1. Introduction

Cocoa (Theobroma cacao L.) is a species native to the tropical rainforests of South America, its beans are the basic input for the chocolate industry and its derivatives, the pharmaceutical industry and the cosmetics industry. Three groups of cocoa are distinguished; the Forasteros: Also known as Amazonian and/or bitter cocoa, they have flattened, small, purple beans with a bitter taste. The liquor has medium acidity and astringency; medium bitterness; low fruitiness and notable chocolate intensity 1. The Criollos: Cultivated in Central America, it is known as fine cocoa, produces an aromatic, fruity and sweet fruit, but has low yields 1. The trinitarios originate when a criollo genotype was naturally crossed with an amelonated genotype from Brazil (forastero from the lower Amazon) 2, they present medium to large sized almonds with reddish cotyledons and develop a pronounced chocolate aroma with an additional fruity flavor 3. Within this group the Imperial College Selection (ICS-95), from Trinidad, has medium fruit, the color of the cotyledons is purple; fruit size is large, 35 seeds/fruit, intermediate seed size, seed dry weight 1.3 g, yield 682 - 2,045 kg/ha; the liquor has an intermediate note of bark and nut, notes of tropical fruit, the intensity of chocolate tends to be moderate 4.

In this sense, the participation of fine cocoa in world production has decreased greatly, from a figure between 40% and 50% at the beginning of this century, to a little less than 5%, (5, currently this decline is mainly due to failures in crop management, including post-harvest and natural and artificial crosses occurred between native and foreign cocoa 6-7. Latin America and the Caribbean supply 80% of the world's fine or flavor cocoa, followed by Asia and Oceania (18%) and Africa (2%). Ecuador is the largest supplier, followed by Venezuela, Costa Rica, and Colombia 5. The chocolate flavor develops from fermentation, this being the most important stage involving two different phenomena, microbial fermentation, and a set of internal biochemical reactions in the cotyledons, which are induced by the elevation of the temperature of the cocoa mass 8. Likewise, the modifications that occur during fermentation are the development of aroma precursors, the flavor of cocoa 9-11. These substances are formed from the moment the cotyledons die, while the rapid reduction of anthocyanins occurs, only they can give cocoa the characteristic flavor and aroma of chocolate during roasting 12. The main objective of this research was to evaluate the physicochemical and sensory effect after the addition of a microorganism in cocoa beans in the fermentation stage, allowing to determine which effect can generate a better cocoa quality.

2. Methodology

2.1. Sample characteristics and processing

Cocoa samples were collected from three different clones: CCN-51, LUKE-40 and ICS 95, naturally grown trees. The physicochemical analysis of the cocoa and the sensory evaluation were carried out at the Biotechnology and Food Quality Control Laboratory, located at the Centro de Investigaciones Amazónicas Macagual - CIMAZ of the Universidad de la Amazonía, in Florencia Caquetá, tropical rainforest, altitude of 250 meters above sea level, average temperature of 25.5 degrees Celsius, average relative humidity of 76.3%. 5 degrees Celsius, an average relative humidity of 76.3%, and an annual rainfall of 3,793 mm, located 22 km from the urban center of the municipality of Florencia, between the coordinates: 1° 30' 4.9" and -75° 39' 47.1" 13.

The sample was a mixture of cocoa beans from three different clones: CCN-51, LUKE-40 and ICS 95. The cobs were opened, carefully with a knife and the beans were removed manually without the placenta (heart). In total, 32,450 g of "cocoa baba" was obtained, of which 18,695 g was from CCN-51, 8,170 g from LUKE-40 and 5,585 g from ICS-95. The sample was divided into five equal parts (6,400 g), according to the number of treatments to be studied (Table 1).

Table 1 Treatments studied to determine the effect on the quality of the application of a microorganism during the cocoa fermentation process.

| No. | Treatments | Reference |

|---|---|---|

| 1 | FI1 | Cocoa + inoculum |

| 2 | FI2 | Cocoa + inoculum |

| 3 | FI3 | Cocoa + inoculum |

| 4 | FN1 | Cocoa |

| 5 | FN2 | Cocoa |

FI1 (Inoculum Fermentation # 1); FI2 (Inoculum Fermentation # 2); FI3 (Inoculum Fermentation # 3); FN1 (Natual Fermentation # 1); FN2 (Natual Fermentation # 2).

