results were in accordance with the theory. The bench will allow further testing in different areas of vibration and condition monitoring of ball bearings.

5. Acknowledgements

The authors would like to acknowledge Colciencias for the support to the research group Procesos de Manufactura y Diseño de Máquinas from Universidad Tecnológica de Pereira, through the project contract RC 472-2001, code 111052128503 which made possible this work.

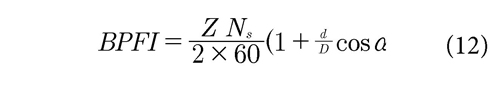

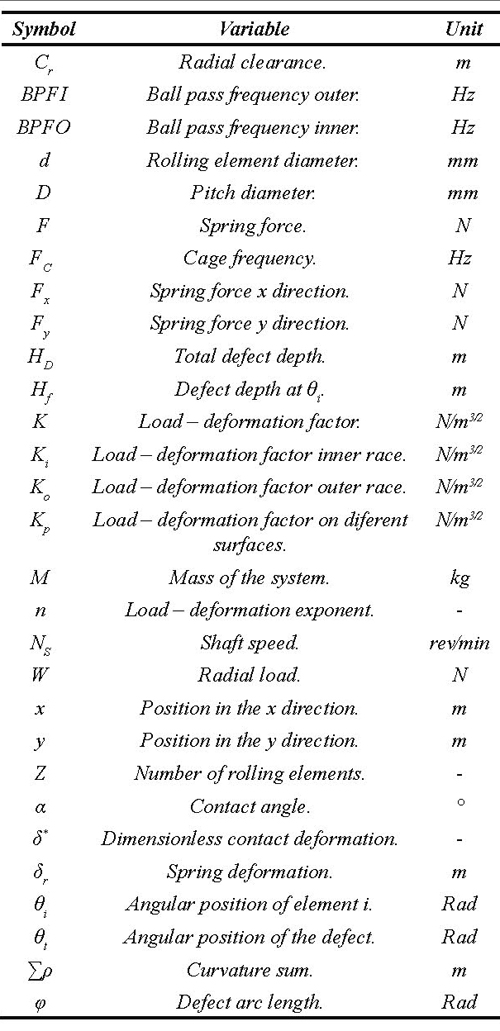

7. Nomenclature

6. References

Cong, F., Chen, J., Dong, G. & Pecht, M. (2013). Vibration model of rolling element bearings in a rotor-bearing system for fault diagnossis. Journal of Sound and Vibration, 332(8), 2081-2097. [ Links ]

Harris, T. & Kotzalas, M. (2007). Rolling bearing analysis-essential concepts of bearing technology. 5th ed. Taylor and Francis. [ Links ]

Kiral, Z. & Karagulle, H. (2003). Simulation and analysis of vibration signals generated by rolling element bearing with defects. Journal of Sound and Vibration, 36(9), 667-678. [ Links ]

Liu, J., Shao, Y. & Lim, T.C. (2012). Vibration analysis of ball bearings with a localized defect applying piecewise response function. Mechanism and Machine Theory, 56, 156-169. [ Links ]

McFadden, P.D. & Toozhy, M.M. (2000). Application of synchronous averaging to vibration monitoring of rolling element bearings. Mechancical Systems and Signal Processing, 14(6), 891-906. [ Links ]

Pan, W. & Tsao, W. (2013). Using appropriate IMFs for envelope analysis in multiple fault diagnosis of ball bearings. International Journal of Mechanical Sciences, 69, 114-224. [ Links ]

Patil, M.S., Mathew, J., Rajendrakumar, P.K. & Desai, S. (2010). A theoretical model to predict the effect of the localized defect on vibrations associated with ball bearing. International Journal of Mechanical Sciences, 52(9), 1193-1201. [ Links ]

Randall, R.B. & Antoni, J. (2011). Rolling element bearing diagnostics - A tutorial. Mechanical Systems and Signal Processing, 25(2), 485-520. [ Links ]

Siegel, D., Al-Atat, H. Shauche, V. & Liao, L. (2012). Novel method for rolling element bearing health assessment - A tachometer-less synchronously averaged envelope feature extraction technique. Mechanial Systems and Signal Processing, 29, 362-376. [ Links ]

Tadina, M. & Boltezar, M. (2011). Improved model of a ball bearing for the simulation of vibration signals due to faults during run-up. Journal of Sound and Vibration, 330, 17, 4287-4301. [ Links ]

Tandon, N. & Choudhury, A. (1999). A review of vibration and acoustic measurement methods for the detection of defects in rolling element bearings. Tribology International, 32(8), 469-480. [ Links ]

Tandon, N. & Choudhury, A. (1997). An analytical model for the prediction of the vibration response of a rolling element bearing due to a localized defect. Journal of Sound and Vibration, 205(3), 275-292. [ Links ]

Wang, Y.-F. & Kootsookos, P.J. (1998). Modeling of low shaft speed bearing faults for condition monitoring. Mechanical Systems and Signal Processing, 12(3), 415-426. [ Links ]

Revista Ingeniería y Competitividad por Universidad del Valle se encuentra bajo una licencia Creative Commons Reconocimiento - Debe reconocer adecuadamente la autoría, proporcionar un enlace a la licencia e indicar si se han realizado cambios. Puede hacerlo de cualquier manera razonable, pero no de una manera que sugiera que tiene el apoyo del licenciador o lo recibe por el uso que hace.