1. Introduction

Colombia is the second producer of panela in the world, after India, and it is also the leading country in per capita consumption, with an average of 24.7 kg/year 1. The panela agroindustry is of great importance for the national economy since it occupies the second line in the supply of employment for the agricultural sector. Besides, the internal consumption of panela is highly, the product is valued nutritionally and sensorially, and possibilities of expansion to other markets are opened 2,3.

The production of sugarcane by-products is mainly carried out by ancestral methods that transfer knowledge from generation to generation, in facilities called "trapiches", which count on traditional equipment and tools and with almost no improvement or study 4. For obtaining panela, the juice of the cane is extracted by compression in mills, which are then filtered, purified and clarified. Afterwards, the juices are concentrated by evaporation in a series of metal containers, heat exchangers or pans. For this, the residual bagasse of the milling is used as combustible material. The determination of the consistency, the adequate heating time and the point at which the process can be completed depends on the knowledge and experience of the operators. The concentrated material is transferred to a shake container, and the panela is molded and packed as a final product 5.

In search of the strengthening of the agro-chain, studies and research have been developed that seek the improvement of primary production (cane varieties, pest control and soil management), the increase of yield and the economy of the transformation process, and the consolidation of markets where medium producers can guarantee supply, added value and quality 6,7.

The design and implementation of efficient processes, which consider the rational use of resources and energy, and compliance with established requirements at the national level, has quite advantageous implications for the competitiveness of traditional productive units. Some studies focused on the control and adjustment of grinding and extraction, pre-cleaning by gravity, chemical or physical clarification, schemes for the burner and the combustion chamber, and wastewater treatment, have been carried out nationally and internationally. From the energetic point of view, the design of the stages of combustion, heat transfer and exit of the gases through the chimney takes special importance 4,8,9.

The objectives of this study were to compile and analyze the scientific information available in the literature on the traditional and emerging techniques of sugarcane transformation, to generate a guide that gathers the essential data of design, improvement and intervention of panela production processes, based on the principles and methods of engineering. In addition, obtain a general diagnosis of the panela agroindustry in Colombia, detecting the strengths, gaps and shortcomings of the production strategies, the quality of the products offered and the diversification of the panela cane as raw material.

2. Products derived from panela sugarcane

2.1. Panela (unrefined non-centrifugal brown sugar)

Panela is a natural sweetener obtained from the extraction and evaporation of sugarcane juice (Saccharum officinarum), also called "guarapos" in Spanish. In the world, it is known by the names described in Table 1. Traditionally, this food is manufactured in artisanal facilities called mills, or "trapiches paneleros" in Spanish 10,11.

Table 1 Denominations of panela in other countries and regions.

| Name | Countries |

|---|---|

| Unrefined non centrifugal sugar | United States |

| Black sugar - Muscovado sugar | Japan and the Philippines |

| Gur - Jaggery | India |

| Piloncillo | Costa Rica and México |

| Rapadura | Brazil, Cuba, Bolivia and Ecuador |

Quezada 12.

Panela is valued for its energy contribution and its contribution to food security and sovereignty. The main component of panela is sucrose, although its composition includes glucose and fructose, vitamins A, C, D, E and B, and phosphorus and zinc. This food product contains five times more minerals than brown sugar and 50 times more than white sugar 13,14. The sugarcane derivatives are attributed health properties, as an antioxidant effect by the action of polyphenols 15, anti-carcinogenic 16,17, and others uses in the prevention of pulmonary diseases 18,19.

2.2. Cane honey

Cane Honey is the product resulting from the evaporation of panela cane juice, reaching a solids concentration of 70° Brix and temperatures between 97 - 98° C 20. It is a viscous liquid, with a bittersweet, translucent flavor, highly soluble in water and of a light brown or amber color. It consists mainly of fructose and glucose. In this case, the use of immature or green canes is preferred, due to the fact that they avoid the rapid crystallization of the product once it has been bottled 7.

Cane honey is used as a substitute for table sugar, since its high solubility allows it to be incorporated into any preparation. Its nutritional properties are similar to those of panela; however, it is a very desirable food for people with caloric requirements, due to its high content of reducing sugars 12.

2.3. Powdered panela

The panela powder is a brownish yellow solid highly soluble in water, composed almost entirely by sucrose. The product is obtained by means of heating, concentration and exhaustive churning of cane honeys, until reaching 96° Brix and temperatures of 125-128° C 14. The agitation of the dehydrated juices favors the aeration and the breaking of the particles at the moment of the solidification, until obtaining granules of diverse sizes, like this: fine grain (Tyler sieve No. 16), coarse grain (Tyler sieve No. 3) and clods or "boronas"5.

