1. Introduction

A CM is a structure formed by systems in two or more phases to microscopic scale, its properties are designed for be better to the properties of the original constituents acting by itself. One of its phases is continuous and no stiff, it is the weak phase and is named matrix. The other one is discontinuous, stiffer and strong, it is called reinforce 1. The investigation of new compounds with characteristics bettering is advancing with fast 2, and the efforts to reduce environmental contamination are undeniable 3, because of this, the investigation about compound materials, using recycled supplies is necessary 4,5. For this, properties of constituents should be known, and if the CM is better, an application should be proposed, showing benefits in structural uses and sustainability.

The studies of compound materials using PP (see Table 1) has been developed since a couple of years, but its, employing PP mixed with natural fibers and ceramics are few 6. In the next lines, investigations carried out with this kind of mixes are described, its will be a reference for the results in this study. The comparisons should be conservators, taking account the variety of Guadua that was employing in the present investigation (see Table 2).

Hurtado et al.7, added nano-clays to PP in concentrations of 3%, 5% and 7%, using an extruder of twin screw. The mechanical properties of the new material increased in the next way, 4% in tensile strength, 40% in flexural strength, 59% in elastic modulus and 57% in flexural modulus, these results shown that the effect of adding particles of ceramics or nano-clays, is beneficial.

Other study of compound material with polymeric matrix in PP, which obtain good results, was carried out by Caicedo et.al 8. They use cedar fibers, doing test specimens by injection, obtaining an increase of 20.3% in tensile strength, and 46.2% in flexure strength. This study shows that natural fibers produce a better mechanical behavior of PP, and that both, extrusion, and injection process are good choice for the making of test specimens.

Furthermore, Passatore et al. 9, observed favorable results in the analysis of Young´s modulus, mixing PP with Piassava in proportions of 20, 40 and 60%. The modulus rises in 90% in comparation to PP mixed with CaCO3, test specimens were manufactured by injection. The study shows the mix with organic fibers produces better mechanical properties in comparation to mixes with inorganic particles.

Germannya et al. 10 mixed PP with alumina particles in proportions of 1, 3 and 5%, finding that the mix in 1% was better in mechanical properties such as tenacity and elongation modulus, while mix with 5% was better in thermal performance. Same results in mechanical properties were obtained by Ordoñez-Benavides 11, who mixed PP with ZSM-5 Zeolites, showing an improved in the elasticity modulus of 14%. These studies keep the evidence of better mechanical properties, mixing PP with minerals.

Rosales et al.12 did mixes of PP with lactic acid and montmorillonite, they deduced that montmorillonite increased the Young´s modulus. Pilaguano et al.13, mixed PP with powder of bamboo in amounts of 5, 10 and 15% and 0.2 and 5% of nano-clays, manufacturing test specimens by extrusion and injection. Improvements in elasticity and flexure modulus were observed, but with bad results in resistance to the impact and tensile. These results are important because mixes of PP with organic and inorganic materials favors properties as elasticity modulus but reduces other properties as tensile strength.

On the other hand, Jaramillo et al 14 made a compound with PP and fibers of pineapple, in which an increase of 22% in tensile strength, 60% in Young´s modulus, 19% in flexure resistance, and 50% in flexure modulus was obtained. A comparation between these results and the findings in investigations of mixes with natural fibers and minerals, shows that tensile strength is affected mainly by the addition of inorganic constituents.

In this investigation, mechanical properties of a CM of PP reinforced with fibers of Angustifolia Guadua and powder of ceramic were studied, the aim is to advance in the knowledge of CM coming from recycled supplies that could be propose as structural material in applications of furniture or shelves.

2. Methodology

In this work, PP was selected, because it material is considered safe for human health 15, then, PP is used in food package (16. Angustifolia Guadua fiber is an item what has similar mechanical characteristics to the steel 17. Powder of ceramic has good thermo-mechanics properties 18. In Tables 1 and 2, mechanical properties of Guadua and Polypropylene are presented 19,20 respectively. Tests of tensile and flexure, under ASTM 638D 21 and ASTM 790D 22 standards were carried out, using experimental methodology, and results were analyzed by ANOVA 23 with Minitab 18 as support.

