1. Introduction

The study is justified because of the need that the pork industry has to identify successful factors seeking to introduce improvements in aspects in which the companies have deficient results. These proposals should serve to strengthen the productive chain, productivity of business processes and product quality. Therefore, benchmarking allows formulating improvement hypothesis for the pork industry such as: benchmarking as a management model allows companies in the pork industry to identify better practices, learn from leading companies, design competitive strategies and implement improvement plans.

Benchmarking is a continuous and systematic process 1-3 for measuring and evaluating products, services, strategies, functions and work processes of organizations well-known for executing the best practices of the leading and the strongest competitors in the industry 4-8. It is used to collect and compare data from different organizations with different operational variants 9,10. In benchmarking, goals are set using external and objective norms learning from others 11-13, likewise, it is a “learning” process linked to “learning from others”. In fact, it is a valuable model of strategic and competitive management providing a disciplinary and logical approach for comprehending and evaluating, in an objective way, the strengths and weaknesses of a company 14,15.

The objective of this article is to carry out a study of benchmarking in four pork farms of Valle del Cauca to determine their competitive profiles. The work is structured in the following way: first, the companies have been characterized; subsequently, factors with a higher and lower development, which benefit or affect competitiveness of the farms, were analyzed, adjusted and corrected; Finally, the pork industry organization is provided with recommendations in order to improve its management and make its market performance more efficient 1,16. Moreover, it is important to mention that this study arose as a result of the research from the graduation project realized in order to obtain the Master’s degree in Business Administration.

2. Methodology

The methodology used in the development of the research was an exploratory-descriptive type with qualitative and quantitative approaches 17. Likewise, the analysis and the systematization of collected data from primary and secondary sources were included. Primary sources are constituted from data provided by the four companies through conversational interviews with managers and staff members as well as in situ observation visits, reports and documents form the organizations and thorough interviews with experts and academics of the industry, secondary sources: institutional information from well-known entities in the subject researched such as: el Instituto Colombiano Agropecuario-ICA ,Corporación Autónoma Regional del Valle del Cauca, Asociación Colombiana de Porcicultores - Asoporcicultores, Ministerio de Ambiente, Vivienda y Desarrollo Territorial, Ministerio de Agricultura y Desarrollo Rural, among others, and tertiary sources: books, graduation projects, specialized journals, data bases such as Scielo, Redalyc, Dialnet Science Direct, among others.

For the development of the study of benchmarking different sections were established each one including the following phases.

2.1 Section 1: Analysis Unit. This section has two phases

Phase one: the four pork industry companies to compare are chosen. These are listed as well-known companies because of their trajectory and market positioning according to Asoporcicultores; namely: organization A: Granja Porcícola Guásimos; organization B: Porcícola Cerdos del Valle S.A; organization C: Agropecuaria el Llanito- and organization D: Porcícola Alemana-. These organizations will be referred to as A, B, C, and D in the rest of the article.

Phase two: the identification of key success factors-KSF- is a fundamental point in the reference of the companies in the research; with this method an organization specifies the opportunity of gaining a significant strategic advantage over its competitors. The factors are identified by surveying specialists in the industry and business, asking them: “What is the secret to succeed in this industry?”, likewise, different complementary questions with different angles were asked in order to establish reasonable criteria for the identification of these factors. Finally, a debate with the specialists is carried out to verify if these are worthwhile or rejected to reach the essence of the problem. For the study, the following key success factors were analyzed: production technology, quality management system, -resolution 2640 del ICA -18, reproduction process management, logistic distribution, purchasing and inventory logistics, environmental management and protection, food sustainability, brand positioning, productive linkage, technical and professional training and management.

2.1 Section 2: Description of key success factors

Phase three: description of KSF. The description is made once the KSF that define the essence of the problem to research are identified. In the fourth phase, each one of the key success factors 3) guaranteeing a successful competitive performance for the individual, department or organization 19 was described.