The physicochemical analysis and sensory evaluation were carried out at the Biotechnology and Food Quality Control Laboratory, located at the Centro de Investigaciones Amazónicas Macagual - CIMAZ of the Universidad de la Amazonía, in Florencia Caquetá, with tropical rainforest, an altitude of 250 meters above sea level, an average temperature of 25.5 ºC, an average relative humidity of 76. It is located 22 km from the urban center of the municipality of Florencia, between the coordinates: 1° 30' 4.9" and -75° 39' 47.1" 13.

2.2. Fermentation process

Each sample of 6,400 g (CCN-51: 3,700g, LUKE-40: 1,600g, & ICS 95: 1,100g), was placed in a wooden box (50 cm wide x length x height) for the fermentation process that lasted 8 days. The boxes were constructed without divisions to facilitate the removal of the cocoa mass during this process and before placing the samples, they were "covered" with banana leaves to avoid bad odors, microorganisms and foreign flavors that could affect the beans. In all the treatments, the first 24 hours were for natural fermentation, after which time the microorganism was added, which had been activated the day before, and the addition was made by means of liquid at a temperature of 30±2 in the first three treatments (FI1, FI2, FI3).

After 48 hours from the beginning of the fermentation process, the boxes were placed in full sunlight for 12 hours daily until the last day of fermentation. During this time, the cocoa mass was turned over to ensure uniform fermentation at 24, 48, 72, 96, 120, 144, 168 and 192 hours. Every 24 hours, shear and pH tests were also carried out to show the changes during this process. In addition, readings were taken of ambient temperature, bean mass height and ambient relative humidity.

2.3. Drying process.

For the drying process, an oven was used at a temperature of 40 °C, the samples were placed in trays 35 cm wide x 40 cm long to facilitate the turning of the cocoa. Drying was achieved in approximately 8 to 10 days. During the first 3 days, the cocoa was turned every 4 hours, then every 2 hours until the process was completed.

2.4. Roasted and husked.

For roasting, a sample of 150 g of healthy cocoa was taken and placed in an industrial oven at a temperature of 200 °C for 20 to 25 minutes. The roasted samples were shelled, and the percentage of husk was calculated using Eq. 1:

2.5. Physicochemical characterization of dry cocoa.

2.5.1. Moisture content of dry beans.

The gravimetric test was performed to determine the exact moisture content of each sample. For this, approximately 10 grams of the sample was weighed and placed in Petri dishes, then placed in the oven, at a temperature of 105 + 1, for 6 hours. After that time, the sample was removed and its moisture content was determined, using Eq. 2 14:

Where:

H: Moisture content expressed in percentage

m0: Weight of empty capsule (g)

m1: Weight of the capsule with moisture sample (g)

m2: Weight of crucible plus dry sample (g)

2.5.2. pH in dry grain.

The husked sample was homogenized, then 2 grams were weighed, 40 milliliters of distilled water were added, filtered, and read until there was no variation 15.

2.5.3. Dry grain titratable acidity.

The dehulled sample was homogenized, then 2 grams were weighed, 40 milliliters of distilled water were added, the sample was filtered, then 3 drops of phenolphthalein were added and slowly NaOH at 0.1N was added from the burette and stirred continuously until the first color change (faint pink) occurs and remains for 15 seconds or the pH is at 8.0± 0.2 with the help of the potentiometer 15.

2.5.4. Dry grain water activity (Aw).

Water activity was measured using the AquaLab 4TE, approximately ten grams of cocoa beans generated by each treatment were weighed. The results were reported in units from 0 to 1 14.

2.5.5. Dry grain soluble solids (°Brix).

It weighed two grams of the sample in all treatments and a Milwaukee digital refractometer (MA884 Wine refractometer) was used to measure Soluble Solids of the cocoa beans. The results were reported in °Brix degrees, which indicate the percentage of soluble solids based on the total solution 16.

2.6. Roasting Process.

This process was carried out in an industrial oven with a temperature of 200 °C in trays that allowed uniform roasting and was maintained until husk detachment was observed. The weight of the samples for each roasting was 500 grams, the average roasting time of the sample was 20 to 25 minutes, after which it was husked and packed in plastic bags.

2.7. Physicochemical analysis of cocoa liquor.

2.7.1. pH cocoa liquor.

