1. Introduction

A supply chain is made up of all the parties involved, directly and indirectly, to satisfy the needs of a customer; a supply chain is dynamic and involves the constant flow of information, goods, and funds between different stages 1. Accordingly, in order to improve the chain performance, coordination between the system's actors is essential through effective, efficient and sustainable integration Internally, integration ensures that organization functions act as part of a coordinated whole, while external integration allows to implement practices jointly with suppliers and customers to build relationships helping achieve continuous flows of goods, materials and information in the supply chain 2.

However, when the supply chain is decentralized, decision-making becomes complex, due to limited access to information throughout the chain, as well as the fact that each echelon is looking for individual benefit. Individual objectives increase conflicts possibility affecting directly flows in the chain 3, such as income, especially in the small producers.

In consideration of the above, the backup contract or also called Backup Agreement is proposed in order to strengthens the commercial relationship between buyer and seller. This agreement fulfills the characteristic to regulate the purchase while maintaining the fixed price, even when changes occur in the market. In consequence, If the price falls, losses are limited. Agreement contract allows the supplier to maintain a backup inventory after supplying an initial order, while the buyer to decide whether take the backup units under initial price conditions according to demand behavior. If some of the backup units are not taken, the buyer will have a penalty. This contract helps the supplier to reduce the uncertainty impact on demand 4.

One way to study the backup contract behavior in regard to small agricultural producers’ income is through system dynamics, which allows establishing variables interrelationships within a decentralized supply chain such as costs, sales, production orders, inventories, among other that can affect the system. In this article, conceptual elements referring to factors involved in a decentralized supply chain that can impact the income distribution of small producers are analyzed. Likewise, the contract behavior in an agricultural supply chain composed of three links (producer, intermediary and retailer) located in Valle del Cauca in Colombia is studied. A simulation time is established and consistency analysis under two working scenarios is done, supported in causal diagrams and simulated Forrester diagrams in Vensim software.

1.2. Problem statement

Agriculture represents one of the economic activities with greatest contribution to a country general development. According to 5 agriculture can be a source of national economy growth, as an economic activity it generates private investment opportunities and promotes industries related to agriculture and rural non-agricultural economy. As a subsistence source, “agriculture constitutes the livelihood of 86% of the world's rural population, in addition to the fact that almost half of humanity lives in rural areas” 6.

According to figures from the jpg (National Development Plan 2018-2022), rural activity in Colombia contributed 6.9% of added value and generated 16.7% of jobs in the country in 2017. However, considering the farmer important work within the commercialization process and the difficulties they must face, their job is not sufficiently recognized. Indeed, small producers face difficulties such as market access, deep-rooted cultural barriers to the production of certain products, lack of associativity, financial credits limitation, all of which influence the equitable bargaining conditions of small producers within the market 7. Author highlights the vulnerability of small producers within the supply chains and exposes difficulties they face in managing to link their products in the value chains, in addition to being overly dependent on third parties in the chains.

The agricultural supply chain decentralization exacerbates the small producer situation, due to decision-making in isolation within the echelons represents greater income distribution inequity, especially for small producers. A backup contract is proposed, to improve flows of resources, information and money performance and coordination between the echelons in the chain. A supply chain of small agricultural producers located in the center of Valle del Cauca, dedicated to the citrus fruits production, is taken as a case study. With this work, the aim is to offer a systemic view of the behavior of the backup contract in the income generation of the small agricultural producer in the decentralized supply chain that is taken as a case study. The following research question is formulated: ¿What is the dynamic behavior of a backup contract in the small producer’s income in a decentralized supply chain?

1.3. Literature Review

Supply chains encompass a series of processes, activities, and tasks at strategic, tactical, and operational level. These imply a dynamic and constant flow of information, materials, and financial resources between each of the actors directly and indirectly involved in the chain 1. Globalization today suggests that organizations establish strategic planning from centralized approaches, where all parties in the chain work under the same objective.

Supply chain coordination means that two entities or more independent companies work together to plan chain operations execution and achieve greater success than acting in isolation 8. Likewise, in 9 it is mentioned how coordination is a vehicle for redesigning decision-making, workflow, and resources among members of the supply chain to improve performance in profit, customer service and answer's capacity. In general, coordination allows to reduce costs and take advantage of the skills between actors to increase the company competitiveness. In 10 coordination is defined as the tool to improve performance and promote a better work in non-collaborative environments. In addition, it exposes an in-depth investigation of supply chain coordination. In 11 a systematic literary review is presented on the coordination in supply chains importance, it is reported about the various mechanisms found in the literature within coordination and how they can be implemented according to the chain general needs.