In the production of powdered unrefined raw sugar there are two critical points: first, the reducing sugars must be maintained between 0.5 and 1.0 %, since they disadvantage the crystallization of the material; second, given the hygroscopic nature of panela, the time between production and packaging should be minimal and should be packed in waterproof materials and in conditions of low humidity 21.

In the literature there is information on bromatological characterization of cane derivatives; however, it should be considered that its composition is affected by the variety of cane and by the conditions of processing and storage. An example of such variations is the one reported in the work of Guerra and Mujica 16, who found significant differences in the composition of two handcrafted powdered panelas and one standardized, due to the transformation practices and the standardization of the process.

The physicochemical requirements of non-centrifugal brown sugar (solid block), honey and granulated panela depend strongly on the production conditions of each of these foods (Table 2). They are much more rigorous in the case of granulated panela, due to its high hygroscopicity and loss of stability and caking. In addition, knowledge of the required quality parameters is a fundamental factor to achieve the standardization and improvement of the processes of transformation and conservation of any cane derivative.

Table 2 Physicochemical characteristics required for some products derived from cane.

| Physicochemical characteristic | Panela | Cane honey | Powdered panela | |||

|---|---|---|---|---|---|---|

| Min | Max | Min | Max | Min | Max | |

| Color (%T 550 nm) * ** | 30.0 | 85.0 | - | 72.0 | No | |

| Reducing sugars (%) | 5.5 | 12.0 | 45.0 | - | 5.7 | - |

| Saccharose (%) | 73.0 | 83.0 | - | 44.0 | - | 90.0 |

| Moisture (%) | - | 9.0 | 17.0 | 23.0 | - | 5.0 |

| Proteins (%) * | 0.2 | - | No | 0.2 | - | |

| Ashes (%) * | 0.8 | 1.9 | No | 1.0 | 1.9 | |

| Impurities (%) | 0.1 | 1.0 | - | 0.3 | 0.1 | 1.0 |

| pH * | No | 3.8 | 4.0 | No |

* No: It refers to a requirement not established by the current regulations.

** % T: Color, measured as a percentage of transmittance at a wavelength of 550 nanometers.

3. Thermal and rheological properties of sugar cane products

The demand for nutritious and organic food in the world brings as a consequence a greater demand for modernization, technological adaptation and quality assurance during production. The chain of transformation of sugarcane is not alien to this trend, which leads to an increase in the scientific information available on its processing, and knowledge of the physical, thermal and rheological properties of panela and its byproducts 13,23.

In the framework of science and engineering, the properties of food can be determined by means of simple and immediate predictive models, or through direct experimental determinations, in which a greater veracity and adjustment with respect to the reality of a product is assured. specific 21. For sugar cane juice, a series of mathematical models have been developed as a function of composition and temperature, which seek to quantify the thermal, physical and rheological properties of this matrix (Table 3). Depending on the temperature and humidity levels used, the juice may behave like cane juice or honey.

The importance of the properties of heat transport and momentum in the design of equipment and processing technologies should be taken into account, for which it is advisable to obtain specific values of these parameters when analyzing the energy and productive efficiency of a facilities for non-centrifugal brown sugar production. Table 4 presents some results reported by different authors.

Table 3 Mathematical models for cane juice properties, and some sugar solutions.

| Substance | Property | Equation * | Reference |

|---|---|---|---|

| Cane juice | Density (kg/m3) | ⍴ = 999.39 + 4.46 𝑋𝑠 (1) | Jagannadha Rao et al.23 |

| Specific heat (kJ/kg.K) | 𝐶𝑝 = 4.149 - 2.46 𝑥 10-2 𝑋𝑠 (2) | ||

| Conductivity (W/m.K) | 𝑘 = 0.603- 3.3 x 10-3 𝑋𝑠 (3) | Montes et al. 24 | |

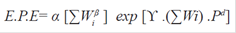

| E.P.E (° C) |

(4) (4) |

||

| Viscosity (mPa.s) | 𝜇=1.718 𝑥10−5 −4.62 𝑥10−8 T (5) | Tiwari et al. 50 | |

| Sugar solutions | E.P.E (° C) | E.P.E = 6.4286 𝑋𝑠 2 + 1.65𝑋𝑠 −0.0036 (6) | Franco 25 |

* In the equations Xs: concentration of solids, α, β, Υ and d are constants for each type of sugar, Wi: mass fraction of each of the sugars in the cane juice, P: pressure (Pa), T: temperature of measurement (K), EPE: elevation of the boiling point of the solution (° C).