Two grams of liquor sample were weighed, 18 milliliters of distilled water were added and homogenized in a mortar, then it was filtered, and the reading was made until it did not present variation by means of a pH measuring device (potentiometer) 17.

2.7.2. Cocoa liquor acidity.

Two grams of liquor sample were weighed, 18 milliliters of distilled water were added and homogenized in a mortar, then the sample was filtered, then 3 drops of phenolphthalein were added and slowly NaOH at 0.1N was added from the burette and stirred continuously until the first color change (faint pink) occurs and remains for 15 seconds or the pH is at 8.0± 0.2 with the help of the potentiometer 17.

2.7.3. Cocoa liquor moisture.

A gravimetric test was performed to determine the exact moisture content of the liquor in each sample. For the present analysis, approximately 10 grams of sample of the product to be evaluated were weighed, placed in Petri dishes, then placed in the oven at a temperature of 105 + 1 for 4 hours, after which the moisture content was determined using Eq. 2 17.

2.7.4. Liquor water activity (Aw)

Water activity was measured using the AquaLab 4TE, approximately ten grams of the cocoa liquor generated by each treatment was weighed. The results were reported in units from 0 to 1 16.

2.7.5. Soluble solids (°Brix) in cocoa liquor.

A Milwaukee digital refractometer (MA884 Wine refractometer) was used to measure the soluble solids of the cocoa bean liquor in all treatments; two grams were weighed for each sample. The results were reported in Brix degrees, which indicate the percentage of soluble solids based on the total solution 16.

2.7.6. Sensory analysis.

The samples of each treatment were evaluated by a team of 6 tasters. With this panel of tasters, tests were carried out to obtain the data that, according to their criteria, showed the best conditions of quality and intensity of the samples.

2.7.7. Preparation of cocoa liquor.

After the roasting process, the cocoa was manually shelled, the cocoa was passed to grinding to turn it into nips using a food chopper (BLACK & DECKER MODEL. HC 3000), so that the almond is crushed into small parts. After having the nips ready we proceed to the grinding to obtain the cocoa liquor, this procedure was performed by adjusting the industrial bean mill until obtaining a particle size granulometry; for this procedure 50 gr of the sample was weighed on the Citizon CT 302 digital semi-analytical balance. Once the process of obtaining the liquor was finished, the samples were refrigerated at a temperature of 4 °C in a HACEB refrigerator with their respective coding. At the time of the sensory analysis, the samples passed through the water bath to melt the liquor and were served in plastic molds to pass later into the hands of the evaluators.

3. Results and discussion.

3.1 Effect on the physical and chemical characteristics of cocoa beans.

3.1.1 Moisture content.

The moisture content of the grain (Table 2) in the samples fermented with inoculum addition (FI1; FI2 and FI3) ranged from 5.5386 to 5.5978 %; these values were very different from those obtained in the samples with natural fermentation (FN1 and FN2), which ranged from 2.7758 to 3.1426%. These values are below the range of 6 to 7% moisture recommended by several authors 12,18,19. They also point out that with this humidity range, the risk of mold attacks on the almonds decreases.

Table 2 Results of physicochemical analysis of dry cocoa beans under natural fermentation and with inoculum addition.

| Treatment | Moisture content (%) | Titratable acidity (%) | pH | Aw | °Brix | Husk (%) |

|---|---|---|---|---|---|---|

| FI1 | 5.6067 | 0.4946 | 4.9 | 0.5176 | 0.3 | 22.24 |

| FI2 | 5.5978 | 0.4368 | 4.7 | 0.5601 | 0.4 | 22.69 |

| FI3 | 5.5386 | 0.4870 | 5.0 | 0.6073 | 0.4 | 22.32 |

| FN1 | 2.7758 | 0.2611 | 5.1 | 0.4899 | 0.4 | 21.79 |

| FN2 | 3.1426 | 0.2701 | 5.0 | 0.5356 | 0.4 | 21.26 |

FI1 (Fermentación con Inóculo # 1); FI2 (Fermentación con Inóculo # 2); FI3 (Fermentación con Inóculo # 3); FN1 (Fermentación Natural # 1); FN2 (Fermentación Natural # 2).

Another author, such as Palacios 20, is more rigorous and points out that cocoa beans should have 5% humidity to guarantee their storage. Thus, fermented samples with the addition of inoculum (FI1; FI2; FI3) are in the ideal range. Although the Colombian Technical Standard NTC 1252 of 2003 recommends 7% moisture in the processed cocoa. The values obtained in this work are below the established range.