In the case presented in 12 the supply network coordination has been approached through system dynamics. This author presents a case applied in the Colombian health sector where two coordination scenarios are evaluated and analyzed (the use of shared information and joint decision-making) in the supply network of oncological medicines in health-providing institutions with services in different cities of the country.

However, coordination and integration become complex when supply chains make decisions in a decentralized way. In 13 the decentralization problem is related to the lack of coordination and how it affects the supply chain performance, generating difficulties in forecasts, response capacities, inventory turnover, customer service quality, among others. In supply chain shown in this article, it has been shown that decentralization alters the flows between links, especially the income flow. Different studies highlight how the link with the least participation and control over decisions in agricultural chains is the one who receives a lower level of income with respect to other participants 7. Small producers, despite playing a fundamental role in the commercial development of the chain, always depend on third parties, which affects the participation and profits generation within their economic activity.

The above has opened the way for authors such as 4 to address the lack of coordination problem in decentralized chains from the coordination mechanisms use. According with 4 the coordination mechanisms help to improve performance measures in the supply chain, since it includes an articulation of decision-making, information exchange, joint promotional activities, the motivation generated among the members while sharing risks and benefits in turn. In 14 a two-period supply contract model is presented as a coordination mechanism for an assembly system operated under a decentralized control mode. Most actors in supply chains can coordinate through the contracts use to improve the supplier-buyer relationship. Contracts allow to determine parameters to be used by buyer to places orders and, to manufacturer satisfies demand. The general objective of using a contract as a coordination mechanism is to increase the supply chain total profit, reduce excess costs and reduce uncertainty by sharing risks between partners 15. In 16 the issue of contracts as comprehensive coordination mechanisms is addressed, and a classification of the different contracts is presented according to the needs generated in the supply chains.

In 17 an income distribution contract is applied in a fruit supply chain as a coordination mechanism between the echelons. To study the behavior, a mathematical model is presented that represents the revenue sharing contract seeking to maximize the supply chain performance.

In 18 a coordination model called ASCEND is used to align inventory decisions in decentralized supply chains. This document works under somen theoretical framework such as multi-agent technology, coordination theory and optimization technology. Inventory alignment becomes a decentralized constraint satisfaction optimization problem, which is then solved through a coordination process based on genetic algorithms. Additionally, the author proposes an incentive alignment mechanism that works with a service level contract and shared costs, considering the associated dependencies.

In 19 a Wholesale Price contract is implemented with a complementary two-party rate agreement or profit-sharing agreement to coordinate the two channels supply chain, manufacturer, and retailer, where it seeks to benefit both actors. Additionally, in 20 the income buyback contract is studied in a supply chain model with income determined from the retailer’s quantity and the purchase price. There is a stochastic demand with income generated from direct sales. Within the results, it is shown that the revenue sharing contract coordinates the supply chain with a single retailer (this is the one who chooses the optimal price and quantity) and allocates the profits from the supply chain.

On the other hand, within the coordination mechanisms is the backup contract or also called Backup agreement, a case of interest for this article because in the reviewed literature a proposal for the application of this type of contract was not found in the scenario of decentralized chains of small agricultural producers, which fulfills the function of regulating the purchase between the supplier and the retailer, which may be relevant to improve the performance of a chain of this type. In 21 they are presented as agreements that allow maintaining the fixed price, despite changes in the market. A commercial relationship is established where the retailer agrees to place a second purchase order within the backup inventory, under the same initial purchase conditions once the demand has been reviewed in the first period. If the retailer does not take some of the units agreed upon within the contract, he must pay an economic penalty to the supplier.

In 22 a model is proposed within the inventory problem according to the application of the backup contract in a catalog company (retailer) and manufacturers, as a coordination mechanism between the parties involved. The research results indicate that the backup agreement can have a substantial impact on expected earnings and can increase the amount committed. Additionally, the arrangements between the two links allow maintaining the benefit expected by the manufacturer for a wide range of parameters. In the taxonomic table presented in Table 1 a description of different applications of the backup contract in different scenarios is made.