Table 4 Thermal, physical and rheological properties reported for products and by-products of cane.

| Product | Property | Temperature (°C) | Value | Reference |

|---|---|---|---|---|

| Cane juice | Density | 105 | 1,023 | Jagannadha et al. 23 |

| (kg/m3 ) | 121 | 1,445 | ||

| Specific heat | 105 | 3.97 | ||

| (kJ/kg.K) | 121 | 2.42 | ||

| Thermal conductivity | 105 | 0.59 | ||

| (W/m.K) | 121 | 0.35 | ||

| Viscosity | 105 | 4.5 | ||

| (mPa.s) | 121 | 988 | ||

| Viscosity | 30 | 1.113 | Escudero et al. 26 | |

| (mPa.s) | ||||

| Panela | Density | - | 1,340 | Fajardo et al. 27 |

| (kg/m3 ) | ||||

| Specific heat | - | 2.2 | Montoya and Giraldo 28 | |

| (kJ/kg/K) | ||||

| Powdered panela | Density (kg/m3) | - | 700 | Fajardo et al. 27 |

| Porosity | 0.5 | |||

| Dry cane juice (powdered) | Specific heat | 30 | 1.05 | Cabrera et al.13 |

| (kJ/kg.K) | 45 | 1.85 | ||

| Thermal conductivity | 30 | 0.345 | ||

| (W/m.K) | 45 | 0.504 | ||

| Thermal diffusivity | 30 | 4.507 x 10-7 | ||

| (m2/s) | 45 | 4.563 x 10-7 | ||

| Mud (cachaza) | Specific heat (kJ/kg.K) | - | 2.8 | Montoya and Giraldo 28 |

3.1. Cane bagasse properties (as fuel)

Bagasse is a fibrous and heterogeneous material that is obtained by compressing the canes in the extraction stage. The bagasse is used for combustion and the generation of the heat necessary in the evaporation of the water contain in the sugar cane juice 29.

The bagasse elemental analysis in dry base changes according to the variety of cane, the maturity state and the crop conditions 30. An average composition of this material was reported by Arteaga et al. 31: 48.0 % of Carbon, 43.1 % of Oxygen, 6.2 % of Hydrogen, 0.4% of Nitrogen and 2.3 % of Ashes. According to Marcelo et al. 32, the empirical formula for bagasse corresponds to C3.73H6.3O2.98N0.00129.

An important thermal property for the design and energy assessment of the combustion process in panela furnaces is the net calorific value (VCN). Montoya and Giraldo 28 cite Eq. 7 to theoretically estimate this parameter:

V𝐶N = 18,309 - 31.09 𝑚𝑟 - 196.05𝑚 z -207.6𝑚 w (7)

VCN in kJ/kg, y m mass fraction of: z, ash; 𝑤, water; 𝑟 residues. And the other hand, Sardeshpande et al. 29 propose:

V𝐶N = 18,260 - 207.1 - 182.06𝑎 -37.1B (8)

where VCN is expressed in kJ/kg; and 𝑥 humidity fraction, 𝑎 ash content and B sugar concentration in residual bagasse.

4. Non-centrifugal brown sugar (panela) production process

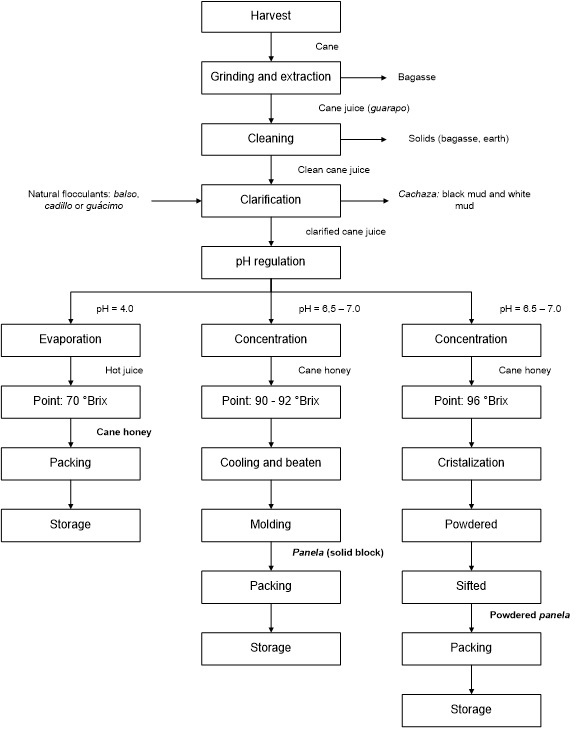

According to Zambrano 33, the benefit of cane is defined like the set of operations after cutting that lead to the production of their derivatives, and which aim to reduce the moisture content of the sugar cane from 77 - 85 % up to 7 - 10 % (Figure 1). Alternative processes have emerged as a product of recent research. For example, Madaeni and Zereshki 34 proposed the partial use of reverse osmosis in the concentration of sugarcane juices, obtaining a total energy saving of 33 %.