The fourth phase is the construction of the competitive profile matrix- CPM- 20 which collects the perceptions that the specialists have regarding the competing companies compared in the study and the importance of each KSF in the system, which in this case is the pork industry. To this end, this matrix is designed in the following way: The first column includes the key success factors; in the second column the weight is assigned according to the relative importance of each factor given by specialists, in a way that when all the weights are added up, the result is a 100% total; each company will be assessed through two dimensions: value and weighted value (see graph). In the value column the qualification assigned by each analyst to the performance of these in each company is presented. The assessment scale is from 1 to 4, where 1 means insufficient and 4 expresses the best performance. The weighted value column is the result of multiplying the weight by the respective value of each company. This methodology provides, in an integral way, the competitive profile of each one of the companies and the factors that should be subject to strategical improvement.

In the fifth phase, the comparative radars or spider diagrams are constructed from the values and weighted values registered in the CPM. These are tools that display in a graph the differences or gaps that exist between the current state and the ideal state of a key success factor. The value graphs are lineal, the weighted ones are surface graphs showing, in an integral way, the performance of each organization. With these results, the researcher critically analyzes and interprets the behaviors and proposes the improvement strategy.

3. Results and Discussion

3.1. Characterization of the companies to compare

The organizations chosen to carry out the comparison are companies from the pork industry located in Valle del Cauca where:

Organization A: It started in 1995 and is located in Palmira, Valle del Cauca. The farm follows the genetic and nutritional sanitary parameters for protecting the environment. The company has managed to standardize its production and it also has an artificial insemination system. Occasionally, it purchases animals from specialized genetic farms supplying mare lines 21. The sanitary aspect is managed by a zootechnician, who follows the established guidelines of the good practices of pork exploitation. It buys its products from ICA certified suppliers, which allows to guarantee quality in production. It is implementing technological developments in the productive system of the organization; in fact, it has implemented a biodigestor system. The farm permanently provides specific trainings according to the needs.

Organization B: It started in 1998 and is located in Yumbo, Valle del Cauca. Producer and marketer of pork. It integrates (vertical integration) all its developed production and pork transformation processes, from the food processing plant up to the final consumer. It ventures in new markets beyond fresh meats and canned foods to exploit new areas such as frozen fast foods and its low cholesterol products for all its production lines. It has high-tech facilities, high genetic (not commercialized), biosecurity, and environmental responsibility. It has veterinarians with a broad experience. It is committed to preserving the environment through a continuous improvement, development and application of technologies to enhance, in an effective way, environmental conditions. Regarding certifications and quality support, it has: platinum category farms (National program for the improvement of sanitary pork status) and GMP (Good Manufacturing Practices). The farm permanently provides specific trainings according to the needs.

Organization C: It started in 1990 and is located in Restrepo, Valle del Cauca. Through continuous improvement plans, this company has positioned itself as one of the leading companies in the pork industry because of the implementation of its programs of: sanitary control, environmental protection, genetic and food security. It has been concerned about dealing with the environment and natural resources. It implemented biodigestor systems and wastewater treatment plants, with a final advantage in composting areas, vermiculture and subsoil improvement. Additionally, it has managed to standardize its production based on 600 females, with an artificial insemination system. In the nutritional area, it is supplied with good consumables and has its own plant for food processing. Its facilities have been designed with the best production models established for these types of exploitations: three site production: ISOLETE WEININ, whereby it has established specific standards for each area guaranteeing a high specificity management. The farm has implemented modern technological processes in the reproduction area, such as, a modern lab for the processing of swine semen and for sample drawing for serological and bacteriological studies. The human resource department is excellent; they train their staff in pork exploitation techniques.

Organization D: It started in 1983 after several transformations, restructurings and strategical changes from a company that emerged in 1958. It is located in Palmira, Valle del Cauca. Currently, this farm is dedicated to the production of pigs for slaughter. Additionally, it has production lines of reproductive males and replacement gilts, all of high genetics. Overall, its four characteristics of competitive advantage are: continuous improvement in its productive processes and its genetics, high performance both in its productive process in the farm as well as carcass lean, leadership from the company’s management and teamwork with its collaborators, direct contact with customers with whom they share the experience, knowledge and services for the benefit of the industry, compliance with the environmental normativity generated by regulatory and monitoring entities in the industry: ICA 22, -CVC 23, Asoporcicultores 24,-MADR 25; among others. The farm permanently provides specific trainings according to the needs.

3.2 Key success factors

In Table 1, KSF, which can be internal or external to the organization, are described. These can be identified as part of the basic design of an activity or a process allowing it to be influenced or actively chosen 26.