Table 1 Properties of Polypropylene.

| Plastic | Thermal Properties | Mechanical Properties | Density | Shrinkage | ||||

|---|---|---|---|---|---|---|---|---|

| Abbreviation | Tm | Tg | Td | Cte. | Stress strain | Compression Stress | ||

| °C | °C | °C | ppm/°C | MPa | MPa | g/cm3 | % | |

| PP | 168-175 | -20 | 107-121 | 81-100 | 31.02- 41.36 | 37.92- 55.15 | 0.900 - 0.910 | 1 - 3 |

Source: Polipropileno s. f. 19

Table 2 Properties of Angustifolia Guadua

| Mechanical Properties | Average (MPa) | S. D (MPa) | C. V (%) |

|---|---|---|---|

| Traction parallel to the fiber | |||

| Maximum Stress | 132 | 24.1 | 1 8% |

| Elasticity Modulus | 17468 | 3655 | 21 % |

| Traction perpendicular to the fiber | |||

| Radial Maximum Stress | 1.1 | 0.3 | 22 % |

| Tangential Maximum Stress | 1.8 | 0.4 | 21 % |

| Compression parallel to fiber | |||

| Maximum Stress | 48 | 3 | 5 % |

| Stress in the proportional limit | 36 | 2 | 6 % |

| Elasticity Modulus | 1913 | 1625 | 9 % |

| Compression perpendicular to fiber | |||

| Radial Maximum Stress | 5 | 0.6 | 12 % |

| Tangential Maximum Stress | 6.8 | 0.9 | 21 % |

S. D= Standard Deviation. C.V. = Coefficient of Variance. Source: Lopez y Correal20

Materials in this project was totally recycled, PP was obtained from lids of different plastic containers, it was washed, dried, and cut manually. The Guadua was provided by Guadua Factoria Company located in Duitama city. It comes in little fibers with a length of 2 to 3 mm, and a diameter of 1 mm approximately. The fibers are waste of a saw. The Guadua is native of the Quindío region, is onion biotype and it comes with a drying and immunizing treatment to avoid lichens. This Guadua is not delignified, what is common for create CM with natural fibers and plastic resins, aimed good adhesion between the constituents. The process was not realized to verify good adhesion of PP and Guadua fibers in extrusion method. Finally, crushed ceramic came from the waste of a construction zone. It was sifted to a size of 150 μm.

Materials were mixed and extruded to a temperature of 260 °C. For each test specimen, 400 grams of mixture were used, Table 3 shows proportions and nomenclature used for the groups of test specimens. In each case, 8 test specimens were extruded.

Table 3 Nomenclature of test specimens.

| Nomenclature | % PP | % Guadua | % Ceramic |

|---|---|---|---|

| PP 100 | 100 | 0 | 0 |

| PPGC 3505 | 60 | 35 | 5 |

| PPGC 3307 | 60 | 33 | 7 |

| PPGC 3010 | 60 | 30 | 10 |

Source: Own elaboration

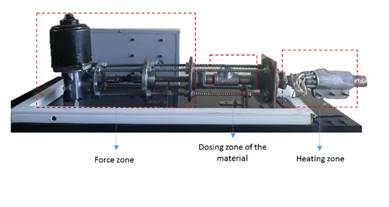

The extrusion process was carried out with an extruder manufactured for the project. It has a capacity of 3 g/min and is powered to 110V. It has a DC motor of 12 V and 60 rpm, has a temperature control PID control in an Arduino board. Heating zone has 7 resistances of 40 W each one, and temperature was measured by a K sensor. The extruder can be seen in Figures 1 and 2, and in Figure 3, molds can be seen too. The constituents were added slowly to the extruder, test specimens of PP only took 7 - 10 minutes in fill the mold, while the other specimens took 10 - 15 minutes. It should be near to room temperature for be removed from the molds.

For the mechanical tests, 8 specimens for each combination were extruded, it means that 32 test specimens for tensile tests were obtained, and in the same way, 32 test specimens for the flexure tests were extruded. Figure 4 shows tensile test specimens, and Figure 5 shows flexure test specimens.

Figure 6 shows a photography in which the mixture of PP and Guadua can be seen, and in Figure 7 two photographs can be observed. In Figure 7a particles of ceramic cannot be seen, while in Figure 7b, the particles its show as glowing dots of orange and yellow hue. The photographs were taken with a Pace Technologies brand inverted microscope, model IM-5000, which has a trinocular tube with inclination of 45°, a magnification of 1x50 were used.