4.1. Sugar cane harvest ("Apronte" in Spanish)

The name corresponds to the operations of cutting, transport and cane conservation in the productive installation. It is desirable to store the raw material in an isolated, paved and covered area indoors 5,10. According to Osorio 6, the time elapsed during this operation must be the maximum of three days, to avoid the destruction of the stem and the accumulation of sucrose inversion, which caused a decrease in the production of panela and affects its quality.

4.2. Grinding or extraction

The cane juices are obtaining in mills that work by compression and rotation of the vegetal material, in a system of three or four horizontal rollers. To have a good extraction in motorized mills, without sacrificing equipment or increasing power, some manufacturers recommend operating under specific conditions of capacity and speed (Table 5). According to Diaz and Iglesias 11, with speeds of 20 rpm or more, the extraction is reduced, the energy consumption is increased and the gears and parts of the equipment wear out.

The main disadvantages in traditional mills of three horizontal rollers are: the contamination of the cane juice with oils and lubricants of the equipment, to the wear of the cylinders, to the deficient maintenance, to the inadequate evacuation of the gases of the engine inside the productive unit 35. Some equipment manufacturers have proposed novel models that mitigate this problem, technological schemes with four horizontal rollers and / or systems to prevent cross-contamination of juices. However, its acquisition cost is considerably higher.

Table 5 Recommended operating parameters for mills

| Mill capacity | Extraction (Kgcane/h) | Power (hp) | Velocity (rpm) | Reference |

|---|---|---|---|---|

| Low | 100 - 600 | 5 | 13 - 18 | J.M. Estrada S.A. 36 |

| 200 - 900 | 4 | 13 - 15 | El Panelero 37 | |

| Medium | 900 - 1,500 | 8 - 16 | 10 - 15 | J.M. Estrada S.A. 36 |

| 1,200 - 1,800 | 6 - 8 | 10 - 13 | El Panelero 37 | |

| High | 1,600 - 2,600 | 16 - 24 | 8 - 12 | J.M. Estrada S.A. 36 |

| 2,000 - 4,000 | 16 - 40 | 8 - 10 | El Panelero 37 |

The extraction of sugar cane juices is the indicator that has more influence on the overall performance of the process and is defined as the ratio between the amount of juice recovered in the mill and the weight of the compressed cane. An extraction between 58-63 % is considered like a good mill performance, in facilities for panela production the mill extraction fluctuates between 40-65 % 6.

As a result of the milling process, a solid by-product called bagasse is obtained, with humidity between 50-60 %. This material should be dried to a maximum humidity of 30 %, to be used efficiently as a fuel in the burner, and thus generate the gases that transfer heat to the juices that are concentrated 38.

4.3. Cleaning and clarification

The cane juice comes out of grinding with a large amount of impurities, which must be eliminated in their entirety to avoid the turbidity of the honey and the final product, and to guarantee the safety criteria from the physical, chemical and biological point of view. The removal of foreign material is of special importance in the manufacture of granulated panela, since it constitutes a barrier to crystallization and affects the appearance of packaged food 39.

4.3.1. Cleaning of cane juice

The juice is usually cleaned without heating, using a natural decanting system due to gravity. This device retains by precipitation a significant proportion of solids, such as earth, mud and sand, and simultaneously, by flotation, light particles such as remains of bagasse, leaves and insects 21. With cold cleaning, great advantages are obtained: clarification is facilitated, energy consumption is lower, formation of scale is prevented, and pigment migration during warming is prevented 40.

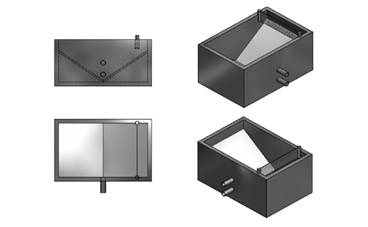

Traditionally, this stage is carried out in rectangular tanks of great height, without any type of standardization or control. However, it is advantageous to use the models proposed by the Center for Research and Improvement of Panela (CIMPA) of the Colombian Agricultural Research Corporation (CORPOICA). These equipment, called pre-cleaners (Figure 2), are constructed of stainless steel and have an angular shape, so that they remove up to 90 % of the impurities 33. In addition, the juice quality can be improved with the use of stainless steel filters with 140 - 180 holes per linear inch, that is, Tyler sieves with mesh numbers of 80 and 100 respectively 14.