3.1.1 Titratable acidity.

As for the percentage of acidity (Table 2), the fermentation treatment with the inoculum (FI1; FI2; FI3) ranged between 0.4368 and 0.4946, allowing us to be similar to the results reported by 21, where the percentage of acidity was 0.45 for the cocoa bean. As for natural fermentation (FN1; FN2), it ranged between 0.2611 and 0.2701, which allows us to be in similarity with the data reported by 22, where they characterized physiochemically regional materials of Colombian cocoa finding acidity values between 0.3 and 0.9%, expressed in percentage of acetic acid.

3.1.2 pH.

The pH of the treatments (Table 2), of the cocoa beans fermented with the inoculum (FI1; FI2; FI3) and with natural fermentation (FN1; FN2), ranged between 4.9 and 5.1, where it is evident that there was no significant change between them; but it could not give results similar to those reported by 21, who evaluated the fermentation process of cocoa beans in two designs of wooden boxes, finding pH values of 5.84.

3.1.3 Water activity

According to Buelvas G, (2016) 23, water activity varies between 0 and 1.0, depending on the behavior of each food, which is different according to its water activity, but in general, a food with water activity below 0.7 is stable to most causes of physical, chemical or biological deterioration; below 0.6 is very stable to spoilage by microorganisms, thus allowing us to be within the ranges established for fermentation treatments with inoculum (FI1; FI2; FI3) and with natural fermentation (FN1; FN2), which oscillate between 0.4899 and 0.6073 Aw (Table 2).

3.1.1 °Brix.

The °Brix content (Table 2), for the treatments of cocoa beans fermented with the inoculum (FI1; FI2; FI3) and with natural fermentation (FN1; FN2), ranged between 0.3 and 0.4; being well below the results of the study of 24, where it has a range for fermented beans that is found in an average of 1.22.

3.1.2 Husk content.

However, the cocoa beans fermented with the inoculum (FI1; FI2; FI3) ranged between 22.69 and 22.24, obtaining a higher percentage of husk than the beans with natural fermentation (FN1; FN2), which ranged between 21.26 and 21.79. The results of this research showed that large kernels presented a higher percentage of husk, contradicting the theory of 25,26, who mention that the content of kernel testa is inversely proportional to its size.

3.2 Effect on the physicochemical characteristics of cocoa liquor.

3.2.1 Moisture content cocoa liquor.

The moisture content of the grain (Table 3), according to the analysis, did not show a significant difference for the samples of fermentation with inoculum addition (FI1; FI2; & FI3), which ranged between 0.6226 and 0.6445 percent; but it did differ significantly from the samples of natural fermentation (FN1 & FN2), which ranged between 0.2596 and 0.2650 percent.

Table 3 Results of physicochemical analysis of cocoa liquor under natural fermentation and with inoculum addition.

| Treatment | Moisture content (%) | Titratable acidity (%) | pH | Aw | °Brix |

|---|---|---|---|---|---|

| FI1 | 0.6226 | 0.2857 | 5.2 | 0.6130 | 0.2 |

| FI2 | 0.6370 | 0.2828 | 5.1 | 0.6827 | 0.2 |

| FI3 | 0.6445 | 0.2743 | 5.0 | 0.6939 | 0.2 |

| FN1 | 0.2650 | 0.3243 | 5.0 | 0.7206 | 0.1 |

| FN2 | 0.2596 | 0.3064 | 5.1 | 0.7124 | 0.1 |

FI1 (Inoculum Fermentation # 1); FI2 (Inoculum Fermentation # 2); FI3 (Inoculum Fermentation # 3); FN1 (Natural Fermentation # 1); FN2 (Natural Fermentation # 2).

3.2.2. Titratable acidity.

The percentage of acidity (Table 3), of the fermentation with the inoculum (FI1; FI2; FI3) ranged between 0.2743 and 0.2857, allowing us to be similar to the results reported by Graziani de Fariñas et al. 21 in 2003. As for natural fermentation (FN1; FN2), it ranged between 0.3064 and 0.3243, which allows us to be in similarity with the data reported by 22, where they characterized physiochemically regional Colombian cocoa materials, finding acidity values between 0.3 and 0.9%, expressed as a percentage of acetic acid.