Source: Own elaboration

Figure 7 Photograph taken with a Pace Technologies microscope (a) Sample PP100 (b) Sample PGC3505.

The tests of tensile and flexure were carried out in the mechanical testing laboratory located in the south headquarters of the Antonio Nariño university in Bogotá city. A universal machine model HT-2102, serial 2129, brand HUNGTA were used. The randomization of the tests was done in a very simple way, the 32 tensile specimens were put into a plastic bag in where were eaten and taken one by one for each test. For the flexure testing, the same process was used. The data of each test were charged in the calculus sheet of the software Minitab 18, and a one-way ANOVA were performed. A significance level of α = 0.05 were used, and the verification of the null hypothesis were done by P value. Make sense to mention that null hypothesis was “all means are the same”, assuming that there is not difference between the configurations of CM.

3. Results

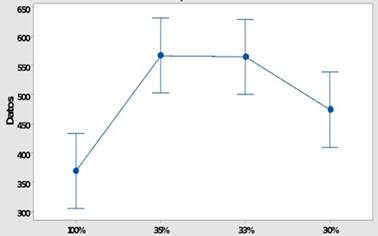

Tensile elasticity modulus: In Table 4, values of tensile elasticity modulus (TEM) and its standard deviation can be seen

Table 4 Tensile elasticity modulus.

| Combination | Tensile elasticity modulus (MPa) |

|---|---|

| PP1000 | 369.8 ± 112.5 |

| PPGC3505 | 567 ± 62.9 |

| PPGC3307 | 565 ± 91 |

| PPGC3010 | 474.5 ± 83.6 |

Source: Own elaboration

Data shows a rise of 53.49% in TEM for the combination PPGC3505 with respect to pure polypropylene, it is in agreement with results of Hurtado et al. 7, Who obtained improvements of TEM in 57%, adding nano-clays to the pure polypropylene, in the same proportions of this work. For the other combinations, rises of 52.79% y 28.31%, in samples PPGC3307 and PPGC3010 respectively, were attained. The last combination in mention has the less improvement in TEM, it could be because with more quantity of clay, the effect of interaction between materials added is higher.

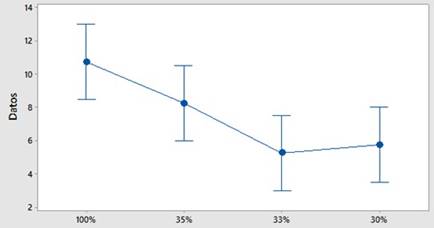

Figure 8 and results of the analysis in the software shows that nule hypothesis can be discarded, then, the favorable effect of the components over the elasticity modulus is confirmed. In Tables 5, 6 and 7, response of ANOVA by Minitab 18 software is displayed, there is found that P value is less than error accepted and the information of the factor and complete ANOVA is presented.

Table 5 One way ANOVA: 100%. 35%. 33%. 30%.

| Nule Hypothesis | All means are equals |

| Alternative Hypothesis | Not all means are equals |

| Significance level | α = 0.05 |

Method. Variances equals are assumed for the analysis. Source: Own elaboration

Table 6 Information of the factor

| Factor | Levels | Values |

|---|---|---|

| Factor | 4 | 100%. 35%. 33%. 30% |

Source: Own elaboration

Table 7 Analysis of Variance

| Source | GL | SC Adjust. | MC Adjust. | F Value | P Value |

|---|---|---|---|---|---|

| Factor | 3 | 209506 | 69835 | 8.77 | 0.000 |

| Error | 28 | 223073 | 7967 | ||

| Total | 31 | 432580 |

Source: Own elaboration

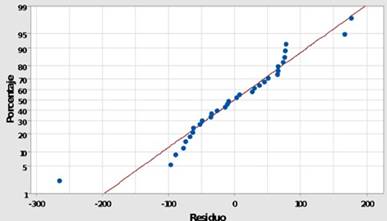

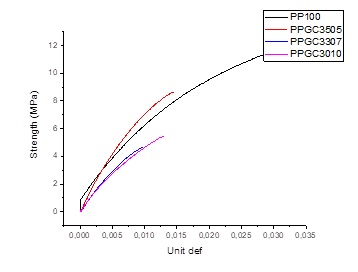

Figure 9 is a plot of normal probability, it shows percentage vs residuals, point fitted to the straight line indicate that normal distribution and constant variance assumptions are valid, and results of ANOVA are reliable. Ultimate tensile stress: In Table 8 values of breaking stress, with its standard deviation, can be seen, and Figure 10 shows stress strain curves obtained from data of the universal machine.