4.3.2. Clarification of sugarcane juices

The content of flavonoids and organic acids in the juices contributes to the darkening of their natural brown color, so they must be removed in order to produce a lighter and brighter color in product 39,41.

Clarification is the elimination of dissolved and suspended solids in the juice, through the combined effect of the heating supplied by the burner and the action of cellulose polymers with binding properties. The solids in suspension aggregate with each other and form a heterogeneous mass that is known as mud, or "cachaza" in spanish, which floats on the juice and is extracted manually 5.

Temperature is an important factor in the addition of flocculant material, so a heating rate between 1.0 - 1.5° C / min on the clarifying pan is recommended. A high temperature favors the reincorporation and dissolution of the polluting material (tempering), while a low temperature prevents the agglomeration and separation of the undesirable solids from occurring. The flocculating agent must be added in two parts and in equal proportions: the first, between 60 - 70° C, and the second, when reaching 75 - 92° C 38. The mud removed from clarification in the first instance is known as black cachaza, while the foam removed in the final stage is called white cachaza 42.

The agro-industry of sugar cane and panela in Colombia allows the use of anionic polyacrylamide, which is added in two fractions of 2 ppm each, at 50° C and 85° C respectively 10,21. However, reducing the concentration of acrylamides to acceptable levels is an important challenge, fundamental for the national and international positioning of panela in the region. This guarantee of quality demands greater control in the variables of the process, avoiding the high temperatures generated by the undesirable compounds. Thus, the use of steam and vacuum evaporators is presented as a prominent alternative; in addition to the fact that the use of extracts and natural clarification agents helps to considerably reduce the presence of acrylamides in the final product.

In Colombia, natural flocculants stand out as balso (Heliocarpus americanus), cadillo (Triumfetta láppulal) and guácimo (Guazuma ulmifoliase) 40,42. Ortiz et al. 43 evaluated the removal of contaminating substances in sugarcane juice and recommend using mucilages in a concentration of 0.3 % weight - volume. Likewise, they were able to identify the cadillo as the best clarification agent in comparison with the balso and guácimo, since it had a higher yield in extraction and presented a lower solids retention in panela.

4.4. Evaporation, and concentration

After clarification the evaporation begins, which partially remove the water from the juices and increase them the solids content from 17° Brix to 70° Brix. Temperatures close to 97° C are reached, at which time the concentration begins and the product is called honey 20. During the concentration, water is removed at a temperature higher than 100° C. When sugarcane juices reach 70 - 75° Brix, it is recommended to add a non-stick and anti-foam agent such as laurel wax or castor oil or coconut oil, to homogenize the honey and avoid burning of panela 38.

The operation that allows determining the final point of panela is called picking, and takes place when the honey has reached 90 - 96° Brix and temperatures close to 120° C 23,38. The plucking is carried out in a traditional way and based on experience, observing the color, density, runoff of honeys and formation of air bubbles; and in very few cases, with the use of portable refractometers.

4.5. Beaten, molding and packaging

Once the final sugar concentration point is reached, the evaporated honeys are transferred to a tray where they are cooled by an intensive and intermittent beaten and lose their adhesion capacity and acquire the ideal texture (grain) to be molded in panela form or any other derivative. The use of stainless steel is recommended as a material for the manufacture of the tray, although aluminum surfaces and molds with Teflon non-stick polymer coating are also commonly used 18.

The molding operation takes place when the honeys have already crystallized, so they are arranged in molds or boxes where the panela reaches its final shape. Packaging and storage represents the last stage of manufacture. Heat shrinkable plastics and laminated aluminum sheets are ideal for storing panela for long periods of time, without altering their organoleptic characteristics 6.

5. Traditional furnace

The furnace is the system where the process of conversion of cane juice into panela is carried out, by evaporation by transforming the fuel energy into heat energy. The shape and size of furnace vary greatly from one producing region to another, but in general it can be said that it consists of a combustion chamber, duct of hot combustion gases, the pans and the chimney 33.

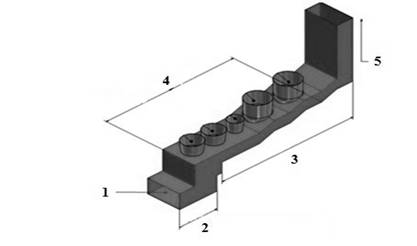

Figure 3 shows the scheme of a traditional furnace. There are two ways to operate a furnace: in parallel flow or in countercurrent flow. The countercurrent flow has been shown that it is more efficient than the traditional scheme; However, it requires greater expertise on the part of workers, since the product tend to burn because smaller quantities of the product in process receive higher rates of thermal energy 44. In this type of configuration, the evaporation zone is located near the chimney, and the section of plucking and concentration on the combustion chamber.