3.2.3. pH

pH of the treatments of the cocoa beans fermented with the inoculum (FI1; FI2; FI3) and with natural fermentation (FN1; FN2) (Table 3), ranged between 5.0 and 5.2, where it is evident that there was no significant change between them; but it could not give results similar to those reported by 21, finding pH values of 5.84.

3.2.4. Water activity

The fermentation treatments (Table 3), with inoculum (FI1; FI2; FI3) ranging from 0.6130 to 0.6939 and the natural fermentation treatments (FN1; FN2), ranging from 0.7124 to 0.7206, are in the records of no deterioration according to Buelvas G, 2016 23.

3.2.5. ºBrix.

The content of degrees °Brix for the treatments of cocoa beans fermented with the inoculum (FI1; FI2; FI3) and with natural fermentation (FN1; FN2) (Table 3), ranged between 0.1 and 0.2, being well below the results of the study of 24, where it has a range for fermented beans that is found in an average of 1.22.

3.3 Effect on sensory analysis characteristics.

3.3.1 Intensity descriptors.

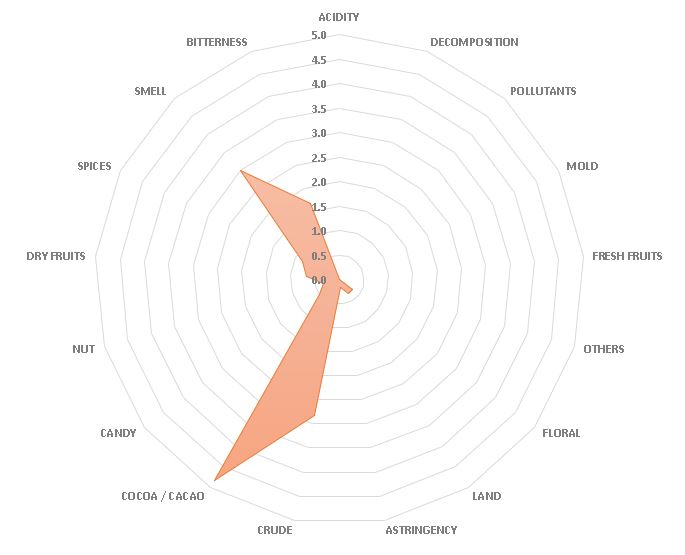

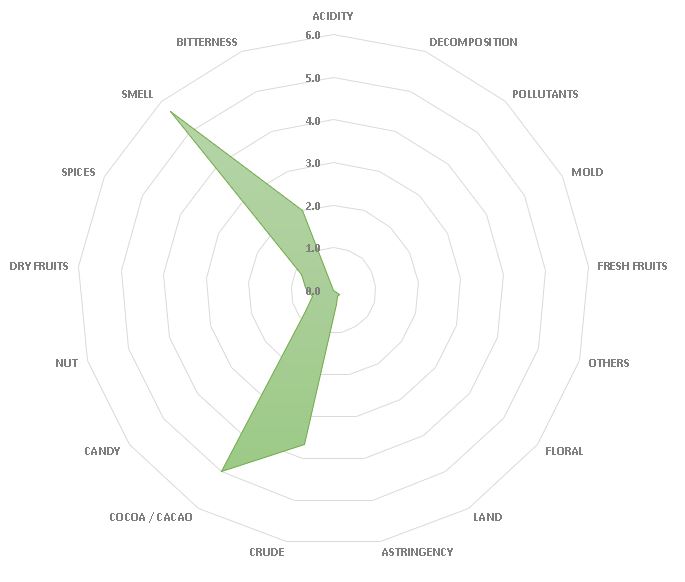

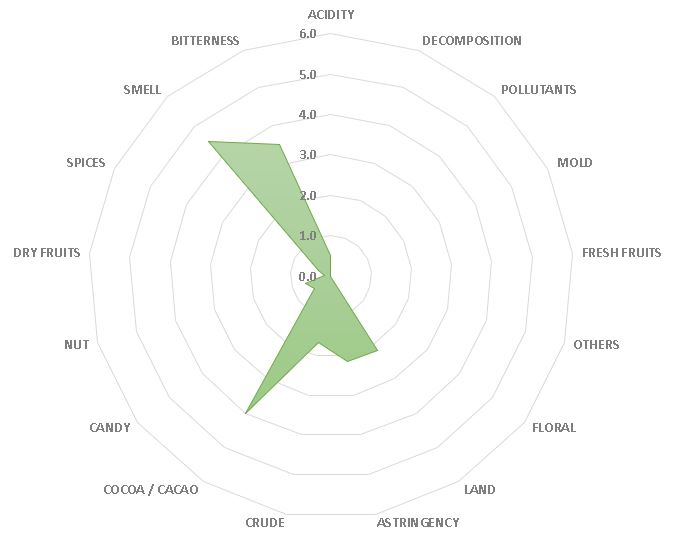