Table 8 Ultimate tensile stress.

| Combination | Ultimate tensile stress (MPa) |

|---|---|

| PP100 | 10.75 ± 4.62 |

| PPGC3505 | 8.25 ± 2.37 |

| PPGC3307 | 5.25± 2.49 |

| PPGC3010 | 5.75 ± 2.37 |

Source: Own elaboration

The ultimate tensile stress data shows that the MC did not overcome values of PP100, even it fall in 23.2% for PPGC3505, 46.5% for PPGC3010 and 51.1% for PPGC3307. This results has the same tendence that results of Pilaguano et al. 13, reduction in tensile resistance may be due to that in high deformations, adherence forces between particles and matrix lost, producing breaking in less stress, in this case, the interaction between factors (percentage of additives) is more evident, because data shows a lift after of a down, forming a concave curve upwards, as is showed in Figure 11.

In this case, like in the elasticity modulus, P value was zero in the software, what indicate that breaking tensile is affected by variations in the material.

Flexural elasticity modulus: Table 9 shows flexural elasticity modulus (FEM) and its standard deviation.

Table 9 Flexural elasticity modulus.

| Combination | Flexural elasticity modulus (MPa) |

|---|---|

| PP100 | 2.17 ± 0.50 |

| PPGC3505 | 2.96 ± 0.67 |

| PPGC3307 | 2.55 ± 0.94 |

| PPGC3010 | 2.75 ± 0.67 |

Source: Own elaboration

Data are not clear for the FEM and it is confirmed by the P value of 0.171 which is higher of significance level defined for the tests, because of this is evident that added materials not affect the FEM of the PP. This contradict studies realized by Hurtado et al. 7, it could be for the addition of Guadua, what will produce changes in adhesion forces between materials.

Ultimate flexural stress: Table 10 shows values of ultimate flexural stress (UFS) and its respective standard deviation.

Table 10 Ultimate flexural stress.

| Combination | Ultimate flexural stress (MPa) |

|---|---|

| PP100 | 28.68 ± 8.67 |

| PPGC3505 | 21.61 ± 6.39 |

| PPGC3307 | 19.72 ± 8.71 |

| PPGC3010 | 28.50 ± 6.61 |

Source: Own elaboration

In UFS like in FEM data has not tended defined, it is confirmed by the analysis in Minitab, in which is observed that P value is higher that α, what make impossible discard nule hypothesis, it means that does not exist a significant difference between means of the groups, then there is no difference in the UFS of the PP100 and the compound materials. Tables 11, 12 and 13 shows the analysis in Minitab 18 by ANOVA, in this, P value with respect to the significance level α can be seen and the rest of information of the ANOVA.

Table 11 One way ANOVA: 100%. 35%. 33%. 30%.

| Nule Hypothesis | All means are equals |

| Alternative Hypothesis | Not all means are equals ales |

| Significance level | α = 0.05 |

Method. Variances equals are assumed for the analysis. Source: Own elaboration

Table 12 Information of the factor.

| Factor | Levels | Values |

|---|---|---|

| Factor | 4 | 100%. 35%. 33%. 30% |

Source: Own elaboration

5. Conclusions

An improvement of 53.49% in the tensile elasticity modulus of the PP was obtained when Guadua in 35% and clay in 5% was added, the other combinations show important rises too, this suggest that the material can be proposed as reinforcement in applications of low load and low tolerance or high adjust requirements. In the statistical analysis of flexural tests is evidenced that there is no significative improvement in the flexural ultimate stress and flexural elasticity modulus, it should be taking account in the moment of propose a possible application. In the ultimate flexural stress, combination of PPGC3010 reach the same values of PP100, it is the compound with the higher quantity of clay and less quantity of Guadua, this suggests that a variation of these materials in higher proportions could make better the ultimate flexural stress.