The researches carried out by the CIMPA have contributed advances and modifications on the structure of the furnaces; this is the case of the combined system kiln (Figure 3), which offers the advantage of increasing energy yields and mitigating the heat transfer in the pan where the final point is gave to panela.

The use of the furnace is the simplest system to produce panela. In processes operated under industrial criteria, the combustion chamber is replaced by a boiler that generates steam. This fluid is used as an energy source in the heat exchangers. This innovation generally leads to an increase in the scale of production, also allowing the reduction of associated costs, favoring the substitution of the traditional and peasant production model for a more technified and entrepreneurial one 45. It is a challenge for the country's research and development to create efficient small-scale production models that consider the social and economic impact of such a strategy.

Solís et al. 18, evaluated a double effect evaporator at vacuum pressure. There was an improvement in the processing times and an optimization and saving of energy resources, since the steam generated by the liquid in a closed system is used. However, the additional costs in technological investment, equipment maintenance and electricity supply limit the access of traditional producers to these advanced techniques.

Figure 3 General diagram for a traditional panela making furnace. 1. Area for bagasse feeding. 2. Chamber of combustion. 3. Gas pipeline. 4. Heat exchangers or pans (pailas in Spanish). 5. Chimney.

5.1. Combustion chamber

In this zone, the reactions between the fuel (bagasse) and the oxidizer (air) are carried out, to generate a stream of hot gases that will transfer heat to the cane juices contained in the pans 46. The combustion chamber is built in rectangular shape, with cast iron doors and with internal and external walls in refractory brick. It is recommended to make an internal isolation with ash or with an air vacuum, to consider the system as adiabatic 45.

The combustion chamber consists of a feed mouth, a grate or support and an ashtray. Traditional combustion chambers only admit bagasses with humidities less than 30 %, and work with excess air between 40 - 60 % to avoid the cooling of gases 29,33,47. In addition, the direct contact of the pans with the flame, and the work temperatures too high, can damage the pans and the fins that increase the heat exchange 37. According to Osorio et al. 45, the ideal working temperatures in this area are between 1,000 - 1,300° C.

The CIMPA experimental station has implemented the WARD type chamber (CWC), which exhibits a reaction volume three times higher than a traditional furnace (Table 6). It also has a pre-drying ramp, allows wet bagasses and works with excess air, facilitating air circulation and preventing the formation of large amounts of CO. For its part, the PLANA camera is a modification of common burners, with fewer advantages than the CWC prototype CWC37,46.

Table 6 Comparison of the indicators for a flat camera and a WARD format (CWC).

| Criteria | Flat camera - CIMPA | WARD - CIMPA |

|---|---|---|

| Temperature (°C) | 900 | 1,200 |

| CO (%) | 7 | 3 |

| CO2 (%) | 12 | 14 |

| Excess air (%) | 40 - 60 | 60 |

| Bagasse humidity (%) | 28 | 40 |

Soler et al. 48

5.2. Heat transfer zone

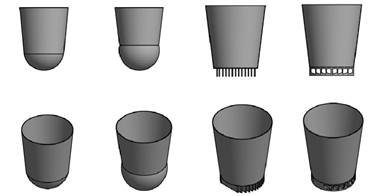

In this section, the hot gases coming from the combustion chamber circulate through a tunnel and transfer part of their sensible heat to the cane juices, removing the water from the product by boiling at atmospheric pressure. The transfer zone consists of the duct of hot gases and heat exchangers, also called pans, bottoms or batteries. Figure 4 presents the most common geometries for panela pans. The heat transfer between the gases and the bottoms is presented by conduction, radiation and convection, while the honeys gain temperature by convection and conduction mechanisms 6,44.

Hernández 49 determined the global transfer coefficients for different pans, commonly used by the Colombian panela agro-chain. The pyro-tubular pan can be seen as the most efficient, since it shows a considerable increase in the area of heat exchange without sacrificing the overall transfer coefficient, by generating a convective turbulence inside the steps or pipes (Table 7). Other studies, such as of Tiwari et al. 50 and Aldana and La Madrid 51, propose a useful methodology for the estimation of the convective coefficient (h) and the global coefficient (U) for the heat transfer in traditional furnaces.

The pans concentration line can be manufactured from metals such as copper, aluminum, stainless steel or iron, and can be designed in different ways depending on the size of the installation, the production capacity and the energy efficiency desired for the process.