Table 1 Backup contracts application in different scenarios: State of the Art and Taxonomy.

| Literature review | Description |

|---|---|

| 23 | They consider a backup contract with a penalty scheme between the retailer and the backup provider in a single product supply chain. When the main supplier cannot supply the products, the backup supplier can always supply the products at a higher price. This contract mitigates supply interruptions and reduces the demand uncertainty level. The expected profit function and optimal decisions are established according to a sequential optimization process. |

| 24 | It proposes a backup contract model, under the price compliance regime in which the producer previously invests in its capacity and supplier must generate its investment before the demand materializes. For this reason, they propose to applicate sanctions for an exigible amount between both parts of the supply chain. The shortage cost for supply and orders are appended to coordinate the chain. |

| 25 | A commitment-penalty contracts portfolio is proposed to improve information between links. Retailer agrees to send prior information on customer demand (forecasts), to reduce the supplier uncertainty. And the latter, supplying vital inventory information to the retailer so as not to fall into a shortage or overstock. Under this direct shipping mechanism between retailer and supplier, profit expected by supplier is maximized and the demand and supply certainty is provided. |

| 26 | Demonstrates how the advance purchase or reservation strategy of a backup provider ensures a return high rate after a dedicated provider outage. |

| 27 | A fashion industry is considered, to which a flexible backup arrangement is applied that allows the retailer to order a backup amount to reduce the uncertain demand risk. A profit function is used to analyze the optimal production lot size and manufacturer profit. |

| 28 | The price problem and management of cloud resources is addressed, from the service provider perspective. A service level agreement (SLA) is established, designed to study a equilibrium-penalty price combinations program between a service contract model and the client's negotiation processes. |

Source: own elaboration

2. Methodology

It is established within the research, to use system dynamics as a tool to simulate the contract behavior in the supply chain and analyze how it can improve coordination, according to the income levels of small agricultural producers. The case study of small producers in the center of Valle del Cauca addressed in this work, raises the decentralization conditions conducive to the proposed analysis.

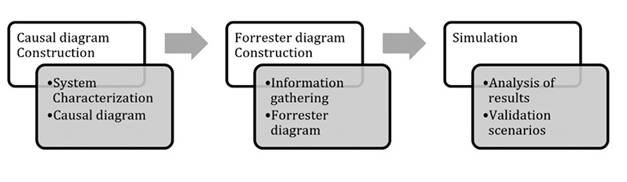

The systems dynamics is made up of three main phases which are shown in Figure 1. The first step consists in carrying out a system characterization to be modeled, through the main variables identification that affect its behavior, aimed to make a causal diagram. Second stage involves a Forrester diagram construction according to the relationship previously established in the causal diagram. In this phase, information must be collected for the main variables that affect the model. In the last stage, the system simulation is intended to be carried out, where a simulation time horizon is established in order to analyze the model main variables behavior in order to obtain relevant conclusions for the study.

Vensim software is used to simulate, which is a computer tool that allows system dynamics to be used studying models’ behavior that represent a system under study. Software requires entering variables, making variable relationship diagrams, also making Forrester diagrams where the variables relationships are indicated, introducing initialization values, mathematical functions that define the behavior of the relationships between the variables, as well as the simulation time. It is a tool that also has graphic aids.

2.1 Phase I- Causal diagram elaboration

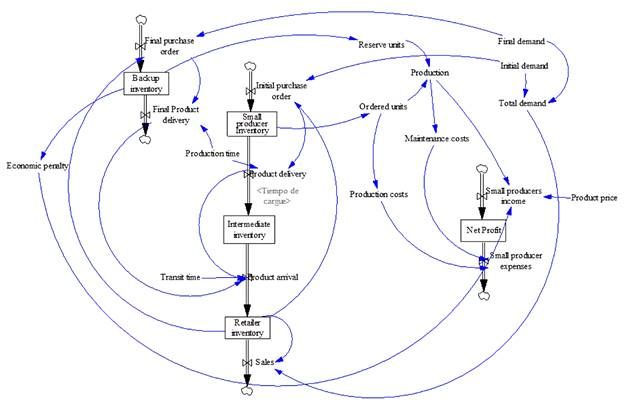

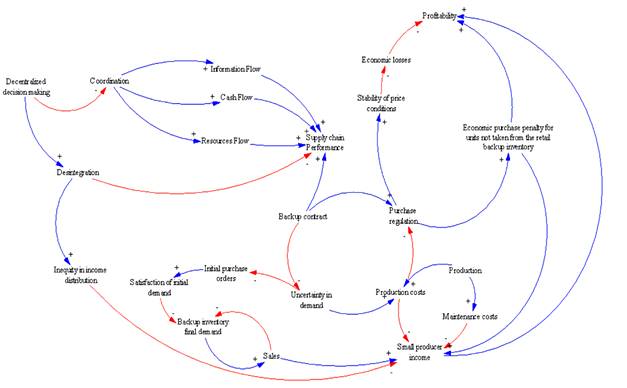

Causal diagram allows the variables analysis included in decentralized supply chains that serves as a support to build the diagram presented in Figure 2. A detailed explanation is presented below, based on the small agricultural producers in the center of Valle del Cauca taken as a study case.