Table 1 Description of Key success factors -KSF

| KSF | Description |

|---|---|

| Production technology | Equipment and systems for the handling of animals in confinement, enabling a follow-up of productive parameters and animal inventory. It is related to the implementation of good practices of the industry, genetics, feeding, reproduction, and animal transportation (standing or carcass lean), biosecurity. These technological production systems develop a corporate management of the production, thus, allowing the commercialization of live animals, meat or carcass lean, according to the demands of the buyers (27). |

| Quality management system: (resolution 2640/07 del ICA) | Norm related to the pork industry referring to the regulation of the sanitary conditions and safety (28) in primary production of pig farming, destined for slaughter or human consumption. (18). |

| Reproduction process management | Makes reference to the activities that need to be carried out to detect the beginning of the reproductive process of females. These activities are: a) daily inspection of the pigs to detect heat; b) collecting, analysis and preparation of semen; c) insemination of the pigs; d) continuous inspection of the pigs condition; e) preparation and accompaniment during birth; f) surgical treatments of piglets (umbilical cord clipping, teeth clipping, tail docking, tattoo branding and castration; g) physical and digital registration of the birth (21). A good management of these activities is essential for the development of the animals and the productivity of the company. (29). |

| Logistic distribution | Makes reference to the activities that need to be done in order to commercialize the final product. For the pork industry, the two main ways of doing this is either standing or carcass lean. Selling standing pigs is the one where the pig farmer sells the product directly and carcass lean pig is the one where the pig farmer assumes the logistic. |

| Purchasing logistic and inventory of consumables | Makes reference to the activities that must be carried out to obtain the necessary consumables (30) for the production of fattened pigs. In the pork industry, more than 80% of primary pork production costs amount to purchasing products. |

| Environmental management and protection of the environment | In general terms, pig farming does not produce waste, but byproducts (liquid swine manure), which can be valued as an extra fertilizer, its irresponsible use can be considered a source of potential nitrogen contamination of water and soil (30), likewise, not generating an income (as a result of selling it as an organic fertilizer), rather a cost when eliminating them. It is very important to offer suitable solutions, such as: a) integration of agriculture and pig farming, b) improving the practices of handling manure, c) cooperation between environmental and research entities, universities and producers (31). CVC is the regional entity that regulates the environmental norms (23). |

| Food sustainability | Food suppliers are divided into raw materials marketers -PM- (mineral and protein) for the elaboration of food for animals and food companies. Producers consume more than 500,000 tons of balanced food; the food mainly used is yellow corn, sorghum, rice, cotton seeds, soy bran cereal draff, which represent 70% of the food and are the most significant items regarding costs in the production systems (approximately a 75.5%) (32). |

| Brand positioning | Makes reference to the place the brand has in consumers’ minds regarding its competitors. It is one of the definite indicators (7) that explains which are the companies with a higher domain in the market. In the pork industry, some specialized shops and supermarkets have developed brands and products from pork; thus, they have increased variety and consumers’ trust. |

| Productive linkage | Productive linkage is the long-term articulation (33) established by corporate units in order to obtain collective benefits. The productive chain of pork is made up of the following links: food suppliers, genetic suppliers and other consumables of production for pigs, slaughterhouses, marketers both wholesale and retail, up to the final consumer (34). Some companies, because of their trajectory and knowledge of the industry, began a strategic alliance process with other links in the productive chain, (31,16). |

| Professional training | It is a collection of actions whose aim is to boost and extend, among companies and busy employees and unemployed people, a training that responds to the needs and contributes to the development of an economy based on knowledge. Working staff in the pork industry must be competent and capable of showing professional qualifications in areas such as: normativity, technical specifications, animal well-being criteria, occupational risks prevention, environmental protection and food safety. If the person is not trained, at the least, he or she should have aptitude, vocation and empathy with animals (27) |

| Management | An important factor, in the success of pork companies, lies in the capacity of management and direction; in particular, in matters related to the integration (35) of production, marketing, financial and investment management. |

3.3 Competitive profile matrix

Table 2 shows the competitive profile of four meaningful companies in the pork industry in Valle del Cauca: organization A, organization B, organization C, organization D.