Figure 4 Heat exchangers used by the panela agroindustry. From left to right: traditional semi-cylindrical, improved semi-cylindrical, finned and pyro tubular 44.

Table 7 Performance of different batteries for panela concentration.

| Pan | Temperature | U | Ratio | Area |

|---|---|---|---|---|

| (°C) | (W/m. °C) | area / volume | (m 2 ) | |

| Semi-cylindrical | 350 - 660 | 20 - 70 | 6.60 | 2.09 |

| Improved semi-cylindrical | 740 - 970 | 70 - 80 | 10.26 | 1.39 |

| Flat pan | 510 - 880 | 30 - 90 | 10 | 1.00 |

| Finned exchanger | 500 - 810 | 15 - 23 | 40.77 | 4.08 |

| Pyro tubular | 520 - 760 | 30 - 35 | 30.73 | 4.11 |

Hernández 49

5.3. Chimney

The chimney is the vertical duct that connects with the end of the combustion chamber. It can have a cylindrical, cone or pyramidal trunk shape, and can be built in a refractory brick or iron sheet 6. This channel produces the air aspiration necessary to burn the fuel, and generates the draft required to transport the gases with the appropriate speed. A simple equation to estimate the drop pressure and the draft generated in the gas pipeline is presented in the work by Shiralkar et al 47.

When the hot gases come out too quickly the heat transfer efficiency down. While the hot gases late to out reduces the temperature (300° C or less) and does not evaporate the water contained in the cane juices. According to Osorio et al. 45, the temperature in the chimney should remain between 400 - 500° C to maintain high energy efficiency of the traditional furnace.

6. Efficiency analysis in tradicional furnaces for panela production

6.1. Energetic assessment of traditional furnace

Energy efficiency is defined as the ratio between the energy used and the energy generated by the fuel. According to Velásquez et al. 9, Velásquez et al. 52 and Marcelo et al. 32, the most considerable losses are due to the combustion gases cooling, the high chimney temperatures and the Poor insulation of the furnace walls. Other important variables on energy efficiency are bagasse: humidity, air excess during the combustion, heat transfer between gases and bottoms, chimney draft and location of the facility 45.

The furnace thermal efficiency without modification is between 15 - 30 %, while the furnace CIMPA have indicators between 35 - 45 %. The energy losses per chimney constitute 70-90 % and the wall losses are 7 % 9.

6.2. Production indices

The production indices allow to estimate the yields of panela or any other by-products; and show together the adequate disposition and use of raw materials and inputs (Table 8 and Table 9).

Table 8 Reported standard yields for panela cane derivatives.

| Product | Productivity yield (Kgproduct/Toncane) |

|---|---|

| Cane juice (guarapo) | 500 - 600 |

| Honey | 126 - 203 |

| Panela (solid block) | 97 - 155 |

| Powdered panela | 91 - 138 |

Da Silva et al. 7

Table 9 Indicators used to evaluate a traditional manufacturing installation for panela and derivatives production.

| Index | Description |

|---|---|

| Crop yield (I1) | Relationship between the mass of the panela produced, and the quantity of cane harvested and processed (Ha). |

| Bagasse yield (I2) Global yield (I5) | Ratio between the dry bagasse generated and the dry bagasse used during combustion. Indicates energy self-sufficiency. Relationship between the dry bagasse used in the combustion and the total amount of panela produced in the process. |

Marcelo et al.32

6.3. Mass and energy balance in traditional furnace

Sardeshpande et al. 29 and Shiralkar et al. 47 developed a mass and energy balances for a traditional furnace with single and multiple batteries. Velásquez et al. 9 and Osorio et al. 45 propose their balances models, focusing on combustion gases as a fundamental basis for the quantification of the production process energy efficiency. Velásquez et al. 52 proposed a guide for the exergetic balances and energy integration in a traditional facility for panela production.

The outcomes of mass and energy balance depend to on the climatic conditions and the production protocols of each facility. These variables have a direct influence on the heat generation, the fuel-combustion reaction, the boiling temperature and the specific by-products obtained. Between different furnaces can vary the fire gases flow and the percentage of mud formation; However, relationships such as bagasse consumption and air demand have recommended values that can be achieved through the standardization of the production process (Table 10).