In Figure 1, the results of the sensory analysis of the descriptors of fermentation intensity with the addition of inoculum # 1 (FI1), on a scale of 0 to 10 that were present in the cocoa bean liquor, are shown in a radial diagram; it highlights its high cocoa flavor with a score of 4.8, aroma of 3.0; bitterness of 1.7; dry fruits and spices of 0.8; sweetness of 0.5; floral and nutty flavor of 0.3 and astringency of 0.2 As for defects, crude was the most outstanding with a rating of 2.8; earthiness of 0.3; the other low quality descriptors were not significant.

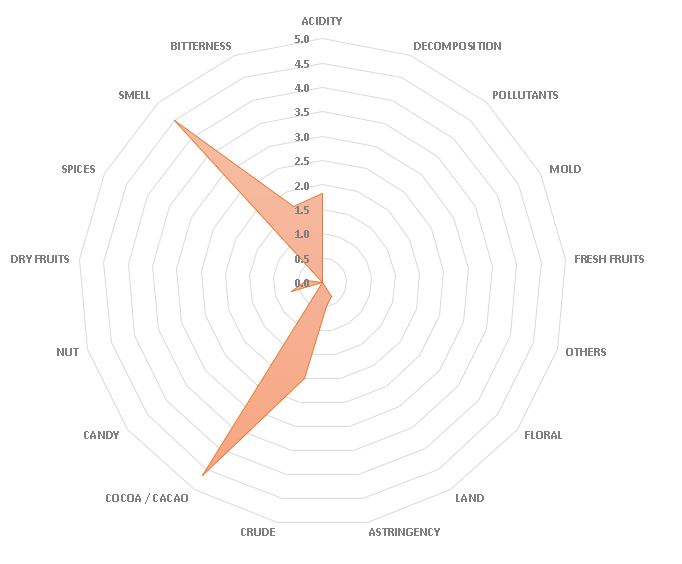

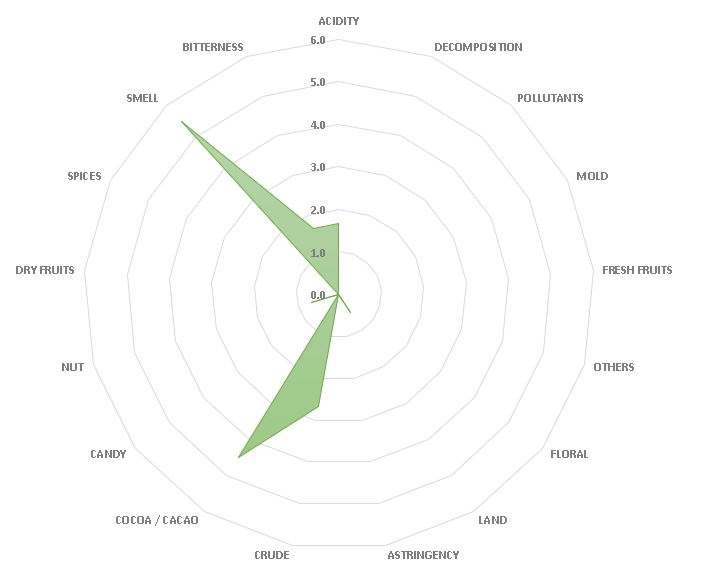

The results of the sensory analysis of the fermentation with the addition of inoculum #2 (FI2); (Figure 2) on a scale of 0 to 10 that were present in the cocoa bean liquor; highlights its high cocoa flavor with a score of 4.7, aroma of 4.5; acidity of 1.8; bitterness of 1.7; nuttiness of 0.7 and astringency of 0.5; the other descriptors were not significant. In terms of defects, the crudeness of the sample was the most outstanding with a rating of 2.0; and earthiness of 0.3.