Source: own elaboration

Figure 2 Causal diagram- Income behavior in the small producer under backup contract implementation in a decentralized supply chain.

Diagram indicates that decentralized decision making in a supply chain cause the coordination between links decreases and consequently the disintegration increases.

In a supply chain disintegrated, the actors set individual objectives, which translates into greater inequity in income distribution and a lower performance during a certain period. In contrast, coordination allows for a greater information flow, resources and money, which positively influences their overall performance. To improve the coordination, performance and income level for small producers, backup contract appears, which increases the purchase regulation between the small producer and the retailer. A purchase regulation implies increase the price conditions stability, that is, a fixed price is proposed for the entire purchase season, even if changes occur in the market. If the price falls, the economic losses are minimal. An economic loss in a supply chain can be seen as a decrease chain profits.

On the other hand, contract requires a backup inventory to be used for retailer to release the final purchase order. In addition, purchase regulation within the backup contract involves to the retailer economic penalty for units not taken from the backup inventory. Penalty increases supply chain income and in turn contributes positively to small producer’s income.

Production involves associated costs as well as inventory maintenance; costs decrease purchasing regulation and, alternatively, decrease the small producer’s income. However, in a backup contract demand uncertainty tends to decrease, because the retailer will be able to plan the second purchase order according to period demand flow. When there is an uncertainty about demand, a negatively affects in initial purchase orders is observed.

On the other hand, if the purchase order is greater, the initial demand satisfaction increases significantly, therefore, the end-demand backup inventory decreases. It is important to point out that with a greater backup inventory of final demand, the sales level increases, which in turn reduces the inventory level. When sales increase, the small producer’s income also increases, consequently, the supply chain income also.

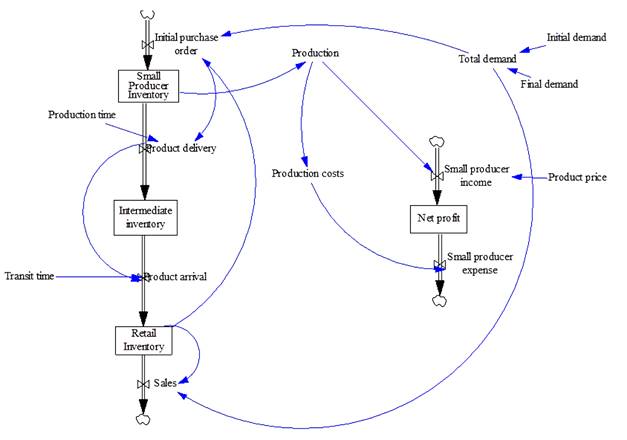

2.2 Phase II- Forrester Diagram Construction

Forrester diagram presented in this article is constructed in base of previous characterization done for a small agricultural producers supply chain located in the center of Valle del Cauca, taken as a case study.

Forrester Diagrams were development in two analysis scenarios, Figure 3 and Figure 4 respectively, in order to compare the small producer’s income before (Scenario I) and after (Scenario II) backup contract is implemented.

Source: own elaboration

Figure 3 Forrester diagram of supply chain without backup contract implementation.

2.2.1 Scenario I (Supply Chain without Backup Contract)

The decentralized supply chain without backup contract (See Figure 3), only considers variables such as demand, purchase orders, inventory, costs and income generated, in the small producer’s echelon.

As can be seen, the initial purchase order is generated from the total demand. According to small producer inventory, the units for that purchase order are produced and finally the product is dispatched to the intermediary. Considering the intermediary inventory and the product dispatch flow from previous link, the product arrival to the retailer is determined. Finally, with the complete retailer's inventory, sales are generated according to established demand. It should be noted that small producer net profit depends on the income and expenses flow generated during production.

2.2.2 Scenario II (Supply Chain with Backup Contract).

This scenario is developed assuming a decentralized supply chain working with a backup contract operated between small producer and retailer (See Figure 4). Therefore, only variables such as demand, purchase orders, backup inventory, purchase penalties, units in reserve, costs and income generated on the small producer’s echelon are considered.