Table 10 Information of mass balances reported by some authors.

| Information | Reported value | Reference |

|---|---|---|

| Percentage of mud (cachaza) formation - compared to juice | 3.00 % 1.50 % | Velásquez et al. 9 Sardeshpande et al. 29 |

| Un-reacted carbon | 4 % of carbon in the bagasse 55 % of combustion residues | Arteaga et al. 31 Osorio et al. 45 |

| Bagasse consumption (kgbagasse/kgpanela) | 2.39 | Sardeshpande et al. 29 |

| Air-fuel ratio (kgair/kgbagasse) | 8.90 | Osorio et al. 45 |

| Gas flow through chimney (kggases/kgbagasse) | 6.40 | Shiralkar et al. 47 |

7. Challenges of the sector in Colombia

The production of panela is the main activities of the national economy, among other reasons, due to its significant participation in the agricultural gross domestic product, the generation of rural employment and its importance in the diet of the inhabitants of the country. Approximately 350,000 people are linked to this agro-industry, that is, 12 % of the economically active rural population; so it is considered as the second line generator of employment after coffee. Panela represents 2.18 % of family spending on food and contributes 7 % of the calories in the population's diet 4,5.

Panela is the livelihood of thousands of farmers, who produce in small and medium sized sugar mills with family labor. About 1.3 % of production is developed industrially, with a capacity of 500 - 700 kg / h, while the rest is carried out in establishments with production capacities of less than 300 kg / h 3,53.

Producers face numerous challenges, among which the introduction of new technologies and the improvement of traditional processes, the prevention of environmental contamination, the development of differentiated products, the promotion of the consumption of panela and its derivatives, and the focus of efforts in favor of an evolutive and equitable market 4,54.

According to Castellanos et al. 4, in Colombia the main research areas of the panela chain are related to the commercialization, the agroindustry transformation and the agronomic and crops phytosanitary management. Within the productive component, the technological development, the treatment and use of by-products, the environmental sustainability and the processes standardization stand out. However, efforts to close the gap with other countries such as India or Brazil, which have the most advances in research, development and innovation, must still be increased.

The Colombian Agricultural Research Corporation (CORPOICA), the Sugar Cane Research Center of Colombia (CENICAÑA), the Research and Improvement Center for Agribusiness (CIMPA), the GIPUN Group of the National University of Colombia, and the University of Caldas through the project "Implementation of the Research, Innovation and Technology Center for the panela sector of the Department of Caldas, BEKDAU Center", are developed studies to the strategies development to improve the quality and presentation of panela, as well as its processes of benefit and transformation. In order to increase demand and diversify the use of sugar cane for panela production in efficient agroindustry production manner.

8. Conclusions

Agroindustry of non-centrifugal brown sugar represents a great importance line for the economy and national social progress, given the high levels of production evidenced, the high rate of consumption per capita, the significant proportion of rural jobs and the contributions of this activity to safety and security food sovereignty. This outstanding sub-agricultural sector cannot develop fully unless it presents an adequate integration between technological development, innovation, competitiveness and profitability.

Panela is traditionally obtained through the different stages of the productive process, that find to eliminate the cane juices impurities and concentrates them until reaching a certain level of solids, which generate the characteristics of texture, taste, color, aroma and nutrition demanded by consumers. Operations such as cleaning and clarification, evaporation and plucking, and beaten and molding have a high incidence on the quality parameters of panela and its derivatives, so they currently require a higher level of standardization, measurement and control. On the other hand, the extraction of sugar cane juices and the generation and heat transfer, directly affect the resources use and the operation costs of the sugar mill.

Although there are improvements in the transformation operations, and the panela quality and its derivatives, it has not been possible to address the problem globally, especially in terms of design, selection, control and automation of sub-processes such as concentration and heat generation. A topic of extreme importance, to favor the technical and economic efficiency in the production of panela, is the use and design of furnaces operated correctly by producers and entrepreneurs.

The yields in the use of raw materials and inputs are quite low in the Colombian non-centrifugal brown sugar sector, even when other viable technological alternatives have been proposed. It is imperative to study in depth the energy use, perform integration processes and efficiency energy increase. A generation and effective heat uses produced in the furnace have a positively impact the panela amount (or its derivatives) produced, and consequently reduce the current prolonged times of transformation.

To achieve the strengthening of this productive system, and to promote safe and competitive entry into new markets, the production of panela should not concentrate only on obtaining panela in solid block. It is important to direct research and innovation studies towards the development of derivatives such as honeys, powdered panela, sweets and beverages, which add value and increase profits for artisan, medium-sized and industrial producers.

A disadvantage when promoting the development of the panela chain: there is not an adequate and sufficient effort to increase the level of technology. In addition, the use of more profitable, efficient and innocuous transformation alternatives is rejected, thanks to the belief that these options run counter to the traditional "know-how" of the producing regions. According to the above, it is important to approach the involved and disseminate the technological advances available in our country and abroad, in order to ensure that the actors involved are aware of their advantages. The above, finally will have a lot more strengthened and beneficial social dynamics.