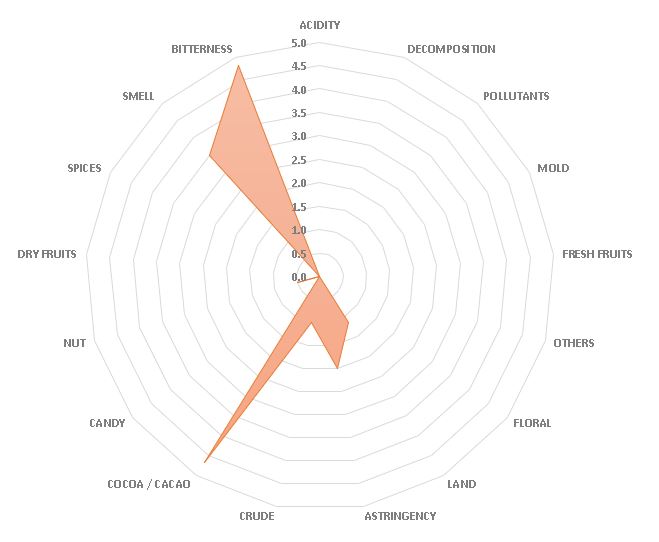

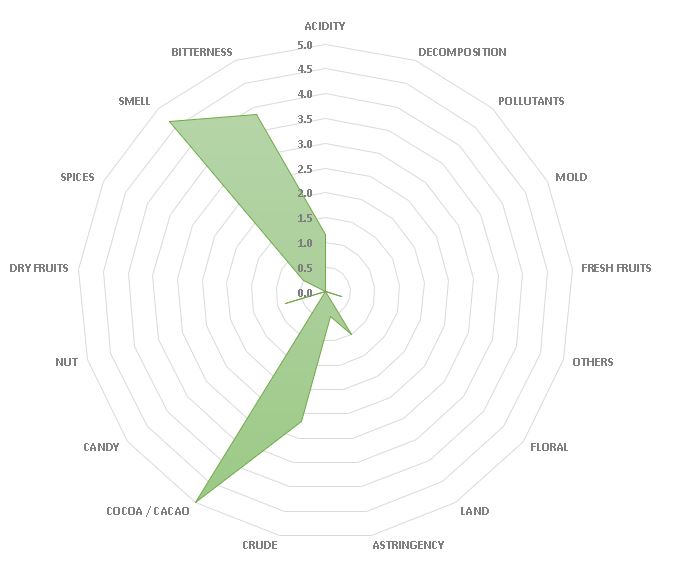

The fermentation with the addition of inoculum # 3 (FI3) (Figure 3), was outstanding for its high cocoa flavor with a score of 5.3; aroma of 4.2; bitterness of 3.7; acidity of 1.0; the other descriptors with non-significant values. As for defects, the crudeness of the sample was the most outstanding with a score of 2.8; and soil of 0.8, the other low intensity descriptors were not significant.