In Figure 4 it is observed that with the initial demand the small producer release the first purchase order. The units for the entire contract are produced from the initial order (ordered units and reserve units for the second purchase order). Regarding the small producer inventory and units ordered, deliveries are done to the intermediary and from there, to the retailer inventory.

On the other hand, after customer demand behavior is known, final purchase order is generated, the small producer reviews the backup inventory level to send product to the intermediary. Units not taken from the backup inventory generate a financial penalty to the retailer. Net profit is made up for income and expenses generated both in the initial order and in the final purchase order.

2.3 Phase III- Simulation

Simulation is carried out in the software Vensim for a 12 months’ time period, information used was obtained from the previous characterization done in the supply chain under study. The supply chain performance is evaluated in both scenarios, without backup contract and with backup contract.

3. Results

Figures 5, 6 and 7 show the supply chain behavior comparison in that two scenarios considered in the studio.

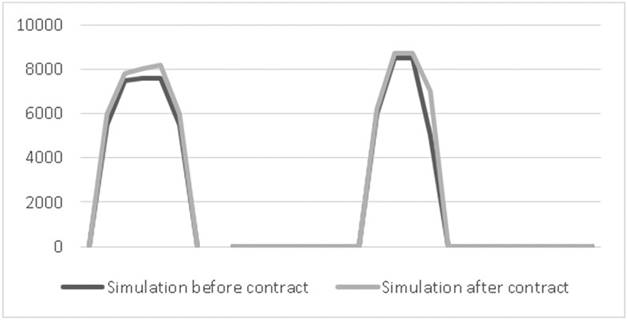

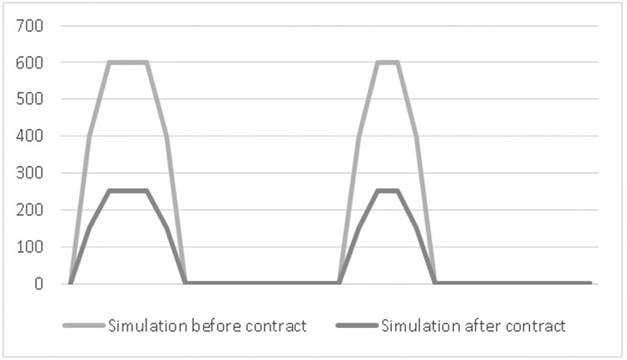

According to Figure 5, there is a slight increase in the small producer’s income (units-Dollars) after contract is implemented, compared to the supply chain income without a contract, so the mechanism coordination was successful for the decentralized supply chain.

This income slight increase is due to economic penalties established within retailer contract, which undertakes to pay a penalty for units not taken from backup inventory, so the small producer decreases the inventory costs impact, increasing alternately income.

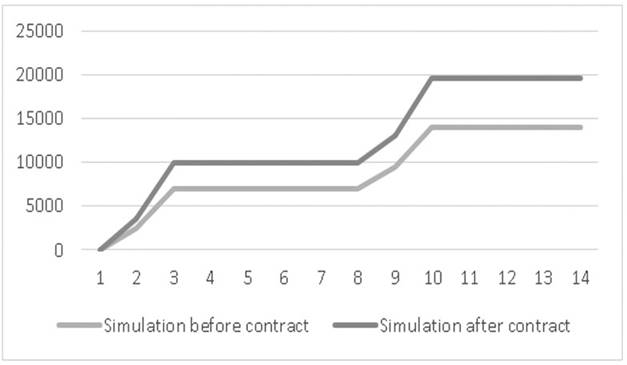

In Figure 6 net profit behavior is presented. Based on the small producer’s income increase and purchase regulation generated by backup contract, net profit increases in the two cycles of the purchase order. In the simulation, a higher net benefit is obtained in scenario I with backup contract in the supply chain compared to scenario II.

Figure 7 shows the inventory reduction in scenario II. Due to backup inventory, the ordered units supply process is done with a first purchase order. The fixed prices for units in reserve encourages the retailer to purchase and to supply fairly quantities (Policies within the contract) for both the small producer and retailer for the second purchase order.

3.1. Sensitivity analysis

Sensitivity analysis allows to vary some problem parameter based on potential criteria changes in the real context. In order to verify optimal problem solution, changes in problem variables are done and results are generated within model 29.