Table 2 Competitive profile matrix (CPM)

| K.S.F. | Weight | Organization A | Organization B | Organizaction C | Organization D | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Value | Weighted Value | Value | Weighter Value | Value | Weighted Value | Value | Weighted Value | |||

| Production technology | 12% | 0.12 | 3.0 | 0.36 | 4.0 | 0.48 | 3.0 | 0.36 | 3.5 | 0.42 |

| Quality management system | 12% | 0.12 | 3.0 | 0.36 | 4.0 | 0.48 | 3.0 | 0.36 | 4.0 | 0.48 |

| Reproduction process management | 8% | 0.08 | 2.5 | 0.20 | 3.0 | 0.24 | 3.5 | 0.28 | 4.0 | 0.32 |

| Logistic distribution | 8% | 0.08 | 2.0 | 0.16 | 4.0 | 0.32 | 3.0 | 0.24 | 3.0 | 0.24 |

| Purchasing logistic and inventory of consumables | 10% | 0.10 | 2.0 | 0.20 | 4.0 | 0.40 | 3.5 | 0.35 | 3.0 | 0.30 |

| Environmental management and environmental protection | 10% | 0.10 | 3.5 | 0.35 | 3.0 | 0.30 | 3.5 | 0.35 | 3.0 | 0.30 |

| Food sustainability | 7% | 0.07 | 3.0 | 0.21 | 4.0 | 0.28 | 3.5 | 0.24 | 3.5 | 0.24 |

| Brand positioning | 6% | 0.06 | 2.0 | 0.12 | 4.0 | 0.24 | 2.0 | 0.12 | 3.0 | 0.18 |

| Productive linkage | 7% | 0.07 | 2.5 | 0.17 | 4.0 | 0.28 | 3.0 | 0.21 | 3.5 | 0.24 |

| Professional and technical training | 8% | 0.08 | 3.0 | 0.24 | 4.0 | 0.32 | 3.0 | 0.24 | 3.5 | 0.28 |

| Management | 12% | 0.12 | 2.0 | 0.24 | 4.0 | 0.48 | 2.5 | 0.3 | 3.0 | 0.36 |

| TOTAL | 100% | 1 | 2.615 | 3.82 | 3.055 | 3.37 | ||||

3.4 Value and weighted value radars

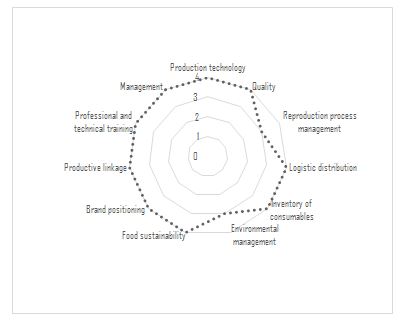

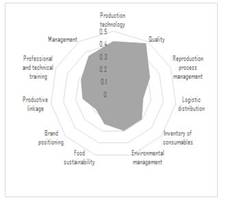

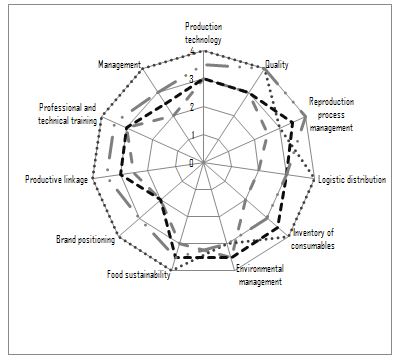

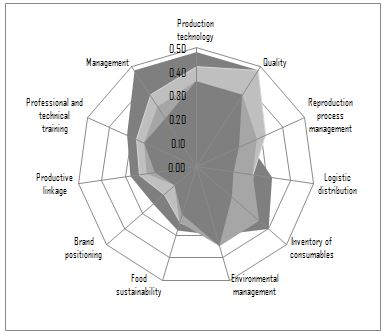

The analysis of the competitive profile matrix is carried out through the radar or spider diagrams 36, consisting of the graphical representation of the measured values in the matrix using a system with oblique axles.

As seen on Figures 1 and 2, organization A shows the highest performance in environmental management and environmental protection. It has a critical performance in the following factors: logistic distribution, purchasing logistic and inventory of consumables, brand positioning and management. However, its performance is acceptable in production technology, quality management system: (resolution 2640 ICA) 18, food sustainability and professional and technical training.