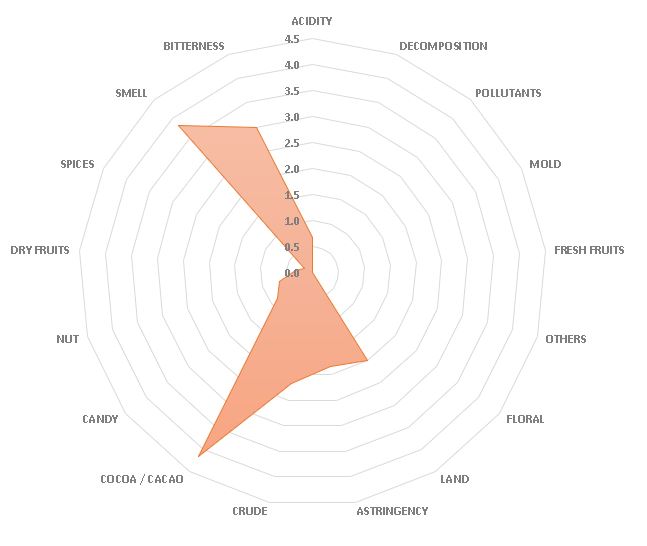

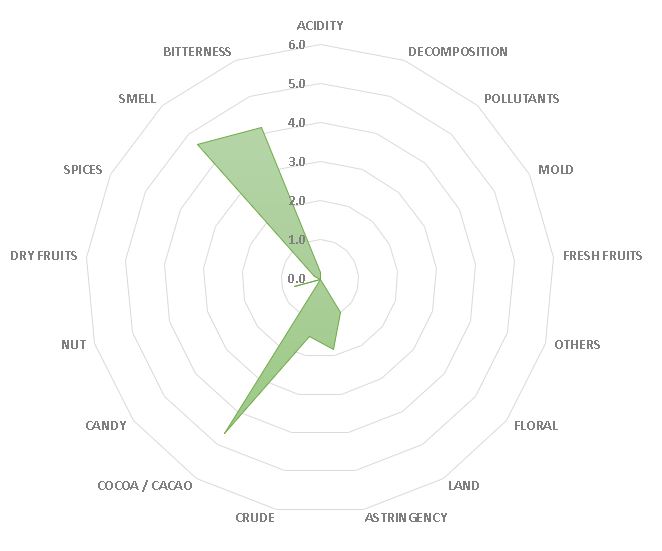

For the results of the sensory analysis of the descriptors of intensity of natural fermentation # 1 (FN1); (Figure 4), on a scale of 0 to 10 that were present in the liquor of the cocoa beans; its high bitterness stands out with a score of 4.8; cocoa with 4.7; aroma of 3.5; astringency of 2.0; and nutty with 0.5; the other descriptors with non-significant values. As for defects, the descriptor of soil was the most outstanding with a score of 1.2; and crude with 1.0.

From natural fermentation # 2 (FN2); (Figure 5) on a scale of 0 to 10 that were present in the cocoa bean liquor; highlights its high cocoa flavor with a rating of 4.2; aroma of 3.8; bitterness of 3.0; astringency of 1.8; sweetness of 0. 8; acidity and nuttiness of 0.7; and finishing with nuts and spices of 0.3; as for defects, the raw descriptor was the most outstanding with a score of 2.2; and earth of 2.0; the other low intensity descriptors were not significant

3.3.2 Quality descriptors.

In the quality descriptors of the fermentation with addition of inoculum # 1 (FI1) (Figure 6), the aroma characteristics are detailed with a score of 5.7; cocoa with 5.0; bitterness 2.0; sweet, nuts and spices with 0.8; nutty with 0.5 and astringency; floral with 0.2; the other quality descriptors were not significant. In terms of defects, the crudeness of the sample was the most outstanding with a rating of 3.7; and earthiness of 0.2; the other low-quality descriptors were not significant.

The fermentation with addition of inoculum #2 (FI2); (Figure 7), details the aroma characteristics with a score of 5.5, cocoa of 4.5; acidity and bitterness of 1.7; nutty of 0.7; the other quality descriptors were not significant. As for defects, crude was the most outstanding with a score of 2.7; and earth of 0.5; the other low-quality descriptors were not significant. For the fermentation with the addition of inoculum #3 (FI3) (Figure 8), the cocoa characteristics are detailed with a score of 5.0, aroma of 4.7, bitterness of 3.8, acidity of 1.2, leaving the other descriptors with non-significant values. As for defects, the crudeness of the sample was the most outstanding with a score of 2.7; soil of 1.0; the other low-quality descriptors were not significant.

For the results of the sensory analysis of the natural fermentation # 1 (FN1); (Figure 9), it shows its high quality of aroma and cocoa with a rating of 4.7, bitterness of 4.2; astringency of 1.8; nuttiness of 0.7 and acidity; spices of 0.2; the other descriptors with non-significant values. As for defects, the crude of the sample was the most outstanding with a rating of 1.5; earth of 1.0; the other low-quality descriptors were not significant. As for natural fermentation # 2 (FN2); Figure 10, its high quality of aroma stood out with a rating of 4.5, cocoa of 4.0; bitterness of 3.5; astringency of 2.2; nutty of 0.7; aroma and sweetness of 0.5, leaving finally spices and nuts of 0.3; the other descriptors with non-significant values. As for defects, the descriptor of earthiness was the most outstanding with a score of 2.2; crudity of 1.7; the other descriptors of low quality were not significant.

4. Conclusions

The natural fermentation treatments showed the greatest changes in acidity and humidity during the drying and roasting process compared to the inoculum’s treatment. Sensorially, the natural fermentations showed a more aromatic profile and pronounced cocoa flavors than the inoculum treatments.