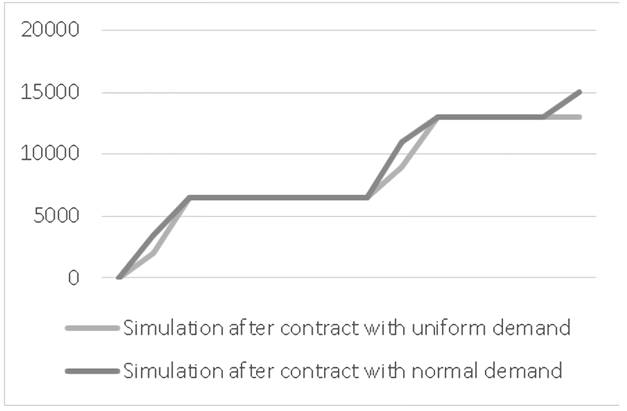

In this case, demand parameter was selected for sensitivity analysis in order to study the effect in the small producer’s income. Demand is considered stochastic following a uniform and normal distribution. The probability distributions study makes it possible to simplify data treatment such as demand, in many real phenomena 24, so it is important to analyze this behavior in the backup contract.

A demand with uniform distribution was simulated, for the initial demand and final demand in the first case study. Analysis results is observed in Figure 8. Net profit obtained in a model with constant demand is higher than model with uniform demand, as shown in the figure. This is due to large part of demand variations are related to the other links sales number, so as the demand is lower for some periods of time, it affects the supply chain income.

A normal distribution was used to simulate for the initial and final demand in a second case study. Based on demand simulated with normal distribution, net benefit is slightly higher than obtained using demand with uniform distribution (See Figure 9). This happens because parameters are more adjusted to the real situation, assuming a demand normally distributed around a dispersed mean µ following a standard deviation σ.

4. Discussion

This article addresses the dynamic systems tool to analyze, model and study the backup contract behavior in a decentralized supply chain, taking a small agricultural producers supply chain located in the center of Valle del Cauca as a case study. In contrast to different authors approach 16, about contract effectiveness to reduce demand uncertainty and supply chain coordination improvement, it was possible to show that backup contract allows performance improvement the monetary and information flows in three echelon decentralized chain, especially in small producer link. Managing a backup inventory with a penalty scheme, guarantees purchase regulation and producer inventory cost reduction. In addition, supply chain increases profit, customer service and response time.

A recent study by 28, shows that accumulated profit for a manufacturer increases as the backup contract flexibility offered by retailer increses. In this study, it has been considered that the producer is authorized to place an emergency order to another supplier to compensate any backup inventory deficit.

On the other hand, it is considered essential to apply the backup contract based on stochastic demands. In this way, the expected economic benefits in the chain are guaranteed. Effective modeling depends on data reliability obtained for the study case. Also, in 17 administrative complexity to implement contracts in small producers supply chain is mentioned. The small producer’s reality is the weakness in their administrative structure that, in any case, is required to implement strategies like this, as well as strengthening the reliable and consolidated products supply.

A significant and highly relevant finding is that backup contracts according with literature review are commonly used in service companies or the logistics sector 29, textile companies 21) or in two-link supply chains. However, within the literature there are no cases that address the backup contracts implementation in small producer decentralized chains, which makes relevant for future research the backup contract implementation approach shown in this work.

5. Conclusions

This study shows the income behavior in the producer echelon with a backup contract implementation, used as a coordination mechanism in a decentralized supply chain located in the center of Valle del Cauca.

Literature review carried out allows to identify a decentralized supply chain structure, build a causal diagram from variables identified and finally, to evidence coordination mechanism effect. Dynamic relationship between supply chain members is redesigned, in terms of cooperation and integration of processes, decision making, resources, information flows and work, seeking to achieve a shared general objective. The backup contract as a coordination mechanism allows to improve performance in the supply chain, reflected in higher profits, better customer service and response time.

Through the system dynamics model implementation, the backup contract behavior on the income, net profit and inventory of small producers was established. According Increases in purchasing regulations determined in the contract (Fixed price and penalty to units not taken within the backup inventory), the small producer achieves a greater economic benefit by applying the backup contract in the decentralized supply chain, represented by a 26% increase in economic profit compared to the chain initial state.

From the sensitivity analysis carried out, it is possible to determine how when considering a stochastic demand within the model, a lower income is generated in small producers, where the net benefit varies relatively 44% compared to the initial scenario. Backup contract viability as a chain integration mechanism is demonstrated, since a 26% increase in net profit is obtained, in comparison to initial decentralized chain that did not use the contract.