Organization B (Figures 3 and 4), leader in the region of Valle del Cauca, presents and excellent performance in the following factors: production technology, brand positioning, productive linkage, competent staff, quality management system, logistic distribution, food sustainability, management and raw material handling. However, it has an acceptable performance in reproduction process management, environmental management and environmental protection 37.

Organization C, as shown on Figures 5 and 6, has a very good performance in the following key factors: reproduction process management, purchasing logistics and inventories, consumables, environmental management and protection, food sustainability. It has a very critical performance in brand positioning and management, while its performance is acceptable in production technology, quality management system: (resolution 2640 ICA), logistic distribution, productive linkage, professional and technical training.

Organization D has an excellent performance in quality systems, reproduction process management, mainly because of its high genetic development in male pigs and sows for obtaining high quality litters, and the advanced system in its productive stages (Figures 7 and 8). It has a very good performance in: production technology, food sustainability, productive linkage, professional and technical training. Its performance is acceptable in logistic distribution, purchasing logistic and inventories, consumables, environmental management and protection, brand positioning and management.

3.5 Interpretation of the results

After realizing the corresponding analysis of the competitive profile matrix (Figures 9 and 10), important consideration arose. First, it is observed that company B is the one leading in the pork industry in Valle del Cauca (weighted value 3.82). This company presents a high economic power and collects, in one organization, the different links in the productive pork chain. The aspects to improve are: reproduction process management, environmental management and environmental protection.

By analyzing C and D, whose weighted values are 3.05 and 3.37 respectively, a similarity is evidenced in several key success factors. However, each one outstands in a particular factor. Farm C shows a good handling in food sustainability since it uses balanced foods as a nutrition source for its animals; this is reflected in the quality of its product. Pig farm D has an excellent management in productive technology because it is based on high animal genetics and productive processes. This allows it to: a) transfer its knowledge to other organizations, b) obtain better productive parameters in animals, c) work in an associational way with other organizations, d) achieve an export type products. Pig farm A has worked hard in environmental management and protection in the good management of waste which positively impacts the environment.

4 . Conclusions

Based on the findings, it is possible to conclude:

It is recommended for farm A to improve its brand positioning; to do so, it needs to invest in advertising and take advantage of the fairs organized by Asociación Nacional de Porcicultores to position its brand. The logistic process needs to be revised, in particular in raw food materials and concentrates which amount to 75% of the production costs. It is important to have an excellent logistic in purchasing, strategic alliances with suppliers and distributors and an adequate control of the distribution to reduce production costs. Thus, it is possible to raise the company’s profit and income. Regarding management, it is pertinent to create knowledge in the use of managerial and administrative tools in specific topics in the pork industry.

It is recommended for farm B to improve the following: reproduction process management, to do so, it can venture in the market of genetics since all its processes are integrated (vertical integration) and because it is well-known in the market for its quality products. Another factor that needs work is environmental management and protection which can be achieved by showing the directives that being environmentally responsible is beneficial for the organization; improving the corporate image enhances the trust of policymakers, investors and reinforcement of product differentiation strategies.

It is recommended for farm C to improve the following: logistic distribution, purchasing logistic and consumables inventory, brand positioning and management. This can be achieved by investing in advertising to engage new customers and take advantage of fairs carried out by Asociación Nacional de Porcicultores each year to position its brand. Likewise, the organization should join customer’s loyalty campaigns organized by Asociación Nacional de Porcicultores and address the stigmas and preconceptions regarding the risks of consuming pork. It should take advantage of having, as a competitive benefit, a high quality product.

It is recommended for farm D to improve in logistic distribution, purchasing logistics and inventory, consumables, environmental management and protection, brand positioning and management. This can be achieved by investing in advertisement to engage new customers and take advantage of fairs carried out by Asociación Nacional de Porcicultores each year to position its brand. Improving the factor of environmental management and protection can be achieved by showing the directives that being environmentally responsible is beneficial for the organization; improving the corporate image enhances the trust of policymakers, investors and reinforcement of product differentiation strategies.

It is clear that organizations A, C and D disregard the other key success factors since the collection of these is what allows them to stand out in the industry and maintain good profit, productivity and sustainability parameters.